Keeping a construction fleet up and running is no small feat. Between heavy excavators, loaders, trucks, and all the tools on site, there are countless parts that keep the operation moving. Equipment downtime can cost your project thousands of dollars in delays and idle labor – often over something as simple as a missing part or fluid. That’s why having a well-planned construction equipment maintenance inventory on hand is critical. In this guide (with a handy checklist), we’ll cover exactly what spare parts and supplies you should stock for your construction fleet, and how to manage them so you’re never caught off-guard by an unexpected breakdown or maintenance need.

Imagine this: one of your bulldozers blows a hydraulic hose on a remote job site. If you’ve prepared an adequate maintenance inventory, you can grab a spare hose from your on-site stock and fix the machine within hours. If not, you’re scrambling – calling suppliers, paying for expedited shipping, or towing the dozer out for repairs – while work grinds to a halt. A little foresight in inventory management can save you from scenarios like this.

Why a Maintenance Inventory is Critical for Construction Fleets

- Minimize Downtime: Every minute a piece of equipment is down, your project suffers. Unplanned downtime in construction is often 20–30% of total equipment availability, and a leading cause is failure to perform maintenance or get repairs done on time. Having the right parts on hand means you can fix issues immediately instead of waiting days or weeks for a replacement. For example, if a key hydraulic fitting fails, having a spare in your inventory could turn a potential 3-day outage into a 30-minute repair. The result? Jobs stay on schedule and you avoid paying crews to stand around.

- Stay on Top of Preventive Maintenance: Preventive maintenance schedules (like 500-hour services or annual overhauls) are only effective if you actually perform them on time. That means having all required filters, fluids, and components ready when maintenance is due. If you’re missing a $10 oil filter when service comes up, you might be tempted to postpone the oil change – and that’s when wear and tear accelerates or small issues turn into big problems. A well-stocked maintenance inventory ensures you can stick to your maintenance checklist without delay, extending the life of your machines.

- Reduce Costs and Surprises: Overnight shipping a part or paying a premium to get something at the last minute can blow up your budget. Even worse, a machine sitting idle could cost hundreds or thousands in lost productivity. By keeping commonly used parts in stock, you cut down on rush orders and emergency rental costs. Additionally, buying certain parts in bulk or during off-season can be cheaper – for instance, stocking up on filters or hoses before the busy summer season might save money and headaches later.

- Safety and Compliance: Worn-out or failing components aren’t just a risk to the machine – they’re a risk to your crew. Imagine operating an excavator with a frayed drive belt or clogged air filter; it can lead to poor performance or even accidents if the machine fails at a critical moment. Replacing worn parts on schedule keeps equipment safe to operate. Also, if you have safety equipment (like backup alarms, fire extinguishers, or seat belts) as part of your fleet inventory, keeping spares ensures you’re never running a machine without required safety gear due to a broken part.

- Project Efficiency: In construction, timing is everything. Crews coordinate their tasks around equipment availability. If a machine goes down because you lack a simple part, other work can bottleneck. For example, if your only skid steer on site has a flat tire and you don’t have a spare or the means to fix it, tasks that depend on it (hauling materials, grading, etc.) are stalled. A small inventory of repair parts and basic supplies on site means many issues can be fixed the same day, keeping the project workflow on track. Moreover, when everyone knows that “we’ve got it covered” for common repairs, it boosts confidence and morale on the team.

A maintenance inventory is like an insurance policy against downtime and delay. It’s a necessary part of construction inventory management. Next, let’s discuss how to plan your inventory smartly, so you stock what you need (but not a warehouse full of stuff gathering dust).

Planning Your Maintenance Inventory Strategy

Building an effective maintenance inventory for your construction fleet starts with planning. It’s not just about buying a bunch of parts “just in case” – it’s about stocking the right items in the right quantities.

Here’s how to plan your strategy:

1. Assess Your Fleet and Maintenance Needs: Begin with a list of all equipment in your fleet – from heavy machines like excavators, bulldozers, and cranes to support equipment like generators and trucks. For each, review the maintenance manual or your maintenance logs. What parts are needed for routine servicing? (e.g., oil filters, fuel filters, hydraulic filters, spark plugs, etc.) What parts tend to wear out or fail more frequently based on your experience? (e.g., hoses, belts, brake pads, bucket teeth.) Create a matrix of equipment vs. the parts they require for maintenance and common repairs.

2. Identify Critical Parts (Critical Spares): Among all those parts, identify which ones are critical to operations. A part is critical if its failure would disable the equipment and halt work, and if it’s not quickly or easily obtainable. For example, a unique hydraulic pump that takes two weeks to order is a critical spare – you’d want at least one in stock. On the other hand, a standard bolt or a common tire size might be easier to source same-day locally, so you might keep fewer of those. Ask questions like: “If this component fails, can we work around it or does the machine go down entirely?” and “How long would it take to get one if we don’t have it?” High criticality + long lead time = keep it on hand.

3. Consider Lead Times and Supplier Availability: Reach out to your part suppliers or dealers to understand how quickly you can get various components. For parts with long lead times (maybe an OEM part that must be shipped from overseas or a specialty item), it’s wise to stock at least one. If you have reliable local suppliers for certain items (say, a nearby shop carries all the common hydraulic fittings you use), you might lean on them for just-in-time supply – but be cautious, as even local stock can run out in a pinch. It’s often safer to keep a minimum quantity in your own inventory for anything that could leave a machine inoperable.

