Construction projects are complex endeavors with tight budgets and schedules. In an industry where profit margins often hover around just 5% of project costs, every efficiency gained can significantly boost the bottom line. One major area of potential efficiency is inventory management – the way materials, tools, and equipment are procured, stored, tracked, and utilized on job sites. Effective inventory management might not sound as exciting as pouring concrete or erecting steel, but it can make the difference between a profitable project and a financial disaster. In fact, studies have found that up to 30% of all building materials delivered to a construction site can end up as waste, and construction site thefts and losses cost billions annually. These issues all eat directly into a project’s profits.

The good news? Better inventory management practices and tools can dramatically reduce these losses and add real dollars back into a contractor’s pocket. By cutting waste, preventing theft, avoiding project delays, and improving productivity, effective inventory control yields a high return on investment (ROI) for construction companies.

In this article, we’ll explore the hidden costs of poor inventory management, how improved practices drive ROI, and what technologies like CyberStockroom’s visual inventory management software are doing to help construction teams manage inventory smarter. Whether you’re a construction manager, a procurement officer, or a small-to-medium contractor, understanding inventory management ROI in construction can help you deliver projects on budget and on time – and ultimately improve your company’s profitability.

The Hidden Costs of Poor Inventory Management in Construction

Before diving into how to improve inventory practices, it’s important to understand just how much poor inventory management can cost construction projects. When materials and equipment aren’t managed effectively, a host of problems can occur – each carrying a price tag that erodes project ROI. Some of the major hidden costs include:

- Material Waste and Surplus: Construction sites are notorious for material waste. In fact, industry research indicates roughly 20–30% of construction materials delivered to a typical site end up as waste. Think about that – nearly a third of all lumber, drywall, concrete, steel, and other materials may be cut off, damaged, or simply never used and thrown into dumpsters. Some waste is inevitable due to off-cuts and breakage, but much of it comes from over-ordering and poor tracking of inventory. Excess materials that go unused represent money spent that you’ll never recoup. Not only that, disposing of construction waste incurs additional costs (dumpster fees, hauling, environmental fees) and has sustainability impacts. Poor inventory management – like lack of visibility into what’s on hand or inaccurate material estimates – directly contributes to these surpluses and waste on site. Every wasted truckload of lumber or pallet of tiles is essentially lost profit. Reducing waste through better inventory control provides an immediate ROI by recovering those costs.

- Theft and Losses: A less visible but equally damaging cost is theft of materials, tools, and equipment from construction sites. Job sites, especially those left unsecured after hours or spread across wide areas, are tempting targets for thieves. According to the National Equipment Register, construction site theft costs the industry over $1 billion annually in the U.S. When expensive items like generators, copper wire, power tools, or even heavy machinery go missing, the direct replacement cost can be enormous. But the indirect costs may be even higher: stolen critical materials can halt work (causing delays), and repeated thefts can drive up insurance premiums. There’s also loss due to simple misplacement or poor record-keeping – tools “lost” on site or materials that can’t be located when needed. Studies show that only around 20–25% of stolen equipment is ever recovered, meaning most losses are permanent. If inventory isn’t tracked carefully, crew members might not even realize something is missing until it’s needed – at which point the project could suffer a setback. Inventory shrinkage (the difference between recorded inventory and actual count) from theft or errors directly eats into profits. For small-to-medium contractors, a few missing high-value items can wipe out the profit on a job. Preventing theft and loss through better tracking and accountability can save a huge amount of money over time, delivering a strong ROI.

- Project Delays and Downtime: Construction is highly schedule-driven – delays can trigger penalty clauses, extend equipment rental costs, and inflate overhead. Poor inventory management often leads to stockouts – not having the right material or part on site when it’s needed. If a critical item (say, a specific fixture, pipe fitting, or a batch of steel beams) isn’t available at the right time, the crew may have to stop work or shift focus, which is inefficient. In a worst-case scenario, work grinds to a halt while waiting days or weeks for replacement materials to arrive. These delays cost real money: workers and machinery sit idle (wages and rentals accrue without productive output), project completion gets pushed out (which can incur late delivery penalties or client dissatisfaction), and there’s often an added rush shipping fee or premium on the last-minute procurement of the missing item. It’s been said in construction that time is money – and nowhere is that more true than when downtime hits due to inventory mismanagement. Every unexpected delay can reduce the overall ROI of the project. For example, if an entire concrete crew is on site but can’t pour because rebar ties or forms were not delivered, you’re paying for a day’s labor with nothing to show for it. Effective inventory management ensures materials and tools are in the right place at the right time, thus avoiding costly stoppages and keeping the build on schedule (and on budget).

