Managing long lead-time materials in construction projects has become a critical planning skill for contractors and project managers. In today’s fast-paced construction environment – especially after recent global supply chain disruptions – many essential materials and equipment can take months (or even over a year) to arrive. If these long lead-time items aren’t properly planned for, they can derail project schedules and blow budgets.

What Are Long Lead-Time Materials in Construction?

Long lead-time materials (sometimes called “long-lead items”) are materials, products, or equipment that require an unusually long time to procure and deliver. In construction, lead time refers to the duration between placing an order for an item and its arrival on site. Most standard construction materials might have lead times of a few days or weeks. In contrast, long lead-time items can take several months or more from order to delivery.

These items typically have extended lead times because they are either highly specialized, in limited supply, require custom manufacturing, or must be imported from far away. The more complex or customized an item is, generally the longer its procurement time. For example:

- Major electrical gear: Switchgears, large transformers, and emergency generators often have lead times of 10–18+ months due to high demand and limited manufacturing capacity. In recent years, contractors have reported generator orders taking over 50–60 weeks (more than a year) to fulfill, when previously they might have taken only a few months.

- Mechanical and HVAC equipment: Custom HVAC units, commercial chillers, and specialized pumps that used to have 2–3 month lead times can now take 9–12+ months. One commercial contractor noted that certain rooftop HVAC systems which used to be delivered in 12–14 weeks are now taking 12–14 months to arrive. Such drastic extensions in lead times have become more common.

- Curtain wall, windows, and facades: Custom curtain wall systems, specialty glass, and high-end windows often have long fabrication times. It’s not unusual for curtain wall components to require 6–12 months from approval to delivery, especially if they are bespoke designs or sourced internationally.

- Elevators and lifts: Elevator equipment and escalators can have lead times around 4–6 months or more, since they are engineered to order for each building. Complex or high-capacity elevators might face further delays due to backlogs.

- Major structural components: Structural steel beams, open-web steel joists, and trusses may see extended lead times when steel mill production is backed up. For instance, steel joists that once took 3–5 months could now take 9–12 months in certain market conditions. Even precast concrete components and specialty lumber can face delays if demand surges or supply is constrained.

- Specialty finishes and equipment: Items like custom millwork, specialized lighting fixtures, high-end appliances, or laboratory equipment might require extra time. If an item is coming from overseas (for example, imported stone or custom tiles), international shipping and port delays also add to lead time. A “long lead” item in this context could even be something as simple as a unique door hardware set or a specific type of insulation, if it’s in short supply or requires custom specs.

How long is “long”? There’s no fixed definition, but generally any item that takes significantly longer than the normal procurement cycle is considered a long lead item. A common rule of thumb is anything over 8 weeks might qualify, but in today’s climate many critical items far exceed that. Lead times have expanded 2x–3x their pre-2020 norms for a wide range of materials. In the U.S. market, lead times for many construction materials have increased by an estimated 25–40% in recent years. The longest delays are seen in complex, customized items – often stretching well into multiple months. For practical purposes, project teams usually flag items as “long lead” if a delay in their delivery would impact the schedule. This often includes items on the project’s critical path (essential for the next phases of construction) that are not readily available on short notice.

Why Long Lead Times Matter More Than Ever

In construction, timing is everything. Projects are carefully scheduled so that the right materials arrive when needed to keep work moving. When a crucial item has a six-month or year-long lead time, it can become the tail that wags the dog of the entire project timeline. Failing to account for these extended durations can have serious consequences:

- Schedule Delays: A delayed material can cause a cascade of hold-ups. For example, if structural steel for a building’s frame arrives late, it pushes back the start of framing and everything that follows. Crews might sit idle or be rescheduled, and critical milestones are missed. A construction project is like a puzzle – if one big piece doesn’t show up on time, other pieces can’t be placed, and the completion date slips. Many builders have learned this the hard way in recent years: some equipment now has lead times so long that it exceeds the entire planned construction duration. There have been cases of large generators or custom mechanical units with lead times of 80 weeks (over 1.5 years) – longer than it takes to build a mid-sized building. In such scenarios, either the project start is delayed to wait for the item, or the project finishes late because everyone was waiting on that one component.

