Managing construction surplus materials effectively is a critical aspect of successful project delivery. Surplus materials are the leftover or unused construction materials that remain once project tasks are completed or when plans change mid-stream. How teams handle these surplus items – along with any returns of materials – can dramatically impact a construction company’s cost efficiency, storage needs, and sustainability efforts. In fact, industry studies show that nearly 30% of all materials delivered to construction sites end up as waste. This represents not only a significant environmental concern but also billions of dollars in lost resources for contractors and developers.

The goal is twofold: minimize the surplus generated in the first place, and then handle any unavoidable surplus wisely. Doing so can save money, reduce clutter and storage issues, and contribute to sustainability goals. In this comprehensive guide, we’ll explore why surplus materials accumulate, the challenges they pose, and best practices for handling surplus construction materials and processing returns.

Why Surplus Construction Materials Accumulate

Even with careful planning, surplus materials are a common reality in construction. Understanding the causes of surplus can help in preventing it. Here are some of the top reasons construction projects end up with excess materials:

- Inaccurate Estimations: Overestimation of material needs is a frequent culprit. If project planners order “a little extra” of everything as a safety buffer, the unused portion can pile up by project’s end. It’s often challenging to predict exact quantities, so many err on the side of caution – leading to surplus if all goes well.

- Design Changes and Scope Creep: Construction projects aren’t static; design modifications or scope changes mid-project can render certain materials unnecessary. For example, if architectural plans change after materials were purchased, you might have excess items that no longer fit the new design.

- Bulk Ordering and Minimum Order Quantities: Suppliers often offer bulk discounts or enforce minimum order quantities, tempting contractors to buy more than needed to get a better unit price. While bulk purchasing can save money per item, it can also result in surplus inventory sitting unused if demand is lower than expected.

- Contract and Procurement Policies: Some contracts require having contingency stock on hand, or procurement officers might purchase extra “just in case” to avoid delays. These contractual obligations and risk mitigation strategies can lead to surplus if the contingencies don’t occur.

- Quality and Damage Allowances: Projects sometimes order additional materials to account for potential waste, breakage, or quality issues (like warped lumber or defective pieces). If the job progresses with minimal damage and all materials are good, the surplus remains unused.

- Project Cancellations or Delays: In cases of project cancellation or major delays, materials already bought may sit idle until another use is found. Similarly, if a project is scaled down, previously purchased items might become surplus.

- Short Shelf-Life Materials: Certain construction materials (e.g., concrete mix, adhesives, some chemicals) have limited shelf lives. Contractors may overbuy to ensure they have enough within a batch, and any unopened, expired stock becomes surplus waste once its usability window passes.

By recognizing these common scenarios, companies can plan more carefully. For instance, improving the accuracy of takeoff estimates, using digital modeling (like Building Information Modeling or other software) to predict material needs, and coordinating closely with design teams can all help reduce unnecessary over-ordering.

The Impact of Surplus Materials on Construction Projects

Surplus materials might seem benign at first – after all, having a few extra pipes or a stack of unused drywall sheets can feel better than having too little. However, unmanaged surplus can lead to several challenges and hidden costs:

- Tied-Up Capital: Every dollar in unused inventory is a dollar not actively working for your business. Surplus stock ties up capital that could be invested elsewhere. Materials sitting in a yard or warehouse cannot be billed to a project until used, impacting cash flow. Over time, carrying a large surplus inventory incurs an opportunity cost and sometimes even interest or financing costs for what is essentially idle stock.

- Storage Costs and Space Constraints: Extra materials take up valuable space on-site or in warehouses. They may require paying for additional storage facilities or expanding on-site laydown yards. Managing space for surplus can be particularly problematic on cramped urban job sites or small warehouses – piles of materials cluttering work areas can even become safety hazards. Efficient use of space is key, and excess items make that harder.

- Material Deterioration and Theft: Construction materials don’t last forever, especially if not stored properly. Lumber can warp or rot if left in the rain, cement can harden in the bag, and electrical components might corrode. Additionally, surplus stock that is not closely tracked can become a target for theft or unauthorized use. Obsolete or damaged materials eventually must be written off, compounding the waste.

- Waste Disposal Costs: If surplus materials end up as scrap or trash, companies face disposal costs. Throwing away unused materials isn’t free – consider the fees for dumpsters, haul-off, and landfill tipping charges. In many regions, these costs are rising due to environmental regulations. Research indicates that effective surplus management can cut waste disposal expenses by up to 90% through reuse and recycling efforts. Failing to repurpose surplus means paying much more for waste handling.