- High Carrying Costs and Storage Overheads: On the flip side of stockouts is the problem of carrying too much inventory “just in case.” While having a buffer stock can prevent shortages, excess inventory comes with its own costs. You pay upfront for materials that might sit unused for months or years – tying up capital that could be used elsewhere. Additionally, storing large volumes of inventory incurs handling and storage costs: renting extra warehouse space or storage containers, paying staff to manage and guard those materials, and perhaps needing equipment to move them around. There’s also the risk of obsolescence or spoilage – certain materials can expire, degrade, or go out of spec if kept too long (think of things like paint, sealants, or even fasteners that might rust). And more inventory on hand can mean more opportunity for theft or damage if not carefully monitored. All these contribute to what are known as inventory carrying costs. In general business, carrying costs can range from 20% to 50% of the inventory’s value per year when you factor in warehousing, insurance, and opportunity cost. Construction inventories can be especially costly to hold, given the space needed for bulky materials. Every dollar spent storing or protecting surplus inventory is effectively reducing your ROI. By optimizing inventory levels – keeping stocks lean but sufficient – construction companies can free up working capital and avoid paying for storage of stuff they don’t immediately need. Good inventory management strikes a balance where you minimize excess without risking shortages, thereby lowering carrying costs significantly.

- Low Productivity and Wasted Labor: One often overlooked cost of poor inventory organization is the lost time workers spend searching for tools, equipment, or materials. On a busy job site, how often have you seen crew members wandering around looking for a particular tool, or driving back to the yard because the widget they need isn’t where they thought it was? Those minutes add up. In fact, a survey by ForConstructionPros found that workers may spend up to 90 minutes per day simply looking for “stuff” – whether it’s tools, supplies, or information. For a midsize construction company with dozens of employees, that can translate to thousands of hours of unproductive time per year. Consider a hypothetical 50-person construction firm: 90 minutes of lost time per person per day equates to roughly 18,000 hours per year wasted on searches and run-arounds. If the average fully burdened labor cost is, say, $40–$50 per hour, that’s easily $700k–$800k of labor cost essentially thrown away annually – just from inefficient inventory and tool management! Even if that estimate is high for your crew, it illustrates a real problem: disorganization costs money. When inventory isn’t tracked and locations aren’t clear, workers might also hoard extra tools or materials “just in case,” further driving up your costs (and ironically making it even harder to find things). Improving inventory management – for example, by clearly labeling storage locations, keeping an updated inventory log accessible to the team, or using technology to quickly check items in and out – can drastically reduce the time wasted. If you could even save a fraction of that 90 minutes a day, the labor hours regained go back into productive work, which improves project timelines and profitability. In short, organized inventory = more efficient crews = better ROI.

- Poor Decision-Making and Missed Opportunities: Another cost that’s hard to quantify but very real is the opportunity cost of not having good inventory data. Without clear insight into inventory levels and usage rates, construction company management might make suboptimal decisions that affect profitability. For instance, you might over-purchase materials “just to be safe” because you don’t have confidence in the stock counts – resulting in leftover inventory that ties up cash. Or you might miss out on bulk discounts or efficient procurement schedules because of last-minute buying to cover unexpected shortfalls. Lack of inventory visibility can also strain relationships with suppliers and project stakeholders: frequent emergency orders or schedule changes due to inventory issues can paint a picture of disorganization, potentially leading to higher prices from vendors or skepticism from clients. Conversely, good inventory management provides data that can be used to negotiate better with suppliers (you know exactly how much of a material you’ll need over the project and can perhaps arrange a bulk purchase or consignment), and to plan project phases more smoothly. It also enables accurate job costing – you can track exactly how much material was used versus estimated, informing future bids and preventing cost overruns. When inventory is effectively managed, it unlocks opportunities to save money and improve processes that a disorganized operation would simply never realize. All of these factors contribute to improved ROI over the long term.

Bottom line: The costs of poor inventory management in construction are very high – often hidden in plain sight. Wasted materials, stolen tools, idle crews, storage expenses, and inefficient buying practices can devour a contractor’s thin profit margins. If left unchecked, these issues can make a difference between a project that comes in under budget and one that loses money. This is why focusing on inventory management isn’t just an operational tweak; it’s a strategic move to improve financial performance. Next, let’s look at how implementing effective inventory management practices can directly address these issues and deliver a strong ROI.

How Effective Inventory Management Boosts ROI

Now that we’ve identified where the money leaks out, how exactly can better inventory management plug those leaks and generate a return on investment? Effective inventory management isn’t just about cutting costs – it also contributes to smoother operations and better outcomes, which can drive profitability from multiple angles. Let’s break down the key ways a well-managed inventory translates to tangible ROI in construction projects:

1. Minimizing Waste and Optimizing Material Use

Every piece of material that goes unused or ends up in a dumpster is essentially money lost. Effective inventory management helps ensure that materials are fully utilized and not over-ordered. This starts right from the planning phase: with accurate inventory tracking from past projects, estimators can forecast needs more precisely, reducing the tendency to pad orders with large “just in case” surpluses. During construction, having a clear view of current stock levels prevents inadvertently reordering something you already have plenty of. It also allows for smarter use of off-cuts and leftovers – for example, keeping an inventory of partial drywall sheets or surplus bricks and finding ways to use them in non-structural parts of the project, rather than automatically ordering new. On large multi-phase projects, good inventory management might mean transferring unused materials from one phase or site to the next, instead of letting them sit or scrapping them. Altogether, these practices can significantly cut down that 30% waste statistic. If you can even halve the typical material waste percentage, the cost savings are enormous – imagine converting 15% of your material budget from waste to productive use. That directly boosts ROI by making the most of every dollar spent on materials.

