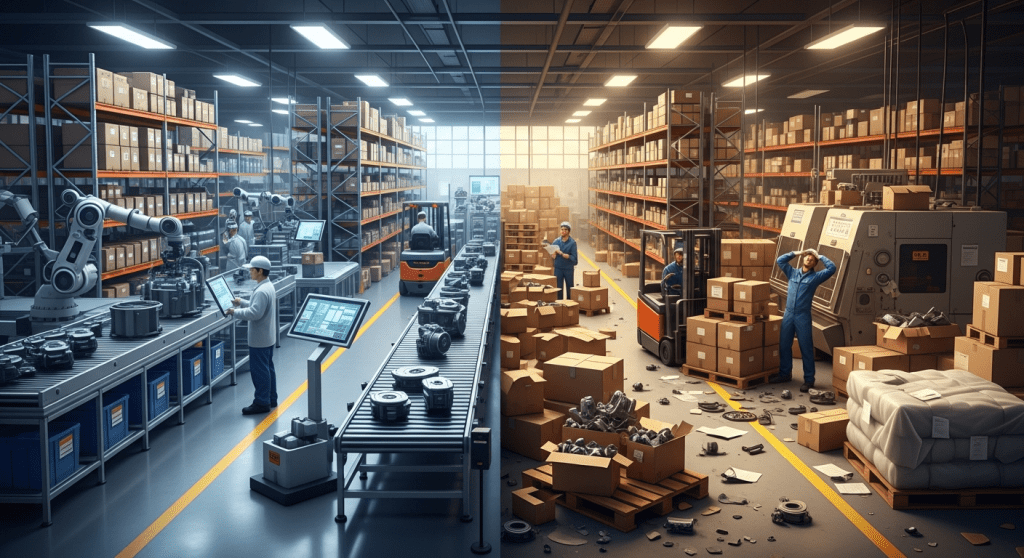

In the fast-paced world of construction, having the right materials at the right time can make or break a project. Every construction project relies on a steady flow of lumber, steel, concrete, fixtures, and other resources. If materials arrive late or run out unexpectedly, crews sit idle and deadlines slip. If you overstock and order too early, you tie up cash and risk damage or theft of unused inventory.

The key to avoiding both scenarios is effective construction material demand forecasting. This how-to guide will explore why forecasting material needs is so critical, the challenges involved, and actionable strategies to stay ahead of demand. By planning proactively and leveraging the right techniques construction teams can ensure materials are available when and where they’re needed – keeping projects on schedule and under budget.

Forecasting material needs isn’t crystal-ball magic; it’s a practical process of using data, experience, and foresight to predict what materials a project will require and when. Done right, it prevents costly delays from last-minute scrambling, and avoids wasteful overspending on surplus stock.

Why Accurate Material Forecasting Is Critical

In construction, materials account for a huge portion of project costs and are fundamental to progress. Accurate material forecasting ensures that you have the necessary supplies on hand before they are needed, which keeps the project moving without interruption. Here are a few reasons why forecasting your material needs is so critical:

- Prevent Project Delays: Timing is everything in construction. If a crucial material like structural steel or concrete doesn’t arrive when scheduled, work can grind to a halt. By forecasting needs in advance, you can schedule orders and deliveries to align with the project timeline. This proactive approach means crews aren’t left waiting around for materials to show up. Avoiding these delays keeps labor productive and your schedule intact.

- Control Costs and Budget: Construction materials now often represent more than half of a project’s costs, and prices have been volatile in recent years. An unexpected shortage might force you into expensive rush orders or using costlier local substitutes. Conversely, over-ordering materials “just in case” ties up capital and can inflate your budget with unused inventory. Forecasting demand helps strike a balance – you order enough to avoid delays but not so much that you waste money. With better predictions, you can also lock in prices and quantities with suppliers ahead of time, protecting your budget from market fluctuations.

- Improve Resource Management: When you plan material needs ahead, you can optimize how resources are allocated across a project. This means planning storage space, scheduling equipment (like cranes or forklifts for unloading), and coordinating labor to install the materials when they arrive. Essentially, forecasting materials goes hand-in-hand with overall project planning. It gives you a clear picture of what’s needed for each phase of work. That clarity reduces the chaos and last-minute scrambles, leading to a safer and more organized job site.

- Enhance Reputation and Client Satisfaction: Completing a project on time and within budget is crucial for client satisfaction. Many project delays and cost overruns trace back to poor materials management – something clients and stakeholders are keenly aware of. By staying ahead of material demand, you demonstrate professionalism and reliability. Fewer delays due to missing materials means you can hit your milestones and handover dates, strengthening your reputation for effective project management.