- Environmental Impact: Construction waste is a major contributor to landfills globally. Excess materials that get tossed out needlessly contribute to environmental degradation – wasted materials mean wasted energy and resources that went into producing them. On the flip side, reusing or recycling surplus significantly improves a company’s sustainability profile. Reducing material waste helps lower the construction industry’s carbon footprint and demonstrates a commitment to responsible building practices.

- Project Delays and Inefficiencies: Ironically, while surplus is extra, not managing it can still cause delays. Cluttered sites make it harder for workers to find what they need – sometimes the materials you do need get “lost” in the mess of stuff you don’t. Crews might waste time moving or working around piles of unused items. Moreover, without clear records, a team might reorder materials not realizing some are available in surplus, leading to duplicate orders. This kind of inefficiency can ripple through project schedules and budgets.

- Missed Opportunities: Failing to track and utilize surplus is essentially leaving money on the table. Those extra tiles or steel beams from Project A might perfectly fulfill a need in Project B – but only if you know about them. Companies that lack a system for redistributing or selling surplus forfeit potential savings or earnings. Some contractors have generated hundreds of thousands of dollars by selling surplus metals and other materials rather than scrapping them.

Surplus materials carry a tangible cost in terms of money, space, and labor. They also present an opportunity for cost recovery and sustainability if handled correctly. The following sections outline best practices to manage surplus materials and returns in construction so that your team can reap the benefits instead of bearing the burdens.

Best Practices for Construction Surplus Materials Management

To effectively handle construction surplus materials and any returns, companies should implement a combination of proactive planning, organized processes, and smart reuse/recovery strategies. Below are some best practices and tips, from planning stages through project closeout, to minimize surplus and make the most of any excess materials:

1. Plan and Estimate Materials Accurately

The best way to deal with surplus is to prevent it from happening unnecessarily. Investing time and resources in accurate project estimating and planning can dramatically cut down how much surplus you generate. Some tips include:

- Use Detailed Takeoffs and Software: Modern digital estimation tools and BIM (Building Information Modeling) technology can help predict precise material quantities needed for each phase of a project. These tools reduce the guesswork and “fudge factor” in orders by providing data-driven calculations. Studies have shown that using BIM for quantity takeoffs can reduce material waste by 15–20% by preventing overordering.

- Leverage Historical Data: Look at records from past similar projects to gauge actual vs. estimated usage. If you consistently had, say, 10% of drywall left over on previous jobs, you might safely reduce orders slightly for the next project. Let history inform your buffer – patterns in usage can guide you to order closer to the true need.

- Include the Team in Planning: Consult with site supervisors or field personnel during estimation. They often have practical insights (like knowing typical waste factors or preferred methods that affect material usage). Involving those on the ground can improve the accuracy of material forecasts.

- Flexible Contracts and Change Management: Since changes are inevitable, build some flexibility into procurement. Negotiate with clients and designers that substantial design changes will prompt a reevaluation of material orders (to potentially cancel or reduce pending orders). Likewise, have clear change order processes internally so the purchasing team is alerted to scope changes quickly and can adjust orders if possible.

- Avoid Over-Buying for Discounts: It can be tempting to purchase in bulk to get unit price breaks. Weigh the savings vs. the carrying cost of surplus. Sometimes buying exactly what’s needed (even if slightly higher per unit) is cheaper in the long run once you factor in storage and waste of leftovers. If you do bulk-buy, ensure there’s a plan to use the surplus on future jobs (and track it accordingly).

Accurate planning won’t eliminate surplus completely, but it will certainly lessen the problem. The goal is to approach ordering with a lean mentality – order what you need plus a reasonable contingency, rather than grossly overestimating “just in case.”

2. Implement Effective Inventory Management and Tracking

Inventory visibility is crucial when dealing with construction materials across multiple sites and warehouses. If you don’t have a clear picture of what materials are on hand (and where), you can’t efficiently use your surplus or process returns. Here’s how solid inventory management helps:

- Maintain Updated Inventory Records: Keep a live, up-to-date log of all materials in your possession – whether they’re assigned to a jobsite, in a central warehouse, or in transit. This can be as simple as a consistently updated spreadsheet or, better yet, a dedicated inventory management system. The key is that when a project finishes, any leftover materials should be recorded back into an “available inventory” list rather than forgotten.

- Use Barcoding or RFID for On-site Materials: Tag materials or pallets with barcodes or RFID tags and scan them when moving items in or out of storage. A quick scan when materials arrive on site, and again when they’re used or removed, ensures your inventory count stays accurate. This reduces human error and makes it much easier to track what’s actually leftover at the end.

