Imagine having a bird’s-eye view of all your materials and products across every warehouse, production line, and storage room. That’s exactly what a visual inventory map provides.

This kind of real-time visibility is a game-changer for production planners. It lets you spot potential shortages or imbalances early and coordinate between sites instantly. By visualizing your inventory on a map, you and your team can quickly identify which materials are available for upcoming production runs and relocate items to where they’re needed – all before a shortage shuts down a line. In short, seeing the whole picture of your inventory makes aligning it with your production schedule far easier and more intuitive.

The High Cost of Downtime from Misaligned Planning

In manufacturing, downtime is the enemy of productivity. Every minute a production line is idle due to missing materials or poor planning translates to lost output and revenue. Unplanned downtime can be shockingly expensive – industry studies estimate that the average manufacturing plant loses 5–20% of its yearly productivity to unplanned stoppages. That could mean hundreds of thousands of dollars (or more) gone per hour when equipment and workers stand idle.

While equipment failures and maintenance issues are well-known causes of downtime, a lack of required materials or components can be just as crippling. If your production schedule calls for a run of products, but the critical part needed isn’t on the shelf when it should be, the whole operation grinds to a halt.

Misalignment between production scheduling and inventory planning often lies at the root of these material-related delays. Consider a scenario: Your schedule says it’s time to build 500 units of Product X this week. However, due to disconnected planning, the purchasing team didn’t realize the production schedule had accelerated – so the needed raw materials are arriving next week, not now. The result? Machines and workers sit idle, orders get delayed, and you’re scrambling with expedited shipping or emergency sourcing. These fire-fighting measures drive up costs and stress, and they still can’t reclaim the lost production time.

Downtime isn’t just about lost product output; it has domino effects on the whole operation. Late deliveries can frustrate customers and damage your reputation. Idle workers and machines eat into efficiency metrics and morale. Rush orders for parts often come at a premium cost. In some industries, an hour of downtime can cost hundreds of thousands of dollars, once you factor in lost productivity, overtime for catch-up, and potential penalties for late shipments. Clearly, misaligned production schedules and inventory plans carry a high price. Avoiding these situations starts with understanding why synchronizing these two functions is so critical.

Why Production Schedules Need Inventory Planning Alignment

Aligning your production schedule with effective inventory planning isn’t just a “nice to have” – it’s essential for smooth operations. Production scheduling and inventory management are two sides of the same coin in manufacturing. If they’re not working in tandem, the gap between them can quickly lead to chaos on the factory floor.

Here’s why proper alignment is so important:

- Ensure Materials Availability: The most obvious reason – if you plan a production run, you need to have the materials for it when you need them. By syncing inventory planning with the production schedule, you ensure that raw materials, components, and parts are procured or on-hand in time for production. This prevents the classic scenario of a line stopping because a $5 component is missing. Aligned planning means no more waiting on parts that should have been in stock.

- Prevent Costly Stockouts and Overstocks: When production and inventory plans are made in isolation, you often get one of two problems – stockouts (not enough inventory, halting production) or overstocks (too much inventory, tying up capital and storage space). An integrated approach strikes the right balance. You’ll produce in quantities that match actual demand and inventory availability, avoiding excessive stockpiles that gather dust and avoiding shortages that cause downtime. This balance cuts waste and carrying costs while keeping production on track.

- Optimize Production Efficiency: A well-aligned plan helps you run production efficiently with minimal interruptions. If inventory planning knows the production schedule ahead of time, they can arrange deliveries and allocate stock in the optimal sequence. Production can then proceed from one job to the next without pause. Essentially, alignment eliminates the bottlenecks – materials flow into the production line exactly when needed (not too early to clutter the floor, and not too late to cause a stop). This keeps workers and machines productive instead of intermittently pausing to hunt for parts.

