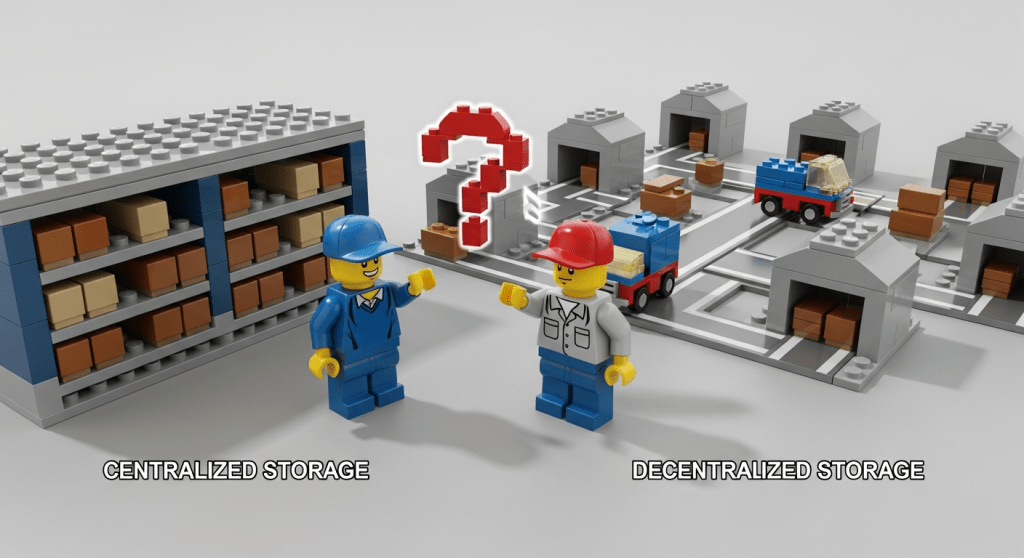

Every business that handles physical products faces a crucial decision: where to store inventory. More specifically, you must choose whether to keep all stock in one place (centralized) or distribute it across multiple locations (decentralized). This choice of inventory storage strategy impacts almost every part of your supply chain – from warehousing and order fulfillment to shipping costs and customer satisfaction.

What Is Centralized Inventory Storage?

Centralized inventory storage means keeping all of your stock in one central location. In a centralized model, a single facility (such as one warehouse or main stockroom) holds most or all inventory, and it typically also handles all logistics operations like receiving, storage, and order fulfillment. All customer orders are shipped out from this one hub, regardless of where the customer is located. Many traditional businesses have used centralized inventory by operating from a lone warehouse or a headquarters store.

Key characteristics of centralized inventory storage include:

- Single Inventory Hub: Inventory is consolidated in one place. This could be a dedicated warehouse, a distribution center, or even a backroom of a flagship store. All stock monitoring and management happens at this hub.

- Unified Operations: Because stock is in one location, related processes (purchasing, quality control, picking/packing, etc.) are also centralized. This often means one set of staff and one system handling inventory control, which can simplify management.

- “One Basket” Risk: The saying “don’t keep all your eggs in one basket” comes to mind – with centralized storage, all inventory is in one facility, so that site becomes a critical single point of success or failure.

Centralizing inventory is common for smaller businesses or those with a local customer base, since one warehouse can often serve a compact region efficiently. It’s also typical in businesses that prioritize tight control and simplicity in inventory management. To better understand this approach, let’s break down its advantages and disadvantages.

Pros of Centralized Inventory

Centralized inventory storage offers several potential benefits for efficiency and control:

- Simplified Inventory Control: With all stock under one roof, it’s much easier to track inventory levels and movements. There’s only one set of records to maintain and no need to reconcile data across multiple sites. This streamlined control means fewer chances for discrepancies – staff know exactly how much inventory is on hand and where it is. Conducting audits or cycle counts is straightforward when everything is in one place. Overall, centralization reduces complexity in inventory management, which can lead to higher accuracy and fewer stock errors.

- Lower Operational Costs: Maintaining a single storage facility generally costs less than running many. You pay rent, utilities, security, and labor for one warehouse instead of several. This consolidation can significantly reduce overhead costs on facilities and staff. For example, you don’t need duplicate warehouse managers or equipment at multiple sites. Additionally, a centralized warehouse can often buy inventory in larger bulk orders (since it’s stocking one big location), which may allow you to negotiate volume discounts from suppliers. Overall, centralization tends to be more cost-efficient in terms of storage and operations.

- Efficient Bulk Shipping: Receiving inventory and replenishing stock can be cheaper and easier with one hub. Suppliers can send large shipments (full truckloads or containers) directly to your central warehouse. By consolidating inbound shipments, you maximize transportation efficiency and minimize freight costs per unit. In contrast, a decentralized network might require splitting shipments to different centers. With centralization, inbound goods flow into one point, often simplifying the supply chain. (Later we’ll discuss how decentralized models handle this differently.)

- Consistency in Processes and Quality: With only one site, it’s easier to standardize procedures. All warehouse staff follow the same picking, packing, and handling processes, which can improve consistency and quality control. Training is more straightforward when there’s a single location – employees become experts in that facility’s layout and systems. Likewise, it’s easier to enforce safety stock policies or quality checks uniformly. This centralized oversight can result in more reliable operations and fewer mistakes compared to juggling different practices at multiple warehouses.

- Visibility and Data Simplicity: A centralized system provides a clear bird’s-eye view of inventory. Management can look in one system and see all stock on hand, which simplifies decision-making. Metrics like total inventory value, turnover rates, or order fill rate are calculated from one dataset. This unified visibility makes it easier to plan purchasing and avoid overstock or stockouts. It also aids demand forecasting and inventory planning, since you’re analyzing one pool of inventory data rather than aggregating across locations. Many businesses find that centralization helps them keep better tabs on inventory health.

