Winter is coming, and for construction companies that means it’s time to brace for harsh weather conditions and ensure your construction inventory is protected from the cold. Frigid temperatures, snowstorms, and icy winds can wreak havoc on construction materials and equipment if proper precautions aren’t taken. From lumber and concrete to tools and fuel, every item in your construction inventory is at risk when winter sets in.

For businesses operating in regions with cold climates, protecting construction inventory during winter is not just about preventing damage – it’s about safeguarding your project timelines and budget.

The Impact of Winter Weather on Construction Materials

Before diving into protective measures, it’s important to understand how winter weather affects construction materials and supplies. Cold, wet, and windy conditions can directly damage many common building materials:

- Moisture and Freeze Damage: Snow and ice bring excess moisture that can seep into porous materials. When this moisture freezes, it expands, leading to cracks or warping. For example, bricks, concrete blocks, and stone can suffer freeze-thaw cycles that cause chipping or structural weakness. Wood framing and lumber can absorb water, then swell, warp, or even rot if not dried properly after exposure.

- Temperature Extremes: Subzero temperatures can make certain materials brittle or unusable. Concrete poured in freezing conditions may not cure correctly, compromising its strength. Paints, adhesives, and sealants often have minimum temperature requirements – if they freeze, their chemical properties and effectiveness degrade. Drywall can become fragile and prone to crumbling when subjected to severe cold and moisture.

- Metal Contraction and Battery Drain: Metal tools, pipes, and equipment parts contract in extreme cold, which can lead to loosening joints or hairline fractures over time. Batteries for power tools or heavy machinery lose charge more quickly in low temperatures, potentially leaving you with equipment that won’t start when needed.

- Delayed Curing and Setting: Materials like concrete, mortar, and certain adhesives take much longer to cure in cold weather. This not only delays construction work but also increases the risk of that material being compromised before it fully sets, especially if it freezes during the curing process.

- General Wear and Tear: Tarps, plastic sheeting, and other protective materials themselves can become brittle in the cold. Straps or bindings holding materials can snap more easily. High winds that often accompany winter storms can rip covers or scatter unsecured items.

Best Practices for Protecting Construction Inventory in Winter

Understanding the vulnerabilities is the first step toward designing an effective strategy to protect your inventory. By recognizing how winter can impact your supplies – from the quality of raw materials to the functionality of tools – you can better prioritize which items need extra care. Now, we’ll look at concrete steps to shield those items from the elements.

1. Store Materials in Weather-Protected Areas

Whenever possible, keep your construction materials in an indoor or sheltered location during winter. An enclosed warehouse, heated shed, or temporary jobsite trailer can provide a controlled environment away from snow, ice, and wind. If indoor storage is limited, prioritize sensitive materials (like cement bags, paints, and electronics) for those protected spaces.

For materials that must be stored outdoors, take extra precautions:

- Elevate Off the Ground: Place lumber, pallets of cement, and other materials on raised platforms or pallets. Keeping supplies off the bare ground prevents direct contact with snowmelt and ice. It also promotes airflow underneath, reducing moisture accumulation from below.

- Use Weatherproof Covers: Cover outdoor stacks with waterproof tarps or specialized weatherproof sheeting. Make sure the covers are secured tightly against winter winds. However, avoid completely trapping moisture – for example, use breathable covers for lumber to allow condensation to escape and prevent mold.

- Choose the Right Location: Store materials in a spot with good drainage. Low-lying areas can collect water when snow melts, so pick a flat, elevated area if possible. Also avoid placing materials directly under eaves or structures where icicles and heavy snow could slide off and damage your inventory.

- Set Up Temporary Shelters: Consider investing in temporary storage solutions like portable storage containers or tents. Shipping containers, for instance, provide solid protection from precipitation. Just ensure there’s some ventilation to avoid condensation buildup inside. On-site, you might use pop-up canopies or frame tents with tarps to cover materials; these can keep snow off important supplies (just clear the snow off the canopy regularly to prevent collapse). Temporary heated enclosures can be used on site to keep materials like paints or adhesives above freezing when in use or curing.