- Better Resource Utilization: Think of all resources – not just materials, but labor and machines too. When your schedule and inventory are in sync, you make the best use of these resources. Workers aren’t standing around waiting for parts; they can keep adding value. Machines don’t sit idle or require costly overtime runs later to catch up. You can also avoid overloading storage space with unnecessary inventory, freeing up room and capital. In short, alignment improves overall operational efficiency, translating to higher output with the same resources.

- Improved On-Time Delivery & Customer Satisfaction: When production runs happen as scheduled without last-minute delays, finished goods are ready on time to meet customer orders. Aligning production with inventory planning means you’re far less likely to miss ship dates because “we’re still waiting on part A to arrive.” Customers benefit from more reliable lead times and consistent deliveries. In turn, you build a reputation for dependability. Satisfied customers are more likely to give repeat business and trust you with bigger orders – a direct competitive advantage stemming from internal planning discipline.

- Reduced Emergency Costs and Stress: Firefighting mode is expensive and exhausting. When inventory planning is an afterthought, every production issue becomes a crisis – expedited shipping fees, panic-buying from alternate suppliers at higher prices, paying overtime to make up lost time, etc. Aligning plans acts as a preventative approach. Fewer emergencies mean less money thrown at urgent fixes and far less stress on your management and procurement teams. Your team can focus on productive work rather than constant damage control.

Challenges When Production and Inventory Plans Are Out of Sync

Before diving into solutions, it’s worth recognizing some common challenges that cause production schedules and inventory planning to fall out of sync. If you’ve experienced any of these, you’re not alone – and understanding them will help you address the root causes.

- Siloed Departments and Poor Communication: In many companies, the production planning team and the inventory/procurement team operate in separate silos. They might use different software, report to different managers, or simply have insufficient communication. The result is that crucial information (like a change in the production plan or a delay from a supplier) isn’t shared in time. Without a feedback loop, the production schedule might forge ahead oblivious to inventory shortages, or the purchasing team might not know about a big order that was just booked. Siloes breed misalignment.

- Inaccurate or Out-of-Date Inventory Data: You can’t plan properly if your data is wrong. If your inventory records say there are 100 units of a component in stock but in reality only 20 are there (perhaps due to counting errors, theft, or unlogged usage), your production plan is in trouble. Inaccurate inventory numbers give a false sense of security. Production may schedule runs assuming materials are available, only to find out too late that they aren’t. Lack of real-time inventory visibility or errors in tracking can quickly lead to nasty surprises and halted production.

- Volatile Demand and Forecast Errors: Market demand isn’t perfectly predictable. Sudden spikes in orders or changes in product mix can throw off even a good plan. If your forecasting process is off or if you don’t frequently update plans, you might schedule production based on a forecast that’s no longer valid. Inventory planning might either overshoot (resulting in excess stock) or undershoot (resulting in shortages) because the demand signals were unclear. Demand variability is a constant challenge – without a robust process to handle it, you’ll see either idle inventory or idle production far too often.

- Long Lead Times and Supply Chain Disruptions: In a global supply chain, the time between ordering materials and receiving them can be weeks or months. If your production schedule doesn’t account for these lead times properly, you could schedule a job for which materials haven’t arrived yet. Additionally, disruptions – from supplier delays, shipping issues, to customs hold-ups – can all throw a wrench in inventory availability. When something like that happens but production plans aren’t adjusted, a collision is imminent. Unplanned downtime often ensues while everyone waits for the late delivery to finally show up.

- Lack of Integrated Systems: Many manufacturers still rely on manual processes or spreadsheets to coordinate production and inventory. Spreadsheets might be updated in one department but not seen by another in real time. Or there may be separate software for production scheduling and inventory control that don’t talk to each other. In such cases, it’s tough to keep plans aligned because there isn’t a single source of truth. The disjointed systems mean it requires extra effort (and vigilance) to ensure everyone is referencing the same information, and slip-ups happen easily during busy operations.