4. Use Maintenance Data and Experience: Data is your friend. Look at your maintenance records from the past year or two. Which parts were replaced most often? How frequently did certain issues occur? Maybe you notice you went through 20 hydraulic hoses and 8 fuel filters last year across the fleet – that’s a clue to keep those well-stocked. Also, involve your mechanics and equipment operators in this conversation. They often know which parts are “consumables” or which failures they’ve seen repeatedly. This helps you forecast what you’ll likely need in the near future. Tip: If you’re just starting out without much data, manufacturer recommendations for service intervals are a good baseline – many equipment makers even provide lists of recommended spare parts to keep on hand for new equipment.

5. Budget and Storage Constraints: Let’s face it, we’d all love to have one of everything on the shelf, but budgets and space are limited. Prioritize the inventory spend on high-impact items. It might not make sense to buy a $5,000 engine control unit to sit on a shelf “just in case” for years (especially if the chance of failure is very low). But spending a few hundred dollars to stock plenty of filters, belts, and fluids that you’ll definitely use is a no-brainer. Plan your inventory like an investment: what will save (or even make) you money in the long run? Also consider storage – large items like tires or bulky engine parts take space. Ensure you have a clean, organized area to store your inventory safely (more on organization later).

6. Standardize Across Equipment (When Possible): If your construction fleet has multiple machines of the same model or manufacturer, good news – you can reduce inventory by stocking parts that fit all of them. For example, if you have five Caterpillar D6 dozers of similar series, they might share many common filters and wear parts. You don’t need separate spares for each machine; you can stock a collective quantity that covers all. Likewise, even across different equipment, there may be overlap: perhaps your excavators and wheel loaders happen to use the same type of battery or light bulbs. Find those common denominators to streamline your inventory list.

7. Plan for Remote Projects: If your company takes on projects in remote areas or spreads out across multiple sites, plan how you’ll distribute your maintenance inventory. You might keep a central warehouse at HQ, but it could be wise to create a job site inventory kit for each site – a container or storage box stocked with essentials so that crews don’t always have to send someone back to HQ for a part. For extremely remote sites, you’ll want to double-down on critical spares on location, since getting parts delivered quickly might be impractical. Also, equip your field service trucks with a basic inventory of the most common breakdown items (these trucks effectively become mobile warehouses – we’ll talk about managing “trunk stock” later).

With a solid plan in place, you’re ready to stock up. But what exactly should you include in your construction equipment maintenance inventory? Let’s go through the must-haves.

Essential Spare Parts and Supplies to Have On Hand

Every construction operation is unique, but there are certain spare parts and consumables that almost every fleet should have readily available. Think of these as the “greatest hits” of maintenance inventory – items that get used up, wear out, or break most often during the course of keeping heavy equipment running. Here’s a breakdown of essentials you’ll want to consider stocking:

1. Filters (Oil, Air, Fuel, Hydraulic)

Filters are the first line of defense for your equipment’s vital systems, and they need regular replacement. Keep a healthy stock of all the various filters your machines use, including:

- Engine oil filters: Critical for protecting your engine by removing contaminants from oil. Most engines need oil and filter changes at set hour intervals (e.g., every 250 or 500 hours). If you have 10 machines and each needs an oil filter every 500 hours, do the math on how many you’ll go through in a year and stock accordingly.

- Engine air filters: Dusty construction environments mean air filters clog up quickly. A clogged air filter can choke an engine and even cause damage over time. Keep spares so operators can swap out dirty filters on site as needed.

- Fuel filters: Bad or dirty fuel can ruin injectors and stall engines. Modern diesel engines often have multiple fuel filters (primary and secondary). Always have extras around – replacing a gummed-up fuel filter is a quick fix to restore power if an engine starts sputtering.

- Hydraulic filters: Your hydraulic systems (excavators, loaders, etc.) usually have filters to keep the hydraulic fluid clean. These might be changed every certain number of operating hours or if the hydraulic oil gets contaminated. Don’t ignore them; a clogged hydraulic filter can starve the pumps of fluid and cause major issues.

- Cabin air filters: For equipment with enclosed cabs (and A/C), cabin filters keep the operator’s air clean and the HVAC system running well. They’re also usually cheap – so it’s worth having some, especially if your crew works in dusty conditions.

Pro tip: Organize your filters by machine or type in your storeroom (and in your inventory system). Label shelves or bins for “Excavator X – hydraulic filter,” “Dozer Y – air filter,” etc., so it’s easy to grab the right one. Filters often have part numbers that are easy to mix up, so a clear system prevents mistakes.

2. Fluids and Lubricants

You can’t perform equipment maintenance without the necessary fluids. Oil, coolant, and other liquids are like the lifeblood of your machines. Always have an adequate supply of:

- Engine oil: For top-offs and oil changes. Use the grade recommended by the manufacturer (which might differ summer vs winter). Running out of engine oil when you’re due for a change is not an option – you don’t want to be that person debating if you can stretch another 50 hours on old oil. Keep enough on hand for at least one full oil change per major piece of equipment (and remember, big engines can hold dozens of quarts).

- Hydraulic oil: Many machines share the same hydraulic fluid type. Leaks happen, hoses burst – you’ll need fluid to refill the system after repairs, plus routine replacements at service intervals. Stock plenty, because when you need it, you might need a lot (filling a completely drained excavator hydraulic tank can consume many gallons).