By thoughtfully selecting and preparing your storage areas, you create the first line of defense against winter weather. A little preparation goes a long way – a pallet here and a tarp there can save thousands of dollars in spoiled materials.

2. Control Temperature and Moisture

Cold and dampness are a destructive duo for construction inventory. Taking steps to regulate the environment around your materials can dramatically improve their winter survival:

- Maintain Moderate Temperatures: If you have storage that can be heated, aim to keep it above freezing (32°F / 0°C) at minimum. Many materials fare best in a moderate range (around 55°F to 75°F), so if you have thermostatic control or portable heaters, use them for enclosed storage spaces. This is especially vital for items like paints, caulks, and adhesives that can be ruined by freezing.

- Use Insulation and Heated Blankets: For materials stored outdoors or in unheated areas, insulating them can prevent freezing. Wrap sensitive supplies (such as buckets of paint or barrels of liquid adhesive) in insulation blankets. There are also electric heating blankets or wraps designed to keep materials like concrete mix or stucco warm enough to remain usable. These can be lifesavers for maintaining the workability of materials in the dead of winter.

- Deploy Dehumidifiers: Moisture control is just as important as temperature. In enclosed storage, use dehumidifiers to keep humidity levels in check. Too much humidity can lead to wood swelling, metal corrosion, and mold on materials like drywall. Aim for a balanced humidity (around 40–50% if possible) to prevent condensation and dampness.

- Ensure Ventilation: Provide proper airflow in storage areas to avoid trapped moisture. If using tarps or plastic covers, periodically uncover or open them on milder days to let any condensation dry out. For lumber, use spacers between stacked boards so air can circulate and dry the wood naturally, preventing mold and rot.

- Add Moisture Barriers: When storing materials directly on concrete floors or the ground, put a plastic sheet or vapor barrier underneath. This prevents ground moisture from seeping up into your lumber, drywall, or insulation rolls from below.

Controlling the climate around your inventory might involve some extra utility costs or equipment, but it’s a worthwhile investment. Keeping your materials in a stable temperature and humidity environment maintains their quality and avoids the far higher costs of replacing damaged stock or redoing work due to material failure.

3. Protect Different Material Types with Special Care

Each category of construction material has its own vulnerabilities in winter. Tailor your protection methods to the specific needs of what’s in your inventory:

- Lumber and Wood Products: Wood should be kept as dry as possible. Stack lumber on level raised supports, and use spacers (stickers) between layers for air circulation. Cover with a breathable tarp — unlike plastic, a canvas tarp or specialty breathable cover can shield wood from precipitation while letting moisture escape. Check on stored lumber periodically and brush off any snow that blows in to avoid prolonged contact with moisture. If lumber does get wet, try to allow it to dry (on a milder day or inside a garage) before it freezes to minimize warping.

- Cement, Mortar, and Dry Mixes: These materials are highly susceptible to moisture. Once wet, cement and mortar mixes can clump or harden, becoming unusable. Store all bags of cement, mortar, grout, or plaster in an absolutely dry space, ideally indoors. Use pallets so they’re off the floor and consider wrapping them in plastic if in a humid area. Even in the cold, never let these materials sit directly on a cold concrete floor; an insulating pallet or board underneath can prevent the cold and damp from seeping in. If you have liquid additives or admixtures for concrete, keep them in heated storage since they could freeze and separate (ruining their effectiveness).

- Paints, Adhesives, and Liquids: Most paints, primers, adhesives, and coatings are not freeze-thaw stable. A single overnight freeze can ruin a bucket of paint or a tub of drywall mud. Always store these in climate-controlled areas. Check manufacturer’s labels for minimum storage temperatures (often around 50°F). If a product has been exposed to freezing conditions, inspect it before use — if the consistency or color looks off, it might have gone bad. Also, keep chemical solvents and fuels in ventilated areas away from any heat sources (for safety), but still above freezing to ensure they remain in usable condition.