- Last-Minute Schedule Changes: Reality often forces changes – a machine goes down, a big rush order comes in, or a quality issue forces rework. Production schedules can change on the fly to adapt. However, if these changes aren’t promptly communicated to inventory planners, you could either cancel a material order that was actually still needed, or fail to order something new that the revised schedule now requires. Agile manufacturing is great, but only if your inventory planning is equally agile and informed. Without a tight linkage, any change in plan can cascade into inventory mismatches.

These challenges underline why simply setting an initial plan isn’t enough – continuous coordination is required. The good news is that each of these issues can be mitigated with the right processes and tools.

How to Align Production Schedules with Inventory Planning (Step-by-Step)

Achieving perfect alignment between your production schedule and inventory planning is a journey, but it’s absolutely attainable with systematic steps. Below is a how-to guide that can help manufacturing teams coordinate these functions and keep everything running smoothly. Think of it as a set of best practices. You can implement these gradually or as part of a continuous improvement initiative in your operations.

1. Start with Unified Demand Forecasting

All alignment begins with a clear picture of demand. Bring together your sales forecasts, customer orders, and market trends into a unified demand plan. This forecast should be the foundation for both your production schedule and your inventory procurement plan. In practice, this often means holding a Sales and Operations Planning (S&OP) meeting regularly (monthly, for example) where stakeholders from sales, production, and inventory/procurement review the upcoming demand.

By agreeing on one forecast, you avoid the scenario where production is planning for one set of numbers while purchasing is planning for another. A unified forecast ensures everyone is working toward the same targets, and it forms the basis for creating a realistic production schedule that the inventory team can support. Make sure to update this forecast frequently – if sales numbers shift or big orders drop in, adjust the plans and communicate those changes across departments. The goal is one source of truth for demand that feeds both production and inventory decisions.

2. Create a Realistic Master Production Schedule (MPS)

With a solid demand plan in hand, you can develop your Master Production Schedule. This is the timetable of what products to produce, in what quantities, and when, over the coming weeks or months. The key here is to make it realistic by considering both capacity and inventory constraints. Don’t schedule more than you can produce (machine/labor capacity), and don’t schedule production for which materials won’t be available in time. It can be helpful to start at a high level – perhaps using aggregate production planning on a monthly basis – and then break it down into a more detailed weekly/daily MPS as the dates draw nearer.

When creating the MPS, collaborate with inventory planners or buyers to sanity-check that supply can meet the plan. If, say, you want to schedule 1000 units in Week 4, but a key component has a 8-week lead time and isn’t due to arrive until Week 6, you’d catch that now and adjust the schedule or expedite the order. A well-crafted MPS is essentially a contract between production and inventory: production agrees to make X items, and inventory/planning agrees to have the necessary materials on hand by then. This ensures from the outset that your production plans are grounded in inventory reality.

3. Implement Material Requirements Planning (MRP)

One of the most powerful tools for aligning production and inventory is MRP (Material Requirements Planning). An MRP system takes your production schedule (what you plan to make) and explodes it through the Bill of Materials (BOM) to calculate exactly what parts and materials are needed, and when. It then compares those requirements against what’s already in stock and what’s on order, and tells you what additional supplies to procure and by what dates.

By using MRP software (often a component of an ERP or a dedicated system), you effectively automate the alignment process. Each time you firm up or change the production schedule, you run MRP and get updated purchase and production orders for components. The MRP will factor in lead times, existing inventory, and even safety stock policies. For example, if your schedule calls for building 500 gadgets in April, and each gadget needs 3 Type-A bolts, MRP will ensure that by April you have 1500 Type-A bolts available (minus any you already have on hand, of course). This prevents the common human error of forgetting a small component until it’s too late. Tip: Integrate your MRP with your inventory management system if possible, so that inventory levels and production plans are sharing data. If you don’t have a full MRP system, you can still practice the principles by manually calculating material needs from your production plan, but as your operation grows this becomes unwieldy – a good software system becomes essential to keep everything aligned and updated in real time.