Additionally, reducing waste has indirect financial benefits. There’s less cost for waste disposal and less time spent handling excess materials. It can even improve your company’s reputation and ability to win bids, as more clients (and regulations) are focusing on sustainability and waste reduction. Being able to say you have a robust material management plan that minimizes waste could make your bids more attractive. In summary, using inventory management to curtail waste and overstock means you spend less and get more output from the materials you buy – a clear return on investment.

2. Preventing Theft, Loss, and Shrinkage

Earlier, we highlighted how theft and loss can silently drain thousands from a project. An effective inventory management system institutes controls and visibility that deter theft and quickly flag any discrepancies. This can be as simple as having a check-in/check-out log for tools and equipment, or as advanced as using software that logs every inventory transaction by user. When everyone from site supervisors to crew members knows that each tool and material is being tracked and accounted for, there’s an added layer of accountability. It becomes much harder for items to just “walk away” without anyone noticing.

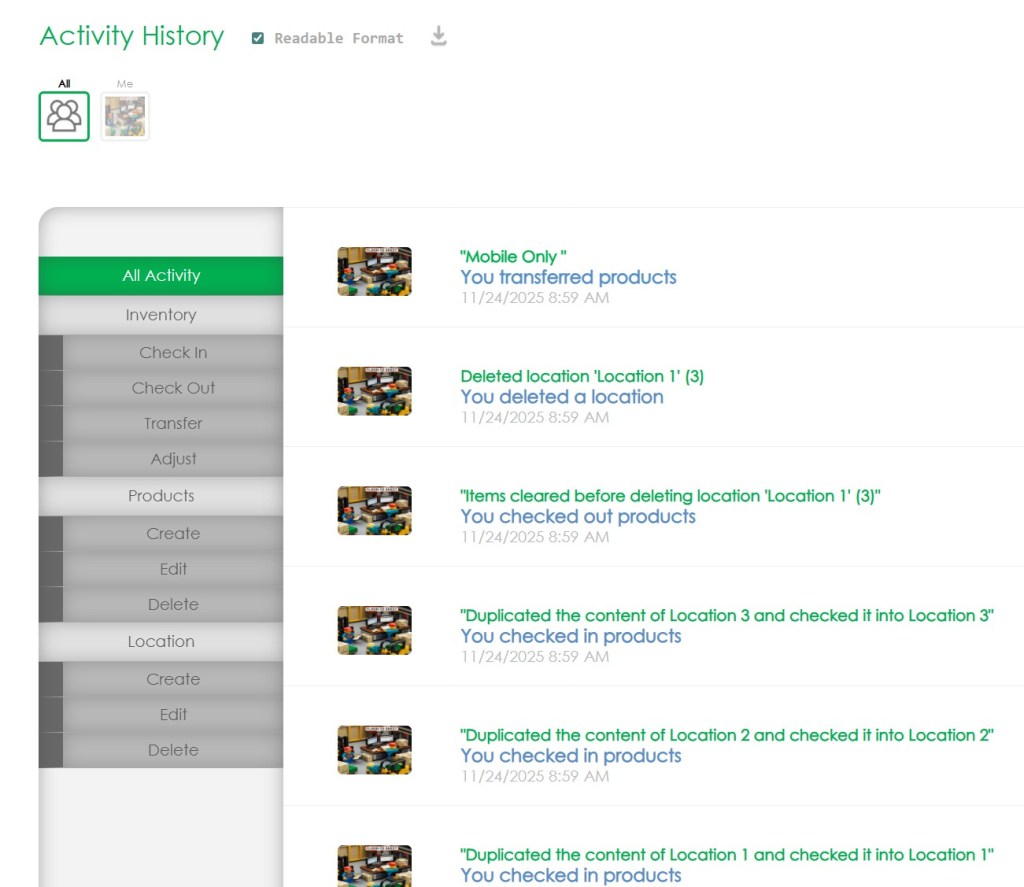

Modern inventory management solutions often include audit trails and activity history for exactly this reason. For example, CyberStockroom (which we’ll discuss in detail shortly) allows you to see who moved or used an item last, when it happened, and where it went. If something goes missing, you have a paper trail (or rather, a digital trail) to investigate. This not only helps recover missing items or pinpoint where loss is occurring, but also serves as a deterrent – employees and even external parties are less likely to steal or be careless when they know the inventory is closely monitored. Some companies also implement periodic cycle counts (spot checks of inventory) using barcode scanners to quickly verify that physical counts match the records. Discrepancies can then be addressed right away rather than discovered months later.

