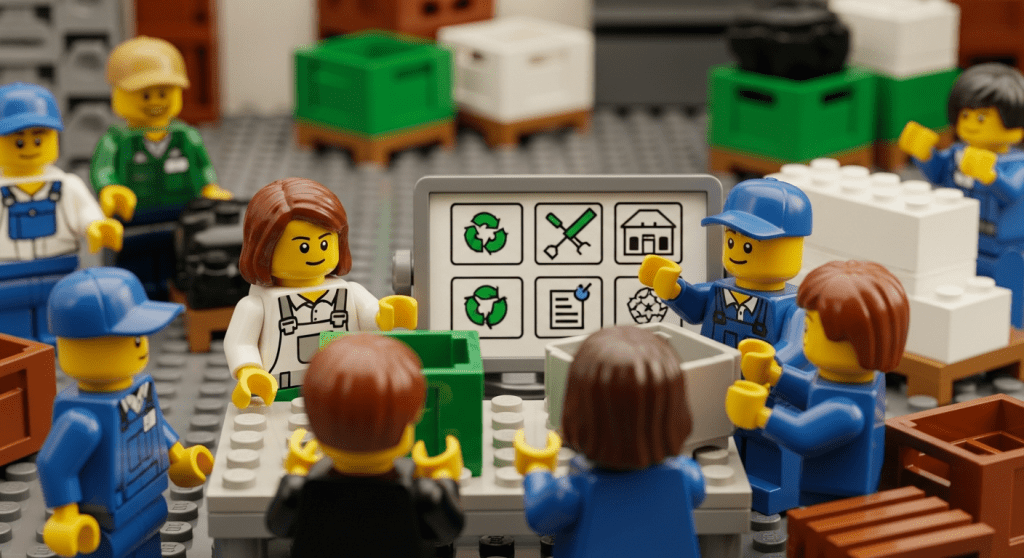

Green inventory management is transforming how industrial operations handle their stock – from raw materials and spare parts to finished products – with a focus on sustainability. In sectors like manufacturing and construction, where large inventories are common, adopting sustainable practices can dramatically reduce waste while improving efficiency and cutting costs. .

By optimizing how inventory is purchased, stored, used, and tracked, companies not only minimize their environmental footprint but also gain better control over their operations. The result is a win-win: leaner, greener warehouses and stockyards that support both business goals and the planet.

Understanding Green Inventory Management

Green inventory management, also known as sustainable inventory management, means managing stock in a way that balances operational needs with environmental responsibility. Traditional inventory management focuses mainly on cost, availability, and service levels. In contrast, sustainable practices go a step further – they aim to meet demand while minimizing waste, reducing resource usage, and lowering environmental impact. This involves considering the full lifecycle of materials and products, from procurement to storage to eventual disposal or recycling.

In practice, sustainable inventory management in an industrial context might include things like avoiding overstocking (to prevent unused materials from ending up as scrap), choosing eco-friendly packaging, using energy-efficient equipment in warehouses, and leveraging technology to increase visibility and reduce inefficiencies. It’s about optimizing inventory levels and processes not just for profit, but also for the planet. Companies that embrace these practices often find that what’s good for the environment is also good for business – reducing waste usually means reducing unnecessary costs, too.

Why Reducing Inventory Waste Matters

For warehouse managers and operations leaders, especially in manufacturing and construction, inventory waste is a silent profit killer and an environmental liability. Excess or mismanaged inventory can lead to materials expiring, rusting, getting lost, or becoming obsolete. Not only does this represent money thrown away, but disposing of unused inventory (whether by sending it to landfill or recycling) has environmental costs. In fact, waste associated with unsold or unused inventory contributes significantly to industrial landfill volume and carbon emissions.

Every product that ends up as scrap embodies wasted energy and resources from production, packaging, and transportation.