4. Maintain Real-Time Inventory Visibility

Having the right plan is one side of the coin; the other is knowing the actual status of your inventory at any moment. To keep plans aligned with reality, real-time inventory tracking is crucial. This means implementing an inventory management system or process that updates stock levels immediately as materials are received, moved, or consumed on the shop floor.

Tools like barcode scanners, inventory management software, or even RFID tags can greatly enhance accuracy and speed. Regular cycle counts or stock audits should be performed to catch any discrepancies between the record and the reality before they become big problems. When your inventory data is accurate and up-to-date, production planners can trust that data when scheduling jobs. For example, if the system shows 100 units of Component Y in stock at Warehouse A, it should truly have those 100 units. High visibility also means seeing across all storage locations – knowing not just what’s in the main warehouse, but also what’s at secondary warehouses, on the production floor, in transit, or even on order from suppliers.

By having a clear window into inventory status, you can proactively adjust: if a certain part is running low faster than expected due to higher production use, inventory planners can trigger a reorder or transfer before it hits zero. Essentially, you can’t align what you can’t see – so bolstering inventory visibility is a foundational step to synchronization.

5. Use Just-In-Time (JIT) Wisely with Safety Stocks

Many manufacturers strive for Just-In-Time inventory to reduce carrying costs – meaning you schedule deliveries of materials to arrive right when they are needed for production, rather than holding large stocks. JIT can work brilliantly to reduce inventory holding costs and keep things lean. However, if taken to an extreme or implemented without coordination, JIT can increase the risk of downtime (because there’s little room for error if something goes wrong).

The key is to use JIT wisely, in tandem with sensible safety stock buffers for critical items. Analyze which materials are truly reliable in delivery and have stable usage – those might be good candidates for true JIT (minimal on-hand stock). For other items that are prone to supplier variability, have long lead times, or are absolutely critical to keep production running, maintain a safety stock.

Safety stock is an extra cushion of inventory that accounts for uncertainties in demand or supply. When aligning scheduling with inventory, factor in these buffers: production can continue even if a shipment is late, because the safety stock covers the gap. The trick is to calculate safety stock scientifically (e.g. based on variability and lead time) so it’s not just a guess. In practice, aligned planning means production knows that inventory has a buffer for key parts, and inventory knows production will still run if the next shipment is a day or two late. This approach avoids downtime without forcing you to hold excessive inventory for everything. It’s a balance: run lean, but not so lean that a single hiccup stops the whole line. By aligning JIT principles with realistic buffers, you get both efficiency and reliability.

6. Coordinate Scheduling with Suppliers

Your production schedule might be perfectly tuned with your internal inventory plans – but remember, your suppliers are a part of this equation too. Forge strong communication channels and partnerships with your suppliers so they understand your production schedule and inventory needs in advance.

Share your forecasts and production plans with key suppliers; many larger companies do this through vendor portals or collaboratively in S&OP meetings that involve major suppliers. When suppliers can anticipate your needs, they can adjust their own production and inventory to meet your schedule – preventing delays.

Also, work with suppliers on lead time reduction strategies or flexible delivery schedules. For instance, if you can give a heads-up that you’ll need an extra batch of material next month, a responsive supplier might stock a bit extra on their end or expedite their processes to ensure you get it on time. In aligned planning, it’s not just your internal teams that are in sync – it’s an end-to-end supply chain synchronization.

Additionally, have contingency plans for critical supplies: identify backup suppliers or alternate materials where possible, in case your primary source runs into an issue. By proactively scheduling and planning with supplier input, you greatly reduce the odds of an unpleasant surprise (“We’re out of part Z and our supplier won’t have it for two more weeks!”). Instead, you’ll be aware of potential supply issues early and can adjust the production schedule or inventory strategy accordingly, before it causes downtime.