- Real-Time Tracking Across Locations: Ideally, all stakeholders – from the procurement office to the site managers – should be able to see the same real-time inventory data. Cloud-based inventory tools allow teams in different locations to update and view stock levels simultaneously. For example, if Site A returns 50 unused bags of cement to the warehouse, the project team at Site B should immediately see that those 50 bags are available for allocation.

- Establish Check-in/Check-out Procedures: Treat certain materials and equipment like library books – when someone takes something, they log it out; when it’s returned or relocated, log it in. A simple check-out system for tools and reusable materials (using a mobile device or log sheet) builds accountability and a usage history. This habit also makes end-of-project reconciliation easier because you know what was used versus what came back.

- Cycle Counts and Audits: Don’t wait until year-end to audit inventory. Periodically count subsets of materials (especially high-value items) to catch discrepancies early. If your records say 20 copper pipes in storage but you only find 15, find out why. Regular cycle counts keep the data honest and trustable.

- Assign Responsibility: Have a clear owner for inventory management – whether a warehouse manager or an inventory specialist on each project. When someone is accountable for tracking materials, things are less likely to slip through the cracks. They can also coordinate surplus logistics (like scheduling returns or moving items to storage).

Effective inventory management underpins all other surplus handling strategies. It’s much easier to reuse or return materials when you actually know what you have and where it is at any moment. Furthermore, good tracking prevents the scenario of “oops, I didn’t realize we already had those extra pipes,” which leads to redundant purchases.

3. Reuse and Reallocate Surplus Materials

One of the best things to do with surplus materials is to put them to work on another project. Establish a formal process to identify and redistribute usable leftovers:

- Create an Excess Materials List: When a project is winding down, compile a list of all significant materials left unused – e.g. “250 bricks, 3 rolls of wire, 20 gallons of paint, 15 lighting fixtures.” Share this list with your operations or procurement team and other project managers. Some companies maintain a running “surplus inventory” spreadsheet or database that any project manager can reference.

- Centralize Storage for Leftovers: If feasible, set up a designated area (or even a small central warehouse) for surplus materials that come back from sites. This acts as an internal “store” of materials. For example, after Project A, you bring all extra conduit and lumber to the central yard. Then Project B’s team can check that yard first before ordering new conduit. This ensures leftovers are actually accessible and known to all teams, not just sitting forgotten in a shipping container on some jobsite.

- Incentivize Reuse: Encourage project teams to use available surplus from previous jobs by making it part of the planning workflow. For instance, procurement officers can first cross-check new material requests against the surplus inventory list. If an upcoming build needs 100 cinder blocks and there are 100 left from another site, plan to transfer those over. Some organizations even budget a credit for projects that utilize internal surplus, effectively rewarding the behavior.

- Facilitate Transfers: Logistically, moving materials between projects or from site to warehouse requires coordination. Assign someone (like an inventory manager) to handle requests for surplus materials and arrange transport. Modern inventory systems, such as CyberStockroom’s visual map, also allow easy transferring of items from one location to another with a simple drag-and-drop operation – making it clear that, say, those steel beams have now been relocated from Yard A to Jobsite B.

- Track Usage and Adjust Estimates: Note whenever surplus from one job is used on another. This feedback can inform future estimates (why was there so much left on Job A?) and also demonstrate cost savings. Over time, you might adjust ordering patterns if you notice certain materials are almost always leftover.

By establishing a culture of reuse, construction firms can significantly reduce both waste and purchasing costs. It turns surplus into an asset. One contractor’s leftover pile of pavers might be another’s lifesaver to finish a driveway without waiting for a new order. However, reuse is only effective if everyone is aware of the available materials – hence the emphasis on lists and communication.

4. Return Unused Materials to Suppliers

Whenever possible, take advantage of return policies to send unused materials back to vendors for a refund or credit. Many building material suppliers allow returns under certain conditions:

- Know Your Suppliers’ Return Policies: At the outset of procurement, understand which suppliers accept returns, within what timeframe, and if any restocking fees apply. Some suppliers might take back standard items (unopened, in re-sellable condition) for a full or partial refund, especially if returned within 30-90 days. Others may only offer store credit or charge a restocking percentage (commonly 10-20%).

- Plan Timing to Meet Return Windows: If a project is nearing completion, identify surplus as early as possible so you can return items within allowable windows. For example, if you bought extra cases of tile from a distributor with a 60-day return policy, aim to finalize what’s needed with enough time to send back the rest.

