Inventory management in industrial construction projects can make or break a project’s schedule and budget. If you’ve ever been on a jobsite scrambling to find a missing tool or waiting on materials that should have arrived yesterday, you know how critical good inventory control is. Construction companies often operate on tight timelines, razor-thin margins, and complex logistics. When inventory goes awry – whether it’s a shortage of steel beams delaying a build, or stacks of unused materials piling up in the yard – the entire project can suffer. These issues aren’t just minor annoyances; they can cause serious delays, cost overruns, productivity losses, and even safety risks on site.

In fact, studies have found that construction workers spend significant time each day simply searching for tools or materials that aren’t where they should be. Those minutes of downtime add up – potentially to several days of lost productivity per worker each year – all due to inventory disorganization or lack of visibility. Clearly, there’s plenty of room for improvement. The good news is that by understanding the unique inventory challenges in industrial construction and adopting the right solutions, project teams can dramatically improve efficiency and avoid costly hiccups.

Challenge 1: Inaccurate Inventory Tracking and Data Errors

One of the most pervasive problems in construction is simply knowing what you actually have on hand at any given moment. It’s all too common to have a mismatch between what the records say and what’s actually in the yard or on the shelf. Maybe your spreadsheet shows 500 bricks in stock, but only 300 can be found on site. Or perhaps a pallet of pipe was marked as delivered and available, when in reality it never arrived or was already used up on another section of the project. These discrepancies can occur for a variety of reasons: human error in logging transactions, lack of real-time updates, or using outdated manual tracking methods (like paper forms and Excel sheets) that aren’t synced with reality. In a hectic construction environment, it’s easy for data to fall out of date even after just a few days of activity.

Why it’s a problem?

When your inventory records are wrong, you risk both overstocking and stockouts – sometimes simultaneously! You might order materials you already have, wasting money and crowding your laydown yard with duplicates. Conversely, you might fail to order something critical because your system said it was still in stock, only to discover too late that it’s all gone. Inaccurate tracking leads to delays, increased costs, and endless frustration.

For instance, imagine ordering extra gallons of paint because records showed none left, only to find a stash tucked away in a corner of the site – now you’ve over-purchased and tied up cash in excess inventory. On the flip side, if your records indicated plenty of copper wiring on hand so you didn’t reorder in time, your electrical crew might be left idle on installation day, waiting for an emergency delivery. Simply put, bad data = bad decisions.

How to solve it?

The key is to maintain accurate, up-to-date inventory records through a combination of regular oversight and smart technology. Here are some effective strategies:

- Conduct regular cycle counts and audits: Don’t wait for a yearly inventory check to catch errors. Implement a cycle counting program, where you count a subset of inventory on a rotating schedule (for example, verify one category or storage area each week). Frequent mini-audits will catch discrepancies early and keep your records reliable. By constantly reconciling your books with the physical stock, you’ll prevent small errors from snowballing into big problems.

- Use real-time tracking tools instead of spreadsheets: Replacing pen-and-paper logs or static spreadsheets with a digital inventory management system is a game-changer. Modern inventory software can update counts in real time as materials are received, moved, or used. For example, using barcodes or QR codes on your materials and scanning them at point of use/delivery ensures that every transaction is recorded immediately in a central database. This greatly reduces human error and time lags. When a bundle of rebar is taken from the yard to the site, a quick scan can deduct it from inventory instantly. With real-time data, what’s in your system truly reflects what’s on the ground.

- Enforce check-in/check-out procedures: Technology alone won’t fix data errors if your team isn’t following processes. Establish a simple check-in/check-out system for tools and equipment and train your crew to use it consistently. For example, whenever a power drill or a generator leaves the tool crib (or is returned), it must be logged – either by scanning its barcode or updating the inventory app. Assigning responsibility in this way creates accountability and a clear usage trail. People are far less likely to “wander off” with a tool or forget to report using the last box of screws if there’s a culture of recording every transaction.

- Keep systems in sync (or unified): Often, inventory data gets out of whack because different people are tracking it in different ways. You might have a procurement department using one software, project managers with their own spreadsheets, and site foremen with handwritten notes. Integrate your systems or move to a single platform so that everyone is looking at the same source of truth. A cloud-based inventory system accessible to all stakeholders – from the warehouse manager to the field crews – ensures that when materials are delivered, consumed, or transferred, the update is visible to everyone. Eliminating information silos goes a long way toward eliminating data errors.