7. Integrate Your Systems (One Source of Truth)

As noted in the challenges, using disconnected tools can hinder alignment. To truly keep production and inventory plans linked, consider integrating your systems or using a unified platform. For example, if you have an ERP system that includes both production scheduling and inventory modules, ensure that everyone is using it as their primary reference. If not, explore integrations between whatever production scheduling software you use and your inventory management software.

Even a simple integration or data sharing (like ensuring the inventory system updates the production planning team with available-to-promise quantities, or the production system automatically deducts inventory when a job is completed) can eliminate a lot of manual coordination.

Modern Manufacturing Execution Systems (MES) and Advanced Planning & Scheduling (APS) tools often have features to link with inventory data in real time. By leveraging technology, you can have a dashboard that shows, for instance, the production schedule for the week alongside color-coded indicators of inventory status for each scheduled job (green means parts are all available, yellow means some are due in just in time, red means shortage). This kind of integrated visibility allows planners to take action early. The goal is to create a single source of truth where production schedules, inventory levels, purchase orders, and work orders all live and update together. When one thing changes (like a delivery delay or a schedule tweak), the connected system reflects the impact across the board, and relevant people are alerted. In short: use the right tools to tie information together – it greatly reduces the heavy lifting needed to keep plans aligned.

8. Monitor Key Metrics and Continuously Improve

Alignment isn’t a one-and-done project; it’s an ongoing process to maintain and improve. Establish key performance indicators (KPIs) that will alert you to misalignment issues early. Some useful metrics include: Stockout frequency (how often do you run out of something needed for production?), Schedule adherence (how often do you complete production orders on the originally scheduled date – and if not, why?), Inventory turnover (are you turning inventory at a healthy rate or is excess building up?), and Downtime incidents due to material shortages (track every time production lost time waiting on inventory).

By tracking these, you can quantify how well aligned your plans are. For example, if you still see frequent last-minute material expedites, that’s a sign something in the planning process needs adjustment – maybe forecasts need improvement or safety stocks need raising. Hold regular review meetings (perhaps monthly or quarterly) to go over these metrics with both production and inventory teams present. This encourages a blame-free, collaborative approach to tweak the system. Perhaps you discover that a particular part has caused downtime three times in the last quarter due to late supplier deliveries – that’s a clear candidate for either finding a more reliable supplier or increasing its safety stock.

Continuous improvement in alignment might also involve investing in better tools, providing additional staff training, or updating procedures as your business grows or changes. Over time, these small adjustments add up. You’ll find that you can gradually raise the bar – aiming for zero production stoppages from inventory issues, ever. Some companies even achieve a “lights-out” synchronized system where production and inventory move in lockstep with minimal manual intervention, thanks to automation and disciplined processes. That’s the ideal state to strive for, and monitoring your performance along the way will guide you there.

By following these steps and best practices, you create a robust process where production scheduling and inventory planning work hand-in-hand.