- Organize and Preserve Materials for Return: Only materials in good condition can be returned. Keep excess items in their original packaging, unopened if possible. Store them carefully so they don’t get dirty or damaged on site. It often helps to set aside a “returns pallet” or area where potentially returnable items are collected, shrink-wrapped, and labeled. This way, nothing accidentally gets used or ruined once you’ve decided it’s excess.

- Streamline the Paperwork: Assign someone to handle return authorizations and logistics. They’ll need to coordinate with the supplier, get Return Merchandise Authorization (RMA) numbers if required, and arrange transport back to the vendor or store. Keeping good records of purchase orders and invoices will make this process smoother when proving you bought the items and are eligible for return.

- Consider Supplier Relationships: Suppliers appreciate repeat business, so if you’re a good customer, they might be more flexible with returns. Open communication is key – sometimes you can negotiate returns outside of normal policy if it’s a one-time thing and the materials are in demand. Having a strong supplier relationship can turn those surplus items back into cash or credit with minimal friction.

- Account for Restocking in Costs: If a restocking fee does apply, weigh that cost against other options (like storing the material for future use or selling it elsewhere). Often, even with a 10% restocking fee, getting 90% of your money back is better than tying up 100% of the cost in idle inventory. Factor restocking losses into your project’s cost evaluations.

Returning materials not only recovers a significant portion of their cost, it also reinforces better estimating practices. Repeatedly returning large amounts might indicate you’re consistently over-ordering, which should prompt a review of your estimation accuracy. Nonetheless, having the return option provides a safety net – it turns potential waste into reimbursements and helps keep your inventory lean.

5. Sell or Liquidate Excess Materials

If you can’t reuse surplus internally or return it to the vendor, the next best option is to sell it externally. There’s a robust secondary market for construction materials, and what you don’t need, someone else might:

- Online Marketplaces: Numerous platforms and apps allow contractors to buy and sell surplus building materials. These range from general classifieds (like Craigslist, Facebook Marketplace) to specialized construction resale sites or apps. For example, some services let you list excess lumber, fixtures, or flooring where other builders or DIY enthusiasts can purchase them at a discount. This helps you recoup some costs while benefiting the buyer with a deal.

- Construction Surplus Exchanges: In some regions, industry associations or informal networks facilitate swapping materials. One company’s leftover steel studs could be sold at a low price to another local contractor rather than scrapped. Keep an eye out for any “excess material exchange” programs in your area or within your contractor network.

- Auction and Liquidation Services: For large quantities of surplus or specialized items, auctioning might be effective. There are auction companies and websites where you can lot your surplus materials (anything from heavy equipment attachments to pallets of tiles) for bidders. This can be a quick way to clear out inventory, though prices vary.

- Salvage Yards and Reuse Centers: Architectural salvage yards or non-profit building material reuse centers will sometimes purchase (or accept donations of) surplus materials. They then resell them to the public. If immediate profit is less of a concern, these outlets ensure the materials get used and you free up space.

- Advertise to Local Contractors: Sometimes the simple approach works – let others in your area know you have materials available. A quick email blast or message in a contractor forum might find you a taker. You could even reach out to contractors who bid on the same project (if you won a project and have leftovers, those who didn’t win might have other jobs needing similar materials).

- Consider Pricing Wisely: When selling surplus, expect to get less than retail – after all, it’s about cutting losses. Price items attractively so they move; earning, say, 50-70% of the original cost back is better than 0%. For brand-new condition items, you can aim higher, but for partial leftovers or opened lots, a deep discount will entice buyers.

- Document the Sale: Treat these transactions professionally. Provide receipts or invoices for whatever you sell, and keep records. This will help with accounting and also avoids any confusion about material origin (especially if later there are warranty or quality questions – the new buyer should know they’re buying surplus “as is”).

By selling surplus materials, construction companies recover value and avoid waste. It’s also an eco-friendly approach – materials get a “second life” instead of heading to a landfill. Online surplus liquidation has become easier with modern marketplaces, so it’s an avenue well worth exploring when you have significant excess on hand.

6. Donate Surplus Materials to Community Projects

Another commendable way to handle surplus is to donate materials to charities or community organizations. This can turn your excess into a social good and possibly a financial benefit through tax deductions:

- Habitat for Humanity ReStores: Habitat for Humanity operates ReStore outlets in many countries, which accept donations of building materials, fixtures, appliances, etc. They either use them in their own home-building projects or sell them to the public to fund their charitable work. Donating leftover materials like doors, windows, hardware, or unopened paint to a ReStore is a popular option in the construction industry.