The ROI from theft prevention is straightforward: every item you don’t lose is money saved. But beyond direct replacement costs, preventing loss means projects stay on track (no delays waiting for replacements) and insurance claims and premiums are kept low. It also means you don’t have to pad your bids as much to account for “expected theft/shrinkage” – you can be more competitive or reap more profit. If effective inventory management saves even 5% of assets from theft or loss that would have occurred otherwise, that could translate to tens or hundreds of thousands of dollars on a large project. That alone can easily justify the investment in a good tracking system or process.

3. Avoiding Stockouts and Costly Delays

Staying on schedule is critical in construction, and materials availability is a big part of keeping the schedule. Effective inventory management gives you a clear line of sight on what you have and what you’ll need, so you can proactively avoid running out of key items. This might involve setting minimum stock thresholds that trigger reorders or alerts. For instance, if you know you must have at least 200 units of a certain fastener on hand to keep work uninterrupted, an inventory system can warn you when you dip below that level before you actually run out. By tracking usage rates, you can anticipate when you’ll need to reorder aggregates, lumber, piping, etc., well in advance.

Furthermore, with a holistic view of inventory across locations, you might be able to redeploy resources to prevent shortages. Suppose Project A is short on a specific size of lumber, but your inventory system shows Project B (or the central yard) has plenty of surplus of that size. You can transfer the material immediately rather than placing an urgent order with a supplier. This kind of responsiveness comes only when you have consolidated, up-to-date inventory data – something that a good inventory management practice or software provides in real time.

The ROI from avoiding stockouts is multi-fold: you eliminate the premium costs of last-minute orders (rush shipping, higher unit prices on small orders); you prevent work stoppages that could cost thousands per hour in labor and equipment downtime; and you stay on track to meet deadlines, which preserves your profitability and reputation. It’s hard to overstate how one small missing part can cause an outsized delay. For example, if an electrical subcontractor can’t finish their work because a specific type of conduit or cable wasn’t on site, it might delay wall closures, which then delays inspections, and so on – a domino effect. Avoiding those scenarios by keeping the right inventory at the right time protects the project’s ROI from erosion due to schedule slips.

4. Lowering Inventory Holding Costs

We touched on carrying costs earlier – all the expenses that accumulate when holding inventory. Effective inventory management aims to keep inventory as lean as possible without compromising operations. One approach borrowed from manufacturing is Just-In-Time (JIT) delivery: coordinating material deliveries to arrive shortly before they are needed in the construction sequence, rather than far in advance. Construction isn’t an assembly line, but elements of JIT can apply (for example, having drywall delivered the week it will be installed, instead of stockpiling it months earlier). This requires confidence in your schedules and your suppliers, but when executed, it slashes the time you pay to store and guard inventory.

An inventory management system can facilitate this by giving you better forecasting and scheduling tools. You can track lead times for different materials and set reorder points such that new stock arrives “just in time.” The result: less money tied up in inventory sitting around, and lower storage costs. Additionally, for any inventory you do need to keep on hand, a good management practice might be to periodically review and clear out obsolete or excess stock (selling it off, returning to supplier if possible, or reallocating to other jobs). Identifying dead stock is much easier when you have a central inventory ledger.

By reducing average inventory levels, you save on warehouse rental, on-site storage accommodations, and even things like insurance (fewer items on site can lower risk premiums). Those savings contribute directly to ROI. It’s essentially getting the same job done with less capital expenditure on inventory at any given time. Companies that optimize inventory often see their cash flow improve too – freeing capital means you can take on more projects or reduce debt.

For a simplified example, imagine a contractor typically keeps $500,000 worth of materials in stock across various sites and yards. Through better inventory planning, they manage to cut that down to $300,000 at any given time without causing delays. If carrying costs are say 25% of inventory value per year (which covers storage, handling, insurance, etc.), that’s a saving of $50,000 per year right there from holding 200k less in stock (and arguably the real benefit is more, since that $200k can now be used for other profit-generating purposes). This is how smart inventory control can directly improve ROI – by trimming the “fat” in the system.

5. Increasing Productivity and Efficiency

One clear return from effective inventory management is that your workforce can spend more time building and less time chasing materials. When everything is organized – tools are logged in/out, materials are stored in designated labeled locations, inventory levels are known and communicated – workers can find what they need quickly and get on with their tasks. This reduces downtime and frustration on the job site. It also allows you to potentially accomplish the same amount of work with fewer people or in less time, which is a cost saving or a chance to take on more projects.