In summary, centralizing inventory tends to streamline control and cut costs. It’s often ideal for businesses that are small or geographically concentrated, where one warehouse can effectively serve their market. By having everything in one place, companies can operate efficiently and maintain tight oversight of their stock.

Cons of Centralized Inventory

While centralized storage has upsides, it also comes with notable drawbacks and limitations:

- Slower Shipping Times (Distance to Customer): All orders ship from one location, which could be far from many customers. This often means longer delivery times on average. For a customer across the country (or in a different country), an item from one central warehouse might take several days or even weeks to arrive via ground shipping. In today’s market, where fast delivery is expected, a single shipping point can put you at a competitive disadvantage for distant customers. To offer 2-day or overnight shipping nationwide from one location, you’d likely incur very high expedited shipping costs. Thus, centralized inventory can struggle to meet the demand for rapid delivery in far-off regions.

- Higher Outbound Shipping Costs: Related to the above, if your customers are widespread, shipping everything from one hub usually raises the average shipping cost per order. Carriers must transport packages over longer distances. You might frequently pay long-zone or air shipping rates to reach distant destinations on time. These costs either cut into your margins or must be passed to customers (which can hurt sales). In short, last-mile delivery is less efficient when all goods originate from a single point. Decentralized models can often ship locally and more cheaply – we’ll discuss that difference later.

- Capacity Constraints and Scalability Challenges: A single warehouse has finite space and throughput. As your business grows (more SKUs, higher order volumes), a centralized facility can become a bottleneck. You might face space shortages, congested aisles, or shipping delays if that one building is overworked. Scaling up might require expanding the warehouse or moving to a larger one, which is a major project. In contrast, a decentralized approach can scale by adding new locations. Centralization can thus be “tough to scale” when growth outpaces the capabilities of the lone site. If you plan rapid expansion or serving new regions, a purely central model may struggle to keep up.

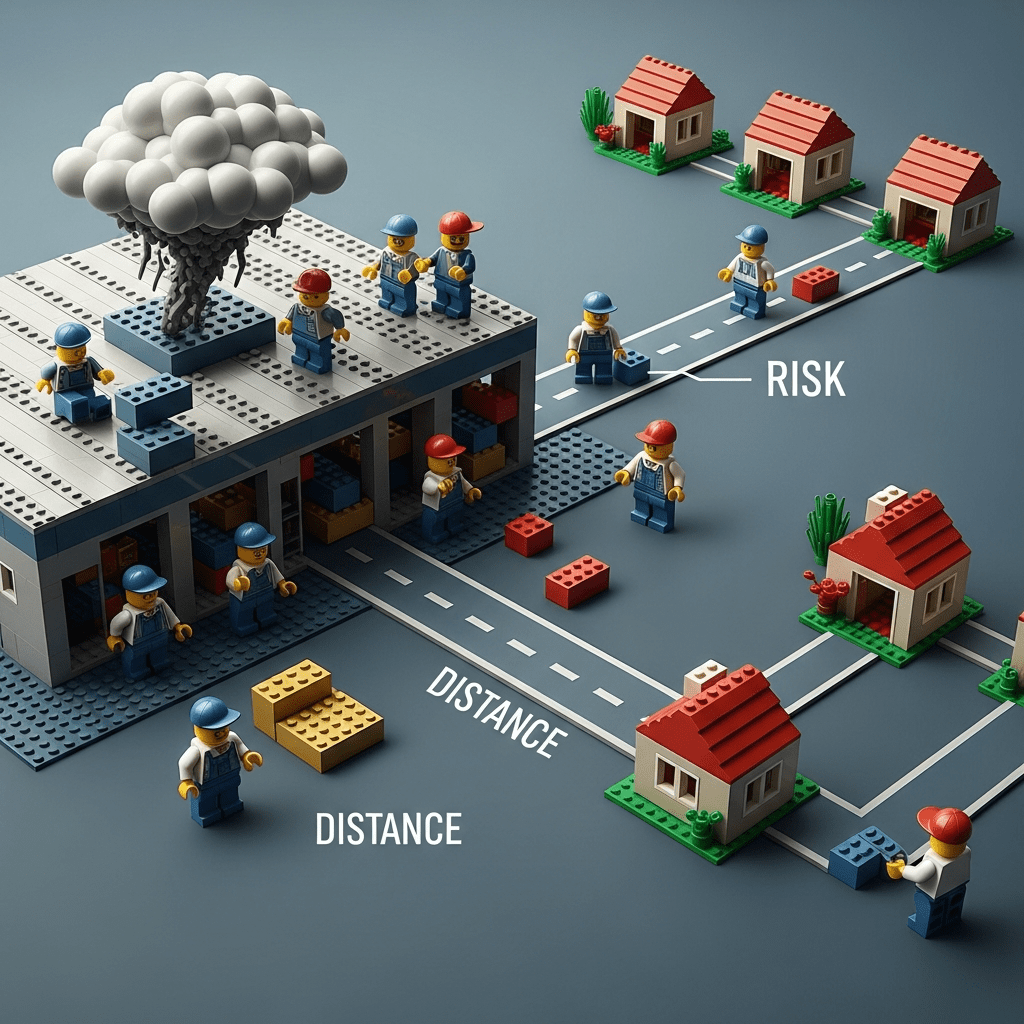

- No Redundancy or Backup Stock Locations: With all inventory in one facility, you risk total disruption if something goes wrong at that site. Scenarios like a natural disaster, fire, flood, or even a prolonged power outage at the warehouse could be devastating. You’d have no alternate warehouse to ship from. Even less catastrophic issues – say a local transport strike or a snowstorm affecting that area – could delay all orders. Centralized inventory leaves you vulnerable to location-specific risks because there’s no built-in backup storage elsewhere. This lack of redundancy can be dangerous for business continuity.