- Local Schools and Training Programs: High schools or vocational colleges with construction technology classes might welcome surplus lumber, drywall, or other materials for students to practice with. Similarly, theatrical groups sometimes seek materials for set building, and art programs may take interesting scrap for projects.

- Community Building Projects: Look for local non-profits or community initiatives – perhaps a community center renovation, a small Habitat build, or a charity house repair program – that could use materials you have. They often operate on tight budgets and would gladly accept quality surplus supplies.

- Tax Deduction Benefits: In many jurisdictions, donating materials (in good condition) to a registered non-profit can allow your company to claim a tax deduction for the fair market value of the items. This can offset some of the cost that would otherwise be a loss. Be sure to get a receipt or letter from the organization documenting the donation and consult your accountant on the proper way to record it.

- Public Relations Boost: Beyond tangible benefits, donating surplus can enhance your company’s reputation. It demonstrates environmental responsibility and community support. You can share stories or social media posts about helping build a local playground with donated materials, for example – it’s positive PR that can resonate with clients and the public.

- What to Donate: Common donations include excess lumber, bricks, roofing shingles, siding, plumbing fixtures, lighting, cabinetry, and flooring that are left over from jobs. Even partially used items like a half pallet of bricks or a few gallons of paint can be useful to someone. Just ensure materials are in usable condition (not broken, moldy, etc.), and check what the organization accepts (Habitat ReStores list acceptable items on their websites).

Donating is truly a win-win: your surplus finds a home where it’s needed, you potentially get financial write-offs, and you avoid disposal costs. It should be one of the first considerations when you have usable materials that you simply don’t have a plan for internally.

7. Recycle and Dispose of Unusable Materials Responsibly

Even with robust reuse and return efforts, there will sometimes be materials that cannot be repurposed – perhaps they’re damaged, expired, or highly specialized to one project. In these cases, the focus should shift to responsible disposal and recycling:

- Sort and Separate Waste Streams: On the jobsite, have separate bins or piles for different material types (metal, clean wood, concrete rubble, drywall, etc.). Many of these materials can be recycled if kept clean and sorted rather than all thrown together. For instance, metal scrap from a site (rebar ends, conduit, copper wiring offcuts) has significant recycle value – collect it and take it to a metal recycler instead of the dump.

- Concrete and Masonry Recycling: Unused concrete or broken masonry can often be crushed and recycled into aggregate or fill. Some projects use mobile crushers to process old concrete on-site. If you have extra concrete blocks or slabs, look for local facilities that accept concrete debris for recycling. It saves landfill space and often costs less than disposal.

- Wood Waste: Clean wood scraps (free of paint or chemicals) can be ground into mulch or biomass fuel. There are also companies that take salvaged timbers for reuse. For plywood, lumber, and timber that can’t be reused as-is, ensure it gets into a wood recycling stream rather than general waste. Avoid burning or tossing in landfill if recycling is available.

- Drywall and Gypsum: Gypsum drywall can be recycled in some areas – turned into new drywall or even used as a soil amendment (gypsum adds nutrients to soil). If you have a large quantity of scrap drywall or unused sheets that got wet or damaged, seek out drywall recycling programs.

- Hazardous Materials: Leftover paints, solvents, adhesives, or other chemicals usually require special handling. These should never be dumped with regular trash. Coordinate with local hazardous waste disposal services or supplier take-back programs for things like paint and sealed chemicals. Some paint stores, for example, will accept back unused paint for proper disposal or remixing.

- Work with Waste Management Professionals: Engage a reputable waste management or recycling company that services construction waste. They can often provide the appropriate containers and guide your crew on what can be recycled. They might also track weights of recycled vs. landfilled material, which can be useful data for reporting your project’s waste diversion performance.

- Document Disposal: As part of project closeout, document how surplus and waste was handled. This might be required for green building certifications (like LEED) or just for company records. It’s good to know, for example, “X tons of material were recycled, Y tons landfilled” and to keep receipts from recycling centers or waste facilities in case of any compliance questions.

- Avoid Illegal Dumping: It should go without saying, but ensure any disposal is done legally and ethically. Dumping excess construction materials on an empty lot or behind a warehouse not only harms the environment and community trust, but it can also result in hefty fines and legal trouble. Responsible surplus management includes the final step of proper disposal when needed.

Recycling and proper disposal are the last lines of defense in surplus management – used when all other options are exhausted. They ensure that even when material must be thrown out, it’s done in a way that minimizes environmental impact and aligns with regulations and good corporate citizenship.