By prioritizing accurate tracking through routine counts, clear procedures, and modern tools, you can drastically improve the accuracy of your inventory data. The payoff is huge: you’ll trust your inventory information when making decisions and avoid those nasty surprises of missing or over-ordered materials. As a bonus, accurate inventory records also help other areas of the business like accounting (e.g. knowing the exact value of materials on hand for financial reports) and safety compliance (e.g. knowing exactly where hazardous materials or expensive equipment are stored at all times).

Challenge 2: Unpredictable Demand and Forecasting Difficulties

Construction projects live and die by planning – and that includes planning the right amounts of materials and equipment. However, demand in construction can be very unpredictable. Project scope and designs can change mid-stream, weather can suddenly alter schedules (affecting how fast materials are used up), and design modifications or on-site improvisations can render some materials unnecessary while requiring new, unexpected items.

In industrial construction especially, a single change in specifications (say, a different type of pipe or a modified layout) can leave you with surplus materials that were already purchased, and new needs that weren’t originally forecasted. Accurately forecasting inventory needs is easier said than done when so many variables are in flux.

The result of poor forecasting is usually either understocking or overstocking – and both are bad news. If you underestimate how much of something you’ll need, you get understocking: not having enough critical materials when you need them. That leads to work stoppages and last-minute scrambles. For example, if the team miscalculates the number of cinder blocks required for a foundation phase and you run out halfway, the masonry work might halt for days while waiting for a new shipment. That delay can cascade through the project schedule, potentially pushing back completion dates and increasing labor costs as crews stand by idle.

On the other hand, overstocking means you bought way more than needed – resulting in leftover “dead stock” and waste. Those excess materials sitting idle are essentially money locked up on your site. They occupy valuable storage space and may deteriorate over time or become obsolete if project specs change. An unused stack of steel beams or pallets of tile gathering dust is money left on the table (or rather, left on the warehouse floor). In the worst case, you might have to dispose of or sell off surplus at a loss, which is wasted capital and effort. Moreover, carrying too much inventory ties up cash that could have been used elsewhere and adds extra handling and management needs. Construction materials can be expensive, so overstocking even 5-10% beyond what’s needed can significantly dent your project’s profitability.

How to solve it?

Tackling the forecasting challenge involves using data intelligently and staying as flexible as possible. You may never predict needs with 100% precision (surprises will always happen in construction), but these best practices can greatly improve your hit rate:

- Leverage historical data from past projects: Past projects are a goldmine of insights. Analyze records from similar projects or previous phases – how much of each material was actually used versus what was planned? Look for patterns and variances. For instance, you might discover that your electrical crews consistently used about 5% more conduit or cable than estimated on past jobs, indicating you should pad your estimates a bit next time. Or you might find that certain materials (like paint or concrete) typically have a known wastage factor that you can incorporate. Grounding your estimates in real data rather than pure guesswork will get you much closer to the mark.

- Use demand forecasting techniques and software: Don’t shy away from a bit of data science. Even simple forecasting methods can help. Tools that perform time-series analysis or regression can project future material consumption based on trends and seasonality. For example, if you know construction activity typically slows in winter or during monsoon season in your region, you can forecast lower material usage during those periods and avoid over-ordering. Conversely, for anticipated busy periods (say a summer rush of work), plan to stock up key materials well in advance. Specialized construction ERP systems or inventory software might have forecasting modules – these can factor in lead times, supplier performance, and usage rates to recommend optimal order quantities.

- Regularly update your forecasts as conditions change: A construction project’s plans aren’t static; your inventory plan shouldn’t be either. Build in checkpoints (weekly, bi-weekly, or at major project milestones) to review your inventory usage versus the plan. If certain materials are being consumed faster or slower than expected, adjust your upcoming orders and forecasts accordingly. For example, if you’re halfway through a project and have only used 30% of the wiring that you thought would be 50% consumed by now (perhaps due to design changes), you might reduce or postpone the next scheduled order of wire. Being proactive and adjusting on the fly prevents looming shortfalls or excessive surpluses.