- Greater Distance from Some Suppliers or Markets: Depending on where your central hub is, it might be far from either your suppliers or key customer regions. For example, if you manufacture abroad, shipping everything to one domestic warehouse may incur extra import handling at that single point. Or if you have a global customer base, one central warehouse (especially if it’s only in one country) might mean slow international deliveries. In essence, centralization is a one-size-fits-all location that inevitably will be suboptimal for some part of your supply chain – either inbound or outbound logistics might be less efficient due to location constraints.

- Less Flexibility: A centralized approach can be less adaptable to regional differences. If you serve varied markets, having inventory in one place means you can’t easily position certain products closer to specific audiences. For instance, if one product sells much better on the West Coast, you cannot station extra stock out west unless you either relocate the warehouse or shift to multiple locations. Centralization may require more predictive distribution planning because you commit all inventory to one spot. It’s inherently less flexible in responding to geographic demand spikes.

Overall, the trade-offs of centralized inventory revolve around distance and risk. You gain efficiency and control by having one warehouse, but you sacrifice some customer service speed and put all your stock eggs in one basket. Centralization tends to work best when your customers are relatively local to the hub or when fast delivery is not the top priority. Small businesses often start centralized for simplicity, but as we’ll see, growing operations might look to decentralize to overcome these limitations.

Is centralized inventory right for you?

It often suits businesses that:

- Have a small to mid-sized, local or regional customer base (e.g. one city or state) so that shipping times remain reasonable.

- Operate with a stable, predictable demand that can be managed from one place.

- Want to minimize costs and have limited resources for managing multiple sites.

- Are in an early stage or not rapidly scaling, making simplicity crucial.

- Have a low risk tolerance for complexity, even if it means accepting some shipping delays to distant customers.

If those conditions match your situation, centralized storage might be the more efficient choice. But if you find some of the cons worrying – particularly shipping speed or single-point failure risk – then a decentralized strategy could be worth considering. Next, let’s explore the decentralized approach in detail.

What Is Decentralized Inventory Storage?

Decentralized inventory storage (also called distributed inventory) means splitting your stock across multiple storage locations. Instead of one big warehouse, a business using decentralization manages several warehouses or fulfillment centers in different geographic areas, each holding a portion of the inventory. For example, a company might maintain warehouses on the East Coast, West Coast, and Midwest to serve those regions. Customer orders are fulfilled from the location closest to the customer whenever possible.

In a decentralized system, each inventory location often operates semi-independently – with its own staff, possibly slightly different processes, and inventory levels tailored to local demand. However, all the sites are part of the company’s network and should be connected via an inventory management system so that the company has visibility across the whole distribution network.

Characteristics of decentralized inventory storage include:

- Multiple Warehouses or Nodes: Inventory is strategically placed in two, five, or even dozens of locations depending on the business size and reach. These can be regional distribution centers, retail store backrooms (for omni-channel fulfillment), or any nodes that store product closer to certain customer groups.

- Geographical Spread: Each storage location typically serves customers in its vicinity. The idea is to shorten the distance between inventory and end consumers. For instance, an e-commerce retailer might keep stock in New York, Los Angeles, and Chicago to cover the Northeast, West, and Central U.S. respectively. Global companies might have warehouses in different countries or continents.

- Localized Fulfillment: Warehouses in a decentralized model handle order fulfillment locally – processing, picking, packing, and shipping orders that come from their region. They function like smaller self-contained operations that collectively enable faster delivery.

- Complex Coordination: With stock spread out, the company needs robust systems to coordinate inventory levels, transfers, and restocking across all sites. Decentralization introduces more complexity in tracking and decision-making (e.g., deciding how to allocate stock to each location, or fulfilling an order that includes items stored in different facilities).

- Redundancy and Scalability: The presence of multiple locations inherently provides some backup (if one facility is down, others can still operate) and makes scaling more modular (you can add new warehouses or expand one location’s capacity as needed). It offers flexibility to grow and adapt by region.

Decentralized inventory strategies have become increasingly popular, especially with the rise of fast shipping expectations in e-commerce. Many large retailers and fulfillment services (like Amazon, Walmart, or 3PLs) leverage distributed warehouses to achieve 2-day or same-day delivery in various areas. Let’s examine the advantages that drive businesses toward decentralization, as well as the challenges it brings.

Pros of Decentralized Inventory

Distributing inventory across multiple locations can deliver significant benefits, particularly in customer service and risk mitigation:

- Faster Delivery to Customers: The most touted advantage of decentralizing is speed. By storing products in multiple regions, you can ship from the warehouse closest to each customer, drastically reducing transit time. For example, an order going to Florida can ship from your Southeast center rather than from a far-away Northeast hub. Shorter shipping distances naturally lead to quicker delivery. This model aligns with modern consumer expectations – today 67% of online shoppers expect 2-day delivery, and distributed inventory makes it feasible to meet these demands without relying on expensive air freight. Faster deliveries improve customer satisfaction and can boost your sales (customers are more likely to buy when fast shipping is available). In short, decentralized inventory enables superior fulfillment speed, delighting customers with prompt service.

- Lower Shipping Costs (for Last-Mile Fulfillment): Not only can orders arrive faster, but they can often ship cheaper when sent from a nearby location. Since distance is a major factor in shipping rates, reducing the average distance an order travels cuts down cost. Instead of paying cross-country or international postage, you pay regional or local rates for many shipments. For instance, ground shipping from a local warehouse may achieve 2-day delivery in-region at a fraction of the cost of flying a package from across the country. By placing inventory closer to end customers, companies can use more economical shipping methods (like ground transport) while still hitting tight delivery windows. Over time, these savings on fulfillment can be substantial, improving profit margins even as you speed up service. (Keep in mind, the cost benefits apply primarily to outbound shipping; we’ll discuss below that inbound and operational costs can rise.)