- Cost Overruns: Delays caused by long lead items often translate to increased costs. Workers and subcontractors may need to demobilize and remobilize when work pauses for missing materials, incurring extra labor charges (e.g. “remobilization” fees). If a project timeline extends, general conditions costs (like site management, equipment rentals, etc.) grow. In some cases, contractors have to pay expediting fees or premium shipping to get a late item faster, which drives up the budget. There’s also the indirect cost of lost opportunities or penalties – for instance, not finishing a project on time might trigger liquidated damages in contracts or delay the owner’s ability to start using the facility.

- Inflation and Price Volatility: In an environment of long lead times, pricing can become a moving target. Some suppliers will only give “price valid on delivery” terms when lead times are very long – meaning even if you order today, the final price you pay is whatever the market rate is when they ship months later. This was seen with certain materials like roofing and lumber during volatile periods. Contractors who thought they had locked in a price found out later the cost went up by the time the item shipped. This makes budgeting extremely challenging and can bust the project’s financial plan. Ordering early can help lock in prices, but that ties up capital upfront (and assumes the vendor won’t adjust pricing later).

- Storage and Handling Issues: If you do order long lead items well in advance, you then face the challenge of storing them safely until they’re needed on site. This can mean paying for warehouse space or making room at the jobsite for materials that might sit for months. Storing large equipment or quantities of materials comes with risks: theft, weather damage, deterioration, or accidental damage from moving them around. For example, suppose a contractor receives a shipment of custom windows six months early to avoid delays. They must ensure those expensive windows are kept secure and in good condition – possibly renting climate-controlled storage or beefing up on-site security. All of that adds cost and complexity. (On the flip side, not having them early could stop the project later – it’s a tricky trade-off!)

- Project Coordination Nightmares: Long lead items add complexity to project management. More stakeholders need to be looped in earlier (designers, vendors, subcontractors), and there’s a need for constant communication and updates. If one team isn’t aware of a long lead delay, they might schedule work crews who then have nothing to do when the item isn’t there. Or a procurement officer might double-order something because they thought it wasn’t coming in time, only to end up with excess later. Without strong coordination, long lead times can lead to redundant orders, rushed last-minute changes, or even workarounds that compromise on quality (e.g., using a less suitable substitute because the ideal item didn’t arrive).

All these factors make managing long lead-time materials a top priority in project planning. In fact, many experienced builders now treat lead times as a primary driver of the project schedule, rather than an afterthought. The “old days” of waiting until a project is awarded and then figuring out what to order are gone – nowadays, you often need to account for procurement of critical items from the very start of project planning. Some owners and contractors will even delay breaking ground on construction until they have certain long lead materials in hand or at least a confirmed delivery date, even if that means pushing the project start by several months. It’s better to wait up front than have a half-built project sitting idle later.

The bottom line is that ignoring long lead times is not an option if you want an on-time, on-budget project. Next, let’s dive into specific strategies and best practices to navigate this challenge.

Strategies for Managing Long Lead-Time Materials

Proactive planning and smart management can significantly reduce the risk that long lead items pose. Here are several key strategies to implement during your project planning and execution:

1. Identify Long Lead Items Early (Pre-Construction Planning)

The first step is early identification. During the pre-construction or planning phase, scrutinize the project’s requirements to spot any materials or equipment with potentially long lead times. This often involves the general contractor, project manager, and procurement officers working closely with architects, engineers, and key subcontractors (like the mechanical/electrical trades) to review the designs and specs. Ask questions such as:

- Which items might take longer than a month or two to arrive? Check major equipment (HVAC units, generators, electrical panels), specialty materials (custom facades, specialty flooring), and anything marked “by owner” as well.

- Are there any custom-made products or imports in the project? Custom = longer lead. Imports may face shipping delays.

- What does current market data say about these materials? It’s wise to consult suppliers or industry sources at this stage. For instance, if you’re building a data center and know transformers and switchgear are in short supply, flag those immediately. If a certain type of insulation is on nationwide backorder, note it.

Once identified, incorporate those long lead items into the project schedule from the beginning. In practical terms, this means including procurement tasks or milestones for those items on your Gantt chart or timeline, with realistic lead durations. For example, if the project’s start date is June 1 but a critical pump has a 20-week lead time, the schedule should show that pump being ordered no later than, say, January or February. Tools like material procurement schedules or lead time trackers can be extremely helpful (some project management software or construction management platforms allow you to tag tasks with required delivery dates for materials).