- Metals and Steel Components: Steel beams, rebar, and other large metal components can handle cold temperatures structurally, but prolonged exposure to moisture will encourage rust. Protect metal components by keeping them under cover to prevent snow and ice from sitting on them. If items will be stored outside all winter, consider applying a protective coating or light oil to steel parts to prevent corrosion (for example, coating hand tools or cast iron fittings with a bit of oil). Small metal hardware (nails, screws, connectors) should be kept in sealed containers to avoid rust-inducing moisture.

- Pipes and Plumbing Supplies: If you’re storing plumbing components, ensure no water is left inside any pipes, pumps, or hoses to prevent freezing and cracks. Store PVC and other plastic pipes in a warmer area if possible, because plastic can become brittle in extreme cold and may crack if handled roughly. If pipes must be stored outdoors, don’t stack them too high (cold, brittle pipes could break under weight) and try to shield them from direct snow and sunlight (which can also degrade some plastics). Covering with a tarp is fine, and you might place caps on pipe ends to keep critters and ice out.

- Concrete and Masonry Units: Precast concrete items, bricks, blocks, and stone can be stored outside, but make sure they’re not saturated with water going into a freeze. Wet bricks that freeze can spall (the surface flakes off). Stack bricks/blocks on pallets and cover the top of the stack with a water-resistant tarp to keep precipitation off, while leaving some room at the sides for airflow. For any masonry units that have arrived shrink-wrapped, maintain that wrapping as an extra moisture barrier until you need to use them.

- Power Tools and Small Equipment: These count as part of your inventory too and need winter care. Bring portable power tools and equipment into heated storage when not in use. Remove any batteries from cordless tools and store those batteries in a warm, dry place – cold can significantly reduce a battery’s performance and lifespan. For gasoline-powered tools (generators, cut-off saws, etc.), make sure to winterize them: add fuel stabilizer to the gas, and ideally run the engine briefly to get the stabilized fuel through the system. Store such equipment in a covered area and try to start them up periodically on milder days to keep them from stagnating. Never leave tools caked with snow or moisture; wipe them down and dry them before storage to prevent rust and electrical problems.

- Heavy Machinery: Large construction equipment (like loaders, excavators, cranes) often stays on site through the winter, but they need attention as well. Use winter-grade diesel fuel or add anti-gel additives to prevent fuel from gelling in the cold. Keep fuel tanks topped off at the end of each day to minimize empty space where condensation can form (water in diesel leads to big problems when it freezes). Check antifreeze levels in radiators and use engine block heaters or coolant heaters on very cold nights to help engines start easier the next day. Hydraulic systems might need a check too – ensure hoses and seals are in good condition (rubber can crack in the cold) and consider using a lower-temperature hydraulic fluid if recommended. While heavy machinery isn’t “inventory” in the sense of consumable materials, a disabled machine can halt your ability to move and use your materials. In other words, caring for machinery is part of caring for the overall inventory workflow.

By thinking in terms of categories, you can create a winter checklist for each type of inventory item. This ensures nothing is overlooked – from the largest steel beam down to the last box of nails, each item gets appropriate protection against the cold and wet.

4. Organize and Label Everything

Winter weather can turn a messy storage area into pure chaos. Short days and poor conditions make it harder to find what you need, and you don’t want crews rummaging through snow-covered piles for materials. That’s why organization is a key part of protecting your inventory in winter:

- Group Materials Logically: Keep similar items together and clearly delineate storage zones. For instance, store all plumbing fixtures on one labeled pallet or shelf, lumber of the same size on a designated rack, and electrical supplies in bins inside the site trailer. By grouping and labeling sections (with signs or color codes), if a sudden freeze or snowstorm hits, your team will know exactly where to go to find specific items or to enact protective measures (like covering a particular group of materials).

- Label Covered Piles: If you have tarped bundles, attach a tag or label on the outside that identifies what’s underneath. This avoids the need to constantly peel back frozen tarps to see what’s there. Use weatherproof tags, marker on duct tape, or spray paint on the tarp itself to mark the contents (e.g., “2×4 Lumber – 8ft” or “Rebar – 20mm”). It sounds simple, but when everything is covered in uniform white snow, a little labeling goes a long way in quickly locating the right materials.