- Geographic Sales Growth and Market Reach: With multiple stocking points, it’s easier to serve customers in new markets. Decentralized inventory supports expansion because you can open a new distribution node in a region where demand is growing. This flexibility lets you tap into national or global markets that a single central warehouse might struggle with. For example, if a predominantly East Coast business gains lots of West Coast customers, adding a Western warehouse lets you serve them competitively. In essence, distributed inventory is scalable – it provides a framework to grow your footprint. It’s particularly beneficial if you aim to go international; establishing regional warehouses in target countries can overcome customs delays and drastically cut international shipping times. Overall, decentralization is conducive to business scaling and global reach.

- Redundancy and Risk Mitigation: By not keeping all stock in one place, you inherently get a backup in case of disruptions. If one warehouse is hit by an unexpected disaster or delay (storms, power failure, local carrier strike, etc.), the other locations are unaffected and can continue fulfilling orders where possible. Some operations even keep a bit of overlapping inventory in multiple sites so that a hot-selling item isn’t completely unavailable if one site runs out or goes offline. This redundancy improves your supply chain resilience – a single point of failure won’t halt your entire business. For example, during natural disasters, companies with decentralized networks often reroute orders to ship from other facilities. In a centralized model, that kind of contingency isn’t available. Thus, decentralizing provides insurance against regional disruptions, making your operations more robust.

- Inventory Optimization for Local Demand: With multiple warehouses, you can customize stock levels to local demand patterns. Each location can carry the product mix and quantities best suited for nearby customers. For instance, a retailer might stock heavier winter coat inventory in northern warehouses and more light apparel in southern ones, reflecting regional climate demand. Or one region might have higher turnover of a certain SKU, so you allocate more of it there. This tailored approach means products are stored closer to where they sell the fastest, which can reduce overall stock holding and ensure high-demand areas don’t run out. It also helps in launching region-specific promotions or handling seasonality by positioning inventory accordingly. Centralized systems, by contrast, treat inventory as one-size-fits-all; decentralized lets you be agile and responsive to local needs.

- Customer Pickup and Local Presence: In some cases, having inventory in multiple locations opens up possibilities like in-store pickup or regional distribution partnerships. For example, if your warehouses double as pickup points or are attached to retail outlets, local customers can retrieve products same-day. Or if you supply other businesses (B2B or retail stores), having regional stock means shorter restock times for them. A distributed model essentially brings you closer to your customers, not just in delivery but in any service aspect. It can improve customer trust knowing you have a presence in their area (for instance, “ships from a warehouse in your region” can be a selling point). This local presence can enhance brand reputation and customer convenience beyond just shipping speed.

Decentralized inventory is all about being closer – closer to the customer, and closer to a fail-safe. By leveraging multiple strategically placed warehouses, businesses can achieve lightning-fast deliveries, potentially lower their per-order shipping costs, and ensure operations continue smoothly even if one location faces trouble. These benefits have made decentralization increasingly attractive in an era where fast, affordable fulfillment is a competitive necessity.

However, these benefits don’t come free; they introduce complexity and cost in other areas. Let’s look at the downsides of managing a decentralized inventory network.

Cons of Decentralized Inventory

Splitting inventory across locations also brings significant challenges and trade-offs that must be managed:

- Higher Operational and Overhead Costs: Running multiple warehouses is expensive. You’ll be paying for extra facilities, each with its rent (or capital cost), utilities, insurance, and so on. You also need to staff each location with warehouse workers, supervisors, possibly additional managers – which multiplies labor costs. Equipment (like forklifts, shelving, barcode systems) might need to be purchased or leased for each site. All these duplicate expenses mean that decentralized inventory typically has a higher base cost of operations than a single-warehouse model. For small businesses, these costs can be prohibitive. Even for larger ones, it requires careful financial planning to ensure the faster shipping is worth the added overhead. In short, more warehouses = more cost centers, which can eat into profit margins if not offset by increased sales or efficiency elsewhere.

- Inventory Holding and Splitting Issues: When you spread inventory out, you often need to hold more total stock to achieve the same service level. This is because each location must be buffered with safety stock to handle local demand variability. There’s a risk of excess inventory in a decentralized system – one warehouse might sit on surplus of an item that’s not selling in that region, while another warehouse runs out of it. Without careful inventory planning, you could see higher overall inventory carrying costs, with capital tied up in slow-moving stock in some locations. There’s also the phenomenon of stagnant inventory: products forgotten in one corner of the network. Additionally, overselling can occur if inventory data isn’t perfectly synchronized – e.g., two different warehouses commit the same item to separate orders due to miscoordination. Managing optimal stock levels across multiple sites is complex, and the penalties for misallocation are either lost sales (stockouts in one place) or overstock (excess in another).

- Complex Inventory Management and Visibility: Keeping track of everything everywhere is a major challenge in decentralization. You’ll need a robust system (typically an advanced inventory management software or warehouse management system) to have real-time visibility of stock across all locations. Coordinating replenishments becomes complicated: you must decide how to distribute new stock deliveries among warehouses, when to transfer goods from one warehouse to another, and how to record all these moves accurately. Fulfilling orders may also get tricky if an order contains items that happen to reside in different warehouses – you might end up splitting the order into multiple shipments or transferring items internally, which can be inefficient. Communication across sites is critical so that sales channels know which warehouse will fulfill an order and inventory counts stay in sync. Without sophisticated tools and well-trained staff, a decentralized inventory can descend into chaos with issues like inaccurate stock records, mis-shipments, or lost products in the system. Essentially, operational complexity increases exponentially with each added warehouse.