- Coolant/Antifreeze: Engines and power systems need coolant, and it should be flushed/replaced on schedule. Also, if you have to repair a radiator or hose, you’ll lose coolant and need to refill. Store concentrate or pre-mixed coolant that meets your equipment specs (diesel engines often require specific coolant types/ratios).

- Transmission fluid & gear oils: For equipment with powershift transmissions or final drives that require special oils (e.g., graders, loaders, trucks), keep some in inventory. While these fluids aren’t changed as frequently as engine oil, if there’s a leak or overheating issue, you might need to top off or replace fluid.

- Grease: Grease is cheap and absolutely essential. Your excavator pins, loader arms, backhoe joints – all need regular greasing. Running out of grease cartridges for your grease gun means pivot points can run dry and start grinding themselves down. Keep a case or two of the proper heavy-duty grease used by your grease guns. (And encourage your operators to actually use them daily!)

- Diesel Exhaust Fluid (DEF): Many modern diesel machines use DEF for emissions control. If your fleet has Tier 4 final engines, you likely have to keep DEF on hand. It’s something you never want to run out of, because if a machine’s DEF tank goes empty, the engine may derate or stop running to meet emissions rules. Store extra jugs or a full DEF tote if you consume a lot, especially in high-use seasons.

- Brake fluid, Power steering fluid: For trucks or equipment that use these, have a few bottles around. These aren’t used in large volume, but a leak in a brake line or steering system can be addressed much faster if you have fluid to refill after the fix.

Make sure all these fluids are stored properly – sealed containers, labeled clearly, and ideally in a temperature-controlled environment (or at least protected from rain/dirt). Also, mind the shelf life: things like DEF can degrade over time (especially in heat), and certain oils might have expiration dates. Use older stock first (first-in, first-out rotation).

3. Belts

Belts transfer power to vital components (like alternators, cooling fans, water pumps, AC compressors). A broken belt can mean instant downtime. Most heavy equipment uses heavy-duty serpentine belts or V-belts. Key points:

- If a belt snaps, your engine could overheat (cooling fan stops), battery stops charging (alternator down), or hydraulics might cease (if pumps are belt-driven). So a simple belt can disable a $300,000 machine.

- Belts are typically replaced as part of preventive maintenance at certain intervals or when wear is noticed (cracks, fraying). But they can also fail unexpectedly.

- Keep spare belts for each major machine. Often one belt can fit multiple models (check part numbers). If you have several similar machines, maybe a handful of common belt sizes will cover all.

- Store belts in a cool, dry place out of direct sunlight – rubber degrades with heat and UV. An inventory cabinet or hanging rack for belts works well.

An operator or mechanic can swap a belt relatively quickly on site if they have a replacement. It’s the kind of part that you might not need often, but when you do, nothing else will do. Don’t wait for a belt to break before you think about getting a new one.

4. Hoses, Fittings, and Seals

Construction equipment is full of hoses – hydraulic hoses, fuel lines, coolant hoses, and more – plus numerous seals and O-rings at joints and connections. These items are notorious for causing downtime because they can spring leaks or break under pressure:

- Hydraulic Hoses: These carry high-pressure fluid and are prone to wear, especially at the fittings or where they flex. Rather than stocking every single hose (there could be dozens per machine), a good strategy is to have a selection of common hose sizes and the associated fittings. If you have the capability, you can also keep a small portable hose repair kit: some shops carry reels of hose and separate fittings so you can fabricate a new hose on the spot to the length you need. If that’s too advanced, at least keep a few pre-made hoses that fit the most critical circuits on your primary machines (like the main boom cylinder hoses on an excavator, which often see abuse).

- Rubber Coolant and Fuel Hoses: These are usually smaller diameter hoses. They can dry out, crack, or get damaged by vibration. Keep some spare radiator hoses (upper and lower) for your bigger engines, if feasible, plus any special fuel lines (though often fuel lines can be improvised with generic fuel hose in a pinch – having a length of generic fuel hose and clamps isn’t a bad idea).

- Seal Kits and O-rings: Hydraulics and engines use a lot of seals. For major components like hydraulic cylinders, valves, or pumps, you can get “seal kit” packages that include all the O-rings and seals needed for an overhaul. It’s wise to have at least one seal kit for any hydraulic cylinder that’s known to need periodic resealing (like maybe the bucket curl cylinders which often take a beating). Also keep assorted common O-ring sizes on hand; a tiny 50-cent O-ring can be the difference between a leak and a functioning machine. There are inexpensive O-ring assortment kits you can buy – throw one in your toolbox.

- Gaskets: Similar to seals, if you’re doing maintenance like replacing a water pump or thermostat, you’ll need gaskets. You might not stock every random gasket, but consider having a sheet of gasket paper to make one in a pinch, or keep critical ones like an oil pan gasket or valve cover gasket if those are known to leak on your gear.

- Fittings and Couplers: Things like hydraulic quick-couplers (for attachments) or grease fittings sometimes break. Also hose clamps for coolant lines or fuel lines can rust out or snap. Maintain a little assortment of extra hose clamps, grease zerks, and common hydraulic fitting caps/plugs. These small bits are life-savers when one goes missing.

By having a variety of hoses, seals, and fittings available, you empower your maintenance team to fix leaks immediately rather than jury-rigging a patch or idling a machine waiting for a minor part.