On the flip side, sustainable inventory management directly benefits the bottom line. By reducing surplus stock and preventing spoilage or obsolescence, companies save on storage costs and write-offs. Operations become more efficient – workers spend less time moving or maintaining unnecessary items, and warehouses require less space and energy when they’re not overflowing with excess goods. Furthermore, today’s customers and regulators are paying attention. Many businesses face pressure to improve their sustainability credentials. Demonstrating that you minimize waste and manage resources responsibly can enhance your brand’s reputation, help meet environmental regulations, and even make your company more attractive to clients who prioritize green practices.

Finally, reducing inventory waste makes your supply chain more resilient and agile. When you trim the fat from inventory and have a clear view of what’s on hand, it’s easier to adapt to changes in demand or disruptions. You’re not tying up capital in piles of unused materials, and you can respond faster knowing exactly where everything is. In essence, green inventory management aligns with the principles of lean operations and continuous improvement, which have long been pillars of operational excellence in industry. It’s about doing more with less – less waste, less cost, and less environmental impact – and reaping more value.

Best Practices for Sustainable Inventory Management

How can industrial companies actually implement green inventory management? The following best practices and strategies are proven ways to reduce waste in inventory operations while maintaining or even improving performance. From optimizing stock levels to rethinking processes and leveraging new tools, these practices will help warehousing and operations professionals make their inventory management more sustainable.

1. Optimize Inventory Levels with Accurate Forecasting

One of the core principles of sustainable inventory management is avoiding excess stock. Every pallet of materials or products sitting untouched on a shelf represents resources that could be put to better use. By optimizing your inventory levels, you ensure you’re holding just what you need – no more, no less. The key to achieving this balance is accurate demand forecasting and inventory planning.

Invest in good forecasting methods and tools that take into account sales trends, production schedules, seasonality, and lead times. In a manufacturing setting, this might mean collaborating closely with sales and production teams to anticipate exactly how much raw material to purchase for the next quarter. In construction, it could involve detailed project planning so materials arrive when needed, rather than piling up on the job site. Data-driven forecasting helps prevent the common scenario of over-ordering “just in case” and then ending up with surplus that goes unused.

Implement techniques like ABC analysis to prioritize which items need the most focus (for example, high-value or fast-moving items should be forecasted and monitored very closely). Use inventory optimization models or software that can suggest optimal reorder points and quantities by analyzing consumption patterns. The result of improved forecasting and optimized reorder policies is a leaner inventory: you free up space, reduce carrying costs, and significantly cut down the risk of materials expiring or getting damaged in storage. This not only reduces waste but also improves cash flow, since less money is tied up in idle stock.

Crucially, optimizing inventory levels also means planning for variability in demand without resorting to huge safety stocks. Strategies like safety stock calculation and dynamic reordering can ensure you have a buffer for emergencies, but one that’s based on rational data (like historical demand variability and supplier lead times) rather than fear. The payoff is big: companies that master this see fewer stockouts and much less waste from excess inventory. They aren’t scrambling to offload surplus parts at a discount or sending truckloads of outdated products to the dump. Instead, their inventory is tight, efficient, and responsive to actual needs – a solid foundation for sustainability.

2. Embrace Lean Inventory and Just-in-Time Strategies

Lean manufacturing principles and Just-in-Time (JIT) inventory go hand-in-hand with sustainability. The mantra of lean is to eliminate waste (“muda”) in all its forms – and excess inventory is one of the biggest wastes identified in lean philosophy. By embracing lean inventory practices, industrial operations can drastically reduce the waste associated with overproduction and overstocking.

Just-in-Time is a strategy where materials and components arrive “just in time” for production or use, rather than far in advance. When properly implemented, JIT reduces the amount of inventory that must be stored and managed, cutting down on storage space and minimizing the risk of goods expiring or becoming obsolete. For example, a manufacturing plant using JIT might schedule smaller, more frequent deliveries of parts from suppliers instead of large bulk orders that sit in the warehouse for months. A construction project might time the delivery of concrete or steel to align closely with the installation schedule, rather than stockpiling materials on-site. By receiving inventory only as it is needed, you avoid the waste of having mountains of unused materials.