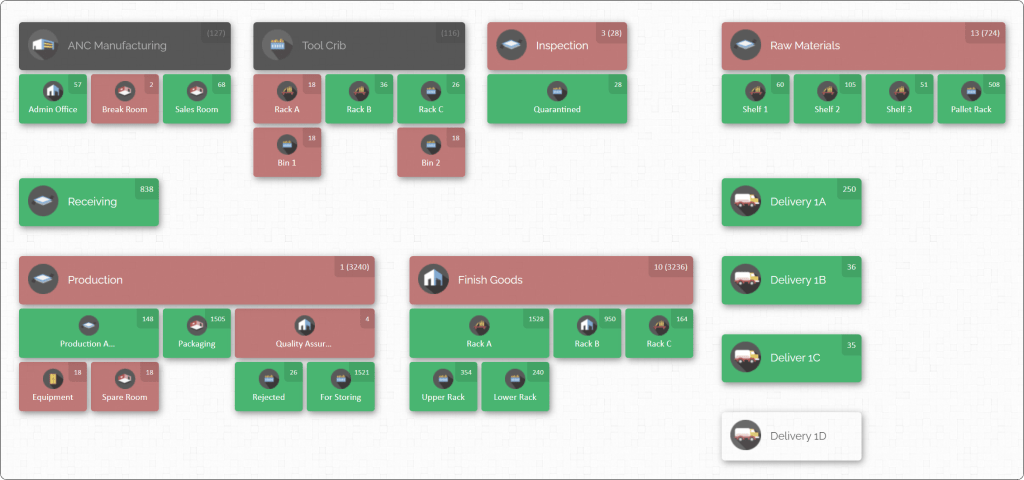

How CyberStockroom Supports Production & Inventory Alignment

In the journey to synchronize your production schedule with inventory planning, modern tools can make a world of difference. One such tool is CyberStockroom, an inventory management platform that takes a unique map-based approach to tracking stock. While many concepts we’ve discussed are process-oriented, CyberStockroom provides features that directly tackle some of the biggest pain points in aligning inventory with production. Here’s how it can help:

- Real-Time Inventory Visibility Across Locations: CyberStockroom gives you a real-time visual dashboard of all your inventory, across all your locations. Think back to the inventory map we mentioned at the start – that’s the core of CyberStockroom. You can zoom into any facility, stockroom, or even specific shelving areas on the map and instantly see what’s stored there and in what quantity. For a production manager, this is incredibly useful. Say you’re scheduling a production run and notice the main warehouse is a bit short on a required material – a quick glance at CyberStockroom’s map might show that a secondary warehouse or another plant has plenty of that item. With that knowledge, you can arrange an immediate transfer (using the tool’s drag-and-drop transfer feature) to get the material where it’s needed, avoiding a potential delay. Everyone from inventory planners to shop floor supervisors can rely on the map as the single source of truth for stock levels, ensuring decisions are based on the latest information.

- Easy Stock Transfers and Allocation: Aligning inventory with production often means moving inventory to the right place at the right time. CyberStockroom simplifies this with an intuitive drag-and-drop interface. Need to allocate 50 units of a component from Warehouse A to Factory B’s storage? Just drag it on the map from A to B – the system will adjust the inventory counts in both locations and log the transfer. This ease of reallocation means you can respond to production needs on the fly without paperwork headaches. By making inventory transfers simple, the tool encourages proactive balancing of stock. Production schedulers can work hand-in-hand with inventory managers to redistribute materials ahead of time for scheduled jobs. For example, if next week’s schedule has a big job at Plant 2, you can ensure Plant 2’s inventory location on the map is stocked up in advance by transferring items from other sites via CyberStockroom. This level of agility helps keep production running without last-minute scrambles.

- Accurate Tracking with Barcoding: CyberStockroom supports barcoding and scanning, which is a boon for accuracy. Users can check items in and out or move them just by scanning barcodes with a scanner or mobile device. Every movement or usage is recorded in the system immediately. The advantage here is that your inventory data stays highly accurate – far fewer manual entry errors or forgotten updates. For production alignment, this means if a production line consumes 100 units of a part, and they scan those out, the inventory count reflects it right away. Planners won’t be misled by an inflated number in the system. And when the next production job is being scheduled, the system’s data is trustworthy. Essentially, CyberStockroom’s barcoding feature helps maintain the integrity of the “real-time inventory visibility” we talked about earlier. Inventory planning can only align with production if it knows what’s truly available; barcoding makes sure that knowledge is correct and up-to-date.

- Cloud-Based Access and Team Collaboration: CyberStockroom is cloud-based, which means your team can access it from any device with an internet connection – whether that’s a desktop on the plant floor, a laptop in the office, or a tablet on the go. Users can simply log in through a web browser from a smartphone if needed. This flexibility ensures that production supervisors, inventory managers, and even procurement folks can all view and update inventory information in real time, no matter where they are. It promotes collaboration: multiple users can be on the system simultaneously, seeing updates live. For example, if the purchasing department receives a shipment of new stock and logs it into CyberStockroom, the production planner across the building will see those quantities update on the map instantly. This immediacy keeps everyone on the same page. Additionally, you can set user permissions so that different team members can access the parts of the inventory map relevant to them or even update the map as they use materials. The outcome is a more connected team – production and inventory personnel essentially share a common workspace (the inventory map), fostering better communication and fewer missteps.