Forecasting material needs is like creating a roadmap for your project’s supplies. It ensures that the project has the fuel it needs to keep running smoothly. Without a good forecast, you’re driving blind – hoping materials will be available when you need them. With a good forecast, you’re steering the project with confidence, knowing what to expect and how to prepare for it. Next, let’s look at some challenges you might face in forecasting, and then we’ll get into concrete steps on how to do it effectively.

Challenges in Construction Material Demand Forecasting

Accurately predicting material needs for construction projects is no small feat. The construction environment is dynamic and often unpredictable, which introduces several challenges to material forecasting:

Variable Project Conditions

Construction projects are highly customized and can change as they progress. Design modifications, scope changes, or unforeseen site conditions can all alter the quantity and type of materials needed. For example, a sudden design change might require additional steel beams, or poor soil discovered on-site could increase concrete foundation requirements. This variability makes it hard to rely solely on the initial project plan for forecasting – the plan might evolve, and your material predictions must adapt accordingly.

Supply Chain Uncertainties

The global supply chain for construction materials can be volatile. Items like lumber, cement, or copper wiring may have long lead times or come from international suppliers. Any disruption – a factory shutdown, shipping delay, or import restriction – can throw off your schedule. Recent global events have shown how quickly material supply and pricing can change. Forecasting in this context requires building in buffers and contingency plans to handle late deliveries or sourcing alternatives if your primary supplier has an issue.

Market Price Fluctuations

Material costs can swing dramatically over the course of a project. For instance, the price of lumber or steel might surge due to market demand or tariffs, directly impacting your budget if you didn’t account for it. If you forecast purely based on last year’s prices, you could be in for a surprise. This challenge means your forecasting should include not just quantities but also an eye on pricing trends and perhaps ordering early (or negotiating fixed prices) for materials likely to spike in cost.

Seasonality and Weather Impacts

Construction activity and material availability often have seasonal patterns. Forecasting needs to account for these cycles. For example, if you’re planning masonry work in winter, you might anticipate a slowdown or add extra time (and order materials earlier) because cold weather can affect curing times or supplier schedules. Weather events like storms, extreme cold, or rainy seasons can also disrupt both the usage rate of materials on site and the delivery of those materials. Seasonal forecasting helps you avoid having excess materials during slow periods or shortages during peak construction seasons.

Limited Inventory Visibility

Many construction firms, especially smaller contractors, still rely on manual methods (spreadsheets, paper logs) to track materials. This limited visibility into current inventory levels and usage patterns makes forecasting less precise. If you don’t have a clear, real-time picture of what materials you already have on hand across your warehouse, job site, or laydown yard, you might forecast needs incorrectly – either overlooking existing stock or missing items that are running low. Inaccurate or out-of-date inventory data is a common challenge that can lead to both over-ordering and stockouts.

Human Factors and Communication Gaps

Forecasting isn’t done in isolation – it requires input and coordination across project managers, site supervisors, procurement officers, and suppliers. If communication is poor (for instance, a site superintendent not informing the office that they used more pipe than expected this week), the forecast can quickly become out of sync with reality. Miscommunication or silos between teams lead to situations where the actual material consumption on-site diverges from the plan. This challenge underscores the need for collaborative forecasting and frequent updates.

Despite these challenges, the good news is that each can be mitigated with the right approach. Next, we will outline a series of steps and best practices to improve construction material demand forecasting. These steps will help you tackle variability, uncertainty, and all the moving parts of construction projects so you can confidently predict your material needs. Let’s move into the “how-to” portion of this guide.

How to Forecast Material Needs in Construction Projects

Forecasting material needs is part science, part art. It involves data analysis, understanding of the project scope, and a proactive mindset. By following these steps and strategies, you can significantly improve the accuracy of your forecasts and ensure materials are available when your project requires them.

1. Define Project Material Requirements Early and In Detail

Start with a comprehensive plan of what materials are needed for the project, and when. This begins in the pre-construction phase by thoroughly reviewing the project drawings, specifications, and work breakdown structure. Break the project into phases or milestones (foundation, framing, plumbing, finishes, etc.), and list out the materials required for each phase. This essentially creates a Bill of Materials (BOM) tied to your project schedule.

Key actions in this step include:

- Quantity Takeoffs: Perform detailed takeoffs from blueprints to quantify all major materials (e.g., cubic yards of concrete, number of bricks, tons of steel, rolls of wiring, gallons of paint). Modern estimating software or BIM (Building Information Modeling) tools can assist in generating accurate quantities. The idea is to know exactly how much of each material the design calls for.