In practice, shifting to lean and JIT requires tight coordination with suppliers and robust scheduling. There’s less margin for error – if a delivery is late or demand spikes unexpectedly, stockouts can happen. However, when done well, the benefits are significant. You’ll see less clutter and better flow in the warehouse or yard, which also improves safety and productivity. Equipment and labor can be focused on processing current orders rather than managing excess stock. And from a sustainability perspective, lean/JIT means fewer resources wasted on producing, storing, and eventually disposing of surplus inventory. It even often leads to lower energy usage, as warehouses can be smaller or sections can be shut down when not needed for storing excess goods.

It’s important to note that a lean approach doesn’t mean running out of stock; it means refining your processes so that inventory moves smoothly and continuously. Tools like Kanban systems (visual signals to trigger replenishment) can help maintain flow without overstocking. Many operations leaders also combine JIT with strategic safety stocks or backup plans for critical items to cushion against supply disruptions – maintaining resilience while still keeping inventories slim. Ultimately, embracing lean inventory is about thinking of inventory as a dynamic flow rather than static storage. This mindset shift leads directly to waste reduction: you produce and stock what is needed, when it’s needed, and very little more. It’s a powerful way to run a greener, more cost-efficient operation.

3. Adopt Circular Economy Principles and Reverse Logistics

A circular economy approach is a game-changer for reducing waste in industrial inventory management. In contrast to the old linear model of “take, make, dispose,” a circular approach keeps materials in circulation for as long as possible. For inventory management, this means planning for what happens after a product’s initial use, and finding ways to reuse, refurbish, or recycle materials rather than simply throwing them away.

One practical strategy is to establish strong reverse logistics processes. Reverse logistics refers to the flow of items back from the end user or the downstream part of the supply chain, returning them to useful service. For example, a manufacturing company can set up a system to take back packaging materials, pallets, or even its own products at end-of-life. Those items can then be reused, repaired, or broken down for recycling. If you produce equipment or machinery, consider offering refurbishment programs – taking back old units from customers, upgrading or repairing them, and either reselling them as certified used products or using the parts. This not only prevents these items from becoming waste, but it can also create a secondary market and additional revenue streams.

In construction, circular principles might involve reclaiming and reusing materials from project to project. Excess materials from one job (like leftover bricks, steel beams, or piping) can be transported back to a central yard and then reallocated to future projects rather than discarded. Some construction firms even partner with recycling organizations or other industries – for instance, grinding down old concrete to use as base material for roads, or sending scrap metal to be melted and reused. By planning inventory with the end in mind, construction managers can drastically cut down on the piles of waste a project generates.

Another aspect of circular inventory management is monitoring product lifecycle and durability. This involves choosing inventory items (be it components, tools, or products you sell) that are durable and repairable, so they last longer and don’t need to be replaced as often. It might also mean keeping an inventory of spare parts to repair equipment instead of junking the whole machine when one part fails. While holding spare parts is an inventory cost, it can be sustainable if it avoids having to scrap large machines prematurely.

Key takeaway: By adopting circular economy principles, companies treat waste as a resource. Inventory managers should ask, “What will happen to this item if we order it and don’t use it, or once it’s used up?” and have a plan beyond the landfill. Not only does this reduce environmental impact, but it often reduces costs – recycling or selling scrap materials recovers value, and reusing items means fewer new purchases. Plus, many customers and business partners appreciate a company that takes responsibility for its products through end-of-life, which can enhance your brand’s sustainability image.

4. Practice Green Procurement and Supplier Collaboration

Sustainable inventory management isn’t just about what happens inside your warehouse – it starts with what and how you procure goods. Green procurement means sourcing materials, components, and products with consideration for their environmental impact and the practices of your suppliers. By making sustainability a criterion in purchasing decisions, you can significantly reduce waste and environmental harm upstream, before items even enter your inventory.

One best practice is to choose suppliers who prioritize sustainability and waste reduction themselves. This could involve selecting vendors who use recycled or bio-based materials, have minimal packaging, or offer take-back programs for their products. For instance, if you’re sourcing parts for manufacturing, you might favor a supplier that uses recycled aluminum over one that uses only virgin aluminum, since the former has a much lower carbon footprint. Or consider a supplier that ships components in reusable containers that you send back to them, eliminating one-time packaging waste. By building these preferences into your procurement policy, your inventory arrives more “green” from the outset.