Consider something as simple as a digital inventory catalog: if a foreman on site can pull up a mobile or web app and instantly see “we have 10 units of item X in the site container and 50 more back at the warehouse, plus some on order arriving Tuesday,” that foreman can make swift decisions and keep the team productive (maybe send a runner to fetch more from the warehouse before they run out, or adjust the day’s plan if something’s arriving late). Without that visibility, the crew might either wait idle or do unproductive workaround tasks. Essentially, information replaces chaos.

Better inventory management also streamlines communication between field and office. Procurement teams know what to buy (and not buy) because they see current stock levels; site teams know what’s available and what’s coming. This alignment prevents miscommunication that could lead to double ordering or lack of needed supplies. When the entire operation runs more smoothly, projects finish faster and with less stress – which often means higher profit margins and the ability to handle more jobs (an ROI in terms of capacity growth).

There’s also a safety and quality aspect: an organized inventory means tools are maintained (not lost or left to rust) and materials are stored properly, reducing accidents or quality issues. While harder to measure in ROI, preventing an accident or a quality rework because the right equipment was available and in good condition can save immense costs (injuries and rework can devastate profitability). So we can say effective inventory control even protects ROI by contributing to a safer, better-run project.

6. Data-Driven Decision Making and Continuous Improvement

In the long run, one of the biggest returns on investing in inventory management is the wealth of data and insights you gain. Modern inventory systems can track usage patterns: how quickly do you go through certain materials? Which tools are underutilized? Which items are frequently lost or need frequent reordering? With this information, companies can continuously refine their operations. Perhaps you discover that a particular type of pipe fitting is always overstocked – you can adjust your ordering practices. Or you find that a certain crew consistently uses more of something than estimated – maybe due to waste or technique – which you can address through training or process changes.

Over time, these adjustments compound into serious efficiency gains. You might improve your estimating accuracy (fewer cost overruns = better profitability, which is ROI on the planning side). You might negotiate better terms with suppliers knowing your exact annual usage of products. You could identify an opportunity to standardize on one type of material across projects to simplify inventory and get bulk pricing. All of these are strategic benefits enabled by having good inventory data.

In essence, effective inventory management turns what was once a messy, reactionary aspect of construction into a well-oiled component of your business strategy. The ROI is not just immediate cost savings, but long-term competitiveness. Companies that manage resources well can bid more aggressively, finish projects with fewer hiccups, and build a reputation for reliability – leading to more contracts. In a way, the ROI of inventory management can also be seen in future business growth.

By now, it’s clear that tightening up inventory control yields returns across multiple dimensions: cost savings, time savings, risk reduction, and opportunity gains. However, achieving this level of control and visibility can be challenging with traditional methods (like paper logs or simple spreadsheets). That’s where dedicated inventory management tools come into play. In the next section, we will look at how leveraging modern technology – specifically a solution like CyberStockroom – can facilitate these best practices and ensure you reap the maximum ROI from your inventory management efforts.

CyberStockroom: A Map-Based Approach to Construction Inventory Management

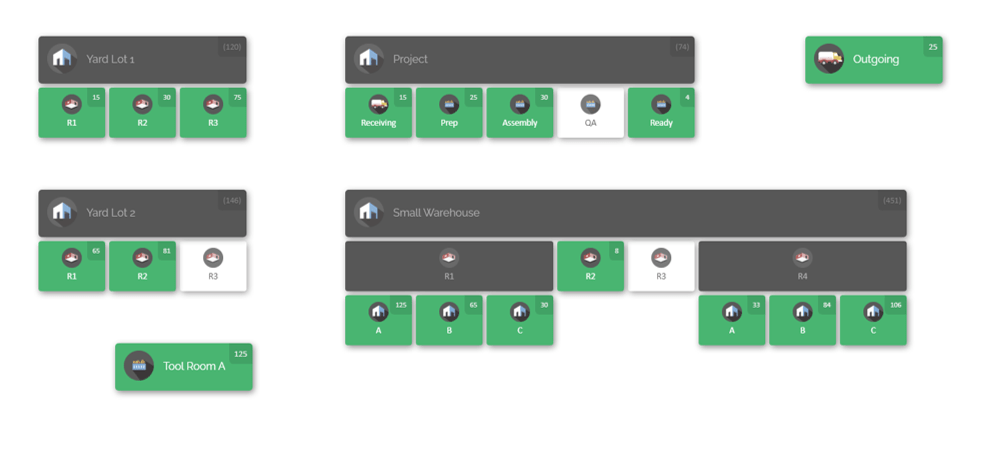

In the realm of inventory management tools, CyberStockroom offers a unique and powerful solution particularly well-suited for construction projects and field operations. CyberStockroom is a cloud-based inventory management software that takes a visual mapping approach to tracking inventory. Instead of just rows in a spreadsheet or tables of data, it provides an interactive map of all your locations and assets, which can be a game-changer for construction teams. Let’s explore how CyberStockroom works and how it can directly contribute to the ROI improvements we’ve been discussing.