Early identification also enables design adjustments if necessary. If you discover in pre-construction that a specified material has an extraordinarily long lead time that could jeopardize the timeline, you have an opportunity to seek alternatives before you’re in the thick of construction. For instance, the design team might be able to swap out a particular finish or equipment model for one that’s more readily available. It’s much easier to make those changes early on paper than to scramble for a substitute mid-project when time is running out.

Tip: Maintain a procurement log for all identified long lead items. This is essentially a tracking sheet listing each critical item, who is responsible for ordering it, the date it must be ordered by, actual order date, expected delivery, and status updates. Share this log with the whole project team (management, site supervisors, procurement staff, etc.) so everyone stays aligned. Regularly update it as items are ordered and arrive. This log becomes a go-to reference throughout the project and helps prevent anything from slipping through the cracks.

2. Build Strong Relationships with Suppliers and Manufacturers

In times of constrained supply, who you know can be as important as what you know. Developing strong relationships with reliable suppliers, vendors, and manufacturers can give you an edge in managing long lead times. Here’s how focusing on supplier relationships helps:

- Better Communication & Transparency: A trusted supplier is more likely to give you a heads-up if something is amiss. For example, they might warn you that a particular component is about to be in short supply or that their factory is experiencing delays. Early warnings allow you to adjust plans or find alternatives before a problem becomes a crisis. If you’re a valued customer, suppliers will keep you in the loop proactively.

- Priority Treatment: When allocation of scarce materials happens, suppliers often fulfill orders for their loyal customers first. If you’ve built a partnership with a vendor, you might get your order expedited or at least not dropped, whereas a contractor with no prior relationship might find their order de-prioritized. In an environment where a supplier is juggling who gets the next batch of product, you want to be at the top of their list.

- Negotiating Flexibility: With a good relationship, you may negotiate holds or reserves. For instance, a supplier might agree to set aside inventory for you if they anticipate a shortage. Or they might lock in a price for you for a period of time despite market volatility, as a gesture of goodwill. They may also be more amenable to partial deliveries (shipping whatever is ready first) to help your schedule.

- Shared Forecasts: Communicate your project pipeline and forecasts to key suppliers as early as possible. If a supplier knows you have three school projects coming up that will need 500 HVAC units over the next year, they can plan production or stock accordingly (or at least not be surprised by your large orders). Some contractors share their procurement schedules with suppliers so that everyone is on the same page regarding expected order dates and quantities.

- Reliable Advice: Suppliers often have broad industry insight. They can suggest alternative products or solutions if they know something will have a long lead. For example, a lighting supplier might suggest a similar fixture model that’s in stock in lieu of the originally specified one that’s backlogged for 4 months. A good supplier essentially becomes an ally in problem-solving, not just an order-taker.

Building strong supplier relationships boils down to treating vendors as partners. Pay them on time, be clear in your requirements, and maintain regular communication. It’s also helpful to diversify who you talk to – for example, stay in touch with both your local sales rep and someone on the operations/logistics side if possible. That way, you get both the “customer service” perspective and the real-time info from the people coordinating orders.

3. Diversify Your Supply Chain and Have Plan B Options

“Don’t put all your eggs in one basket” is a saying that fits well here. Relying on a single source for a critical material can be risky. If that supplier has an issue, your project has an issue. To mitigate this risk:

- Source from Multiple Suppliers: Where feasible, identify secondary suppliers for key materials. Even if you prefer Supplier A (perhaps due to cost or prior relationship), it’s wise to have Supplier B and C on your radar. For example, if you typically get your structural steel from one mill or distributor, have an alternate vendor who can step in if the primary one falters. This doesn’t mean you have to place duplicate orders (which would be costly), but you should at least know who else carries the item and how quickly they could fulfill an order if needed.

- Local vs International Options: Global supply chains are unpredictable. If your main plan was to import custom fixtures from overseas, consider identifying a domestic supplier as a backup, even if the cost is higher. The domestic source might deliver faster in a pinch, or at least not be subject to international shipping uncertainties. For instance, many contractors learned to find local or regional manufacturers for things like millwork or metal parts when ports were congested and overseas shipping times went through the roof.