- Maintain Inventory Lists or Maps: Keep an inventory list and even a map of your storage yard or warehouse layout. Note what materials are stored where for the winter. This can be as simple as a clipboard with a sketch and item counts, or better yet, use an inventory management software (more on that soon) to log locations. Being able to reference a list and know that “50 sheets of drywall are in Warehouse A, 200 bricks are in Yard B under tarp #3” saves time and prevents items from being forgotten outside.

- Plan Access and Rotation: Organize your storage so that items you’ll need during the winter are the most accessible. For example, keep cold-weather construction supplies like insulated tarps, heaters, ice-melt pellets, or snow shovels at the front of storage where you can grab them quickly. Materials not needed until spring can be placed towards the back or bottom of piles. Also consider the order of use: if you know you’ll use certain materials sooner, place them on top of stacks or at door fronts. This avoids unnecessary digging and moving things around in freezing temperatures.

- Regular Inventory Checks: Winter conditions can change quickly, so make it a habit to inspect your inventory periodically. After severe weather events (heavy snow, high winds, sudden thaws), check that covers are intact, that no water has seeped into containers or boxes, and that everything remains in its proper place. These routine checks also help you spot if any materials are showing signs of moisture damage or if quantities are running low. Use the opportunity to update your inventory records if anything was moved or used.

By staying organized, you not only protect your materials from the elements but also protect your project from delays. Time lost searching for or salvaging materials in winter is time you can’t afford on a tight construction schedule. A well-organized inventory is like a well-organized toolbox – it keeps your team efficient and your materials safe, especially when conditions are tough.

5. Plan for Winter Supply and Demand

Protecting your inventory isn’t just about physical storage – it’s also about smart inventory management in anticipation of winter’s challenges. Consider the following planning tips:

- Stock Up Before Storms: In winter, deliveries can be delayed by weather and treacherous travel conditions. Analyze your project schedule ahead of the season and identify critical materials for ongoing jobs. Ensure you have enough of those on hand before major snowstorms or cold snaps hit, so work isn’t halted because a delivery got snowed out. For example, if you know you’ll need a lot of concrete blocks or roofing materials in January, arrange to have them delivered and stored by late fall. Better to warehouse extra materials safely than to be caught short when a blizzard closes roads for a week.

- Avoid Overstocking Vulnerable Items: While you want a healthy buffer of stock to avoid delays, be cautious about over-ordering things that are extremely sensitive to long-term cold storage. For instance, don’t stockpile more gallons of paint or adhesive than you’ll realistically use over the winter, since keeping a huge surplus through months of freezing temperatures increases the risk of spoilage if your storage situation falters. It might be wiser to plan smaller, more frequent shipments of those sensitive items (as long as you can get them) rather than one big order that sits all winter.

- Use Winter-Grade Products: Whenever available, opt for materials designed for winter use. There are cold-weather formulations for concrete mix, mortar, and certain adhesives that perform better in low temperatures (they might have accelerators or anti-freeze components). Similarly, fuel and oil for equipment come in winter grades (e.g., winter diesel or multi-viscosity oil that flows better in cold). Using these winter-grade supplies can reduce the chance that standard materials fail or get damaged due to cold conditions. It’s an upfront investment that can pay off in reliability.

- Coordinate with Suppliers: Talk to your suppliers about their winter operations. Some suppliers close during parts of winter or reduce their delivery schedules. Plan your inventory around these schedules – for instance, if a lumber yard shuts down for the last two weeks of December, make sure you have enough lumber before that period. Also inquire if they offer heated delivery trucks or special packaging for cold weather. If you absolutely need something delivered on a freezing day, knowing it won’t arrive frozen solid is important.

- Prepare Emergency Site Supplies: Keep a winter emergency kit for your jobsite in terms of inventory. This might include extra fuel (stored safely in proper containers), de-icing salt or sand, snow shovels, tarps and plastic sheeting, rope or bungee cords, and portable propane or kerosene heaters. These items aren’t directly part of building a structure, but they are crucial for protecting your site and inventory. For example, if an unexpected ice storm coats everything, having salt and shovels means you can clear your storage area and prevent accidents or further damage. If a tarp rips, having spares and rope means you can quickly re-cover the materials. Think of these as the “just in case” inventory that supports your main inventory.