5. Electrical Components (Batteries, Fuses, Lights)

Your equipment’s electrical system needs some love in the spare parts department too. Key electrical-related spares include:

- Batteries: Many heavy machines have multiple large batteries (often 24V systems with two 12V batteries in series). Batteries generally last a few years, but they can die unexpectedly – especially in extreme weather or if the machine has been sitting. Keeping at least one spare heavy-duty battery on hand (or whatever is used across your fleet) is wise. Alternatively, if your fleet mostly uses the same battery model, have a rotation plan where you replace batteries proactively and keep the older-but-still-good ones as backups. Nothing is worse than trying to start a loader on a freezing morning and finding the battery has given up.

- Fuses and Relays: Modern equipment has extensive electrical circuits protected by fuses and relays. A tiny blown fuse can disable, say, your fuel pump or ECU and the machine won’t start. Luckily, fuses are dirt cheap. Stock an assortment of the relevant blade fuses or fuse links your machines use. Same for relays – a bad relay can cause intermittent faults; having spares to swap in for troubleshooting can be a project-saver.

- Light Bulbs: Not mission-critical to operation, but for safety you should replace broken lights promptly. Keep spare bulbs for headlights, tail lights, indicator lights, and warning beacons that your machines use. Many construction crews work early mornings or nights, and functioning lights are legally and practically important.

- Starter Motors and Alternators (Maybe): These are larger components and not cheap, so whether to stock them depends on your situation. If you have multiple older machines that frequently have starter or alternator issues, having a spare might be justified. Otherwise, you might keep a good relationship with a local rebuild shop for quick turnarounds. However, at least know the model/part numbers so you can source them quickly if needed.

- Sensors and Electronics: Today’s equipment has various sensors (engine temp, pressure, etc.). Most of these won’t be user-replaceable without diagnostics, but a couple of common failure ones (like a DEF sensor or an oxygen sensor if you have them) could be worth having if they’ve caused you trouble before.

- Wiring and Connectors: Not exactly a “part” you buy pre-made, but carrying some rolls of electrical wire, crimp connectors, and a spare battery terminal or two can help fix minor electrical issues on the fly (like a corroded wire that needs replacing).

Ensure your mechanics or electricians have the right tools to replace these parts – for instance, the proper wrenches for battery terminals, fuse pullers, etc., so they can quickly swap them out. Often electrical fixes are quick and can return a machine to service immediately.

6. Undercarriage and Tires

For heavy equipment, the undercarriage (the tracks and associated parts) on track loaders, dozers, and excavators, and tires on wheeled equipment, deserve special mention. They literally carry the load and take a beating:

- Track Parts: If you run tracked machines, consider stocking common wear parts like track links, track pads, and possibly extra track bolts (which can shear off). Sprockets, idlers, and rollers are wear items too, but those typically wear over many hundreds of hours – you might plan those replacements and have parts ready a bit ahead of time rather than stocking them far in advance. However, if a particular part is known to fail (maybe a certain roller that often leaks out its oil), keep a spare. Track tensioners (recoil springs) are rare to replace but if one breaks, your machine is down; think about your risk tolerance on those.

- Tires: For wheeled loaders, dump trucks, mixers, etc., a flat or damaged tire will sideline the machine. While you probably won’t keep a full inventory of expensive tires (they are bulky and costly), having at least one spare tire for critical vehicles is a good idea, especially if those tires are an uncommon size. At minimum, have materials for quick tire fixes: tire plug kits for small punctures, a spare inner tube if your equipment uses them, and the ability to re-inflate large tires (an air compressor on site). You might also keep a spare wheel/rim assembly if your operations are far from tire shops – it’s much faster to swap the whole wheel than to dismount and patch a tire in the field.

- Ground Engaging Tools (GET): This includes things like bucket teeth, cutting edges on dozer blades or grader blades, and scraper edges. These parts wear out as part of their job. It’s smart to have replacements ready because dull or broken GET components drastically reduce efficiency (imagine trying to dig with half the teeth missing – it’ll slow you down and stress the machine). Stock extra bucket teeth and pins/clips for all buckets, extra cutting edges for blades, and so on. They’re usually easy to swap, and doing so at the right time improves productivity and prevents bigger problems (e.g., running a dozer blade with a worn-through cutting edge can start wearing into the blade moldboard – an expensive fix).

- Brake Pads/Shoes: For equipment that has service brakes (like trucks or wheel loaders), consider keeping a set of brake pads on hand. While brake wear is gradual, if you have a machine out in the field that suddenly needs brakes, having a set ready means you can fix it overnight and not wait days.

7. Engine and Drivetrain Parts

Major engine and drivetrain failures are less common, but when they happen, they cause big downtime. You likely won’t stock an entire engine (though some large companies do keep a spare engine or transmission for very high-value equipment). However, a few engine-related parts to consider for inventory:

- Belt Tensioners and Pulley: If you’re stocking belts, remember that the tensioner pulley or idler pulleys can also fail (bad bearings). These are smaller parts you can obtain and store relatively cheaply.

- Starter and Alternator (mentioned earlier in Electrical) – these literally bolt to the engine. If one machine’s starter dies and you have no spare, can you rob one from another machine temporarily? Possibly – some brands use common starters across models. If not, a spare might save you.

- Injectors and Fuel System Parts: Clogged or failing fuel injectors can sideline an engine or make it run poorly. Depending on your mechanical ability, you might not swap injectors on a job site, but having a few extra (or at least the rebuild kits for them) could be useful if fuel quality is a problem in your area. Same goes for fuel lift pumps or filters housing if those have issues.

- Sensors/ECU parts: As mentioned, probably not stocking, but know how to get them fast.