- Alternate Materials or Models: Work with your design team to pre-approve some alternates. If Product X is severely delayed, is there a Product Y that could be used instead? For critical systems, sometimes the project specifications can be written to allow more than one manufacturer or model (“or approved equal” language). This way, if one specific item is unavailable, you’re not stuck – you have a list of acceptable substitutes to pivot to. As an example, if a certain brand of switchgear is quoting 50-week delivery, maybe an alternate brand that meets the same technical specs can do it in 30 weeks. It’s important that the architects/engineers and owner are involved in these decisions so that any substitute still meets the project requirements.

- Inventory Buffer for Essentials: Diversification isn’t just about different suppliers – it can also mean having a buffer stock as a safety net (more on this in the next point). By keeping a small surplus of essential items, you’re not 100% reliant on immediate new deliveries. This is particularly useful for frequently used consumables or standard materials (like certain fasteners, pipes, wiring, etc.) that could unexpectedly become scarce. In a sense, your inventory acts as a “backup supplier” to tide you over short-term shortages.

Diversifying does require more effort – you have to qualify multiple vendors, possibly manage more contracts, and keep track of more quotes. But it greatly enhances your resilience. When one avenue closes, another can be pursued without panic. This approach paid off for many during recent supply chain disruptions: companies that already had alternative sources or dual sourcing strategies could adapt much faster than those who were tied to a single pipeline.

4. Plan for Contingencies: Buffers in Time and Inventory

In construction, we often aim for efficiency and just-in-time delivery to reduce inventory costs. However, when lead times are unpredictable or long, a little slack in the system can be a lifesaver. Planning contingencies means both scheduling extra time and holding some buffer stock or backup options. Let’s break this down:

- Schedule Contingency: It’s prudent to add some padding to your project schedule specifically to account for potential material delays. This could mean extending the overall timeline slightly or at least not planning critical activities back-to-back without any float. For example, if historically you’d allow 8 weeks between ordering and needing a particular item, you might now allow 12 or 16 weeks in the schedule. Owners and stakeholders are happier if you finish early than if you promise an aggressive timeline and then miss it due to supply issues. Be transparent and realistic when building the schedule: explain that given current market conditions, the team is incorporating, say, a 4-week buffer for material X in case of delays.

- Budget Contingency: Similarly, consider a contingency in the budget for material cost increases or rush shipping fees. Material prices have fluctuated widely; having a contingency (often a percentage of material costs) set aside can cover unanticipated cost spikes. It might also cover the cost of using a more expensive alternate supplier on short notice if needed. Essentially, hope for the best price but plan for the worst-case scenario by reserving some funds.

- Safety Stock for Key Materials: For critical, often-used materials, maintain a small inventory buffer if you can. This doesn’t mean hoarding excessive quantities (which ties up too much cash and space), but a reasonable reserve can absorb shocks. For instance, if your project consistently uses a certain type of cement or a specific size of lumber, and you know supply is hit-or-miss, keep some extra on hand. If your job needs 100 units of something over its duration, you might store an extra 10–15 units beyond immediate needs as a cushion. This way, if a scheduled delivery is late, work doesn’t grind to a halt – you dip into the buffer while awaiting the shipment. Once the delayed batch arrives, you replenish the buffer. This strategy should be selective: reserve it for materials that would truly stop work if they ran out (and which don’t have easy substitutes).

- Pre-ordering Critical Path Items: We touched on early ordering in identification, but it’s worth reiterating as a contingency strategy: if an item is so crucial that the project cannot proceed without it, strongly consider ordering it extra-early, even before final details are 100% confirmed. In some cases, owners and contractors choose to purchase certain long lead items during design or immediately upon project funding, rather than waiting for full documentation. This ensures the clock starts on manufacturing as soon as possible. It’s a bit of a gamble – if the design changes, you might have to deal with a mis-ordered item – but for things like structural steel, major HVAC equipment, or specialty components on the critical path, many decide that the risk is worth having the item secured. (A real-world example: some projects during supply crises ordered steel or mechanical units even before permits were issued, because a 6-month fabrication time was unavoidable. They’d rather store the steel until the site was ready than start late.)