- Increased Coordination and Administrative Burden: Along with technical complexity comes the human and administrative burden of managing a dispersed operation. Standardizing processes across multiple warehouses (often in different regions or countries) is difficult – each facility might develop slight differences in how they receive goods, perform counts, or pick orders, which can lead to inconsistent results. You also have to coordinate communications across time zones or distances; solving a problem in real time might be harder when your team is spread out. More warehouses also mean more vendor relationships if you outsource any functions (like more 3PL contracts to manage). Accounting and inventory auditing become more involved, as records come from various places. All told, decentralized systems demand strong management oversight and coordination efforts to keep everything running in unison. The organizational complexity is a significant drawback that can strain companies that aren’t prepared for it.

- Distribution of Inbound Goods (Upstream complexity): We often focus on the outbound (customer side) of decentralization, but it also affects inbound logistics. If you manufacture products or receive them from suppliers, a decentralized approach means you have to distribute incoming inventory to multiple warehouses. This could involve splitting purchase orders and sending portions to different centers, or transporting goods from a central intake point to satellite warehouses. Such distribution adds cost and complexity – for example, you might receive a container of goods at one port, then incur extra trucking to send half of it to another regional warehouse. In some cases, instead of one full truckload shipment to a single warehouse, you might be sending several less-than-truckload (LTL) shipments to various site. Smaller shipments are relatively more expensive per unit than bulk shipments. Therefore, inbound freight costs and handling can increase under a decentralized model, partially offsetting the savings on outbound shipping. Companies need to plan their supply chain carefully to efficiently feed inventory into a multi-warehouse network.

- Lower Economies of Scale at Each Location: A single big warehouse can be operated at high efficiency and high volume, leveraging economies of scale in labor and processes. When you break inventory into multiple smaller warehouses, each location may not handle enough volume to be as efficient. For instance, you might need to run each warehouse at half capacity, or each has downtime in between batches of orders – whereas one big center could run 24/7 at full capacity. You may also lose bulk purchasing advantages for warehouse supplies, or volume discounts with local carriers, because each ships fewer orders individually. Essentially, decentralizing can reduce operational efficiency per location if scale isn’t maintained. This is why very small businesses often can’t effectively decentralize – each warehouse would be underutilized. It’s important that the volume of orders in each region justifies having a separate fulfillment center there.

- Technology and Security Concerns: More nodes mean a wider surface for potential issues, including IT challenges. Ensuring real-time data synchronization across locations is vital. If your software isn’t truly cloud-based or updated instantly, you could face data lags that lead to stockouts or double-selling. There’s also a cybersecurity aspect: multiple sites accessing central data, potentially over various networks, can introduce vulnerabilities. From an IT perspective, you have to support systems in multiple facilities, which could mean higher tech support and infrastructure costs. All warehouses must have reliable internet, scanning devices, etc. – a failure at one site shouldn’t bring down your whole inventory system. Maintaining high-quality technology and consistent training at each location is an ongoing commitment with decentralized inventory.

To sum up, the downsides of decentralization center on higher costs and greater complexity. Businesses must invest in more infrastructure and robust management to coordinate a multi-warehouse operation. Mistakes can multiply if the system isn’t well synchronized. Decentralized inventory is only advantageous if you can effectively manage these challenges; otherwise, the model can backfire with inefficiencies or cost overruns.

Is decentralized inventory right for you?

It tends to benefit businesses that:

- Have a broad or dispersed customer base (nationwide or international) demanding fast delivery. If your customers are everywhere, you likely need multiple locations to serve them competitively.

- Prioritize shipping speed and customer experience, enough that you’re willing to incur higher operational costs to achieve it.

- Are in a growth phase, scaling up to new markets where being closer to customers will drive more sales.

- Can invest in technology and management needed to coordinate multiple sites (or partner with a 3PL that provides a distributed network).

- Have product characteristics that require proximity – e.g., heavy or bulky items where shipping distance heavily affects cost, or perishable goods that must travel quickly.

- Value risk mitigation and want redundancy to protect against disruptions.

If those align with your company’s situation and goals, decentralizing inventory could be worth the complexity. Many mid-sized and large companies find that the benefits in service level outweigh the added costs, especially in the age of e-commerce expectations.

That said, it’s not an all-or-nothing choice; some businesses use a hybrid approach – for example, maintaining one primary central warehouse and a couple of smaller regional warehouses. This can capture some benefits of both strategies (we’ll touch more on that later). Before we conclude which approach is best, let’s consider how technology can help manage inventory effectively in either model. In particular, we’ll examine CyberStockroom as an example of an inventory management solution designed to give visibility and control in both centralized and decentralized contexts.

Using Technology to Streamline Inventory (How CyberStockroom Helps)

Whether you opt for a centralized or decentralized inventory strategy, one thing is clear: you’ll need strong inventory management practices and tools to run it well. Modern inventory management software can dramatically simplify the challenges we outlined for each approach. CyberStockroom is one such tool – a cloud-based inventory management platform known for its unique map-based interface. In this section, we’ll discuss

CyberStockroom’s capabilities and how they relate to central vs. decentralized inventory operations.