- Document a Winter Plan: From an operational perspective, write down a simple winter preparedness plan for each project or site. This plan should outline what steps to take as temperatures drop or when a big storm is forecast. Include details like: who on the team monitors weather and makes the call to secure the site? Who is responsible for covering materials or turning on heaters? Is there a threshold at which work stops and inventory is secured (for example, if more than 6 inches of snow is predicted)? Having a documented plan and assigning responsibilities ensures that when winter weather looms, everyone knows their role in protecting the inventory and the site.

Planning ahead reduces the chance of unpleasant surprises. A lot of “protection” comes down to foresight – knowing what could go wrong and mitigating it before it happens. With smart planning and stock management in place, you’ll be well-prepared. Now, let’s look at how technology can further assist in managing and protecting your winter inventory.

Using Technology to Safeguard Inventory

While traditional methods like tarps and heaters are vital, modern technology can add an extra layer of protection and efficiency for your construction inventory in winter. An inventory management system is one such tool that can revolutionize how you track and safeguard materials across various locations. CyberStockroom, for example, is an inventory management software that offers features tailor-made for keeping tabs on all your construction assets – even through harsh weather. Here are some ways technology like CyberStockroom can help you protect and manage inventory when winter comes:

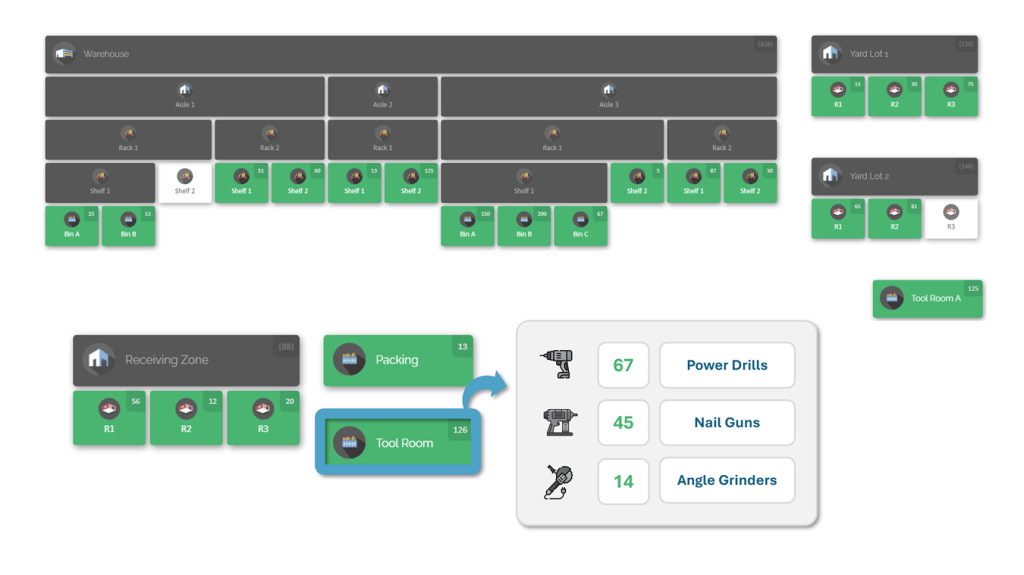

Visual Inventory Map for Visibility

CyberStockroom uses a unique map-based interface to give you a bird’s-eye view of all your inventory. You can create a virtual map of your business – including warehouses, storage yards, job sites, and even vehicles. When winter hits, this visual map becomes incredibly useful. You have instant visibility into where everything is stored and in what kind of environment. For instance, you might see that your insulation rolls are in Warehouse A (which is heated), while extra lumber is in Yard B (outdoors but under tarp). Seeing it on a map helps you quickly identify which items might be at risk in a cold snap. It’s like having a live blueprint of your inventory – you can immediately plan to move certain materials to warmer storage because you’re literally seeing their locations at a glance.