- Common Hardware: Sometimes a critical bolt or nut might strip or go missing during a repair. Keep an assortment of high-strength bolts and nuts in the sizes commonly found on your equipment (metric and SAE as appropriate). A $1 bolt could hold you up if it’s a size you don’t have readily – include these in your inventory kit. Likewise, cotter pins, snap rings, and other little hardware that you remove during service – have spares because they can get damaged.

8. Miscellaneous Supplies and Tools

Rounding out your maintenance inventory, don’t forget general consumable supplies and tools that are used up during maintenance tasks. These might not be specific to one machine but are vital for everyday operations:

- Shop Supplies: This includes things like engine oil filters and fuel filter wrenches, funnels, clean rags or shop towels, brake cleaner or degreaser spray, threadlocker fluid, anti-seize compound, electrical tape, zip ties – all the small support items that help you actually do the maintenance. While not “inventory” in the parts sense, you should keep these stocked so your mechanics aren’t improvising (or worse, skipping steps like cleaning parts or securing fasteners properly).

- Fasteners: We touched on bolts and nuts; also consider a box of self-tapping screws (for securing loose panels), wood screws or nails if you need to temporarily board something up, etc., depending on what random fixes come up on site.

- Personal Protective Equipment (PPE): If a critical piece of PPE breaks (say a face shield or a harness if you’re doing something at height), you should have backups so work isn’t halted for lack of safety gear.

- Portable Equipment: Think portable lights, extension cords, even a spare small generator if your site needs power for tools – while these aren’t maintenance “parts,” not having them can impede maintenance work (imagine trying to do a night repair with no working lights or your welder generator is down and you have no backup).

- First Aid and Spill Kits: Again, not a part of a machine, but a part of running a job. Oil spill cleanup materials, rags, drip pans, etc., should be around so that maintenance activities don’t create hazards or environmental issues.

This might seem like a daunting list – and indeed, building a maintenance inventory from scratch can be a significant task. But once you have these items in place, you’ll find that your ability to respond to maintenance needs and unexpected breakdowns improves drastically. It’s far better to have a part and not need it immediately, than to need it and not have it.

However, having the inventory is only half the battle. Managing it properly is the other half. Let’s explore some best practices for organizing and tracking your maintenance inventory so it remains effective and cost-efficient.

Best Practices for Organizing and Managing Your Inventory

So you’ve stocked up on essential spare parts and supplies – now how do you keep this inventory under control? Mismanaging your inventory can lead to parts going missing, not knowing what you actually have, or discovering too late that the “spare” you counted on is gone. Avoid those pitfalls with these best practices:

Centralize and Catalog Your Inventory

Create a master inventory list of all parts and supplies you have on hand. At minimum, note the part name/description, part number (if applicable), which machines it fits, the quantity you have, and where it’s stored. This could be in a spreadsheet, an inventory management software, or even a well-organized logbook – whatever you’re comfortable with – but it should be kept up to date. Consider also tagging items with labels or barcodes that correspond to entries in your system for easy identification.

Organize by Category or Equipment

In your storage area, group similar items together in a logical way. There are a few approaches:

- By equipment: Have sections or bins for each major piece of equipment’s spares. For example, all of Excavator #3’s specific spare parts go in one labeled bin. This can be helpful if different machines use very different parts with little overlap.

- By type/category: Alternatively, group by type of part: a shelf for all filters (subdivided by filter type or machine), a cabinet for electrical parts, a section for hoses and fittings, etc. This way, when someone needs a certain filter, they know exactly which shelf to check.

- Hybrid: Often a combination works best – general consumables grouped together (all oils in one area, all hardware in one drawer, etc.), and unique high-value parts labeled by equipment.

The key is to label everything clearly. Use sturdy labels or tags for shelves and bins. And make sure when someone takes a part, they don’t just leave an empty unmarked spot – they should update the record (and ideally put a placeholder or tag indicating that stock is low or out)

Implement a Checkout System

This is crucial for accountability. If any team member (mechanic, operator, etc.) takes a part from inventory for use, there should be a simple process to check it out. This could be as informal as a whiteboard where they write “Took 1 x hose Part#123 for Backhoe on 5/10” or as formal as using an inventory software to scan a barcode and assign that part to a work order or machine. The goal is to avoid the situation where five filters quietly walk off over months and then when you need one, the bin is empty and no one knows where they went.

One effective method is a “Parts Issue Form” or digital equivalent – essentially a small log where each part taken is recorded with date, user, and purpose. It sounds tedious, but it quickly becomes routine. Additionally, limit access to the inventory: if you have a storeroom, you might have a designated parts manager or at least require that people notify someone when taking parts. This cuts down on loss and theft.

Set Reorder Points (Min/Max Levels)

Avoid running out by setting a minimum stock level for each item. For example, you decide to always keep at least 5 engine oil filters for your bulldozers. If you hit that minimum (say you’re down to 5 because you just used one), that’s the trigger to reorder. Some items might have a higher min level due to high use (you might set 20 as the min for grease cartridges if you burn through them). For rarely used but critical parts, your minimum might be 1 (if you use the one you had, you must reorder a replacement). If you have an electronic inventory system, it can often alert you when stock is low. If you’re manual, it’s on the parts manager or whoever monitors inventory to regularly check and reorder.

Also consider a max level – the most you’d reasonably store – to avoid overstocking. If your min is 5 and max is 10 for an item, you’d reorder up to 10 and then hold off. Overstocking ties up capital and space, plus items can degrade over time.