Visual Inventory Mapping

As we saw in the demo map example above, CyberStockroom allows you to create a virtual map of your business – including multiple job sites, warehouses, laydown yards, storage containers, trucks, and even individual crews or rooms – basically any location where inventory might reside. Each of these is represented visually on the dashboard. This map-based interface mirrors the real-world layout of your operations, which makes it incredibly intuitive. Construction managers and crew leads can literally see where everything is in real time. For example, on your CyberStockroom map you might have icons for “Jobsite A – Building Floor 1”, “Jobsite A – Container 3”, “Central Warehouse”, “Truck #5 (John’s truck)”, etc. Clicking or zooming into any of these reveals the inventory within that location.

The benefit of this visual approach is immediate situational awareness – something especially valuable in construction where things change daily. Instead of digging through logs or calling around to find resources, the map shows you at a glance if, say, a generator is on Truck #5 or at the Laydown Yard, or which site currently has spare safety harnesses available. This addresses the productivity issue: no more long searches for stuff – you consult the map and you know exactly where to go or whom to ask. It also aids in resource allocation: if one site has extra materials, the map makes that obvious so you can initiate a transfer to where they’re needed. The ROI here is better utilization of what you have (fewer idle assets) and less redundant purchasing.

Real-Time Multi-Location Tracking

CyberStockroom is cloud-based and updates in real time. As items are received, moved, or used, the system can be updated to reflect the new counts in each location. If someone transfers five lighting fixtures from the warehouse to Site B, a simple drag-and-drop on the map (or a quick transaction entry) will move that inventory in the system. Everyone with access can now see those five fixtures are en route or have arrived at Site B. This level of shared, up-to-date information keeps field crews and office staff on the same page. Procurement knows what’s on hand across all sites before placing orders; site supervisors know if they can expect supplies from elsewhere or need to request more. The real-time aspect is critical – it means your decisions are based on the latest data, avoiding the pitfalls of out-of-date stock information that lead to mistakes.

From an ROI perspective, real-time tracking reduces the lag and errors in inventory management. It minimizes scenarios like double-ordering a part that was already delivered to another site, or keeping workers waiting because the materials were actually sitting in a trailer but nobody realized. It also improves accountability: you can assign items to specific people or teams (e.g., 10 tablets assigned to Electrical Crew, or a concrete mixer assigned to Site X). CyberStockroom even has features to manage inventory by person or team, which is great for tool tracking – you can see which crew or technician is currently in charge of a piece of equipment. Knowing “who has what” means when something is needed, you know who to contact, and when something goes missing, you know who last had responsibility. This dramatically cuts losses and speeds up retrieval of items, reinforcing those ROI gains from theft prevention and productivity.

Drag-and-Drop Simplicity and Ease of Use

One barrier to implementing any system is user adoption – if it’s too complex, field personnel won’t use it. CyberStockroom addresses this with a simple, drag-and-drop interface for managing inventory on the map. Moving items between locations in the software can be as easy as dragging an icon from one site to another on the screen. Cycle counts or adjustments can be done quickly through the interface. It also supports barcoding: you can generate barcode or QR code labels for your inventory items or bins, and then scan them (with a scanner or device) to update counts or perform check-in/checkout. For example, a tool crib manager might scan a drill’s barcode when handing it out to a crew member and assign it on the system to that person, then scan it back in when it’s returned. CyberStockroom logs these actions automatically.

The combination of an intuitive map and barcode support means field teams actually find the system helpful rather than cumbersome. There’s minimal training needed to interpret a visual map, and scanning is faster than writing things down. The ROI tie-in: when the system is easy to use, compliance goes up, data accuracy goes up, and you truly get the benefits of inventory visibility. An unused system is wasted money – but CyberStockroom’s design avoids that by engaging users with a visual and interactive experience.

Loss and Theft Prevention Features

CyberStockroom explicitly touts features for Inventory Loss & Theft Prevention. It keeps a complete activity history of all inventory transactions – essentially an automatic ledger of what happened to each item. You can filter this history by user, by date, by location, or by activity type, which makes auditing a breeze. If something is missing, you could quickly pull up, for instance, all movements of “Welding Machine #3” in the past month and see who moved it from where to where. Or filter by a certain user to review all items they checked out in a period. This level of transparency is a strong deterrent against internal theft or negligence. It also helps identify any procedural issues – for example, if you see frequent inventory adjustments (writing off missing stock) at one particular site or shift, you can investigate further or tighten security during that window.

By helping you “see everything, lose nothing,” CyberStockroom essentially safeguards your assets. The ROI here is straightforward: fewer lost tools and materials mean less repurchasing and less downtime. And if something does go missing, the time to detect and respond is much faster, potentially allowing recovery or at least learning of how to prevent it next time.