- Historical Data and Reporting: Another useful aspect of CyberStockroom is that it keeps a complete activity history of your inventory movements and usage. Every transfer, check-in, check-out, and adjustment is logged. Over time, this becomes a rich dataset that you can analyze. The system allows generating reports on inventory levels, turnover rates, stockouts, and more. How does this help align with production? By studying the history, you might identify patterns – for instance, every time you schedule Product Z, you seem to run low on Component Q. With that insight, you can adjust your planning (maybe increase safety stock for Q when a Product Z run is coming up, or order extra ahead of time). Essentially, CyberStockroom can function as a feedback mechanism: it provides the data to conduct post-mortems on any production/inventory issues and continuously refine your alignment. Additionally, having solid inventory records helps in S&OP meetings or discussions about capacity: you can bring up actual numbers of how inventory was consumed versus planned, to improve future scheduling accuracy.

In summary, CyberStockroom acts as a bridge between production and inventory teams. By providing real-time, easy-to-understand inventory information (through that visual map and user-friendly tools), it ensures that production scheduling decisions are always made with full awareness of inventory status.

For manufacturers striving to avoid downtime, implementing such technology can be a smart investment. It tackles several of the alignment challenges (data accuracy, visibility, communication) head-on. Of course, tools are most effective when paired with good processes, but having a platform like CyberStockroom in your arsenal makes it much easier to execute the best practices we discussed earlier.

The Payoff: Benefits of Perfectly Aligned Production and Inventory Plans

Putting in the effort to align production schedules with inventory planning yields significant rewards. Manufacturers who achieve a high level of synchronization between these functions often see noticeable improvements in their operations. Let’s paint a picture of what success looks like – the concrete benefits you can expect when production and inventory march in lockstep:

- Near-Zero Material-Related Downtime: First and foremost, the nightmare scenario of a line down due to missing parts becomes extremely rare. With alignment, you catch potential shortages well in advance. Materials are where they need to be, when they need to be there. Any minor hiccups are resolved before they impact production. Over time, you might find that weeks and months go by without a single production stoppage for inventory reasons. That reliability translates directly into more units produced and more orders fulfilled on time.

- Higher Productivity and Throughput: When downtime is minimized, the factory can achieve its full potential. Machines and workers stay busy making product, rather than waiting or reworking schedules. You can hit higher production throughput targets because everything flows smoothly. This might mean meeting growing customer demand without needing to add extra shifts or equipment – you’re simply utilizing what you have more effectively. The overall operational efficiency climbs, which is often reflected in KPIs like OEE (Overall Equipment Effectiveness) and labor productivity metrics.

- Lower Inventory Costs and Waste: Alignment doesn’t just avoid shortages; it also curbs excess. By planning inventory tightly around the production plan, you prevent over-ordering and overstocking. Your inventory levels become leaner and more optimized for the actual production needs. This leads to lower carrying costs (less money tied up in stock, less warehouse space occupied) and reduces waste from obsolescence or spoilage (especially if you deal with perishable or high-tech components that can become outdated). Essentially, you free up working capital because you’re not purchasing materials too far ahead of demand. One side benefit: if finance or upper management ever questions inventory levels, you can demonstrate that inventory is at the “right” level to support the production plan – no more, no less – which is a hallmark of good operations management.