- Secure Storage and Logistics: If you’re building in these buffers by pre-purchasing, make sure you have a plan for where and how to store items. As noted, storage can add cost and complexity. If storing on-site, invest in proper security (fencing, cameras, guards if valuable) and protection (tarping, climate control for sensitive equipment, etc.). If off-site, use a reliable warehouse service and keep inventory records of what’s there. Allocate some budget for handling these materials multiple times (receiving them, then moving to site later). Essentially, treat stored materials as part of the project scope – assign someone to oversee them.

The goal of all these contingencies is to create a cushion against uncertainty. In an ideal world, everything arrives “just in time” and you never need the buffer. But in the real world of long lead times and surprise delays, these buffers can spell the difference between a minor hiccup and a major project crisis. They give you breathing room to handle the unexpected without derailing the whole project.

5. Optimize the Construction Schedule for Flexibility

Even with best efforts, some delays might still occur. A savvy project manager will build flexibility into the construction plan to accommodate shifting timelines of materials. Here are some ways to do that:

- Out-of-Sequence Work: Think creatively about the construction sequence. If a certain long-lead component is late, can other work proceed in the meantime? For example, if specialized light fixtures for a building interior are delayed, perhaps the team can switch the schedule to focus on exterior work or non-affected interior sections while waiting. Or if an HVAC unit delivery is pushed out, maybe crews can do as much ductwork and piping as possible and leave a spot to install the unit later, rather than doing nothing. Resequencing tasks can keep workers productive and avoid complete stoppage. This requires having a Plan B in the schedule – essentially, identify tasks that could be swapped or moved up if needed.

- Milestone Adjustments: Sometimes interim milestones or phase completions might need tweaking. Communicate with the owner about potentially adjusting certain turnover dates if one area is impacted by a late material but another is not. For instance, perhaps one wing of a building can be finished on time while another is a month late due to a delayed item – you may negotiate a staged turnover.

- Temporary Solutions: In some cases, you can use temporary equipment or materials to bridge a gap. For example, if a permanent transformer for a building isn’t in yet, a temporary generator or smaller transformer might be used to power systems for testing or interim use, until the permanent one arrives. Or if a custom door is late, install a temporary door so work can continue and swap it later. These workarounds can be costly and require rework, so they aren’t ideal, but for crucial situations they can be project-savers.

- Parallel Workstreams: Prefabrication and modular construction can help mitigate schedule impacts. If certain assemblies can be fabricated off-site (maybe a mechanical skid or electrical panels on a frame), that fabrication can run in parallel with site work. Even if the prefabrication itself has components with lead times, you might gain some schedule efficiency overall. For instance, a prefabricated bathroom pod could be built in a factory while you wait for some fixtures, then delivered complete, rather than doing all sequentially on site.

- Close Monitoring and Agility: Make the project schedule a living document. Conduct frequent (weekly) schedule reviews purely focused on procurement and delivery statuses. If a delivery date slips, update the schedule immediately and communicate the ripple effect to all stakeholders. An agile schedule lets you rearrange tasks on short notice – crews might be reassigned for a week to another area or another project if something isn’t available as planned. It’s better to reshuffle proactively than have people standing around or, worse, doing work that will have to be redone.

The overarching principle is flexibility. By not locking yourself into a rigid sequence, you can respond to late materials with less drama. The construction plan should have some built-in “elasticity” – a capability to stretch or compress around those long lead-time challenges. Of course, maintaining this flexibility requires excellent communication, which brings us to our next point.

6. Communicate Early and Often Across the Team

Effective communication is the glue that holds all the above strategies together. When dealing with long lead times, it’s not just a procurement issue – it’s a whole team issue. Everyone from the front office to the jobsite needs to be informed so they can plan accordingly. Key communication practices include:

- Regular Procurement Meetings: Hold dedicated meetings (or segments of project meetings) to review the status of long lead items. In these meetings, the procurement log we mentioned can be reviewed line by line. Discuss: What’s ordered? What’s the confirmed delivery date? Any changes or red flags? Bring in the purchasing agents, project manager, site superintendent, and relevant subcontractors to these discussions. Weekly updates are not overkill when dealing with critical items in a volatile supply environment.