- Phase-by-Phase Planning: Align material needs with the construction schedule. For example, determine when the concrete pour for the foundation is scheduled – that date tells you when rebar, formwork, and ready-mix concrete must be on site. Do this for each phase: framing materials by the framing start date, roofing materials by the roofing start, and so on. By mapping materials to timeline, you can forecast timing of demand in addition to quantity.

- Long Lead Items Identification: Identify any materials or equipment with long procurement lead times and forecast their needs especially early. Items like custom-fabricated steel, specialty HVAC units, or imported finishes might need orders placed months in advance. Flag these in your plan so they are never ordered last-minute. Your forecast for these items might extend well beyond the typical timeline (e.g., ordering elevators or generators far ahead of when installation occurs).

- Include Allowances for Waste and Spares: Construction inherently involves some waste – off-cuts of lumber, breakage of tiles, spillage of concrete, etc. Include a sensible buffer in your initial material estimates to account for this. For critical materials, a common practice is adding around 5-10% extra as a contingency. For example, if the plans call for 1,000 bricks, forecasting 1,100 can cover breakage or future small changes. The goal is to prevent minor overruns from halting work. Similarly, consider ordering a few extra units of items that might need replacement or have quality variability (like extra floor tiles in case some arrive damaged or to have matching spares).

By defining the requirements early with as much detail as possible, you create the foundation for an accurate forecast. Essentially, you’re ensuring no material need slips through the cracks in the planning stage. This proactive planning document will guide procurement and serve as a baseline that you update as project conditions change.

2. Analyze Historical Data and Trends

While every project is unique, there is a lot to learn from past projects and industry data. Historical data can provide insights that make your material forecasts more realistic. Instead of guessing or relying solely on the project specs, look back at what actually happened in similar situations:

- Review Past Projects: Examine records from your organization’s previous projects that are comparable in scope and size. How closely did the estimated material quantities match the actual usage? You might find, for instance, that in the last three office building projects, the estimated drywall was consistently 10% short of what was eventually needed due to design tweaks or measurement variances. Such insights let you adjust your new forecast (maybe this time you plan for that extra 10% up front). Or perhaps you notice you always over-order certain materials – that’s money left on the table and inventory left in the yard. Use those lessons to avoid repeating the same mistakes.

- Identify Patterns and Seasonality: If you have data on material consumption rates or delivery times across the year, analyze it for patterns. For example, you might discover that projects in the rainy season use more gravel (to stabilize muddy sites) or that lumber deliveries tend to be slower in winter months. Recognizing these trends allows you to refine your forecasts. If you know a particular material usually has a two-week lead time but stretches to four weeks during the holidays, your forecast and ordering timeline should reflect that.

- Market Trend Analysis: It’s also valuable to review broader market data for key materials. Industry reports, supplier feedback, or even historical price charts can indicate trends. If lumber prices have been rising steadily each month, your forecast might include an assumption of higher cost or potential scarcity in the near future. Likewise, if data shows a certain material’s demand is skyrocketing industry-wide (perhaps a surge in infrastructure projects is making cement more scarce), you can forecast potential procurement challenges and plan accordingly (e.g., secure a contract or find alternate suppliers early on).

- Use of Analytics Tools: If available, leverage any analytics or forecasting tools that can crunch your historical data. Some construction management software or inventory systems have reporting features that highlight usage patterns, average consumption rates per unit of work, etc. For example, an inventory tool might show that your company uses an average of X pounds of rebar per 1000 square feet of construction in past projects. Such metrics can serve as a quick check on your new project’s forecast – does it align with historical norms or is there a discrepancy worth investigating?

Learning from history grounds your forecast in reality. It helps answer questions like: Are my estimates reasonable? Am I accounting for known pitfalls? It shifts your planning from pure estimation to data-informed projection. When you combine the project-specific BOM from step 1 with historical trend insights from step 2, your forecasting becomes much more robust and defensible.

3. Incorporate Market Factors and Risk Buffers

Construction doesn’t happen in a vacuum; external factors can significantly influence material needs and availability. A savvy material forecast will account for these market and risk factors to avoid being caught off guard. Here’s how to incorporate them:

- Watch the Supply Market: Stay informed about the supply landscape for your key materials. If there are news of shortages (e.g., a global cement shortage or a spike in demand for drywall due to rebuilding after a hurricane), factor that into your forecast. It might mean ordering earlier than usual or ordering a bit extra to buffer against allocation limits. Similarly, keep an eye on lead times – if suppliers indicate that the lead time for structural steel has extended from 4 weeks to 8 weeks, update your planning so you request that steel two months ahead of need instead of one. Essentially, adjust your forecast timing based on current supplier information.

