Imagine two warehouse supervisors talking about the same product but using completely different names. One refers to it as “Blue Widget Large” while the other calls it “BL-LG Widget”. They’re actually discussing the exact same item – yet because of inconsistent naming conventions, neither realizes it immediately. Situations like this can cause confusion, delays, or even costly mistakes in a warehouse operation.

In any warehouse or stockroom, keeping inventory organized isn’t just about where items are stored, but also how they are named and labeled. Standardizing your inventory naming and coding system might not be the most glamorous part of warehouse management, but it is one of the most crucial. In fact, establishing a clear inventory naming convention standard is a foundational best practice for efficient inventory management. It helps ensure that every team member and every system is referring to products in the same, consistent way.

The Problem with Inconsistent Inventory Naming

Without a standardized system, inventory names and codes can quickly descend into chaos. Different people or departments may label the same item in various ways, and over time your records become cluttered with duplicates and ambiguities. Here are some common issues that arise from poor or inconsistent inventory naming:

- Duplicate or Confusing Entries: The same product might be entered multiple times under slightly different names or codes. For example, “Bolt 3in”, “3-inch Bolt”, and “3in bolt” could all end up in the system as separate entries. This duplication skews stock counts and makes it hard to know the real quantity on hand.

- Difficulty in Searching and Tracking: If every item follows a different naming pattern, team members have to remember (or guess) which term to search for. One person might search the system for “adapter” while another might look for “connector” for the same item, leading to wasted time or missed information.

- Picking and Packing Errors: Inconsistent names increase the chance of human error. A warehouse picker could mistake one item for another if the names look alike or aren’t clearly distinguishable. For instance, items labeled “Widget L Blue” vs “Widget Blue L” could be easily mixed up during a hurried pick, resulting in the wrong product being shipped to a customer.

- Training New Staff Becomes Harder: When naming is all over the place, new employees have a steep learning curve. They might struggle to learn all the different aliases for products or the quirks of how things are labeled. This can slow down onboarding and increase reliance on tribal knowledge (i.e., “Ask Joe, he’s the only one who knows what this code means”).

- Miscommunication Between Departments: Perhaps your purchasing department refers to an item by a vendor’s part number, while the warehouse has its own label for it. If someone from accounting, sales, or management is discussing inventory, the terms might not line up, causing confusion. In industries with strict compliance or lot tracking (like food, pharma, or cannabis), these inconsistencies can even lead to compliance issues when reporting or auditing inventory.

- Challenges in Reporting and Analysis: Good inventory analysis relies on clean data. If items aren’t named consistently, generating accurate reports is a nightmare. You might end up with separate entries for what should be one item, making it difficult to gauge true stock levels, sales velocity, or reorder needs. Trends can be misinterpreted because the data is fragmented across multiple labels for the same thing.

In short, a lack of naming standard leads to inefficiency and errors. It’s like having a library where books are randomly labeled by different people – one calls it “Moby Dick”, another files the same book under “Whale Story”. Finding what you need or trusting the catalog becomes nearly impossible.

These problems not only waste time and money, but they also erode confidence in the inventory records. Warehouse operations thrive on accuracy and clarity, and inconsistent naming undermines both. So how do we fix it? By implementing a standard naming and coding convention for all inventory items.

Why Standardizing Inventory Naming and Coding Matters

Adopting a standard inventory naming convention isn’t just about tidiness – it directly impacts the productivity and accuracy of your warehouse. When every item is labeled and coded in a consistent, logical way, the entire inventory management process becomes smoother. Here are some of the key benefits of standardizing how you name and code inventory:

- Quick Identification and Retrieval: With a clear naming system, staff can immediately recognize what an item is from its code or name without extra guesswork. This speeds up tasks like picking orders, restocking shelves, or verifying inventory during cycle counts. A standardized code (e.g., a SKU) that encodes key info like item type or size means a worker can tell at a glance, “Ah, this code means it’s a large blue widget,” and grab the right item quickly.

- Improved Accuracy and Fewer Errors: Standard names and codes help ensure that everyone is speaking the same language. The risk of grabbing the wrong item due to a naming mix-up goes way down. For example, if there’s only one code for Product X across the company, there’s less chance of accidentally misidentifying it. Consistency acts as a safeguard against human error in picking, receiving, and data entry.