Real-Time Tracking and Updates

With a cloud-based system like CyberStockroom, any changes to inventory are updated in real time and visible to the whole team. Say your crew moves a batch of plywood from an open yard into a temporary heated trailer to protect it from an oncoming blizzard. Using the software, they can simply drag-and-drop those items on the inventory map from “Yard B” to “Heated Trailer C”. Instantly, everyone – from the project manager at HQ to the site supervisor – knows the plywood’s new safe location. This level of real-time tracking keeps all team members on the same page. No matter how many sites or storage areas you’re juggling, you won’t lose track of where materials have been relocated. In turn, this prevents the classic scenario of “I thought those pipes were still on site under the tarp, not back at the warehouse” confusion.

Loss and Theft Prevention

Unfortunately, winter downtime can lead to increased theft on some construction sites – shorter days and holiday breaks mean there may be less supervision at times. CyberStockroom helps combat this risk by keeping a detailed log of inventory transactions. Every check-in, check-out, or transfer of materials is recorded along with who did it and when. If something goes missing, you can trace back to see the last recorded movement or user interaction with that item. Beyond theft, this history also helps prevent loss from simple forgetfulness. For example, if a crew member moves some copper pipe into a locked shed for safekeeping, but doesn’t tell anyone, that pipe might be “lost” for the rest of winter. With an inventory system, that movement would be logged, and everyone would know where it went. This kind of transparency and accountability acts like an extra security camera on your stock, complementing your physical locks and lights.

Jobsite & Warehouse Coordination

One of the challenges in winter is deciding what to keep on the jobsite versus what to store in a central warehouse for warmth and safety. CyberStockroom makes this coordination much easier by showing stock levels across all locations in one dashboard. If a major blizzard is forecast and you decide to pause work for a few days, you can easily identify high-value or weather-sensitive items at the jobsite and plan to send them back to the main warehouse (and update the system accordingly, so everyone knows those items moved). Conversely, if you suddenly need something from off-site storage – say more propane heaters or concrete blankets at a job – you can see what’s available in your warehouse and allocate it quickly. The software essentially acts as a communication bridge between multiple storage points. It ensures that nothing is forgotten out in the yard and that the right materials are in the right place at the right time. This level of coordination can be the difference between a minor weather delay and a major disruption.

In essence, CyberStockroom (and similar inventory management tools) streamline the process of protecting and managing your construction inventory through the winter. The software won’t physically put a blanket on your materials or shovel snow, but it ensures you have complete awareness and control over your inventory. By knowing exactly what you have, where it is, and its status at all times, you can make informed decisions swiftly when winter weather threatens your assets. The correlation is clear: a well-managed inventory is far less likely to suffer winter losses. Technology makes that management easier, more proactive, and more accurate – a true game-changer for construction inventory people who want to stay one step ahead of the weather.

Site Security and Safety Measures for Winter

Physical protection of materials should go hand-in-hand with site security and general winter safety. Winter can introduce conditions that endanger not only your inventory but also your worksite’s overall security and the well-being of personnel. Here are some measures to consider:

- Lighting and Surveillance: With shorter daylight hours, ensure your storage areas are well-lit during early mornings and evenings. Install motion-activated lights around material storage zones – these not only help workers see hazards (like ice patches or debris) but also deter trespassers. Consider security cameras monitoring the areas where valuable inventory is kept. Modern CCTV systems can be weatherproof and have night vision capabilities. Even if you can’t monitor them 24/7, the presence of cameras and signage (e.g., “Surveillance in Use”) can discourage theft or vandalism. Good lighting and a watchful eye will protect your materials from those who might take advantage of winter lull periods.

- Fencing and Locks: If you store materials on an open site, invest in sturdy perimeter fencing and lockable gates. High winds and heavy snow can damage flimsy fencing, so inspect your perimeter regularly and repair any weaknesses. All storage units, trailers, and containers should have quality locks – use weather-resistant padlocks that won’t rust or freeze up. It’s also wise to clear snow away from gates or container doors; a pile of snow can freeze into a blockade, making it hard to access your own inventory (and easy for thieves to hide footprints). Essentially, maintain the security barriers and keep them functional despite the weather.