- Account for Price Escalation: Inflation and price volatility in construction materials can derail a budget quickly. If your project spans many months or years, and you know (or suspect) that certain commodities are trending up in price, consider forecasting when to buy or lock prices. For example, if lumber prices are expected to rise throughout the year, you might front-load your purchases for lumber early in the project (if storage allows) to save cost. Some contractors also include an escalation clause or contingency in their budget forecast for materials – say, a 5% price contingency – especially for long projects. This isn’t “material quantity” per se, but it’s a financial forecast that ensures funds are available if prices jump. In terms of physical materials, if cost escalation might limit availability (e.g., suppliers prioritize orders from those who pay the new higher price), having a forecast that gets your order in early can secure your allocation before any chaos hits.

- Seasonal and Weather Considerations: Incorporate expected seasonal impacts. If you’re planning to pour concrete in January in a cold region, forecast that you might need cold-weather additives or blankets (additional materials that wouldn’t be needed in summer). Or forecast potential delays – perhaps order materials earlier in autumn to avoid delivery issues during winter snow. In hot climates, certain materials might deteriorate in storage under high heat; thus you plan more just-in-time delivery during summer months. Also, anticipate weather-related surge demand: after major storms or during hurricane season, construction materials (like plywood, generators, roofing) often see regional demand spikes. If your project is in an affected region, forecast and procure proactively rather than waiting.

- Risk Buffers and Contingency Stock: Beyond just waste allowance, think of broader risk buffers. What if a supplier fails to deliver on time? One strategy is keeping a small contingency stock of critical materials on hand, especially those with unpredictable supply. For example, you might always keep a week’s worth of certain fasteners or pipes in reserve beyond what your immediate forecast calls for, as a cushion. While you don’t want to hoard excessive inventory, a calculated buffer for high-risk items can be the difference between a slight hiccup and a major work stoppage. When forecasting, identify which materials are critical path (i.e., if you run out, the project stops) and consider building a safety stock for those.

- Regulatory and Political Factors: Sometimes external factors like new tariffs, environmental regulations, or import/export restrictions suddenly affect material availability. Keep an ear to industry associations or news about any policy changes that could impact your materials. For instance, a new tariff on imported steel would mean your domestic steel supply might tighten and prices rise – adjust your forecast to possibly source early or find alternative suppliers. If a certain chemical is being phased out (say a type of insulation or solvent), forecast switching to an approved alternative and secure it ahead of the rush.

By incorporating these market and risk factors, your material forecast becomes resilient to surprises. You’re essentially anticipating “what if” scenarios and planning for them. This proactive stance is at the heart of staying ahead of demand – it’s not just about calculating how many bricks, but also ensuring those bricks will be available and affordable when needed.

4. Communicate and Collaborate with Your Team and Suppliers

Forecasting shouldn’t be a solo exercise done in isolation. It requires collaboration and clear communication across everyone involved in the construction process. Engaging both your internal team and external partners (like suppliers) helps make your material planning more accurate and more likely to succeed. Here’s how to do it:

- Internal Team Coordination: Make sure all departments – project management, site supervision, procurement, and even accounting – are on the same page regarding material needs. Regular meetings or check-ins can be invaluable. For example, as a project manager forecasting materials, you should regularly consult with site supervisors and foremen: Are there any recent changes in the field? Are materials being used faster or slower than expected? Is the crew encountering any issues (e.g., higher waste than planned due to rework)? Front-line feedback allows you to adjust forecasts in real time. Also ensure that any changes in the construction schedule are immediately communicated to the procurement team – if a phase is accelerated or delayed, your material delivery plans should shift accordingly.

- Supplier Communication: Treat your key suppliers as partners in the forecasting process. Share your projected material requirements with them as early as possible. Suppliers appreciate knowing your future needs because it helps them manage their own inventory and production. For instance, if you forecast needing 100 tons of structural steel in Q3, giving your steel supplier a heads-up in Q1 (even if it’s not a formal order yet) allows them to plan capacity or reserve stock for you. This proactive sharing can secure priority in supply and possibly better pricing. It also opens a dialogue: the supplier might say “We anticipate longer delivery on that item during that period, so consider ordering a bit earlier,” which is golden information for you.

- Negotiation and Agreements: Use your forecast to negotiate favorable terms with vendors. If you know you’ll need 10,000 square feet of tiles over the next six months, you might strike an agreement now for the full amount, even if delivery will be staggered. This can lock in pricing and ensure the supplier allocates inventory for you. Collaboration in forecasting can lead to bulk order discounts or guaranteed stock. For critical materials, you might even arrange a vendor-managed inventory (where the supplier maintains a certain level of stock at your site or nearby, based on your forecast, replenishing as needed). These arrangements require trust and clear communication of needs.