Another crucial aspect is supplier collaboration and transparency. Work with your suppliers to align on inventory and sustainability goals. For example, share your demand forecasts and lean inventory approach with them so they can produce and deliver in sync with your needs (preventing overproduction on their side). Collaborating on programs like vendor-managed inventory (VMI) can reduce overall stock levels and waste in the supply chain. In a VMI arrangement, the supplier takes responsibility for managing certain inventory at your site – they keep it stocked at agreed levels, which often leads to efficiencies and less overstock. As partners, you can set mutual goals for reducing packaging waste or increasing the recyclability of materials.

Local sourcing is another green procurement strategy. Whenever feasible, source materials closer to where they’ll be used. For manufacturing and construction operations, local suppliers mean shorter transportation distances, which reduces fuel consumption and emissions. It also often means you can get deliveries faster and in smaller batches (supporting JIT strategies) because lead times are shorter, further reducing the need to stockpile. Plus, local suppliers might be more willing to work with you on special sustainability initiatives (like taking back pallets or drums for reuse) due to the proximity.

Lastly, evaluate the lifecycle impact of the items you’re ordering. If you have a choice between two products to keep in inventory – say, two types of paint, or two models of a machine part – consider not just price and quality, but which one is more environmentally friendly over its life. Does one type last longer (meaning less frequent replacement)? Is one made with fewer toxic materials or is easier to recycle? By asking these questions during procurement, inventory managers can gradually shift their stock toward greener alternatives. This proactive approach prevents future waste (you won’t be stuck with inventory that’s hazardous or hard to dispose of) and supports suppliers who are doing the right thing. Over time, as more customers demand sustainable options, the whole supply chain becomes greener – and your operation will be ahead of the curve.

5. Minimize Packaging and Material Waste

Take a look around any warehouse or storage area and you’ll notice a significant portion of waste comes from packaging. Cardboard boxes, plastic shrink wrap, foam fillers, wooden pallets – while these are often necessary to protect goods, they quickly pile up as trash if not managed sustainably. Minimizing packaging waste is a tangible best practice that not only reduces environmental impact but can also cut costs and improve efficiency.

Start with how materials and products come into your facility. Whenever possible, order in bulk or in reusable containers. For example, rather than receiving 100 small boxes of screws, a supplier might be able to ship you the same screws in one large reusable tote. Bulk purchasing can reduce the total packaging per unit of product. Many suppliers offer options for packaging reduction if customers ask – you might request that your raw materials come on pallets with recyclable corner boards instead of thick wood crates, or that multiple components are packed together instead of individually. Over time, these small changes can eliminate a large volume of cardboard, plastic, and other packing materials that would otherwise go to waste.

Inside your operation, look at your own packing and handling processes. If you’re distributing products or sending items to job sites, explore more sustainable packaging options: biodegradable packing peanuts, recycled-content boxes, or even innovative materials like mushroom-based foam or cornstarch packaging. Also consider right-sizing your packaging – use boxes or containers that fit the product dimension closely so you’re not using excess filler. This not only reduces waste but can lower shipping costs (smaller, lighter packages). For industrial products or equipment that require protection, invest in durable, reusable packaging like hard plastic cases or metal bins that can be sent back and forth.

Another angle is implementing a packaging return or recycling program. Work with partners to retrieve and reuse packaging. Some companies, for example, tag and return wooden pallets or steel drums back to the supplier for reuse multiple times. If reuse isn’t feasible, set up convenient recycling streams within your facility: clear areas for workers to place cardboard, shrink wrap, and other materials for recycling rather than tossing them in general waste. Make sure these materials actually get to a recycling facility – partner with a recycling service if needed – so that they don’t end up in a landfill.