- Efficient Communication: When sales, warehouse, procurement, and management all use the same terminology, there’s far less room for miscommunication. A standardized naming convention means if someone from the sales team asks about Item ABC-100 by that code, the warehouse staff know exactly what they mean. It streamlines cross-department conversations and ensures everyone is on the same page, whether it’s in meetings, emails, or documentation.

- Faster Training and Onboarding: A new hire can learn the inventory system much faster if there’s a logical pattern to item names or codes. Instead of memorizing a hodgepodge of arbitrary names, they can pick up the code logic (for example, “ABC” category items are always accessories, “XYZ” are always spare parts, etc.). This not only reduces training time but also boosts the new employee’s confidence in managing stock on their own.

- Better Inventory Tracking and Analytics: Clean, consistent data is easier to analyze. When all transactions for an item roll up to one unified name/code, you can trust your reports. You’ll accurately see how much was sold, where it’s stored, and when to reorder, without having to merge or deduplicate records. Forecasting and inventory optimization become more reliable, because you’re not inadvertently treating the same item as two different things in your system.

- Scalability as You Grow: As your operation expands – more products, more SKUs, perhaps additional warehouse locations – a standard naming convention will scale with you. You’ll already have a framework for adding new items in a consistent way. This prevents chaos as the catalog grows. It also allows any new warehouse or site you open to immediately align with the company-wide system. Essentially, standardization future-proofs your inventory management against growth-related confusion.

- Integration with Technology: A consistent coding system works hand-in-hand with technology like barcode scanners, warehouse management systems, and reporting tools. For instance, if you decide to implement barcoding, having standardized SKUs means you can generate barcode labels for each SKU and be confident each one is unique and meaningful. Your software will also thank you – integrations or data imports/exports are smoother when you don’t have to clean up inconsistent item names. (Imagine linking your inventory system with an e-commerce platform or accounting software – uniform SKUs make the data sync much easier and error-free.)

- Professionalism and Credibility: This is a more subtle benefit, but not trivial. When your inventory is well-organized and uniformly labeled, it gives an impression of professionalism to anyone who interacts with it. Auditors, new managers, or even clients touring your facility will immediately notice the difference between a rag-tag naming approach and a well-ordered one. It shows that your operation pays attention to detail and runs a tight ship, which can boost confidence among stakeholders and customers alike.

In summary, standardizing inventory naming and coding creates a domino effect of positive outcomes: everything from daily warehouse tasks to high-level decision making gets easier and more accurate. It’s about creating one source of truth for what each item is called. Once that’s in place, you eliminate the confusion and inefficiency that comes from multiple naming systems colliding.

Now that we know why it’s so important, let’s talk about how to actually create these standard naming conventions. What does a good inventory naming standard look like, and how can you develop one that fits your business?

Best Practices for Establishing Inventory Naming Conventions

Creating a naming convention for your inventory requires some upfront thought, but it pays off massively in the long run. Here are some best practices and guidelines to help you design an effective inventory naming and coding system:

- Keep It Simple and Consistent: Choose a format for your item names or codes and stick with it. Simplicity is key – you want codes that are easy to read and communicate. For example, decide if your items will be identified by a numeric SKU, alphanumeric code, or a combination of descriptive words. Once decided, apply that same format everywhere. Avoid unnecessary complexity or too many different formats. Consistency means if you use a hyphen to separate parts of a code (like ABC-123), do that every time; if you abbreviate “PKG” for package in one code, use the same abbreviation for all similar items.

- Use Meaningful Categories or Prefixes: It often helps to build some meaning into your item codes via prefixes. A few letters at the start of a SKU can designate a broad category or product family. For instance, ELE-### for all electronics parts or OFF-### for office supplies. This way, anyone can tell at a glance what general area a code refers to. Prefixes can also be vendor codes if that’s useful (like SNY-### for products from Sony). But limit the prefix to a short identifier – the goal is quick recognition without making the code unwieldy.

- Incorporate Key Attributes (When Relevant): Depending on your industry, including certain product attributes in the naming convention can be very useful. For apparel or retail, size and color might be critical (e.g., a code ending in -BL-LG for “blue, large”). For machinery parts, you might include material or model (e.g., GASK-STEEL vs GASK-RUBR to indicate gasket material). However, include attributes thoughtfully. Only encode the details that truly help distinguish variants. You don’t need to cram every spec into the name – just the ones that someone picking or ordering that item absolutely needs to differentiate.