- Transparent Updates to Schedules and Logs: Make sure that any schedule changes due to material delays are immediately communicated to those affected – the site team, the client, and other trades. For example, if the arrival of the curtain wall is pushed back by 3 weeks, let the interior trades know that their start will also shift by 3 weeks. Avoid the trap of hoping a delay “might resolve itself” – being upfront allows everyone to adjust plans realistically.

- Informing the Client/Owner: While owners may not need to know every tiny delay, for major issues it’s best to loop them in early and manage expectations. If you foresee that a long lead item could extend the project timeline or require a significant change, have that conversation as soon as possible. Most clients appreciate candor and seeing that you have a mitigation plan, rather than finding out at the last minute. For instance, “The custom lights you chose are back-ordered for 2 months; we can either wait and push the opening date, or consider an alternate fixture. Here’s our recommendation…” That kind of proactive communication builds trust.

- Field-to-Office Feedback Loop: Ensure the field crews and site supervisors provide feedback to the procurement team as well. Sometimes the field might discover an issue (e.g., a delivered item is defective or missing parts) that will require a reorder – that needs to get communicated up the chain immediately so the lead time clock starts again. Or if site conditions change and a different material is now needed, the office needs to know to place a new order. Encourage a culture where reporting these things promptly is standard.

- Use Collaborative Tools: Modern cloud-based project management and inventory tools can serve as a single source of truth where everyone can check the latest status. For example, using a shared online schedule or an inventory management system means a site manager can log in and see if a shipment has been marked as delivered to the warehouse, or a procurement officer can see that the site has received and logged the materials. Even a shared spreadsheet on a cloud drive is better than siloed information. The key is that information flows quickly – an email that sits unread or a paper note on someone’s desk is not sufficient in a fast-moving project.

- “Rip off the Band-Aid” with Bad News: If despite all efforts, a critical item is going to be late or is missing, communicate that immediately to all stakeholders and implement the backup plans. It’s human nature to sometimes delay delivering bad news in hope that a miracle will occur, but in construction that only makes things worse. It’s far better to say, “Yes, we have a problem: the shipment got delayed in transit and will slip two weeks. Here’s how we propose to adjust…” than to let everyone find out when workers show up and materials aren’t there. Early communication gives you a chance to rearrange tasks or obtain a stop-gap solution to minimize downtime.

Clear and frequent communication ensures that long lead-time issues are managed in a no-surprises environment. When everyone is informed, the team can collectively adapt and problem-solve. This collaborative approach can turn a potential project disaster into a merely manageable inconvenience.