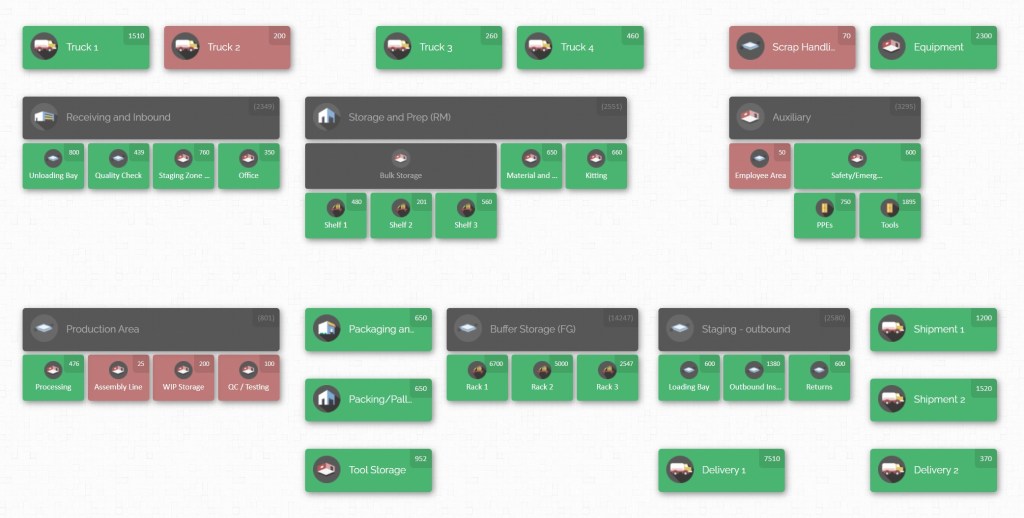

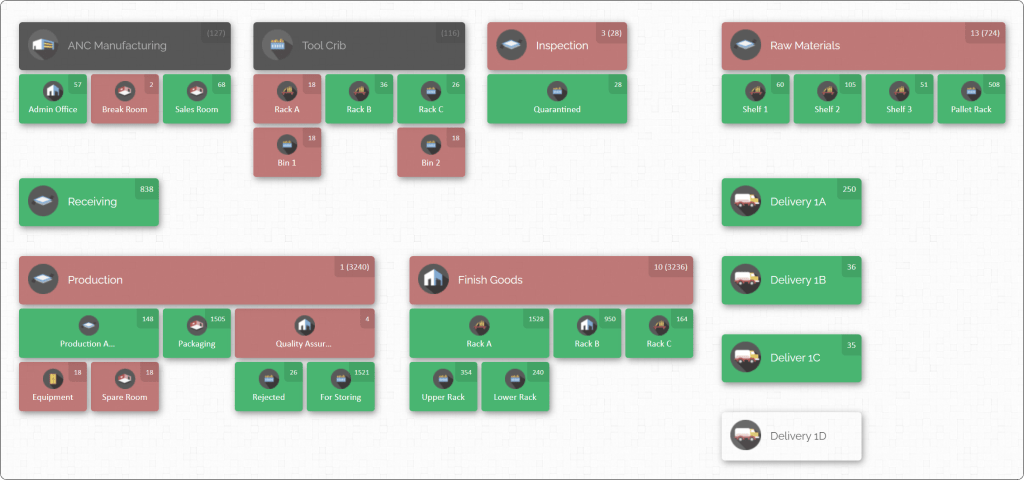

CyberStockroom’s Inventory Mapping

One of CyberStockroom’s standout features is its visual inventory map. Instead of viewing inventory as just spreadsheets or lists, CyberStockroom lets you create a digital map of all your inventory locations (warehouses, stockrooms, even trucks or specific rooms) and see your products laid out across that map in real time. For example, you can design a map with a central warehouse and also add regional storage facilities – or, if you’re centralized, perhaps different zones within one big warehouse (receiving, backstock, front store, etc.). The map is fully customizable: you can define multiple locations and sub-locations (like sections, aisles, bins) to mirror your real-world layout. This visual approach immediately shows how your products are distributed across locations and how much is in each spot.

For a centralized inventory, CyberStockroom’s map might show one primary warehouse broken into sub-areas, giving you granular visibility of where each item is stored in that facility.

For a decentralized network, you would see all your warehouses on one screen – providing an instant overview of your entire inventory spread. This addresses one of the big challenges of decentralization: maintaining visibility across multiple sites. With a quick glance at the map, you can tell, for instance, that Warehouse A has 120 units of Product X, Warehouse B has 50 units, etc., ensuring you’re aware of stock levels everywhere.

Real-Time Updates and Transfers

CyberStockroom is cloud-based and updates inventory data in real time as transactions occur. This means if someone checks out items from the warehouse or transfers stock from one location to another, the system immediately reflects it. In a multi-warehouse scenario, such real-time synchronization is critical to prevent the dreaded problems of overselling or phantom stock.

CyberStockroom allows products to be checked in, checked out, or transferred between locations with simple operations (including a drag-and-drop interface). For example, if you need to reallocate inventory – say move some stock from your central hub to a regional warehouse – you can record that transfer in the system, and the map will update the quantities at each site accordingly. This helps keep your decentralized inventory balanced and optimized: managers can visually identify if one location is overstocked while another is understocked and then execute a transfer to even it out.

Ease of Use and Training

Because of its visual design, CyberStockroom can be quite intuitive for staff to use. Traditional inventory systems can be abstract, but a map-based system is like giving your team a familiar floor plan with live data. For centralized operations, this might simplify training new employees on where items are and how to find them (they can literally see it on the map). For decentralized operations, it helps local teams understand the overall context and helps central management ensure each site is following the same playbook. CyberStockroom supports features like permissions and user roles, so you can allow local warehouse managers to update their site’s inventory while headquarters still oversees everything. This keeps everyone on the same system, maintaining consistency across locations.

Barcode Scanning and Accuracy

CyberStockroom supports barcoding and Quick Scan functionality. Scanning reduces manual data entry errors, ensuring that the counts in the system match reality. In a centralized warehouse, fast barcode scanning streamlines check-in/check-out, making it easier to keep accurate counts. In a decentralized network, having a standardized scanning process across all locations means each site’s data stays accurate and updates centrally.

Loss Prevention and Accountability

Because you can see who moved what where (CyberStockroom logs check-in, check-out, and transfer activities), it provides accountability that’s valuable in both centralized and decentralized setups. In a single warehouse, knowing the history of inventory movements can highlight if items are misplaced or lost internally. Across multiple warehouses, it’s even more important: CyberStockroom offers an audit trail of transactions, so you can trace issues like shrinkage or discrepancies to the source location and take action. Essentially, the software helps enforce good practices and transparency. When every item’s journey is tracked on the map, the chances of things “falling through the cracks” diminish. This can address concerns like theft or loss which sometimes plague multi-site operations if oversight is weak.