- Secure Loose Items: Winter storms bring strong winds – do a thorough “yard clean-up” of loose debris and materials before winter sets in, and continue to keep the site tidy. Items like sheets of insulation, metal roofing panels, plastic buckets, or even small tools can become dangerous projectiles in high winds or get buried under snow if not secured. Tie down or weigh down any materials that might blow away. Use storage bins for loose fasteners or small parts. For partially built structures or scaffolding, secure any materials (netting, temporary covers, etc.) so they don’t tear loose in a gale. This not only protects those materials from being lost or ruined, but also prevents damage to other inventory (or nearby property) from flying objects.

- Slip and Trip Hazards: Protecting inventory also means making sure the people handling that inventory can do so safely (a dropped box of tile because someone slipped on ice still results in lost inventory!). Keep pathways to storage areas shoveled and treated with ice melt. Use sand or gravel on icy spots to improve traction. If you have materials stored under snow, clearly mark them with stakes, cones, or tall flags. This way, equipment operators like plow drivers or forklift operators know there’s something under that snow and won’t accidentally plow into a hidden stack of materials. Additionally, provide proper winter PPE to workers (insulated boots with good grip, gloves, etc.) so they can move materials safely. A safe site means fewer accidents that could damage materials or slow down work.

- Emergency Access: In case of an emergency at the site (such as a fire, a burst water pipe, or any incident that requires urgent attention), ensure that emergency services can reach your storage areas. Keep driveways and access roads plowed and accessible. Do not pile snow or materials in a way that blocks fire hydrants, emergency exits, or access routes. Also, if you have large equipment like cranes on site that will be inactive for a while, follow recommended procedures to secure them (e.g., high winds and snow loads can affect cranes – they often need to be set in a specific safe position or even dismantled if not used for long periods). Properly stored and secured heavy equipment will be less of a hazard to your stored materials (and to people) in extreme conditions.

- Regular Safety Training: Brief your crew on winter-specific protocols. This includes how to safely remove snow from tarped materials (using soft brooms or plastic shovels so as not to tear covers), how to walk cautiously on ice and recognize black ice areas, and how to lift or handle materials that might be heavier if water-logged or frozen. Ensure everyone knows the signs of hypothermia and frostbite, and establish a schedule for warm-up breaks if they’re working outside. A healthy crew that’s alert and knowledgeable is more likely to take good care of your inventory too. They’ll cover things properly, handle fragile materials carefully in the cold, and avoid mistakes that could cause damage.

Security and safety may not be the first things that come to mind for “inventory protection,” but they are integral to it. A theft or an on-site accident can wipe out supplies just as surely as a snowstorm or freeze can. By winterizing your security measures and safety procedures, you create a well-rounded defense for your materials, equipment, and people throughout the cold season.

Conclusion

Harsh winter weather doesn’t have to spell disaster for your construction materials and inventory. With proper planning, storage solutions, and management strategies, you can significantly reduce the risks that snow, ice, and freezing temperatures pose to your supplies. We began by understanding the unique challenges winter brings – from moisture causing freeze-thaw damage to cold rendering certain materials useless or hard to work with. Armed with that knowledge, we outlined proactive steps: store materials smartly, control temperature and moisture, give special care to different material types, keep everything organized, and plan your inventory levels according to seasonal demands.

Crucially, we also saw how leveraging technology like CyberStockroom can give you an edge in this battle against the elements. A map-based, real-time inventory system ensures nothing “falls through the cracks” (or worse, gets buried under snow unnoticed). It keeps your team coordinated and informed, enabling quick action when conditions change.

By implementing these best practices, construction inventory managers and contractors in winter-prone regions can save thousands of dollars in prevented damage and avoid countless hours of delay. Your projects will stay on track and your materials will remain in good condition, ready for use when needed. Winter comes every year – but if you protect your construction inventory with the right tactics, you’ll greet the cold months with confidence instead of concern. Bundle up, stay organized, and let the winds blow – your inventory is ready to weather the storm.

Leave a comment