- Avoid Ambiguous Characters and Symbols: Steer clear of characters that can be easily misread or cause technical issues. For example, the letter “O” and the number “0” (zero) often get confused, as do the letter “I” and number “1” in certain fonts. It’s best to avoid using O, I, or L in isolation for that reason. Also avoid symbols like / or \ (which might be interpreted as a file path by software), commas (which can confuse CSV files), or other punctuation that could trip up databases or barcode scanners. Stick to alphanumeric characters and maybe simple dashes or underscores if needed. The goal is a code that a human or a computer will never misinterpret.

- Choose a Manageable Length: Determine an ideal length range for your codes – generally long enough to cover the needed info, but short enough to be quickly readable. Many businesses find something in the range of 6-12 characters is plenty. For example, HVAC-1001 is 9 characters including the hyphen. It’s descriptive but still concise. If codes get too long (say 20 characters), they become prone to typos and hard to fit on labels. On the flip side, too short (like just 2-3 characters) and you’ll run out of unique combinations or they may not convey enough info. Aim for a consistent length where possible, as this also looks neater in lists and reports.

- Ensure Uniqueness: This might sound obvious, but it’s vital: each item must have a unique identifier under the system. No two different products should end up with the same code or name. This is where a centralized approach (and ideally software) is helpful to prevent duplicates. When designing the convention, think ahead to make sure you won’t accidentally overlap codes. For instance, if one category uses numeric codes 001-999 and another category does too, you’ll need a prefix or different number ranges to keep them distinct. Uniqueness ensures that when someone references an item code, there’s zero confusion about which item it refers to.

- Don’t Overload Codes with Info: There’s a balance to strike between descriptive codes and “anonymous” codes. Some companies use entirely random or sequential numbers with no embedded meaning (which can simplify adding new items), while others include a lot of product details in the code (which can become cumbersome). A best practice is to avoid trying to make the code do too much. It’s there to identify, not describe the item fully – that’s what your item description field is for. For example, a code HD-100 for “Half-Door Cabinet, 100cm” is fine, but you don’t need CABINET-HALFDOOR-GRAY-100CM-METAL-2SHELF as a code – that’s what the description is for. Overly complex codes are hard to maintain; keep them lean and let your inventory system store the detailed specs separately.

- Document the Naming Schema: Once you decide on the rules (prefixes, lengths, formats, abbreviations, etc.), write it down in a clear reference document. This guideline document should be available to everyone who has the authority to create or modify item names/codes. It might include a list of approved category prefixes, a table of common abbreviations (e.g., “PK” for pack, “BK” for black color, etc.), and examples of correct format. Having it documented ensures that even as personnel changes or memory fades, the standard persists. Make this part of training for relevant staff.

- Plan for Growth and Changes: Design your naming system with the future in mind. If you currently have 100 products but expect to expand to 1,000, make sure your coding scheme can accommodate that. This could mean reserving a certain number of digits for numbers or leaving some sequences unused for future categories. Also consider product line changes: if you might start selling a new category of items next year, have a prefix or scheme in mind for them so they slot right in. The last thing you want is to run out of numbers or have to completely overhaul the system in a year or two because it wasn’t scalable.

- Regularly Audit and Clean Up: Even with standards in place, perform periodic checks on your inventory data to catch any stray deviations or mistakes. It’s good to do an audit perhaps annually (or more often for fast-moving inventories) where you or a data manager reviews item listings for any anomalies – e.g., an item that doesn’t fit the naming pattern (perhaps entered by someone who didn’t follow the guide). Clean up duplicates or incorrect names when found. This keeps the data healthy. Think of it as spring cleaning for your catalog. Regular maintenance prevents small inconsistencies from accumulating into bigger problems over time.

By following these best practices, you’ll create a naming convention that is logical, robust, and user-friendly. It should serve your team well and reduce confusion. The convention might be as simple as “Category abbreviation + incremental number” for a smaller operation, or a slightly more structured code for a larger one – but whatever it is, if it’s well-thought-out and consistent, it will do the job.