Cloud-Based Access Anywhere

As a cloud platform, CyberStockroom lets you log in from any location – you could be at headquarters monitoring all sites, or a manager traveling between facilities, or even working remotely, and still keep tabs on inventory. This ubiquity means a decentralized inventory doesn’t feel so distant; you carry the overview of your entire stock in your pocket, effectively. If you’re centralized, cloud access is still useful for flexibility (you don’t have to be on-site to check inventory status or place orders for restock). It also ensures that all locations see consistent, up-to-date information without needing complex networking – as long as they have an internet connection, they’re looking at the same live database.

In summary, CyberStockroom acts as a central nervous system for your inventory. It gives a holistic view that is crucial for making informed decisions about stocking and fulfillment in any model:

- If you’re centralized, CyberStockroom helps optimize that single hub – you get precise location mapping inside the warehouse, quick updates on stock levels, and easy auditing.

- If you’re decentralized, CyberStockroom shines by giving you one platform to manage all warehouses – a unified map to visualize inventory distribution and tools to coordinate transfers and updates seamlessly across the network.

By adopting such technology, many of the headaches of both strategies (like lack of visibility in decentralization, or risk of errors even in centralization) can be alleviated. Essentially, the right software makes either inventory model far more manageable than it would be with manual processes or siloed systems.

Important Note: When leveraging CyberStockroom or similar systems, it’s best to ensure your team is well-trained on using the software and that you’ve configured the inventory map to truly mirror your physical layout. The accuracy of the system depends on disciplined use – e.g., always scanning items when moving them. But once the process is in place, it becomes a powerful tool to maintain control.

Centralized vs. Decentralized: Which Strategy Is Best for You?

After weighing the pros and cons, you might be wondering which approach comes out on top. The truth is, there is no one-size-fits-all winner – the best inventory storage strategy depends on your business’s specific needs, resources, and goals. Both centralized and decentralized models have their place, and some businesses even find a hybrid middle ground to get the best of both worlds. Here, we’ll outline key factors to consider when deciding and discuss scenarios where one strategy may be preferable over the other.

Key Factors to Consider in Your Decision

- Customer Geography and Delivery Expectations: Start by analyzing where your customers are and how quickly they expect products. If your customer base is concentrated in one region, a single location near that region might suffice. But if you have customers spread across the country or globally, and especially if they demand fast shipping (1-2 day delivery), a decentralized network will likely be needed to meet those expectations. Consider the service level you want to offer: is standard 5-7 day shipping acceptable, or do you need to offer 2-day or overnight options to stay competitive? If speed is critical and customers are far-flung, leaning toward multiple warehouses is wise. Conversely, if most customers are local/nearby or are okay with slower shipping, centralization can work and save you money.

- Business Size and Growth Plans: The scale of your operations and your growth trajectory play a big role. Small or early-stage businesses with limited order volume often find centralized inventory simpler and more cost-effective – they can’t justify the expense of extra warehouses. If you only ship, say, 50 orders a week, one location can handle it and multi-site would be overkill. However, if you’re growing rapidly or plan to enter new markets, you should plan for a decentralized approach (either now or in the future). A telling sign is when your single warehouse consistently struggles to meet demand or when shipping costs and times to certain regions become problematic. High growth e-commerce brands, for example, often start centralized but add nodes as soon as volume and capital allow, to maintain service quality. Ask yourself: what will my business look like in 2-5 years? If expansion to new regions is on the horizon, you may need a distributed inventory strategy to support that scaling.

- Product Characteristics (Size, Weight, Perishability): Consider what you’re storing and shipping. Large, heavy items (furniture, appliances) are very expensive to ship long distances – decentralizing can save significant costs by positioning those items closer to customers. Perishable or time-sensitive goods (food, some pharmaceuticals) similarly benefit from being stored near end markets to reduce transit time and spoilage risk. In these cases, decentralized inventory is often almost a necessity. On the other hand, small, lightweight products (e.g. jewelry or small electronics) might ship cheaply via air from one location, so centralized could work fine even for global sales. High-value items might be better centralized for security and oversight. Also, if your product requires special storage conditions (climate control, hazardous material handling), concentrating those in one site might be more feasible than equipping multiple sites. Your decision should account for the nature of your products and how that influences shipping and storage.

- Inventory Stability and SKU Count: Think about your range of products and demand variability. A centralized system works best when you have a manageable number of SKUs and fairly predictable demand across them. If demand is stable, one location can stock appropriately and fulfill reliably. However, if you have a very broad catalog or highly seasonal/fluctuating demand, decentralization allows you to distribute different SKUs to where they sell most or flex inventory in one region without affecting another. Also, if you carry items that might not all fit well in one warehouse (perhaps some require cold storage, others don’t, or vastly different handling needs), you might use different facilities specialized for each category – which is a form of decentralizing based on product type. In short, if one warehouse can easily organize and manage your entire product range, centralize. If not (too many SKUs, too many differing needs), multiple warehouses or segmented inventory might make more sense.

- Cost Budget and Capital Availability: Your financial resources will inevitably shape your strategy. Centralized inventory is generally less expensive to maintain, so if you’re on a tight budget, it might be the only viable option initially. Decentralization requires the capital to set up new warehouses (or the budget to hire 3PL services) and ongoing higher costs. Do a cost-benefit analysis: estimate the cost of an additional warehouse vs. the expected gains in shipping savings or increased sales from better service. If the numbers show that an extra location would pay for itself in improved sales or significantly reduced shipping expense, that tilts toward decentralizing. But if the costs outweigh the benefits, you might stick with one location and perhaps explore intermediate solutions (like using a 3PL’s network on a smaller scale, or temporarily using pop-up distribution centers during peak season). Available capital and ROI on new facilities are crucial factors – many businesses expand their inventory network gradually as they can afford it.