- Consider Just-in-Time ordering (with caution): Many construction firms aim for a just-in-time (JIT) inventory approach – scheduling material deliveries to arrive right when needed rather than stockpiling far in advance. JIT can minimize on-site storage needs and reduce the chance of materials sitting around unused. It’s especially helpful for bulky items that are hard to store or things liable to theft. However, JIT comes with risks: it relies on highly reliable suppliers and predictable schedules. If you go JIT on a critical item and the supplier has a delay, your whole project could stall. So use JIT strategically: for materials where you have strong supplier relationships and confidence in lead times. For items with long or uncertain lead times (or where the supplier is new/unproven), it might be wiser to keep a buffer stock on hand just in case.

- Improve cross-team communication: Often, the people doing the purchasing aren’t on site every day, and the folks in the field may see changes coming before anyone else. It’s vital to loop your field teams into the forecasting process. Establish a clear channel for site managers or foremen to alert procurement when there’s a change (e.g. “We’re consuming gravel faster than expected on this foundation” or “The client just decided to add an extra utility building – which means we’ll need more piping that wasn’t in the original plan”). Some companies hold brief weekly meetings between project managers, site supervisors, and purchasing to discuss inventory status and upcoming needs. Catching a change early – and updating your forecasts – can save you from a world of pain later.

Better forecasting is both an art and a science. While you may never get it perfect, using data and staying agile will help you avoid most of the pain of shortages and surpluses. The result is fewer frantic last-minute runs for materials, less money wasted on unused stock, and a smoother project overall. It’s all about anticipating needs as best as possible, and being ready to adjust when reality doesn’t match the plan.

Challenge 3: Managing Inventory Across Multiple Locations (Jobsites, Warehouses, & Yards)

Unlike a single-store operation, construction inventory is spread across multiple places. A typical industrial construction company might have a central warehouse or yard, several active jobsites, maybe some satellite storage areas or containers on each site, and even materials and tools kept in trucks or trailers moving between locations. Juggling inventory across all these sites is a massive challenge.

Things have a tendency to “disappear” into the cracks between locations – a bundle of pipes might get delivered to Warehouse A but never made it to Jobsite B as expected, or a compressor ends up on Truck 7 and no one on the other site realizes it’s actually available because they assume it’s lost. Keeping track of what’s where in real time is hard when you have so many moving pieces.

The visibility gap caused by multiple locations often leads to inefficiencies and costly mistakes. For example, imagine the crew at Site X is idle because they’re missing a specific size of drill bit or a spare part, not knowing that exact item is actually sitting in a storage container at Site Y just a few miles away. Without a clear view, the team at Site X might re-order the part (incurring unnecessary cost and delay) while existing stock lies underutilized elsewhere. Similarly, companies without centralized tracking often end up duplicating purchases – buying more of something because each site manages its own inventory in isolation. One project might be overstocked with lumber while another is short, and without communication they won’t realize they could redistribute rather than reorder. Multiple locations also make it easier for items to be misplaced or lost during transfers. If a shipment of fixtures was sent from the warehouse to a jobsite but never logged properly upon arrival, those fixtures could essentially vanish from records even though they exist physically (until someone finds them weeks later in a random trailer).

How to solve it?

Successfully managing multi-location inventory comes down to centralized visibility and coordination. Here’s how you can achieve that:

- Centralize your inventory tracking: Instead of each jobsite or warehouse keeping separate records, use a unified inventory system that covers all locations. This could be software that lets you set up multiple sites/zones within one database. The idea is that a manager at HQ and a foreman in the field are looking at the same live inventory information. For instance, a single dashboard could show inventory levels at Warehouse, Yard A, Site X, Site Y, and even “In Transit” or on specific trucks. When everything is tracked in one place, you can instantly reallocate resources—if Site X is short on concrete forms, you can see that Site Y has extras and arrange a transfer rather than placing a new order.

- Map out your storage locations (physically or digitally): It helps to create a clear inventory map or directory of all locations and sub-locations where materials might reside. This can be as simple as a spreadsheet list of locations or as fancy as an interactive digital map (more on that later). The key is to not rely on tribal knowledge (“Joe knows that spare pipe is usually kept behind the site trailer”) but rather document it. Label storage areas on each site (Zone 1 – Laydown Yard, Zone 2 – Tool Crib, Zone 3 – 2nd Floor Storage Room, etc.) and track inventory with those tags. This way, when something is moved from one place to another, it’s recorded as moving from Location A to Location B, instead of falling into a black hole.