8. Store Surplus Materials Safely for Future Use

If you decide to keep surplus materials for later use (a very common practice), make sure you store them correctly to preserve their value:

- Organize the Storage Area: Don’t just dump leftovers in a heap. Assign areas or racks for different material types. Pallet racking is great for stacking extra boxes of flooring or cartons of tile. Lumber should be neatly piled off the ground (and preferably under a roof or tarp). Create clear labels or signage so anyone visiting the storage can identify where things are (e.g., “Electrical conduit – corner rack, Shelf B”).

- Protect from Weather: Exposure to the elements can ruin many materials. Store surplus indoors if possible. If outdoor storage is the only option, use weather-proof covers: tarps for lumber, shrink wrap for palletized goods, and covered bins for loose items. Ensure proper ventilation under tarps to avoid moisture buildup. For example, keep drywall or bags of cement absolutely dry; once wet, they’re useless.

- Prevent Damage: Delicate items like glass windows or ceramic tiles should be stored upright and cushioned to avoid breakage. Coiled materials like cables or hoses should be secured to prevent kinks. Also consider climate – if you’re storing paint or adhesives, they often need temperature-controlled environments (not too hot or freezing cold) to remain usable.

- Security Measures: A yard or warehouse with valuable surplus can attract thieves. Consider security for your surplus storage: fencing, locks, cameras, or even periodic security patrols if needed. Copper wire, for instance, is a high-theft item – keep it locked up. Having an inventory system with check-in/out can also deter “silent” pilfering by employees or subcontractors because everything is being tracked.

- First-In, First-Out (FIFO): When adding new surplus to storage, place older stock so it’s easy to get to and use first. This is particularly important for anything with expiration or shelf-life (sealants, certain engineered wood products, etc.). Using a FIFO system means the next project will take the older material before the newer, keeping the inventory fresh.

- Regular Inspection: Periodically inspect your stored materials. Make sure nothing is deteriorating. Do quick inventory counts to ensure nothing has gone missing. Check that tarps are secure, no leaks in the storage roof, no pest infestations (rodents can chew through insulation rolls or nest in pipe stacks!). Keeping the area clean and monitored will preserve those materials for the long haul.

- Catalog the Stored Materials: This ties back into inventory management – maintain a catalog of what’s in storage. Even a simple list on the storage room door can help. Better yet, update your digital inventory system so that surplus stock in storage is visible to all project planners.

Storing surplus for future use is only as good as the management of that storage. If done haphazardly, materials might degrade or be forgotten. But if done well, you essentially create a mini warehouse of free materials for upcoming jobs, which is a great way to improve profitability and reduce waste.

9. Conduct Post-Project Reviews and Learn from Surplus

Each project’s leftover materials offer lessons. Once a job is complete and you’ve tallied up what’s leftover, take a bit of time for a post-mortem analysis:

- Review Estimates vs. Actuals: Compare your initial material estimates to what was actually used. Identify where you had the most surplus. Was it a certain type of material that was over-ordered? Understanding these variances can help refine future project estimates so you don’t overbuy next time.

- Gather Team Input: Ask the project manager or site supervisor why they think surplus occurred for certain items. Maybe they’ll point out that a change order left extra pipes unused, or that they intentionally ordered a bit extra of something due to long lead times. Such context is important for improving processes (maybe next time, hold off on ordering certain finishes until designs are 100% locked, for example).

- Document Lessons Learned: Create a brief report or even a checklist of lessons. It might note things like “We consistently had 15% extra tiles – consider ordering 10% overage instead of 20% next time” or “Supplier X accepts returns easily, we should prefer ordering from them when possible.” Over time, these lessons can be compiled into company guidelines for material management.

- Adjust Standard Practices: If you identify a pattern (like always having too much of a certain material), update your standard operating procedures or estimation guidelines to reflect that. Continuous improvement in inventory forecasting is key to long-term waste reduction.

- Share Success Stories: Also note what went right. Maybe one project did an excellent job reusing materials from a previous job, saving $50,000 in new purchases. Highlight that in internal meetings – it reinforces the importance of these surplus management practices and motivates teams to be proactive. Recognize teams that kept waste minimal or saved money; this positive reinforcement can make others take surplus management seriously.

- Track Waste Metrics: If you implement many of these best practices, track your improvement. For instance, calculate the percentage of materials wasted vs. ordered for each project. You might see that percentage decline as you get better at managing surplus. Share these metrics with leadership – they’ll be interested to see cost savings and waste reduction quantified.