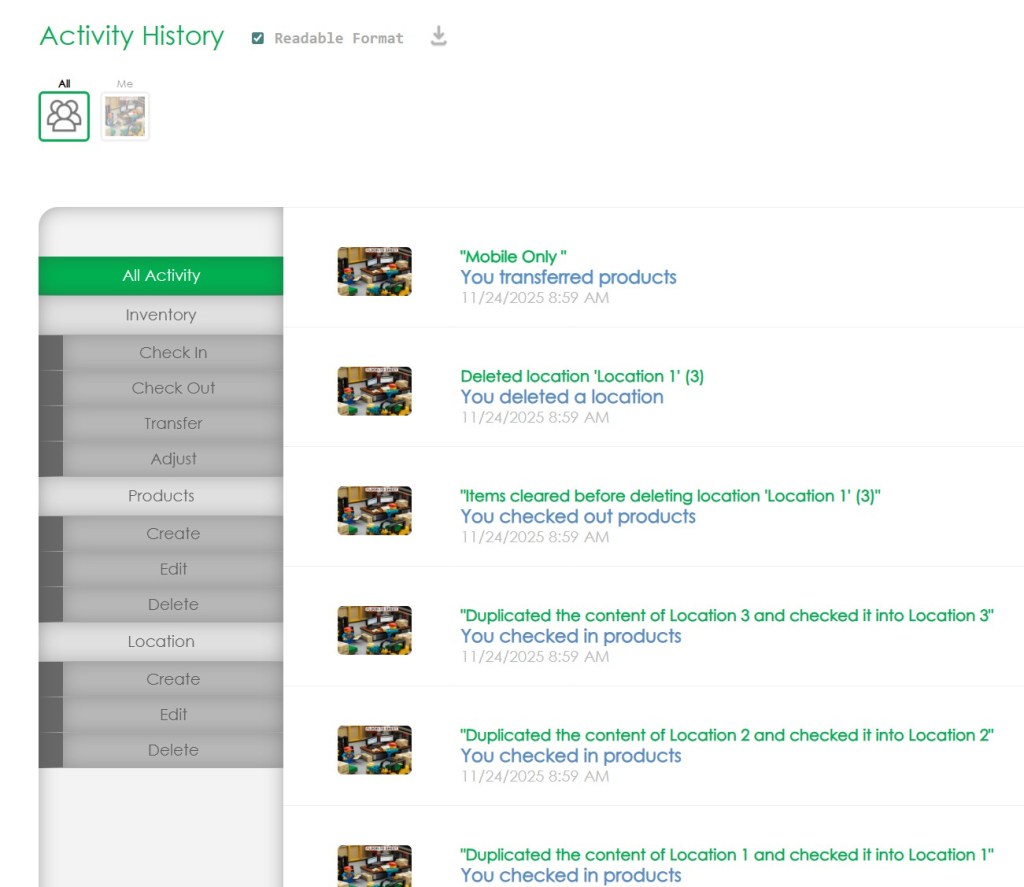

CyberStockroom for Better Inventory Management

Managing long lead-time materials isn’t just about planning and human effort – it’s also about using the right tools to stay organized and informed. This is where modern construction inventory management software comes into play. A platform like CyberStockroom can significantly improve how you track and control materials, especially those critical items with long lead times. Let’s explore how leveraging such technology can make a difference:

Visual Inventory Map and Multi-Location Tracking

One of CyberStockroom’s signature features is its interactive inventory map. Imagine looking at a digital map of all your warehouses, storage yards, and job sites, with icons showing exactly what materials and equipment are at each location. This visual approach is incredibly useful when dealing with pre-ordered items and distributed inventory. For example, if you pre-purchased a set of specialized light fixtures six months early and they are sitting in an off-site warehouse, you’ll see them pinned on your inventory map.

When the project is ready for them, there’s no risk of forgetting them in storage – their presence and quantity are clearly visible in the system. For companies juggling multiple projects, this is a game-changer: you can instantly see which project’s long-lead items are stored where. No more combing through spreadsheets or walking the yard to locate that one pallet of custom facade panels you bought in advance.

Real-Time Updates and Cloud Accessibility

CyberStockroom is a cloud-based system, meaning all updates happen in real time and everyone accesses the same live data. When a new item is ordered, received, or moved, it’s logged into the system immediately. This real-time tracking is critical for long lead items because it provides transparency throughout the procurement journey. Let’s say your procurement officer marks an item as “Ordered” in the system and notes an expected delivery date. The project manager and site supervisor can both see that status – so they know it’s in the pipeline. When the item arrives and is marked “In Stock” in CyberStockroom, an update could alert relevant team members. This eliminates the classic scenario of materials arriving unbeknownst to the field team or vice versa. Additionally, because the system is accessible via any device (computer, tablet, smartphone with internet), a site manager can check status on the fly. Picture a superintendent at the jobsite using a tablet to verify if the long-lead windows have arrived at the warehouse – no calls or guesswork needed, it’s right there on the screen.

Barcode Scanning and Quick Check-In/Out

Long lead items often involve valuable equipment or custom components that you really cannot afford to lose or misplace. CyberStockroom supports barcoding and QR code scanning, which makes tracking the movement of materials efficient and accurate. When that long-awaited shipment of electrical switchgear arrives, you can tag each unit with a barcode label. As it goes into storage, a quick scan logs its location in the system. Later, when it’s dispatched to the jobsite, another scan transfers the inventory record to the site. This granular tracking means you maintain an audit trail of where each item has been. If someone wonders, “Where is that custom pump we ordered last year?” – the system can tell you it was received in Warehouse A, then moved to Jobsite B two weeks ago, and is now on Floor 3 ready for installation, for instance. Reducing ambiguity at this level is extremely reassuring for project managers.

Assignment and Accountability

CyberStockroom lets you assign items to specific people, crews, or sub-locations. Why does this matter? Consider a scenario where a special piece of equipment (say a laser surveying instrument or a expensive valve) is needed for installation, and it arrives early. You might issue it to a particular subcontractor or team lead for safekeeping until use.