- Assign responsibility for transfers and updates: When moving materials between locations, have a clear procedure and ownership. For example, if a truck delivers generators from the main warehouse to three different sites in a day, make sure the receiving party at each site signs off or logs the receipt in the system. Many errors in multi-site management happen during handoffs. By making someone accountable for updating the inventory record whenever an item leaves or arrives at a location, you close the gap where things often get lost. Even a simple paper transfer form that gets entered into the system can work if digital real-time logging isn’t available.

- Regular inter-site inventory reviews: Encourage communication between site managers about inventory status. A weekly call or report can highlight if one site has surplus materials that another site could use. This inter-site “marketplace” approach can significantly reduce waste. For example, before Site A returns a rental or sells off excess scaffolding, it should check if Site B or C could use it for their upcoming phase. Having a central inventory coordinator role at the company can facilitate this sharing of resources across projects.

- Leverage technology for multi-location visibility: Modern inventory management tools offer features tailor-made for this challenge – from cloud-based apps accessible on any device (so field teams and office teams see the same data), to GPS tagging or location tags for equipment, and visual maps that show where everything is. Even something like a shared Google Sheet updated daily is better than nothing, but ideally, you want real-time cloud software where moving an item from “Warehouse” to “Jobsite Alpha” is as simple as a few clicks or a barcode scan. The investment in a good system pays off quickly when you stop losing track of expensive assets scattered across the countryside.

When you can see all your inventory across all locations at a glance, it’s a game-changer. You’ll avoid double-buying materials you already have, make sure critical equipment isn’t sitting idle in the wrong place, and generally run a much tighter ship. Multi-location inventory management transforms from a guessing game into a coordinated strategy – ensuring that the right stuff is in the right place at the right time.

Challenge 4: Theft and Loss of Materials/Equipment

Construction sites can unfortunately be a magnet for theft and inadvertent loss. They are often open environments, sometimes in remote locations, with lots of people coming and going. High-value materials (like copper wire, lumber, or power tools) and equipment (generators, skid steers, etc.) are tempting targets for thieves. In industrial construction, where machinery and materials can be worth tens of thousands of dollars, the stakes are especially high. Even well-secured sites face the issue of things simply “walking away” if not closely monitored. And it’s not only external theft – internal theft or unintentional misplacement by employees contributes to losses too.

The scale of this problem is eye-opening. In the United States alone, it’s estimated that hundreds of millions of dollars worth of construction equipment and materials are stolen each year (some estimates put equipment theft at around $300 million to $1 billion annually). Globally, the figure is even higher. Additionally, some industry surveys suggest as much as 5-10% of a construction project’s cost can end up lost to theft, loss, or shrinkage. Those missing copper pipes, stolen tools, or lost fixtures directly hit the project budget and can cause work delays while replacements are procured. Beyond the immediate financial loss, there’s also the indirect cost: downtime, insurance claims, and the administrative hassle of dealing with police reports or scrambling to find a backup for a stolen piece of equipment.

How to solve it?

While you may never eliminate theft and loss completely, there are several steps that drastically reduce the risk and impact:

- Improve site security and access control: Basic as it sounds, ensure your jobsites have appropriate physical security – fencing, lighting, cameras, and maybe even security patrols for high-value items. Limit access after hours and keep valuable inventory in locked containers or sheds whenever possible. The harder you make it for unauthorized people to get in or move things out, the lower your theft incidents will be. Even during work hours, a sign-in/sign-out for visitors or subcontractors can create a sense of accountability.

- Use inventory check-out & assignment systems: One effective deterrent to internal loss is implementing a check-out system for tools/equipment. Assign tools to individuals or crews when they’re taken from storage, and log it (either manually on a sheet or ideally in an inventory app). For example, note that Crew B has the laser level or John Doe signed out the concrete mixer today. Knowing that items are being tracked and that there’s a record of who last had it tends to discourage “wandering off” or casual misplacement. It also gives you a trail to investigate if something goes missing (“It looks like this generator was last checked out to Team X on Friday, let’s follow up with them on where it went”).

- Leverage technology for tracking and alerts: Consider tagging high-value assets with barcodes, GPS trackers, or RFID tags if appropriate. Even simple barcode labeling of all tools and materials can help – because it enforces that items get scanned when moved. More advanced systems might use GPS or Bluetooth tags on big equipment to provide real-time location (so you’ll know if a machine leaves the site boundary at 2 AM, for instance).