The idea is to treat surplus as a learning opportunity. Each leftover item tells a story about planning or execution. By paying attention to those stories, a construction firm can become more efficient and reduce surplus generation in the future. Over time, you’ll still have some surplus materials (it’s nearly impossible to predict every need perfectly), but you’ll likely see the quantities shrink and the handling of them become routine rather than chaotic.

How CyberStockroom Can Help Manage Construction Surplus

Modern problems require modern solutions. A lot of the best practices above can be supercharged with the help of technology and inventory management software. One such tool tailored for visual inventory tracking is CyberStockroom – a cloud-based inventory management platform that uses an intuitive Inventory Map to give you a bird’s-eye view of all your materials across various locations.

CyberStockroom’s Visual Inventory Map

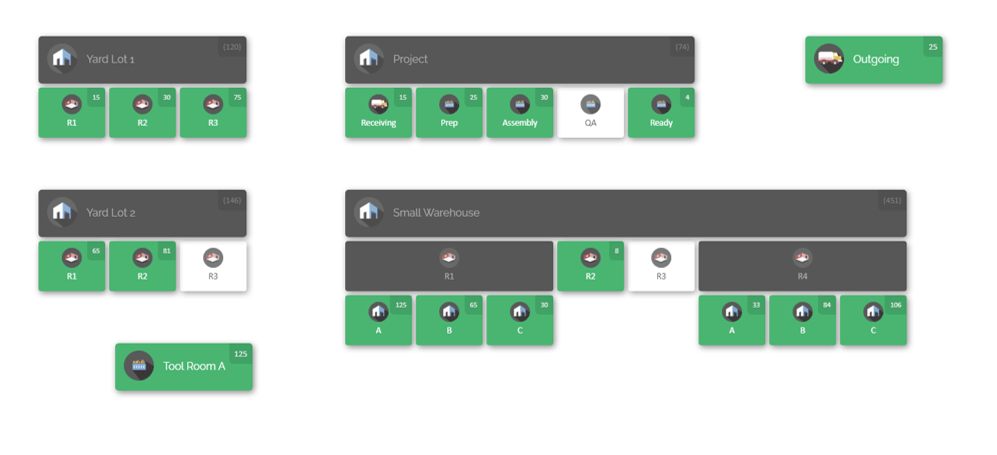

At the heart of CyberStockroom is a visual map interface. Think of it as a digital floorplan or site map where every location (warehouses, laydown yards, storage containers, even individual rooms or zones on a site) is represented visually. You can click on a location on the map and instantly see what materials or equipment are stored there. For construction companies, this means you could have a map of your main warehouse, your jobsite A, jobsite B, etc., all in one dashboard:

- Real-Time Location Tracking: CyberStockroom shows where every item is. For instance, you can see that Jobsite A has 20 beams and 5 are surplus marked for return, Warehouse has 50 surplus pipes in the “Excess Materials” section, and Jobsite B is running low on bricks. This real-time visibility makes it straightforward to match surplus to needs – you might notice on the map that the warehouse has those 50 pipes just when Jobsite B’s project manager requests pipes, enabling an immediate internal transfer.

- Drag-and-Drop Transfers: The software allows you to literally drag items from one location on the map to another to record a transfer. If you decide to move surplus drywall from Site A back to the central warehouse, just drag it on the map. The system updates the inventory counts in both places automatically. This mirrors the physical movement and keeps everyone updated without manual data entry in multiple sheets.

- Multi-Level Maps: Construction inventory isn’t just in one big box; it’s distributed. CyberStockroom lets you create nested locations (for example, Yard -> Container -> Pallet). You could map out a laydown yard with zones (like the earlier demo map image: pipes zone, steel zone, scrap zone, etc.). If you keep a “Surplus/Returns” zone in your yard, it will be clearly visible on the map. Anyone can zoom in and see exactly what’s in that surplus zone.

- Centralized Cloud Access: Because it’s cloud-based, your team in the field and in the office all access the same system via computer or mobile device. CyberStockroom is a web platform (no separate app installation needed) and is accessible from tablets or smartphones as well as desktops. This ensures that a project manager on-site can update inventory or check stock levels on their iPad or phone, while the office-based procurement team sees those changes instantly.

- User-Friendly Interface: Construction crews often resist clunky software. CyberStockroom’s map-based approach is intuitive – it’s like looking at a familiar jobsite layout. This visual design helps drive adoption because even non-technical staff can quickly understand how to find items or update their status. For example, dragging a tool icon from the “Site Trailer” to “Maintenance Shed” on the map is more intuitive for many than entering a transfer in a spreadsheet. High user adoption means the inventory data stays accurate and useful.