Designing the convention is one part of the puzzle.

Using CyberStockroom to Streamline Naming Standards

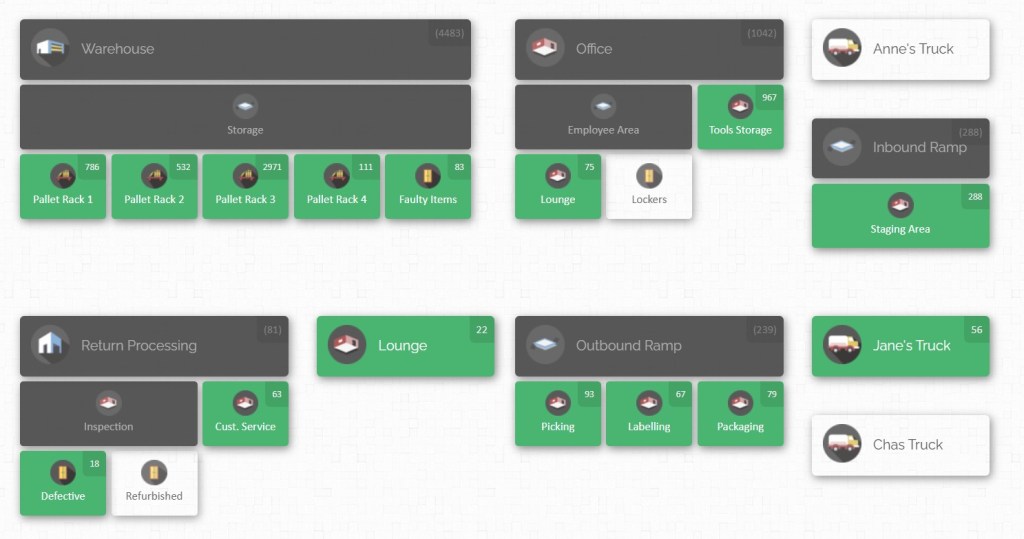

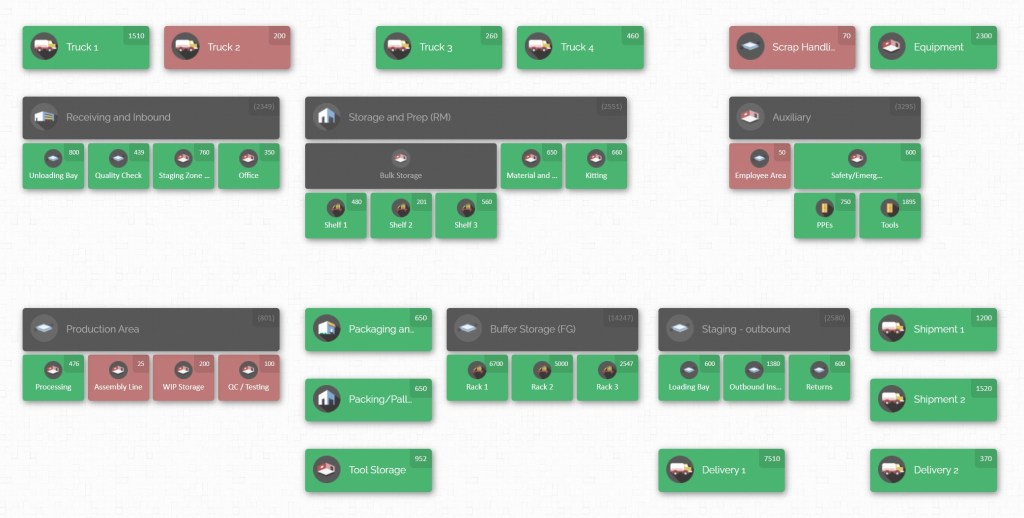

Implementing a standard naming system is much easier when you have software that supports your efforts. CyberStockroom, for instance, is an inventory management platform built with simplicity and clarity in mind, which aligns perfectly with the goals of standardized naming. Here’s how CyberStockroom can help you establish and maintain consistent inventory naming and coding:

Centralized Inventory Catalog

In CyberStockroom, all your products are stored in one centralized catalog (or database). When you add a new product, you give it a name or SKU code according to your convention. Because it’s a single system, everyone in your team sees and uses the same item definitions. This eliminates the risk of one department using a different naming scheme than another – the software becomes the “single source of truth” for item names and codes.