- Perform surprise audits and jobsite sweeps: Periodically (and randomly), do a quick audit of tools and materials on site. For example, at the end of a day, have the crew lead check that all power tools that started the day on site are accounted for and returned to the lockup. Or do unannounced counts of critical materials mid-project to ensure nothing has mysteriously dwindled. These spot checks not only catch losses sooner, they also signal to the team that management is keeping an eye on inventory – which can deter opportunistic theft.

- Promote a culture of accountability: Ultimately, encouraging everyone on the project to treat materials and tools as important assets goes a long way. Make it clear that missing equipment isn’t just “part of the job” but something that affects everyone’s success. Some companies even offer small incentives or recognition for teams that minimize loss and return all their tools. When crews take ownership – like treating a shared tool as if it were their own – there’s less chance of negligence. Pair this culture with clear procedures (like always locking the tool crib, always signing tools in/out, etc.), and you’ll significantly reduce inventory disappearance.

Thieves thrive on easy opportunities and lack of oversight. By increasing oversight (through both technology and policy) and reducing easy opportunities (through security measures and accountability), you can protect your valuable inventory. Preventing theft and loss not only saves money, but also keeps your projects running smoothly – no more unexpected halts because a vital piece of equipment vanished overnight.

Challenge 5: Supply Chain Delays and Lead Time Uncertainty

In recent years, the construction industry has faced significant supply chain volatility. Global and regional factors – from pandemics to trade disputes to natural disasters – have caused material shortages and unpredictable lead times for key construction inputs. Industrial construction projects are especially vulnerable because they often require large quantities of materials (steel, concrete, piping, etc.) and specialized equipment that may have limited suppliers. A delay in the supply chain can ripple through and hold up an entire project. For example, if custom-fabricated steel beams that were supposed to arrive in June get pushed to August due to a mill backlog, you might have to pause structural work for weeks. Likewise, critical items like transformers, generators, or HVAC units often have long lead times, and any hiccup in procurement or delivery can throw off your carefully planned schedule.

Even more routine materials have seen unpredictability. One month, lumber prices skyrocket and supply dwindles; another month, a sudden surge in construction activity or a transportation strike could make getting cement or drywall sheets a challenge. Lead time uncertainty means you can’t always count on “order now and it arrives in 2 weeks like usual” – sometimes it might be 6 or 8 weeks, or indefinite. This makes planning inventory levels tricky. If you don’t account for potential delays, you risk running out of materials and stalling work. If you try to play it safe by ordering extra early or keeping large buffers, you then face storage issues and the risk of overstock if the supply chain stabilizes faster than expected.

How to solve it?

While you can’t control global supply chains, you can mitigate their impact on your projects with some foresight and strategic planning:

- Plan ahead and order early (for critical items): Identify which materials or equipment have historically long or volatile lead times and plan for them well in advance. For instance, if you know elevator components or custom panels need 3-4 months lead time, place those orders as early as possible in the project timeline. Build procurement of long-lead items into your project schedule as milestones. Essentially, treat key materials procurement with the same importance as project phases – track it and give yourself a cushion whenever feasible.

- Qualify multiple suppliers: One supply chain best practice is to avoid sole dependence on a single supplier for any crucial material, if you can. Build relationships with secondary and tertiary suppliers or local distributors who can step in if your primary source has issues. Even if you prefer Supplier A for cost, having Supplier B as an approved backup can save you if A suddenly can’t deliver. For globally sourced items, consider dual sourcing from different regions when possible to spread risk. It might also be worth keeping contracts or agreements in place that allow you to expedite orders on short notice (even if at a premium) as an emergency option.

- Maintain a buffer stock for unpredictables: This might sound contrary to just-in-time, but for certain items it’s wise. If there are materials that will halt your project if unavailable, keep a safety stock of them, especially during times of known uncertainty. For example, many contractors began stockpiling essential building materials during the height of recent supply disruptions. While holding extra inventory has carrying costs, compare that to the cost of a project delay — a few pallets of extra drywall on hand might be worth it if drywall supply becomes constrained for a month. Analyze which items justify a buffer (often those with low shelf-life concerns and moderate cost but high criticality) and which don’t.