Minimizing material waste also extends to the items in inventory themselves. For manufacturing operations, this might mean repurposing off-cuts and scraps from the production process. If you cut metal sheets and have leftover bits, those can be inventoried as raw material for smaller parts or recycled directly rather than discarded. In construction, leftover materials like half-used paint cans or excess tiles can be saved in an inventory system for future jobs (with proper storage to keep them usable), instead of being trashed at the end of a project.

By attacking the problem of packaging and material waste on multiple fronts – inbound, internal, and outbound – companies can make a sizable dent in their waste generation. These efforts also tend to streamline operations. A leaner packaging approach often means faster unpacking, less clutter to work around, and fewer disposal tasks, which improves productivity. And it sends a strong message to employees and stakeholders that waste reduction is a priority at every step of the inventory lifecycle.

6. Implement Advanced Tracking Technology (Inventory Mapping with CyberStockroom)

Leveraging technology is essential to managing inventory efficiently and sustainably. Modern inventory management systems provide real-time visibility into stock levels and locations, which is crucial for identifying waste and opportunities for optimization. One innovative approach is using inventory mapping software – for instance, CyberStockroom offers a visual inventory management platform that can be a game-changer for industrial operations aiming to go green.

Inventory mapping means you have a live, interactive map of all your inventory across various locations. Imagine being able to pull up a digital map of your entire warehouse or multiple warehouses and job sites, and instantly see where every item is stored and in what quantity. CyberStockroom’s platform enables exactly that. It allows you to break down your business into a map with zones for different locations: warehouses, production areas, storage yards, even service trucks carrying spare parts. With a quick glance, a warehouse manager can see, for example, how many units of a certain part are in Warehouse A’s tool crib vs. Warehouse B’s main store or out at a construction site. This level of visibility helps prevent the classic waste scenario of “lost inventory” that gets reordered unnecessarily. When you can easily find what you have and where it is, you’re far less likely to purchase duplicate materials or let items languish forgotten in a corner.

CyberStockroom’s map-based interface also makes inventory transfers and adjustments extremely intuitive. Using a simple drag-and-drop action, you can move items on the digital map from one location to another to reflect a physical transfer – say you decide to consolidate all excess steel beams from multiple yards into one central location. Everyone using the system will see that update in real time. This capability is powerful for sustainability because it enables dynamic re-balancing of stock: you can quickly shift surplus inventory to where it’s needed, instead of buying new stock for that location. For example, if one construction site has dozens of extra pipes and another site needs some, a manager viewing the map can spot this and arrange a transfer, ensuring the excess gets used and not wasted. In effect, the software helps you use what you already have more effectively, reducing unnecessary new purchases (and the waste that would come from eventual surplus).

Another feature that supports green goals is detailed tracking and history. CyberStockroom keeps an activity log of inventory movements, who moved what, and when. This audit trail means you can analyze patterns – perhaps noticing that a certain component keeps getting returned or disposed of, indicating a recurring overstock issue or a quality problem. By having data at your fingertips, you can pinpoint where waste is occurring in your inventory lifecycle and address the root cause. The system can also support barcoding and scanning, which improves accuracy in counts and reduces human error (a common cause of inventory discrepancies and subsequent waste). When your inventory data is accurate, you don’t over-order “just to be safe.”

CyberStockroom is a cloud-based solution, which means it can be accessed from anywhere by the team – whether on the warehouse floor, in the office, or at a job site with a tablet. This connectivity ensures that all stakeholders share the same real-time information. There’s no need for paper printouts of stock lists that quickly go out of date. Going digital and cloud-based in inventory management not only cuts down on paper waste, but also enhances collaboration. When operations leaders, purchasing, and sustainability officers all see the same inventory picture, they can work together to find opportunities to reduce excess and waste.

In summary, using advanced inventory tracking technology like CyberStockroom’s inventory mapping is a best practice that underpins many of the other strategies we’ve discussed. It’s much easier to implement lean or JIT principles, for example, when you have confidence in your inventory data and visibility into every corner of your operations. Likewise, identifying candidates for circular reuse or redeployment across sites becomes straightforward when you can visually spot where surpluses exist. Technology acts as an enabler for sustainable practices, and investing in a robust inventory management system is an investment in efficiency, transparency, and waste reduction.