Custom Fields for Additional Info

Recall the best practice about not overloading your codes with too much information. CyberStockroom allows you to use custom fields for products. This means you can keep the item code simple, but still record all the important attributes (like color, size, supplier, etc.) in separate fields. For instance, you might have a product with code “CAB-100” and then custom fields indicating it’s a “Cabinet, Half-Door, Gray, 100cm”. The code stays clean, but all those details are still attached to the item in the system. This structured approach ensures consistency because anyone adding a new item has designated places to input each type of info, rather than jamming it all into one name string.

Barcoding

CyberStockroom supports barcoding, meaning you can print barcode labels for your standardized item codes and use scanners for transactions. This ties directly into naming conventions – since you have unique SKUs or codes for each item, those become the identifiers on your barcodes. Staff can scan an item during check-in or check-out, and the system will pull up the exact standardized name every time. The combination of barcodes and standardized codes dramatically cuts down data entry errors. CyberStockroom makes it straightforward to implement this: you can generate barcodes for item codes and the system will recognize them instantly when scanned.

Real-Time Updates Across the Team

Being cloud-based, CyberStockroom ensures that when someone updates an item name or details, that change is reflected for everyone, everywhere. So if you decide to rename an item or correct a naming inconsistency, the team on the warehouse floor, the managers in the office, and even a remote team member will all see the updated standardized name in real time. This instant synchronization supports your standardization efforts – you won’t have lingering old names in someone’s outdated spreadsheet or personal notes, because the live system is always current.

User-Friendly Interface

One challenge with maintaining a naming convention is getting everyone on board. If the system is clunky, people might create workarounds outside the system (like personal item nicknames). CyberStockroom’s map-based interface is intuitive and even visually appealing, which encourages staff to use it as intended. When they do all inventory transactions in one system that’s governed by the naming standards, compliance with the convention becomes natural. It’s far easier to reinforce, “Use the item code from the system,” when the team actually enjoys using the system to begin with.

Scalability and Flexibility

As your naming needs evolve, CyberStockroom evolves with you. Adding new categories or adjusting your naming scheme? You can easily create new location sub-maps, new custom fields, or new product categories in the software without breaking your existing data. The flexible structure (like being able to rearrange your map layout or update product info on the fly) means your naming convention can adapt to changes in your business. The system won’t lock you into a rigid format if you find a need to tweak the conventions later; you can update your documentation and adjust item entries accordingly while keeping everything organized.

In summary, CyberStockroom functions as a partner in your standardization journey. It’s not just a passive tool; it actively reinforces good inventory practices by design. The combination of a clear naming convention with CyberStockroom’s features like the Inventory Map and centralized database creates an environment where errors and inconsistencies have little room to survive.

For warehouse managers and operations people, using a platform like this means less time policing how items are named and more time reaping the benefits of a well-organized inventory. CyberStockroom essentially bakes your naming rules into daily operations – ensuring that whenever someone moves inventory, views stock levels, or adds a new item, the standard conventions are front and center.

How to Implement a Standard Naming System in Your Warehouse

By now, we’ve covered why you need a standard naming system and what it should look like. The next question is: How do you put this into practice? Implementing a new or improved naming convention across your inventory may seem daunting, especially if you have a lot of existing data. But with a structured approach, you can make the transition smoothly. Here’s a step-by-step plan to get you started:

- Audit Your Current Inventory Data: Begin with understanding the status quo. Pull a report of all current item names, codes, and descriptions in your inventory system (or spreadsheets). Identify duplicates, inconsistencies, and any unclear labels. This audit will highlight the scope of changes needed. You might find, for example, that you have 5 different naming formats in use, or several items that are essentially the same but labeled differently. Make note of these issues as targets to fix.

- Design or Refine Your Naming Convention: Using the best practices we discussed earlier, develop the new naming standard that you want to implement. If you already have a partial system that just needs refining, decide what changes are needed (maybe adding prefixes, or standardizing abbreviations). Involve key team members in this process – warehouse leads, inventory controllers, etc. – as they will have practical insights and it helps get buy-in. The outcome of this step should be a clear documentation of the convention (rules, examples, prefix list, etc.).