- Adjust and Update Together: Keep the communication channels open throughout the project. If your forecast changes – say the design altered and now you need a different flooring material – inform the supplier immediately, even if the order was months away. On the flip side, ask suppliers to alert you promptly if they foresee any supply issues that could affect your plans. Perhaps a certain type of pipe is being phased out or a raw material shortage is looming; a good supplier relationship means you hear this news early and can adjust your forecast (maybe choosing an alternate material or placing an order sooner).

- Documentation and Shared Forecasts: It often helps to document the forecast in writing and share it. Internally, this could be a living document or spreadsheet that all relevant team members can view (or edit with permissions). It might list materials, needed quantities, needed-by dates, and status (e.g., “ordered”, “delivered”, “pending”). Externally, you can share a summarized forecast or procurement schedule with suppliers. Some construction firms even invite suppliers to planning meetings or use collaboration software where suppliers can see upcoming demand and update delivery statuses. The more visibility everyone has, the fewer surprises down the line.

In essence, no forecast lives in a bubble. Construction projects are team endeavors, and keeping everyone informed and involved turns your material forecast into a coordinated plan. Communication ensures that what’s on paper (or in software) matches the reality on the ground and in the market. It also builds accountability – when everyone knows the plan, they can work together to execute it and flag any issues early.

5. Leverage Technology and Inventory Management Tools

Modern problems require modern solutions – and forecasting material needs is no exception. Technology can dramatically improve the accuracy and efficiency of your forecasting. Instead of relying on gut feel or static spreadsheets, consider integrating tools that give you real-time data and analytical forecasting power:

- Inventory Management Software: Implement a construction-focused inventory management system to track all your materials across locations and projects. These systems act as a central hub where you can see current stock levels, incoming orders, and usage rates. With such software, forecasting becomes easier because you’re always basing it on up-to-date information. For example, if your system shows that you have 500 bags of cement in the warehouse and you typically use 50 bags a day on active sites, you know exactly how many days that stock will last. Many inventory tools also allow you to set low-stock alerts – so you get notified when a material falls below a threshold, prompting you to include a reorder in your forecast. The benefit here is preventing unexpected stockouts through automation.

- Forecasting and Analytics Tools: Some advanced platforms or modules (and even good old Excel, with the right skills) can use historical data to forecast future demand. They can apply models like moving averages, linear regression, or more complex predictive algorithms to your past consumption data and upcoming project schedule. For instance, an analytics tool might analyze your last 10 projects and tell you “given the size of this new project, you can expect to use X tons of rebar per month.” Such predictions can serve as a second opinion or a baseline to compare against your manual forecast. Even if you don’t have fancy software, you can use spreadsheets to model different scenarios: what if the project accelerates, what if waste is higher, etc., to see how material demand would change.

- Barcoding and scanning can greatly increase data accuracy – instead of someone manually jotting down that 10 pipes were used (and possibly forgetting to report it), they scan items out and the system updates immediately. Real-time consumption data flowing in from the field means your forecasting can adjust on the fly. If, for example, a particular lumber bundle is depleting faster than expected due to on-site changes, you’ll see that trend this week, not a month later when you do an inventory count.