Integration of Field and Warehouse Management

Many construction companies struggle to coordinate inventory between the main warehouse (or yard) and the various job sites. CyberStockroom’s multi-location map bridges that gap. You can see inventory across all locations in one place. So, if a site is running short on something, a warehouse manager back at HQ can see that and send more, or vice versa. CyberStockroom even supports use cases like Laydown Yards and Trunk/Vehicle stock – these are scenarios often relevant to construction: a laydown yard being a staging area for bulk materials, and trunk stock referring to items kept in service trucks or foreman’s pickups. By mapping these too, nothing falls through the cracks. A small contractor, for example, might have significant inventory spread between a storage yard and the backs of three trucks – CyberStockroom would allow tracking all of that seamlessly.

The ROI from this comprehensive tracking is less over-purchasing and maximal usage of what’s already in your ecosystem. Perhaps previously each project manager ordered tools separately and you ended up with duplicates; now you can easily see an idle concrete saw in storage that can be reassigned to another site, avoiding a new purchase. Over time, this resource sharing and visibility can save capital expenditures and reduce the total inventory you need to own.

Cloud-Based and Remote Access

Since CyberStockroom is cloud-based, anyone in your organization with permission can access the inventory information from anywhere – whether they’re in the main office or out on a remote jobsite with a tablet. This is crucial for construction, as team members are always on the move. There’s no need to physically be in the warehouse to update records or to call someone to check a spreadsheet. A project engineer on-site could check the stock levels via a laptop or mobile browser and make decisions instantly. This kind of accessibility ensures the inventory data is leveraged fully whenever and wherever decisions are made. In terms of ROI, it means faster decision cycles and less waiting. Problems can be solved on the fly with the most current info, reducing downtime.

In summary, CyberStockroom exemplifies how leveraging technology can amplify the benefits of good inventory management in construction. Its visual, easy-to-use platform tackles the very problems that hurt ROI – lack of visibility, disorganization, and slow communication. By implementing such a system, construction companies can truly operationalize the best practices (like those we talked about in the previous section) and see real financial returns: reduced waste, lower costs, timely project completion, and more productive use of resources.

Best Practices to Maximize Inventory Management ROI in Construction

Implementing an inventory management improvement is most effective when combined with sound practices and a company culture that values organization. Here are some best practices construction firms should adopt to fully realize the ROI potential of effective inventory management:

- Establish Clear Inventory Processes: Define how your team will handle inventory from end to end. This includes procedures for receiving materials (e.g., always check deliveries against purchase orders and immediately log them in the system), storing items (assign specific labeled locations for different categories of materials and tools), issuing materials to crews (perhaps require a sign-out in the system or a supervisor’s approval for key items), and returning or disposing of unused items. Clear processes remove ambiguity and ensure everyone knows their role in managing inventory. Make inventory management a part of the daily routine on site, not an afterthought.

- Train and Involve the Team: Even the best system won’t help if people don’t use it. Take the time to train your staff – both office and field – on how to use new inventory tools or follow new procedures. Explain the why as much as the how: when crews understand that spending a few minutes to log tool check-outs or to neatly organize materials can save hours of headache later (and even help the company’s profitability, which in turn can benefit them), they’re more likely to cooperate. Encourage a mindset where team members treat materials and tools as valuable assets, not just jobsite clutter. Some companies even incentivize good inventory practices (for example, recognizing a project team that has minimal material wastage or no lost tools in a quarter).

- Perform Regular Audits and Cycle Counts: Don’t wait until the end of a project to find out your inventory records were off. Schedule periodic mini-audits. This could be as simple as a weekly walkthrough where a supervisor or storekeeper uses a mobile device to scan a sample of items and ensure counts match. Or monthly comprehensive counts of high-value items. Regular auditing helps catch discrepancies early, allowing you to investigate and correct issues (like mysterious disappearances or data entry errors) before they balloon. It also reinforces accountability – if workers know inventory will be checked, they handle it more carefully.

- Apply the 5S Principle to Storage: Borrowing from lean methodologies, the 5S (Sort, Set in order, Shine, Standardize, Sustain) principle is very applicable to construction inventory. Sort – keep only necessary items and remove junk or obsolete materials from your storage areas. Set in Order – organize what’s left in a logical way (e.g., all electrical materials in one container, all plumbing in another; tools hung on shadow boards, etc.) and label everything clearly. Shine – keep storage areas clean and tidy, which makes it easier to spot issues and also preserves materials. Standardize – use consistent storage methods across sites (so any crew can find items in any location because the system is familiar). Sustain – maintain this discipline over time with regular checks and by making it part of site culture. Well-organized storage directly reduces time wasted searching and lowers the risk of loss or damage, thereby boosting ROI.