7. Improve Energy Efficiency in Warehousing Operations

When thinking about inventory sustainability, don’t overlook the energy used to store and handle goods. Warehouses, distribution centers, and storage yards can be surprisingly energy-intensive. Lights blaze, HVAC systems run to keep climates controlled, and forklifts or other machinery are constantly on the move. Improving energy efficiency in these operations is a critical best practice – it reduces the carbon footprint of your inventory management and often yields significant cost savings.

Start with the low-hanging fruit of energy conservation: lighting. Warehouses traditionally have long hours of bright lighting for safety and productivity, but older lighting systems can waste a lot of electricity. Upgrading to LED lighting can dramatically cut energy use (LEDs can use up to 50-70% less energy than traditional bulbs and last longer). Even better, install motion sensors or smart lighting controls so that lights dim or turn off in aisles or zones that aren’t in use at a given time. In a large storage facility, it’s common that only a few areas have activity at any moment – there’s no need to illuminate every corner 24/7. Many companies have found that investing in efficient lighting systems for their warehouses pays for itself quickly through lower utility bills.

Climate control is another big factor. If your inventory includes items that need to be kept at certain temperatures (for example, certain chemicals, pharmaceuticals, or even food ingredients in a manufacturing plant), then HVAC (heating, ventilation, air conditioning) is likely a substantial energy draw. Optimizing climate control might include using smart thermostats that adjust temperatures based on time of day or when areas are occupied. In some cases, it could mean segmenting the warehouse – only cooling or heating specific zones where sensitive inventory is, rather than the whole building. Investing in better insulation or high-speed doors that reduce air exchange can also maintain temperatures more efficiently. Every bit of energy saved in warehousing is a reduction in the environmental impact (less fossil fuel burned for electricity) and a cost reduction on your balance sheet.

Equipment and vehicles used in inventory handling are part of the energy picture too. Modernizing your material handling equipment can make a difference. For example, electric forklifts produce no on-site emissions and can be charged during off-peak energy hours, unlike older propane or diesel forklifts that emit greenhouse gases and particulate matter. Even within electric equipment, newer models often have better battery efficiency and energy management systems. Additionally, practicing good maintenance on all machinery ensures they run efficiently – well-maintained motors and engines use energy more cleanly and effectively.

Consider also implementing energy monitoring in your facility. By tracking energy usage by zone or by equipment, you can identify anomalies or opportunities. Maybe you’ll discover that a particular section of your warehouse is drawing a lot of power at night – perhaps due to an HVAC setting that can be adjusted. Or you might notice that charging all electric forklifts at the same time spikes demand (incurring higher fees), so you stagger their charging schedules. These optimizations come from measuring and then managing energy use.

Finally, some companies are going a step further by integrating renewable energy into their warehouse operations. Solar panels on warehouse roofs are increasingly common, turning those large flat spaces into energy-generating assets. Even if you can’t cover all of your electricity needs with solar, it can offset a portion and visibly demonstrate a commitment to sustainability. Other practices like using skylights for natural lighting or energy-efficient roof designs (to reduce heating/cooling loads) contribute to a greener warehouse.

In summary, making your inventory storage and handling more energy-efficient is a best practice that tackles a different side of “inventory waste” – the wasteful use of energy resources. It complements the material-focused strategies by addressing the operational footprint. And the good news is, energy-saving measures often pay off. They reduce operational costs, sometimes dramatically, and make your facilities more sustainable and resilient in the face of rising energy prices or carbon regulations.

8. Train Employees and Foster a Sustainability Culture

Even the best sustainability strategies can fall flat without the support and understanding of the people who execute them. Employee training and engagement is a vital best practice when implementing green inventory management. Your warehouse staff, purchasing team, production supervisors, and other personnel need to be informed about new processes and motivated to participate. Fostering a culture of sustainability ensures that waste-reducing practices aren’t just one-time mandates, but an ongoing way of doing business.