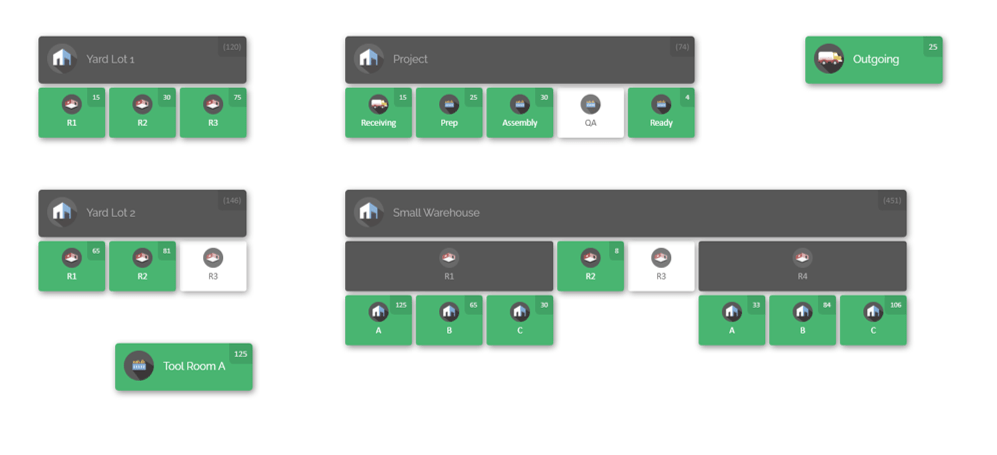

- Visualization and Mapping Tools: Having a clear visualization of your inventory distribution can also aid forecasting. CyberStockroom, for instance, uses a visual map-based interface for inventory. Imagine looking at a digital map of your construction site or warehouse that shows little icons or markers for materials and their quantities. You can instantly grasp where everything is and how much is left. Such a system helps in planning transfers (maybe one site has excess pipes that another site will need next month – you can forecast shifting stock instead of buying new). It also makes it intuitive to spot anomalies, like “Why does Site A have so few of Material X left? They’ll run out in two days!” A visual system can prompt faster forecasting decisions because it’s easier for humans to interpret a picture than a long spreadsheet.

- Cloud-Based and Collaborative Platforms: Modern inventory and project management tools are often cloud-based, which means your data is accessible anywhere, anytime, by whoever needs it (with permission). This facilitates collaboration we talked about earlier. Everyone sees the same real-time data – the site manager sees that an order is scheduled for delivery next Tuesday, the procurement team sees the site’s consumption rate, management sees the overall picture. When evaluating technology, prioritize systems that are user-friendly and accessible to your whole team (office and field). If the tool is too complicated or only lives on one person’s computer, it won’t yield the full benefits.

Embracing technology might require an initial investment of time and money (for software licenses, training, etc.), but the returns are significant. You get better accuracy, time savings, and the ability to manage more complex projects with confidence. The construction industry is increasingly adopting digital solutions for these reasons. By leveraging tech for forecasting, you move from reactive fire-fighting (“oh no, we ran out of tiles today!”) to proactive management (“our system shows we’ll need more tiles next week, let’s reorder now”).

CyberStockroom: A Visual Approach to Staying Ahead of Material Demand

Modern inventory tools like CyberStockroom deserve a special mention in any discussion about construction material forecasting. CyberStockroom is an inventory management platform with a unique visual twist – it represents your inventory on an interactive map. While it’s often touted for tracking assets and stock across various locations in real time, these same features make it a powerful ally in forecasting material needs for construction projects. Here’s how CyberStockroom can help you stay ahead of demand:

Real-Time Inventory Visibility

With CyberStockroom’s map-based dashboard, you gain instant visibility into all your materials across job sites, warehouses, trailers, and storage yards. For example, you can pull up a map of a construction job site and see that you have 200 units of lumber on Floor 2, 50 more in the ground-floor storage, and another 500 in the central warehouse. This real-time snapshot means your forecasts are always starting with accurate current data. You’re not guessing or working off last week’s inventory counts; you know exactly what is on hand. This accuracy is crucial when predicting what additional materials you’ll need and when. If you see on the CyberStockroom map that a certain material is running low at a location, you can proactively include a replenishment in your forecast before it becomes an urgent issue.

Location-Based Demand Planning

Construction projects often span multiple sites or multiple zones within one site (for instance, multiple buildings in a development, or different floors of a high-rise under construction). CyberStockroom allows you to break down your inventory by these sub-locations on the map. This means you can forecast needs per location rather than one lump sum for the whole project. Perhaps Building A will finish roofing in 2 weeks and will need more drywall, while Building B is just starting foundation work needing rebar and concrete forms. The map lets you isolate these needs visually. By clicking on a location, you can drill down into what’s there and what’s been used. This detailed view helps you tailor your forecasting to each crew’s needs, ensuring each team has the right materials at the right place and time.

Drag-and-Drop Transfers and Allocation

One powerful feature of CyberStockroom is the ability to drag and drop inventory between locations on the map to simulate or record transfers. How does this relate to forecasting? Suppose you notice that one job site has a surplus of a material (say extra pallets of tiles) and another site’s forecast shows a shortfall of that same tile type. With CyberStockroom, you can plan to reallocate existing resources before buying new. By virtually dragging those tile pallets from Site A to Site B on the map, you not only update the system to expect that transfer, but you’ve effectively adjusted your forecast – now you know Site B’s demand can be met partially by this transfer. This prevents unnecessary new orders and makes your overall material usage more efficient. In forecasting terms, CyberStockroom helps you optimize what you have before you order more.

Audit Trails and Usage History

CyberStockroom automatically logs every movement or change in inventory – who moved what, from where to where, at what time. Over the course of a project, this builds a rich usage history. You can easily pull reports or just visually backtrack to see how fast materials were being consumed at each stage. This data can feed back into your forecasting process.