- Centralize Inventory Information: Whether you use software like CyberStockroom or a simpler method, it’s critical to have one central source of truth for inventory data. Avoid fragmented systems (one foreman’s notebook, another’s Excel file, etc.). Centralization means if a project manager needs something, they don’t have to call six people – they look at one dashboard or sheet. It also means updates are applied consistently. This central inventory system should ideally integrate with other project management facets: for instance, tie material usage to job costing. Many modern solutions or manual strategies can link inventory consumption to specific cost codes or project phases, giving better financial insight.

- Plan Inventory with the Project Schedule: Align your inventory management closely with your construction schedule. As you plan each phase, identify the critical materials and tools needed and ensure the inventory system reflects having them reserved for that time. Use the lead times to plan when to order or transfer items. Inventory management shouldn’t be reactive (“oh, we’re pouring next week, do we have rebar?”) but proactive (“the schedule shows we’ll need rebar in two weeks; our inventory system shows current stock, and if it’s not enough, we initiate order now”). Having your inventory manager or coordinator involved in project planning meetings can facilitate this.

- Leverage Supplier Relationships and Programs: Good inventory management also means knowing when NOT to hold inventory yourself. If you have reliable suppliers who offer just-in-time delivery or vendor-managed inventory, take advantage of that. For example, some suppliers will stock a consignment of materials at your site or their nearby warehouse which you only pay for as you use. This reduces your burden of carrying inventory. But to effectively use such services, you need accurate usage data (to trust the supplier’s refilling cadence) – which comes back to tracking what you use. By integrating supplier deliveries into your inventory tracking (e.g., logging what comes in promptly), you can maintain lean stocks without risking shortages. The ROI here is in shifting inventory costs upstream whenever possible and saving your capital.

- Monitor and Iterate: Finally, treat inventory management as a continuous improvement process. Monitor key metrics: inventory turnover (how fast you’re using inventory), shrinkage rates (percentage of inventory lost/damaged), stockout incidents, average storage cost per project, etc. Use your data to identify where there’s still waste or delay. Perhaps you notice that one type of material consistently gets overstocked – you can adjust ordering practices. Or a certain crew has more missing tool incidents – maybe they need extra training or a different process. Iterate on your inventory practices, adjusting policies or system configurations as needed. Over time, these refinements will further improve your ROI. Essentially, make inventory management a strategic focus, not a set-it-and-forget-it task.

By following these best practices with the aid of modern inventory management tools, construction companies can extract the maximum benefit – and therefore maximum ROI – from their efforts. It’s about combining people, process, and technology in harmony to master the flow of materials and assets.

Turning Inventory Control into Competitive Advantage

In the rough-and-tumble world of construction, where unexpected challenges lurk around every corner, having control over something as fundamental as your inventory can be a breath of fresh air. We’ve seen that the ROI of effective inventory management in construction projects is undeniable. From reducing material waste and saving tens of thousands of dollars, to preventing theft and avoiding costly delays, strong inventory practices directly contribute to a healthier profit margin. They help projects finish on time and on budget – which not only improves the financial outcome of that project, but also bolsters your reputation for reliability (leading to more business down the line).

Embracing tools like CyberStockroom and the best practices we outlined can transform inventory management from a headache into a strategic advantage. Imagine running projects where crews always have what they need when they need it, where warehouses and laydown yards are organized and efficient, and where there’s virtually no “lost” equipment. Not only does such a scenario improve your current project’s bottom line, but it builds a foundation for scalability – you can take on more projects or larger ones without chaos, because your inventory processes scale with you. In a competitive construction market, being known for efficient operations and minimal waste can set you apart from competitors who are still drowning in disorganization.

Of course, change requires initial investment – whether it’s time spent training staff or money spent on software and system implementation. But as we’ve detailed, the return on that investment is swift and significant. Often, the savings from one or two prevented errors or avoided delays can pay back the costs many times over. It’s not unrealistic for a mid-size contractor to recoup their investment in an inventory management improvement within a single project cycle, and then continue reaping the benefits on every project thereafter.

In closing, managing inventory effectively in construction is all about visibility, accountability, and optimization. When you can see your inventory clearly, you can manage it proactively. When everyone is accountable for the assets under their watch, losses shrink. And when you continuously optimize how you purchase, store, and use materials, you eliminate waste and maximize value. Construction projects will always be challenging, but by mastering inventory management, you eliminate one big source of uncertainty and cost. The result is a leaner, more resilient business that squeezes the most value out of every dollar and every hour – which is the very definition of improving ROI.

So, whether you’re laying foundations, erecting skyscrapers, or renovating homes, keep a close eye on your inventory. Treat it with the importance it deserves, equip yourself with the right tools and processes, and you’ll build not only structures, but also a stronger, more profitable company. After all, in construction as in any business, efficiency is profit – and few things drive efficiency like knowing exactly what you have, where it is, and how to use it best. Here’s to building a future with less waste, less stress, and more success through effective inventory management.

Leave a comment