- Stay informed about market trends: Assign someone (or a team) to monitor market and supply chain news relevant to your materials. If resin shortages are causing PVC pipe delays, or a spike in construction activity is expected in Q3 that could strain cement supplies, you want to know early. Industry reports, supplier communications, and even networking with peers can provide heads-up about looming issues. By being aware, you can adjust your inventory strategy – maybe accelerating some orders or finding alternative materials – before a crisis hits.

- Communicate and collaborate with suppliers: Keep an open line of communication with your vendors. Treat them as partners in your project’s success. If you have a critical deadline, let them know and see if they can prioritize your order (sometimes they can adjust production schedules if they know how vital it is for you). Also, get in the habit of asking for realistic lead times and updates. It’s better to know early if something slips from 4 weeks to 6 weeks lead time than to find out the week it was due. Some construction firms even integrate their inventory system with supplier systems or use vendor portals to track order statuses in real time. At the very least, frequent check-ins on order status can prevent unpleasant surprises.

By proactively managing supply chain risks, you can cushion your projects against external shocks. Yes, you may spend a bit more effort (or money) building buffers and backups, but that insurance can pay off massively by preventing downtime. In essence, hope for the best but plan for the worst: assume that some deliveries will be late or short, and have a Plan B ready. When the global logistics machine hiccups, you’ll be one step ahead while others are left scrambling.

Challenge 6: Lack of Real-Time Communication and Visibility

Another challenge, closely related to multi-location management, is the communication gap between the field and the office (and within teams) regarding inventory. Construction projects involve many people: project managers, site supervisors, warehouse managers, procurement officers, subcontractors, etc. If these players aren’t all sharing information in real time, you get situations like this: A site supervisor sends an email or leaves a voicemail for the procurement department asking for additional materials, but by the time the message is received and processed, two days have passed. Meanwhile, the crew was waiting and perhaps made do with a workaround or sat idle. Or consider a scenario where the warehouse ships out a batch of parts to the jobsite, but that information isn’t relayed to the site crew – they might go and reorder those parts not realizing they’re already en route.

Data silos and delayed communication can cause over-ordering, under-ordering, and general confusion. It’s frustratingly common to hear “I thought you were ordering that!” or “We have that item? Nobody told me; I just bought another!” on construction teams with poor communication. Without a real-time view of inventory and requests, teams often rely on phone calls and emails that can be missed or on reports that are out-of-date the moment they’re printed. The result is materials not being where they’re needed when they’re needed, or conversely, multiple people ordering the same item because each thought it wasn’t ordered yet. This lack of visibility also means that management doesn’t have a clear picture of overall inventory status at any given time – making it hard to make informed decisions or adjustments quickly.

How to solve it?

The solution here is to create a single source of truth for inventory and ensure open lines of communication. Some tips to achieve that:

- Adopt a cloud-based inventory system: We’ve touched on this in earlier points, but it’s worth emphasizing: a cloud system accessible by all key personnel (with appropriate permissions) means that whether someone is in the head office, in a site trailer, or on the go with a smartphone, they can all see the same information. If a field engineer uses the last box of fixtures and marks it in the system, the procurement team can see that immediately and reorder if needed – no emails required. Cloud software updates in real time, so everyone stays on the same page regarding stock levels, recent transactions, and incoming deliveries.

- Implement clear communication protocols: Technology aside, set some ground rules for how inventory requests and updates are communicated. For example, establish that all material requests must go through the inventory system or a shared channel (instead of individual texts or verbal requests that can be forgotten). Or decide that each afternoon, the site foreman will send a quick inventory update to the warehouse if any stock is running low, so the warehouse can prepare a transfer for the next morning. Regular check-ins, like a short weekly coordination meeting between sites and procurement, can also surface needs and avoid miscommunication.

- Use dashboards and reports for transparency: Many inventory tools allow setting up dashboards that show critical info at a glance – such as items below minimum stock, pending orders, and recent usage. Make these dashboards visible to relevant team members. For instance, a project manager could have a dashboard showing key materials for their project and their status.

- Encourage a culture of updating on the fly: Often, communication breaks down simply because people put it off. (“I’ll update the log later…”, “I’ll call the office when I get a chance.”) Encourage and train your team to make inventory updates part of the task itself. If you take five minutes after unloading a delivery to log it in the system or shoot a message to the team, that information is immediately available to all. It’s much easier to keep everyone informed than to have folks chasing information. Make it easy as well – for example, using a mobile tablet on site to tick off received items as they arrive, rather than filling out paperwork that only gets entered into a computer hours later.