By assigning that item in the system to the responsible person or crew, everyone knows who has it or where it’s allocated. This kind of accountability is a strong deterrent against loss or theft – a common concern when materials sit waiting. If something with a long lead time “walks off” or gets misplaced, the project could be in big trouble. But with software tracking, the last known custodian is recorded. Many companies have found that when workers know inventory is being closely tracked (with names attached to check-outs), they are far more careful with those items.

Integrating Field and Office via One Platform

One of the biggest benefits of using CyberStockroom is breaking down information silos. The field team often has one perspective (“We have 5 of those beams on site”) and the office has another (“We think there are 7, according to our last spreadsheet”). With a unified platform, both field and office are literally looking at the same dashboard. Warehouse managers, site supervisors, and procurement officers can all update and view inventory status in real time. This real-time communication reduces errors like double-ordering or forgetting existing stock. For example, if Site A suddenly needs an extra water heater and marks it in the system, Site B’s manager can see that Site A took the last spare unit from the warehouse – so they won’t mistakenly expect that unit to be available for them. Everyone is on the same page, which is vital when juggling scarce long-lead materials.

Visualizing Project Readiness

Because CyberStockroom’s interface is visual and intuitive, it can be used as a planning aid in meetings. Project teams can bring up the inventory map during planning sessions to visually confirm that all critical items for the next phase are either on site or at least within reach. For instance, before a major installation, the team can quickly glance at the map and list: “Okay, we have the chillers here in the warehouse (green icon showing in-stock), the air handlers are in transit (perhaps noted as such), and the specialized piping is at the fab shop (another location on the map). We’re just waiting on the control panels which are due next week.” Having this information centrally displayed avoids a lot of “did anyone order X? where is Y?” confusion. It instills confidence that nothing vital is missing when you mobilize a crew for an install.

In summary, CyberStockroom and tools like it bring order and visibility to what can otherwise be a chaotic aspect of construction management. By digitizing the inventory process and providing a bird’s-eye view of all materials, they support the strategies we discussed earlier:

- You can only plan early and accurately if you know what you have and what’s coming.

- Supplier coordination is helped by data (e.g., showing a supplier your usage rates or proving you didn’t receive something).

- Diversification and contingency rely on tracking what alternative stock you might already have.

- Communication is improved when everyone can refer to the same source for material status.

For general contractors, inventory managers, and procurement officers, leveraging such technology is fast becoming a best practice. It not only helps manage long lead-time materials but also overall construction inventory in a more efficient, less error-prone way. In a landscape where delays and shortages are still a threat, having real-time inventory visibility is like having an insurance policy for your schedule – you’re far more prepared to respond quickly and keep the project on course.

Proactive Planning for Success

Long lead-time materials in construction projects may be a challenging reality, but with proactive planning, clear communication, and the right management tools, their impact can be minimized. Today’s construction environment demands that general contractors, inventory managers, and procurement officers think several steps ahead. By identifying critical items early, adjusting schedules and budgets to fit realistic procurement timelines, and coordinating closely with suppliers and your own team, you can prevent a long lead item from becoming a show-stopper.

It’s also about balance – balancing the risks of ordering too early versus too late, balancing just-in-time efficiency with just-in-case preparedness. Each project will strike that balance differently, but the principles remain the same: knowledge and preparation are your best allies. Know the market, know your materials, and prepare accordingly.

Finally, embracing modern solutions like construction inventory management software can provide a competitive edge. When you have a real-time pulse on your materials – where they are, when they’re needed, and what’s coming down the pipeline – you can make decisions with confidence. Instead of reacting to problems, you’re anticipating them and implementing solutions in advance.

In the end, managing long lead-time materials is about de-risking your project’s supply chain. It’s one more facet of project planning that, when done right, can save your schedule and safeguard your budget. With careful planning and the help of tools like CyberStockroom’s inventory platform, even the longest lead times can be navigated successfully. Your projects will stay on track, your crews will stay productive, and your clients will be happy – which is the ultimate goal for everyone in the construction industry. Here’s to building smarter and staying ahead of the supply curve!

Leave a comment