First-In, First-Out (FIFO)

Whenever applicable, use the oldest stock first. This is mostly an issue for things like fluids (which might have shelf lives) or rubber parts that age. Mark your inventory with dates received if needed. For example, rotate your oil supply so the older containers get used first. Same with filters – filters generally don’t spoil, but their gaskets can dry out after many years; better to use the ones that have been sitting longest when doing maintenance. FIFO prevents waste due to expiration or obsolescence.

Protect and Preserve Inventory

Store parts in conditions that won’t ruin them. That means keeping electrical parts dry and dust-free, storing rubber parts (belts, hoses) in cool, dark areas to avoid dry-rot, and keeping fluids sealed. Ensure that sensitive electronics are kept in anti-static bags or original packaging. Rust-prone parts might need a light coat of oil or rust inhibitor if they’ll sit long (for instance, spare metal hydraulic cylinders or engine parts). Basically, treat your spares as if they were already installed in a machine – you want them in ready-to-use condition when called upon.

Regular Inventory Audits

Schedule a routine (monthly, quarterly, etc.) to audit your inventory. This can be a simple count of certain items or a full inventory check. The purpose is to catch discrepancies between your records and reality. Maybe your log says you should have 3 track rollers on the shelf, but a count shows only 2 – where did it go? Perhaps someone took one and failed to record it, or it got misplaced. Audits help correct these issues and maintain accuracy. They also give insight into usage rates – if you’re consistently reordering something frequently, maybe increase the stock of that item.

Coordinate Inventory with Maintenance Planning

Tie your inventory management closely with your maintenance schedule. If you know a big 1,000-hour service is coming up on your excavator next month, check that you have all the parts needed for it ahead of time (and if not, procure them). This way, you’re proactively using inventory for scheduled maintenance, not just reacting to breakdowns. Good maintenance software (or even a shared calendar) that shows upcoming services can prompt you to ensure parts are available.

Also, when you decommission or sell equipment, make sure to adjust inventory – if you had parts only for that old machine you sold, you might repurpose them for other uses or phase them out to save space.

Security and Loss Prevention

Unfortunately, parts can grow legs and disappear if you’re not careful (especially things like power tools or easily pawned items, but even new batteries or expensive filters might tempt someone). To prevent theft or misuse, keep valuable inventory in a secure area. Lock up the storeroom and control the keys. Consider cameras if the value is high. CyberStockroom and similar systems also help by adding transparency – when every part is logged and tracked by user, people are less likely to pocket something. Some companies even use RFID tags or barcodes that they scan at exit points, but that might be overkill for smaller ops. The goal is to make sure parts only leave inventory for legitimate maintenance needs.

Train and Involve Your Team

Lastly, success in inventory management comes from people as much as systems. Train your mechanics, technicians, and even operators on the importance of the inventory process. If you expect them to fill out a log or update software when they take a part, explain that it’s not about micromanagement – it’s so the team isn’t left high and dry later. Encourage a culture where if someone sees stock is low, they flag it or reorder it rather than assume “someone else will do it.” Perhaps assign a specific person (or rotate among team leads) to be responsible for inventory checks weekly. When everyone treats the parts room with respect – not as a free-for-all – it stays orderly and reliable.

By implementing these practices, you create an inventory that’s accurate, reliable, and ready to support your construction operations. Now, a lot of this can be streamlined with the help of technology. Let’s talk about how using an inventory management tool can make your life much easier – and introduce CyberStockroom as a solution tailored for this kind of job.

Leveraging Technology: Inventory Management Software for Construction

Manually tracking inventory with spreadsheets or paper can work, but it’s labor-intensive and prone to error (we’ve all forgotten to mark down something we took, or mis-typed a part number).

Today’s cloud-based inventory management tools are a game changer, especially for construction fleets that have inventory spread across multiple locations. Here’s how leveraging software can help:

- Real-Time Tracking: With digital inventory management, the moment a part is used, you can update the system. This instantly adjusts the count in the database. Anyone on your team can then see the current stock levels in real time. No more guesswork or calling the warehouse to ask “do we still have that part?”

- Easy Search and Identification: Good software lets you quickly search for a part by name, category, or number and see if it’s in stock and where. For example, you could type “CAT 320 excavator filter” and find all matching filters in your inventory and their quantities. This beats rummaging through shelves or spreadsheets.

- Multi-Location Visibility: If you have inventory at different sites or in different depots, software provides a unified view. You might see that a certain part is out at Site A but available at Site B. This opens up possibilities to transfer inventory between sites as needed instead of always buying new – saving time and money by using what you already have in the network.

- Usage Analytics: Over time, the software can produce reports on what parts are being used most, which equipment is consuming the most spares, how often certain parts fail, etc. This data is gold for refining your maintenance strategy. For instance, if you see you replaced 15 hydraulic hoses on one bulldozer in a quarter, you might investigate why (perhaps routing or pressure issues) or make a maintenance change. Or if a particular model of truck is eating up brake pads faster, maybe drivers need retraining or better quality pads are needed. It helps you move from reactive to proactive.

- Accountability: Since software can log who issued or used a part (if users have logins or use an ID to check out parts), there’s a clear trail. This tends to greatly reduce “mystery disappearances” from stock. Team members know it’s being tracked, which encourages them to follow procedure. And if something is unaccounted for, you have records to investigate.

Clearly, technology can amplify all the good practices we discussed. But you might be thinking, “This sounds great, but what specific software should I use?” That’s where CyberStockroom comes into play – it’s an inventory management platform with features that fit construction companies exceptionally well. Let’s explore that in detail.