For example, if you see that over the past week the site used 20% more copper wire than anticipated (perhaps due to design changes in electrical layouts), you can adjust the forecast for the coming weeks accordingly. The system’s history can also highlight patterns like “we tend to run low on certain equipment every Friday” which might indicate a need to forecast extra for end-of-week usage or improve mid-week replenishments. Essentially, CyberStockroom serves as a living record of your material flow, and that information is gold for making informed predictions.

Preventing Losses and Surprises

One often overlooked aspect of staying ahead of demand is accounting for losses – theft, misplacement, or damage of materials. CyberStockroom’s real-time tracking and location assignments help reduce the risk of unaccounted losses. Each item is assigned to a location or even to a specific person or crew. If something goes missing, it’s noticed quickly. Why is this important for forecasting? Because if materials “disappear” without a system like this, you might think you have more stock than you actually do, and your forecast will be off. With CyberStockroom, if some high-value tools or materials are moved or missing, you see it and can respond (e.g., reorder or relocate replacements) before it impacts the project timeline. By maintaining accurate inventory counts through diligent tracking, the tool ensures your forecasts aren’t derailed by hidden shrinkage.

Ease of Use and Team Adoption

The visual, intuitive nature of CyberStockroom means that field teams and warehouse staff can adopt it without steep learning curves. Why is this relevant? Because a forecasting system is only as good as the data put into it. If your team finds it too cumbersome to update inventory transactions, you won’t have reliable data to base forecasts on. CyberStockroom’s drag-and-drop and map interface simplifies the process. When everyone from the crane operator moving pallets to the site manager issuing materials can quickly update the inventory status, your data remains accurate. This high user adoption closes the loop between actual site activity and your forecasting model. You can trust the numbers on your screen, making forecasting more of a science and less of a guess.

In summary, CyberStockroom aligns perfectly with the best practices of material forecasting: it provides visibility, encourages data-driven decisions, and enables proactive management of resources. By integrating a tool like this into your workflow, you give yourself a significant advantage in staying ahead of material demand. Instead of reacting to shortages or oversights, you’re actively managing and forecasting with real intelligence. It’s like having a bird’s-eye view of your entire inventory and project needs on one screen – a capability that not long ago was unheard of in construction. With this kind of technology, even smaller construction firms can enjoy enterprise-level control over their materials, ensuring that the right materials are in the right place at the right time throughout the project.

Best Practices and Continuous Improvement

Improving material forecasting is an ongoing process. As projects progress and you gather more data, you should continuously refine your approach. Here are some additional best practices to keep your forecasting sharp and your projects running smoothly:

- Conduct Regular Inventory Audits: Even with great software and diligent tracking, it’s wise to periodically do physical inventory checks. Regular audits (say monthly, or at the end of major project phases) will catch any discrepancies between reported stock and actual stock. This helps in two ways: first, it corrects your data for future forecasting, and second, it can highlight process issues (e.g., a certain material consistently missing indicates a theft or misuse problem to address). Think of audits as tune-ups for your inventory system – they ensure your forecasting engine is running on all cylinders.

- Document Assumptions and Learnings: Whenever you create a material forecast, document the assumptions behind it. For example: “Assuming 5% waste on tiles due to cuts and breakage” or “Supplier X lead time assumed 2 weeks based on last project.” Having these notes means if reality diverges from the plan, you can pinpoint why and adjust the assumption next time. Also document what you learn: “Tiles waste was actually 8%, adjust future buffer” or “Supplier X had delays, maybe choose a backup supplier or increase lead time next project.” Over time, this builds a knowledge base that makes each forecast smarter than the last.

- Train and Involve Your Team: Ensure that the team members responsible for various parts of the forecasting and material management process are well-trained and understand the importance of it. This might involve training site supervisors on how to use inventory software or educating the procurement team on reading forecasting reports. Importantly, foster a culture where field crews understand why logging material usage or reporting issues promptly matters. When the whole team is invested in the process, the data and outcomes improve. You might consider brief workshops or toolbox talks on material management best practices, so even the crew handling materials daily have that awareness.

- Use a Rolling Forecast Approach: In construction, conditions change – sometimes week by week. Instead of making a single static forecast at the project start, use a rolling forecast method. This means you regularly update and extend your forecast as the project moves forward. For instance, every month (or every major milestone), you review the forecast versus actual usage to date, then adjust the remaining forecast accordingly and extend it out further if needed. Rolling forecasts are always looking ahead a set period (say 3 months ahead, constantly updated). This way, you’re not locked into assumptions that proved wrong; you’re continuously correcting course. It combines planning with agility.