Streamlining Surplus and Returns with CyberStockroom

How does this translate specifically to managing surplus materials and returns?

- Recording Surplus Immediately: As a project ends, the site manager can quickly update CyberStockroom to mark what materials are leftover and their location. For example, “15 bags of cement – moved to Warehouse surplus area” is recorded by dragging those items to the warehouse on the map. Now everyone knows those 15 bags are available for use or return. This real-time logging prevents surplus from being “out of sight, out of mind.”

- Facilitating Internal Reuse: When planning a new project, looking at the CyberStockroom inventory map can become a standard step. It’s easy to visually scan for materials in stock. You might spot that there are several stacks of unused lumber in Yard A. The project manager can then plan to transfer those to the new site (and reflect that by a drag-drop on the map, which also creates a transfer log). In this way, CyberStockroom acts as the bridge connecting surplus on one job to needs on another.

- Tracking Returns to Vendors: If you decide to return items to a supplier, you can still use CyberStockroom to manage that process. One approach is to create a location on the map called “Returning to Supplier” or similar. Move the items there to indicate they are no longer in general inventory but pending return. Once returned (and credit is issued), you can remove them from the system. This provides a clear audit trail – you won’t mistakenly count those items as available stock, and anyone can see that the materials are in the return pipeline.

- Preventing Lost Materials: CyberStockroom’s map helps ensure surplus doesn’t get “lost” or misplaced. Every item’s last known location is documented. If something is missing, you know where it was supposed to be and who had access. This accountability discourages theft and casual “borrowing” of materials without record. It essentially gives you x-ray vision into your inventory across sites, so nothing slips through the cracks.

- Better Site Organization: By using the map, teams tend to keep the physical layout more organized too. If your CyberStockroom map has a designated zone for “Scrap/Returns” on site, workers are more likely to actually put surplus materials in that zone (because that’s what the software reflects). This keeps sites cleaner and makes end-of-project collection of surplus easier – it’s all in the expected area.

- Quick Reporting and Analysis: Because all inventory and movement data is logged, CyberStockroom can help generate reports on your surplus. You could run a report of all items marked as surplus across all projects, or see how many materials were transferred versus newly purchased for a given job. These insights can support the continuous improvement and lessons learned efforts discussed earlier. It’s much easier to analyze surplus patterns when you have digital data at your fingertips rather than piecing together notes from different sites.

- Ease of Setup and Integration: CyberStockroom is straightforward to implement. You can import existing inventory lists via CSV to get started. It doesn’t require complex integration with other construction management software. For most contractors, using it as a stand-alone inventory system is sufficient and means fewer points of failure. The simplicity and focus of the tool means you can get up and running quickly and start seeing benefits on the very next project.

CyberStockroom acts as a force multiplier for the best practices we’ve discussed. It enforces discipline in tracking materials, makes transfers and reuse straightforward, and keeps everyone informed. By integrating a tool like this into your operations, handling surplus materials becomes a much more organized, data-driven process rather than an ad-hoc scramble at the end of a project.

Conclusion

Surplus construction materials and project returns don’t have to be a headache or a loss. By implementing these best practices – from accurate upfront planning and robust inventory management to creative reuse, returns, sales, and donations – contractors and construction managers can turn surplus from a costly problem into an opportunity. The key is to be proactive: plan well to avoid excess, but also have clear procedures ready when surplus does occur.

Not only does smart construction surplus materials management save money and reduce waste, it also contributes to a more sustainable construction industry. Every time a beam is reused on another job, or a pallet of unused brick is sold or donated instead of trashed, that’s a win for the bottom line and the environment. Companies that excel at this often see improved project profitability, cleaner and safer sites, and a reputation boost as efficient, eco-conscious builders.

Finally, leverage technology and tools like CyberStockroom’s inventory mapping to keep track of it all. In the modern era of construction, information is as valuable as materials themselves. Knowing what you have, where it is, and how it can be redeployed is power. With clear visibility and coordination, handling surplus materials and returns becomes just another well-managed aspect of your project workflow – not an afterthought.

By embracing these practices, construction firms globally – from small contractors to large engineering companies – can build smarter. You’ll waste less, utilize more, and ensure that every material you purchase delivers value either to your current project or to another purpose down the line. Surplus will no longer be viewed as a pile of junk to get rid of, but rather as a resource to be managed and maximized.

Leave a comment