How CyberStockroom Simplifies Construction Inventory Management

You’ve likely gathered by now that CyberStockroom is a tool designed to help businesses track inventory – but what makes it especially useful for construction fleets managing maintenance parts, tools, and materials? In this section, we’ll correlate CyberStockroom’s features to the needs we’ve been talking about throughout this guide.

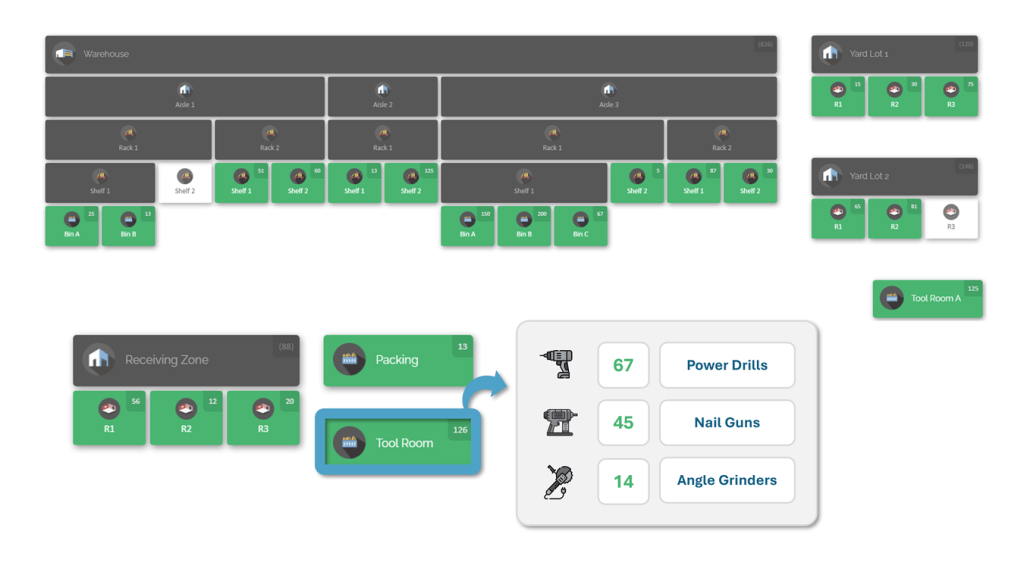

Visual Inventory Map

CyberStockroom’s most distinctive feature is its Inventory Map interface. Instead of just rows in a spreadsheet, you get a digital map of all your locations. For a construction company, this means you can set up your map to reflect:

- Your headquarters or main warehouse where bulk inventory is stored.

- Each job site you’re actively working on (with maybe sub-locations like “Site A – Storage Trailer” or “Site A – Main Office” if you want to be detailed).

- Your laydown yards or equipment yards.

- Service trucks or vans that carry spare parts (yes, you can include vehicles as movable inventory locations on the map!).

- Any other relevant location, even crews or individuals if you assign equipment directly to people.

With this map, at a glance you get that bird’s-eye view: for instance, you might see Site Alpha (3 items), Site Beta (10 items), Warehouse (150 items), Truck 7 (25 items), etc. Clicking into any location pops up exactly what’s there. This visual approach is immediately intuitive – it answers the crucial “what do we have and where is it?” question without fumbling through lists. In the heat of a breakdown, you could literally open the map and see if the part you need might already be at a nearby site or if it’s back at the warehouse.

Drag-and-Drop Transfers

Construction inventory is always on the move – parts get sent to sites, tools move around, leftovers come back. CyberStockroom lets you perform inventory transfers by simply dragging an item from one location on the map to another. Say you finish a project at Site A and you want to consolidate unused parts back to the main store: just select those items and drop them onto the Warehouse icon on the map to “move” them in the system (of course physically someone will move them, but the system is now updated). Or if a field mechanic takes a part from the truck and installs it at Site B, you can drag it from “Truck” to “Site B (or to an equipment-specific location if you track per machine) and mark it as used or installed. This beats manually adjusting numbers in two places (subtract here, add there); the system does it in one intuitive action.

Barcoding

CyberStockroom supports barcoding, meaning you can tag your parts with barcodes (or QR codes) and use a scanner or your phone camera to check items in or out. For example, your parts storeroom could have barcodes on each bin. When a mechanic picks a part, they scan the barcode and select the destination (like the work order or location it’s going to). This automatically deducts from inventory. Since it’s cloud-based, a person at the home office and a supervisor on site both see that update immediately. And because there’s a mobile-friendly interface, your team can do this on an iPad in the shop or a tablet on site – no specialized devices required.

Trunk Stock and Field Service Workflow

If you have service trucks, CyberStockroom has you covered. It allows you to manage “Trunk Stock” – essentially treating each vehicle’s inventory as its own mini-warehouse. This is fantastic for field mechanics who carry common spare parts with them. You can assign parts to a specific truck, and as the mechanic uses them, they update the system. You’ll always know, “What does Joe’s truck have on it right now? Did he already use the last 2 hoses he had?” It brings a lot of clarity to mobile operations. Additionally, if mechanics restock from the main warehouse to their truck, that transfer is tracked. No more mystery about whether a part is sitting on a truck, at a site, or truly not available – the map will show you.