- Integrate Material Forecasts with Schedule and Budget Forecasts: Material demand doesn’t exist in isolation – it directly affects the project schedule and cost. Integrating your material forecasting with scheduling software (or at least aligning it with your project Gantt chart) ensures that material arrivals sync with task start dates. Likewise, tying your material forecast into cost forecasts (budget tracking) will help you manage cash flow for purchases. Many project management platforms allow linking procurement items to schedule tasks. Even if you do it manually, periodically cross-check: “Does our schedule update (which shows a two-week delay in framing) align with our material plan (should we delay lumber delivery accordingly)? Are our projected material costs for next quarter fitting within the cash flow plan?” This holistic view prevents siloed decisions.

- Plan for Surplus Utilization: Inevitably, there will be leftover materials at the end of a phase or project. A smart material manager will forecast not just the needs, but also what to do with any surplus. Can excess materials be returned to the supplier? Can they be stored for a future project? Or transferred to another active site that needs them? Forecasting isn’t only about shortages – it’s also about efficiently handling excess. By thinking ahead about surplus, you can reduce waste. For instance, if you forecast that you’ll likely have 100 extra sheets of drywall after Project A, and you know Project B (starting soon) will need drywall, you can plan a transfer. This prevents unnecessary purchases for Project B and uses up what would otherwise sit idle. It’s a way of recycling forecasted surplus into new demand.

- Stay Informed and Be Ready to Pivot: The construction industry, like any other, evolves with new technologies, regulations, and economic shifts. Keep yourself educated through industry news, supplier discussions, and professional networks. If a new forecasting tool or technique emerges that could benefit you, be willing to adopt it. Likewise, if an unforeseen event occurs (say a sudden cement plant closure in your region), be ready to pivot your plans – maybe switching materials or suppliers, or altering the project sequence to accommodate. The best forecasters are not those who never face surprises, but those who respond to surprises quickly and effectively. Being proactive is great, but being adaptive is equally important.

By following these best practices, forecasting becomes a cycle of continuous improvement rather than a one-and-done task. Each project gives you more experience and data, which should feed into your next project’s planning. Over time, you’ll find that your forecasts get closer to reality, and material management becomes almost a background discipline – quietly efficient, minimizing drama. When material forecasting is dialed in, your team can spend less time frantically chasing materials and more time building. It’s a win-win for everyone involved.

Proactive Planning for Construction Success

In the construction industry, staying ahead of demand when it comes to materials is one of the smartest moves you can make. We’ve seen how effective forecasting of material needs can keep projects on schedule, control costs, and reduce the stress and chaos that often accompany complex builds. By carefully defining your material requirements, learning from past data, accounting for external factors, fostering open communication, and leveraging modern tools like CyberStockroom, you transform material management from a reactive fire-fighting exercise into a strategic advantage.

Think of forecasting material needs as building a solid foundation for the project – it supports everything else. With a clear forecast, your procurement is smoother, your site work is uninterrupted, and your budget is protected from nasty surprises. Yes, challenges will always exist – a surprise design change, a sudden supplier issue, or an unpredictable spike in prices. But with the proactive approaches outlined in this guide, you’ll be in a far better position to navigate those challenges. You’ll spot problems earlier and have contingency plans ready, rather than scrambling at the last minute.

Staying ahead of demand is also about mindset. It’s about instilling a culture of planning and foresight in your team. When everyone from managers to on-site crew understands the plan for materials and buys into it, the results are powerful: less waste, less downtime, and more efficiency. Projects finish on time (or even early), and client satisfaction soars because there were no unnecessary holdups waiting on parts or supplies.

As you implement these forecasting techniques, remember that perfection isn’t the goal – continuous improvement is. Every project is an opportunity to refine your process. Celebrate the wins (like a phase completed with no material shortages at all!) and investigate the hiccups (maybe a certain material was harder to predict – why, and how can we get it right next time?). Over time, you’ll build an intuition backed by data that makes forecasting feel more natural and less of a chore.

In conclusion, forecasting material needs in construction projects is all about being prepared. It’s an investment of effort upfront that pays dividends throughout the life of the project. By staying proactive and using the strategies discussed – from data analysis to technology and teamwork – you equip yourself to meet material demand confidently. The result? Projects that run smoother, profits that are more predictable, and a team that isn’t constantly reacting to problems because they’ve already planned for them. In construction, there will always be surprises, but with solid forecasting, fewer of those surprises will be about missing materials. You’ll be ahead of the demand curve, ready to build success one well-planned delivery at a time. Here’s to building smarter and finishing stronger!

Leave a comment