- Improved Flexibility and Responsiveness: When production and inventory are in sync, your operation becomes more agile. Need to ramp up production because a big rush order came in? You can do it confidently because your inventory planning process is alert and can secure the needed materials quickly (or you might already have some buffer stock in place from your safety stock strategy). Conversely, if demand softens and production schedules need to dial back, you won’t be caught with a massive surplus of raw materials that were ordered blindly. In an aligned system, changes in demand can be absorbed more gracefully – production adjusts and inventory plans adjust in tandem. This kind of responsiveness is crucial in today’s market where demand can be unpredictable. It prevents situations like being stuck with excess inventory for a product you’re no longer making, or not being able to capitalize on a surge in demand due to slow supply reaction. Strategic alignment essentially builds resilience – your operation can flex and bend without breaking when faced with change.

- Better Cross-Department Collaboration: An often overlooked but very real benefit is the positive effect on team collaboration and morale. When production schedulers, inventory planners, buyers, and suppliers are all working from the same playbook, there’s less finger-pointing and stress when issues arise. Instead of reactive blame games (“Production always schedules unrealistic targets!” vs. “Purchasing always runs us out of parts!”), the culture shifts to proactive problem-solving. Regular communication and aligned goals mean the teams function more like a single unit. This improved working relationship can, in turn, lead to new ideas and innovations on how to further improve operations. Employees appreciate not being in constant crisis mode, which can reduce burnout and improve retention. There’s a real pride that comes from consistently meeting production goals without drama – it’s a team win that everyone contributed to.

- Higher Customer Satisfaction and Trust: Ultimately, the benefits of alignment ripple outward to your customers. You deliver on time more consistently, which keeps customers happy. Perhaps you even shorten lead times because your efficient planning lets you produce faster or hold lower finished goods stock yet still meet demand quickly. Happy customers lead to repeat business and positive word-of-mouth. In many industries, reliability is a key differentiator – if clients know that your company can be counted on to deliver as promised, that’s a competitive edge. Aligning production and inventory planning underpins this reliability. It’s no exaggeration to say that mastering this internal coordination can become a selling point. You might find customers giving you more orders because you’ve proven you can handle them without delays or excuses. Trust is built over time, and every successfully met schedule strengthens your customer relationships.

All these benefits underscore why aligning production schedules with inventory planning is worth the effort. It’s about creating a harmonious operation where everything is in the right place at the right time, all the time. Companies that achieve this level of coordination often also find that it supports other initiatives like lean manufacturing or continuous improvement, because you’ve eliminated a major source of waste (waiting and overproduction due to misplanning).

Conclusion

Downtime is the silent killer of manufacturing productivity, but it doesn’t have to be inevitable. By diligently aligning your production schedules with smart inventory planning, you can turn potential downtime into uptime and keep your operations running like a well-oiled machine. We’ve explored how integrating forecasting, using tools like MRP, maintaining inventory visibility, and leveraging technology such as CyberStockroom’s visual inventory platform can all come together to create a robust, synchronized system.

It’s clear that when production and inventory plans work in unison, the results speak for themselves – higher efficiency, lower costs, and happier customers. Yes, it requires effort: breaking down departmental silos, investing in the right systems, and continuously fine-tuning your processes. But the payoff, in terms of avoided crises and improved performance, is enormous.

For production managers and inventory planners, there’s nothing more satisfying than seeing a plan executed without a hitch – materials arriving just in time, products rolling off the line on schedule, and trucks heading out the door to customers as promised. That level of execution excellence is within reach when you prioritize alignment. Use the steps and strategies discussed in this guide as a roadmap. Start with small improvements, communicate relentlessly, and consider modern inventory tools to boost your capabilities. Over time, you’ll build a resilient operation where downtime due to planning issues is virtually eliminated.

In the fast-paced world of manufacturing operations, alignment is your ally. By ensuring that your production schedule and inventory planning are always on the same page, you create a powerful engine for growth – one that can respond to demand, avoid costly interruptions, and drive your business forward. Here’s to a future of seamless production runs, optimal inventory levels, and a thriving, downtime-free manufacturing floor!

Leave a comment