Real-Time Visibility and Audit Trail

Every transaction in CyberStockroom is logged. If someone moves or uses an item, the activity log notes who did it, when, from where to where. This is great for accountability and troubleshooting. If an inventory count is off, you can look back and see all the movements of that item. It’s also helpful for theft prevention – if things disappear, you have a record of the last known location and user. And when auditors or project managers ask for where resources went, you have a digital paper trail. For construction projects, sometimes clients want to know that materials they paid for actually went to the site – you could produce a report of inventory usage thanks to this feature.

Import from Spreadsheet & Easy Setup

If you’ve been managing on Excel, the idea of moving to software might seem daunting. CyberStockroom actually makes it easy by letting you import CSV files of your existing inventory data. So you can export your current spreadsheet and bring it into the system in one go – no need to re-type everything.

Cloud-Based and Secure

Being cloud-based means you don’t have to maintain servers or worry about backing up the inventory database; that’s handled for you (CyberStockroom is hosted on secure Amazon Web Services, with encryption and robust backups). And you can access it from anywhere – whether you’re in the office, at home, or on a job site with a phone. If you have multiple offices or managers, everyone can connect to the same system globally.

Focus on Construction Needs

Unlike some generic inventory software, CyberStockroom has carved a niche with field operations like construction, trades, and service companies. It’s not overloaded with features you don’t need; it’s focused on location-based tracking, ease of use for non-IT folks, and quick visual comprehension. It even helps with things like job site theft prevention by keeping tabs on where tools and equipment are supposed to be, which can correlate with your security efforts (if something goes missing from the map, you know to investigate).

In summary, CyberStockroom acts like a digital twin of your physical stock. It’s the tool that complements the best practices we discussed: you still decide what to stock and how much, but CyberStockroom ensures you know what you have, you can find it quickly, and you can keep track of it effortlessly. The result is a leaner, more responsive inventory operation – exactly what a busy construction environment needs.

Maintenance Inventory Best Practices: Quick Checklist

We’ve covered a lot of ground. For a handy reference, here’s a quick checklist distilling the key points for establishing and managing an effective construction equipment maintenance inventory:

- ✅ Identify Critical Equipment & Parts: List your fleet and mark which parts are essential to keep each machine running (and those with long procurement lead times).

- ✅ Stock the Essentials: Keep adequate quantities of high-turnover and critical items – filters, fluids, belts, hoses, common electrical parts, and wear items like teeth and blades. Don’t forget general supplies (grease, bolts, etc.).

- ✅ Organize Your Storeroom: Set up labeled sections or bins by part type or equipment. Make everything easy to find and clearly labeled to avoid confusion.

- ✅ Implement a Checkout System: Require that every part taken for use is logged (on paper or digitally). Limit inventory access to responsible personnel to maintain control.

- ✅ Set Reorder Levels: Define minimum stock levels for each part based on usage rates. Monitor inventory and replenish before you hit critical lows to prevent stockouts.

- ✅ First-In, First-Out: Use older stock first, especially for items that can expire or degrade. Mark dates on items if needed and rotate your inventory.

- ✅ Regular Inventory Audits: Schedule routine counts to ensure recorded quantities match actual quantities. Investigate and reconcile any discrepancies.

- ✅ Integrate with Maintenance Schedule: Before scheduled maintenance, ensure all required parts are on hand. Align your inventory planning with your PM calendar so nothing is missing when a service is due.

- ✅ Use Inventory Software: Consider a tool like CyberStockroom to track parts across multiple locations, enable quick searches, and maintain real-time accuracy. Leverage barcoding and mobile access if possible to reduce manual errors.

- ✅ Train Your Team: Educate everyone involved on the importance of inventory procedures. Create a culture of accountability where people know that properly tracking parts usage is part of the job, not an afterthought.

- ✅ Review and Adjust: Periodically review which parts you stock. If some haven’t been used in years, evaluate if they’re still needed (or if the equipment they fit is gone). Add new spares to inventory when you acquire new machines or as failure patterns emerge. Your inventory should evolve with your operations.

By following this checklist, you’ll build a robust maintenance inventory that strikes the right balance – not too little (risking downtime) and not excessive (wasting money and space). It becomes an asset to your company, quietly

Conclusion

In the high-stakes world of construction, where deadlines are tight and margins thin, having the right part at the right time can make all the difference. An effective construction equipment maintenance inventory is your safety net against unexpected breakdowns and delays. It empowers your team to perform proactive maintenance and rapid repairs, keeping your fleet humming and projects on schedule.

We’ve discussed how to identify what you need on hand, from the simplest fuse to the big-ticket components, and how to manage those items efficiently. By investing thought, time, and a bit of resource into organizing your inventory now, you save yourself from scrambling later – it’s an investment that pays off in uptime, safety, and peace of mind.

Moreover, by adopting modern inventory management practices (and tools like CyberStockroom’s visual inventory system), even the challenge of tracking parts across various sites and trucks becomes manageable and transparent. You’ll gain visibility into your operations that helps you make smarter decisions and reduces the chaos when things go wrong.

In the end, construction is all about being prepared and adaptable. A well-stocked and well-managed maintenance inventory embodies that spirit of preparation. So take this guide as motivation to audit your own inventory processes. Shore up any gaps in your parts list, get your storeroom in order, and consider leveraging technology to keep it all straight. Your future self – standing next to a fixed machine that could have been down for days – will thank you.

Keep building, keep maintaining, and keep those engines running! Your projects depend on it, and now you have the roadmap to ensure a tiny missing part never brings them to a halt. Happy wrenching and organizing!

Leave a comment