- Test the Convention on a Sample: Before applying it to everything, test your naming scheme on a small subset of items. Take a dozen products of various categories and apply the new naming/coding to them. Does it make sense? Are the codes still unique and clear? Show this sample to team members who will use it daily and get feedback. Maybe they’ll suggest a better abbreviation or catch a potential confusion. It’s better to tweak the system now than after you’ve rolled it out everywhere.

- Update Item Names/Codes in the System: Once you’re confident in the new convention, it’s time for a bulk update. Depending on your inventory size, you might do this all at once or in phases. Using your chosen inventory software, update each product entry to the new standardized name or code. Many systems allow importing a spreadsheet to update multiple items at once, which can speed things up. As you do this, double-check that each item still has a unique identifier after the change and that spelling/formatting exactly follows your documented rules.

- Communicate the Changes: Inform your entire team (and any other stakeholders like purchasing or finance) about the new naming system. Share the documentation widely. Explain why the change is happening – emphasize the benefits such as easier finding of items and fewer errors. People are more likely to embrace the change if they understand the reasoning. Also, provide a quick-reference sheet or guide that employees can keep at their workstation, listing common prefixes or examples. This helps in the early days when they’re still getting used to the new codes.

- Relabel as Needed: If your warehouse uses physical labels on shelves, bins, or products, you’ll need to update those to match the new naming convention. Print new bin labels with the standardized names or codes. If items themselves are tagged or barcoded with the old identifiers, plan a relabeling effort for those too. This step is crucial – the physical and digital worlds must be in sync. It might be a big one-time project to relabel, but consider doing it in sections to minimize disruption (for example, one aisle or product category at a time).

- Train the Team: Hold a training session or toolbox talk to walk the team through the new naming conventions. Show them examples of old vs new labels, demonstrate searching for items in the system using the new names, and make sure everyone knows how to add a new item following the standard. Encourage questions – sometimes a rule that seemed clear on paper might confuse someone, which is valuable feedback. Ensure every relevant team member, from managers to stock clerks, is comfortable with the new system.

- Monitor and Support: After implementation, keep an eye on how it’s going. Monitor for any slip-ups or cases where someone might have added a new item not following the convention. It can help to assign an “inventory naming champion” or data steward – a person responsible for periodically reviewing new entries and overall data hygiene. Encourage the team to give feedback if something about the convention isn’t working well in practice. Sometimes small adjustments might be needed, and that’s okay if it makes the system more user-friendly while keeping consistency.

- Celebrate the Wins: When you notice the positive effects – like faster picks, clearer reports, or a big drop in mis-picks – share that success with the team. Recognizing improvements reinforces why the standardization was worth the effort. For example, if cycle count discrepancies went down compared to last quarter, point to the naming cleanup as one contributing factor. Celebrating these wins will help maintain enthusiasm and compliance with the system moving forward.

Implementing a standardized naming convention is a project, but as outlined, it’s very manageable step-by-step. The key is to be methodical and patient. You may have to run old and new systems in parallel briefly (with cross-references) to ensure nothing is lost in translation, but once the new system takes hold, you’ll wonder how you managed before.

Conclusion

In the fast-paced environment of warehouse operations, clarity and consistency can make the difference between a smooth day or a logistical headache. Standardizing inventory naming and coding is one of those behind-the-scenes practices that profoundly improves how your business runs. It reduces errors, accelerates processes, and gives everyone from the stockroom to the front office a common language to work with.

By investing the time to create a solid inventory naming conventions standard – and by using supportive tools like CyberStockroom to maintain it – you set your operation up for long-term success. The payoff comes in many forms: quicker training of staff, more reliable inventory counts, easier expansion to new locations or sales channels, and ultimately, better service to your customers (since the right products are always identified and delivered).

Remember, the goal is to be able to answer the fundamental inventory questions (“What is it? How many do we have? Where is it located?”) without hesitation or confusion. A well-crafted naming system, consistently applied, ensures that you can answer those instantly and accurately every time.

If your warehouse or business is struggling with messy inventory data or you’re preparing to scale up, there’s no better time to implement naming best practices than now. Start small, get the system in place, and watch how much easier daily inventory tasks become. Your future self – and your whole team – will thank you for standardizing your inventory naming and coding today.

Leave a comment