Start by educating your team on the why and how of sustainable inventory practices. When rolling out initiatives – whether it’s a new recycling program, a switch to a different inventory system, or changes in ordering policy – take the time to explain the reasons behind them. For instance, if you’re implementing a Just-in-Time approach, explain to the warehouse crew and procurement team how reducing excess stock will not only help the environment but also make their jobs easier (less clutter, clearer priorities) and help the company financially. People are more likely to support changes when they understand the benefits and see management’s genuine commitment.

Incorporate sustainability into regular training sessions and Standard Operating Procedures (SOPs). If you have a procedure for cycle counting, for example, include steps to flag any dead stock (items with no movement for a long time) so that the management can decide on reuse or safe disposal – this makes waste reduction a routine part of inventory control. Train employees on proper material handling to reduce damage (damaged goods often become waste). Make sure everyone knows how to use the inventory management software or tools (like CyberStockroom or others) that you’ve put in place to track and optimize inventory – a tool is only as effective as its users.

Beyond formal training, encourage a culture of continuous improvement and sustainability. This could involve setting up cross-functional teams or suggestion programs to find new ways to reduce waste. Front-line employees often have keen insights into inefficiencies – maybe they’ve noticed that a certain packaging is always discarded or that a particular item frequently expires on the shelf. Create channels (like a monthly meeting or an anonymous suggestion box) where workers can propose solutions, and recognize or reward those ideas that get implemented. Something as simple as a quarterly “Green Champion” award for a team member who contributed to waste reduction can boost engagement.

Leadership should also lead by example. Operations leaders and warehouse managers should be visibly involved in sustainability initiatives – if there’s a volunteer day to clean up and recycle old inventory, management should roll up their sleeves alongside everyone else. When employees see that sustainability isn’t just a PR slogan but a real priority valued by their bosses, they are more likely to take it seriously and put in the effort.

Communication is key to maintaining momentum. Share the results of your green inventory efforts with the team. For example, “In the last six months, we reduced expired stock by 30% and recycled 5 tons of packaging material – saving the company $X and preventing Y tons of waste from landfills.” Celebrating these successes shows employees that their actions make a difference. It also reinforces the idea that sustainability and efficiency are part of the company’s identity. Over time, new habits form: workers start to naturally consider the eco-impact of their day-to-day decisions, whether it’s how they dispose of a broken pallet or how carefully they manage stock to avoid damage. That’s when sustainability becomes truly embedded in the culture.

Conclusion: Toward Leaner and Greener Operations

Reducing waste in industrial inventory management is a strategic imperative in today’s world. For warehouse managers and operations leaders in manufacturing, construction, and other industrial sectors, adopting green inventory practices isn’t just about being environmentally friendly – it’s about building a more efficient, resilient, and profitable operation. By implementing the best practices outlined above, companies can cut out the fat of excess inventory, streamline their supply chains, and lessen their environmental footprint all at once.

The journey starts with a mindset shift: viewing every piece of inventory not just as a cost on the balance sheet, but as a potential source of waste if not managed correctly. From there, practical steps follow – forecast better, buy smarter, use lean principles, close the loop on materials, invest in the right technology, and engage your people in the mission. Tools like CyberStockroom can provide the visibility and control needed to support these initiatives, making it easier to see what you have and optimize how you use it. But technology alone isn’t a silver bullet; it works best in tandem with thoughtful processes and a culture that strives for continuous improvement.

As you move forward on this path, remember that sustainability is an evolving target. Start with some “quick wins” to build momentum – perhaps a successful pilot of a JIT system with a key supplier, or a project to recycle and repurpose scrap material that’s been piling up. Celebrate those wins and use them as proof that green inventory management delivers real results. Then keep pushing the envelope, reviewing your performance and seeking new ways to reduce waste.In the end, green inventory management is about creating value by eliminating waste. It’s good business and good stewardship. With careful planning and the commitment of your team, your industrial operation can achieve inventory excellence that reflects not only in your quarterly reports but also in a positive impact on the environment. That’s a legacy worth aiming for – an operation that is truly lean, efficient, and sustainable for years to come.

Leave a comment