- Risk Management and Business Continuity: How critical is it for your operation to have backup plans for disruptions? If you’re in an industry where downtime or inability to fulfill orders is absolutely unacceptable (for example, medical supplies or just-in-time manufacturing components), then having multiple inventory sites provides a safety net that might be worth the cost. On the other hand, if you assess that the risk of a major disruption at your warehouse is low or can be mitigated in other ways (good insurance, contingency contracts with alternate shippers or emergency stock agreements), you might not need to decentralize purely for risk reasons. Consider the environment of your main warehouse: is it in an area prone to natural disasters? If yes, decentralizing could be part of disaster preparedness. Also consider future uncertainties – the recent global supply chain challenges have shown that flexibility is valuable. Decentralization increases flexibility and resilience, so weigh how much you need those qualities versus how much you’re willing to spend for them.

- Management Bandwidth and Expertise: Be realistic about your team’s ability to handle complexity. Decentralized inventory requires more management oversight, advanced systems, and coordination. Do you have (or can you hire) experienced operations managers who have run multi-warehouse networks? Are your processes well-documented and standardized enough to replicate across sites? If not, it might be better to stay centralized until you build that capability. Alternatively, you could use third-party logistics (3PL) providers to manage some warehouses for you – essentially outsourcing the expertise. If you choose to centralize, you still need good management but it’s a narrower scope. Align your strategy with your organization’s strengths: if your company excels in logistical sophistication, you can pursue a complex distributed model successfully; if not, simplicity might be safer to ensure operational soundness.

- Fulfillment Model (B2C vs B2B vs Omni-channel): Your channels can also influence the decision. Direct-to-consumer e-commerce often pushes towards decentralization for speed. But B2B distribution might lean central if you’re shipping bulk orders to retailers or installers, where timing is less critical than consistency (and those partners might place large orders that justify freight shipping from one point). If you operate brick-and-mortar stores, you might centralize inventory to distribute to stores (as a hub-and-spoke model) or treat stores themselves as mini-distribution points (decentralized). Many retailers now use omni-channel fulfillment (ship-from-store or regional fulfillment centers) to get closer to customers – that’s effectively a decentralized approach. So consider your sales channels: online retail likely benefits from multiple fulfillment centers; a single wholesale warehouse to ship pallets to stores might stay centralized. Often businesses find a mix: e.g., a central warehouse for store replenishment plus a few e-commerce fulfillment centers for direct orders.

Finding a Balanced Approach

It’s worth mentioning that hybrid strategies are common. You don’t have to choose extremes of all-in-one vs. dozens of warehouses. Many businesses start with one central hub and then add a second warehouse in a key region to relieve pressure – this creates a semi-decentralized model that may be enough to significantly improve delivery times to a chunk of customers. Some will then add a third as they grow, and so on. Each addition should be justified by data (customer distribution, shipping costs, etc.). There is also the approach of using a 3PL (third-party logistics provider) that already has a network of warehouses. For example, instead of you running three warehouses, you might partner with a 3PL that places your stock in their facilities in different cities. This can achieve similar benefits without you directly managing each site (though at a cost, and you give up some control). Services like ShipBob, as mentioned earlier, advertise combining “the simplicity of centralized with the reach of decentralized” by letting merchants tap into their multiple locations. This underscores that a balanced approach often yields the “best of both worlds” – centralized control but decentralized reach.

Another hybrid tactic is maintaining a core central warehouse for the bulk of inventory and using smaller satellite warehouses or forward stocking locations just for fast-moving items needed in certain areas. Your central hub might still handle, say, 70% of your volume and all long-tail products, while satellites handle 30% (mostly high-demand, region-specific orders). This limits the scope of decentralization to what truly needs it, controlling costs while reaping benefits for key SKUs.

Final Thoughts

In deciding between centralized and decentralized inventory storage, the best approach is often to start with data and strategy:

- Map out your customer locations and service goals.

- Calculate costs for different scenarios.

- Consider trialing a new warehouse if decentralizing – perhaps through a 3PL to test the impact before fully committing.

- Ensure you have the technology infrastructure (like CyberStockroom or an equivalent system) to support whichever model you choose. Without good inventory tracking, centralization can suffer from inaccuracies and decentralization can spiral out of control. Strong inventory management is the backbone of both strategies.

It’s also not irrevocable – businesses can transition from one model to another as they evolve. Some start centralized and move to distributed as they grow; a few might even consolidate from decentralized to centralized if they downsize or find inefficiencies (for example, after a merger, a company might close redundant warehouses to cut costs, re-centralizing some inventory).

In conclusion, evaluate your operations holistically: If efficiency and low cost are your top priorities and your market footprint is limited, centralized inventory is likely best for now. If customer experience, speed, and flexibility are paramount in a competitive broad market, leaning toward a decentralized inventory strategy will give you the edge despite higher complexity. Many firms find a middle ground, using centralization where it makes sense and adding decentralization to solve specific pain points (like slow shipping to certain regions).

The ultimate goal is to have the right products in the right place at the right time – and at the right cost. By understanding the trade-offs and leveraging tools (such as inventory mapping software like CyberStockroom) to maintain control, you can design an inventory storage approach tailored to your business needs. Regularly re-assess the decision as conditions change (market expansion, new technology, cost fluctuations). Inventory strategy isn’t static; it should adapt with your business.

Choose the strategy that aligns with your operations and customer expectations, and remember that with careful planning (and perhaps a bit of help from modern inventory tech), you can mitigate the downsides of whichever model you implement. With the information from this guide, you’re better equipped to make that decision between centralized vs. decentralized inventory storage – and to keep your supply chain running smoothly either way.

Leave a comment