When communication is flowing properly and everyone can see the status of inventory in real time, it eliminates so many headaches. The field isn’t left in the dark about where their materials are, and the office isn’t guessing what the field might need. It becomes a synchronized dance instead of a disjointed shuffle. Essentially, visibility = no surprises. And in construction, fewer surprises mean projects stay on track.

Challenge 7: Material Waste and Surplus at Project End

Walk onto almost any construction site near the end of a project, and you’re likely to find piles of leftover materials – half-full boxes of tiles, extra bags of cement, lengths of conduit, paint cans, you name it. Some surplus is good as a buffer, but often it’s well beyond what might be needed for final touch-ups. This points to a challenge in inventory optimization: material waste.

Construction by nature can be wasteful if not carefully managed; industry studies frequently show significant percentages of purchased materials end up never being used in the completed project.

Why does this happen? Sometimes it’s due to conservative over-ordering (“let’s get 10% extra to be safe”). Other times, changes in design or scope make certain items no longer needed even though they were already bought. And in some cases, poor tracking leads to reordering items that were actually already available (they were just misplaced or not visible in the system), creating duplicates. Whatever the cause, leftover materials represent money spent that didn’t translate into progress. They also create additional tasks – you have to store them, try to return or resell them (if possible), or as a last resort, dispose of them. All of that is extra work and cost. There’s also an environmental impact: wasted materials often end up as construction debris in landfills, contributing to environmental strain and lost embodied energy.

Furthermore, holding excess inventory on site throughout the project can clutter the work area, potentially causing safety hazards or reducing productivity (workers navigating around stacks of unnecessary stuff). Overstock can tie up cash flow as well – money that could have been used elsewhere is sitting in a heap of unused rebar. In industrial construction, where project budgets are huge, even a small percentage of waste can equate to a big dollar amount.

How to solve it?

Reducing waste and surplus requires better inventory optimization throughout the project lifecycle, especially as the project nears completion. Here’s how to minimize the leftover problem:

- Refine your estimating and ordering practices: This ties back to better forecasting (Challenge 2). The more accurately you can predict what’s truly needed, the less extra you’ll end up with. Use those historical insights and ongoing updates to avoid grossly over-ordering. If you notice you’re consistently having 20% of a certain material left over, that’s a red flag to adjust your estimating formula or cut down the “just in case” padding.

- Implement cut-off points for bulk ordering: As a project progresses past a certain point, be cautious with automatic reorders. For example, if you’re 80% through the flooring installation, pause and assess exactly how much more is required rather than blindly ordering another full batch. It might take a bit more effort to do room-by-room counts near the end, but it can prevent ordering, say, five more pallets of tiles when you only need two. Some contractors adopt a policy like “no bulk orders in final 10% of project without review” to curb excess.

- Find ways to reuse or reallocate leftovers: Despite best efforts, you’ll likely still have some surplus. The key is to make it not go to waste. One approach is to transfer usable leftovers to other projects. If your company has multiple projects running, that extra box of electrical fittings or gallon of paint might be just what another site needs next month. A centralized inventory system can help flag these opportunities (e.g., marking leftover items as available for redeployment). Additionally, consider donating or recycling materials that you can’t use – some organizations take unused construction materials for charitable building projects, which can give you a tax benefit and goodwill. Selling excess back to suppliers or on secondary markets is also an option for high-value items (even if at a discount). Anything is better than paying to haul perfectly good materials to a dump.

- Use inventory alerts for slow-moving stock: If you’re using software, set up alerts for items that aren’t being used as expected. For example, if you bought 100 units of something but haven’t used any in three months (and the project phase that needed them is almost done), that’s a sign you might have a surplus. Early identification allows you to cancel pending orders or return unopened stock if possible. Some suppliers will take back standard items if they’re still in sellable condition, especially if arranged not long after purchase.

- Engage in end-of-project inventory closeout planning: As you near project completion, assign someone to do a thorough inventory of all remaining materials and categorize them: needed for final tasks, transferable to other jobs, returnable, etc. This “closeout inventory review” ensures nothing falls through the cracks. It’s similar to how companies handle year-end inventory, but focused on project end. The outcome should be an action list (e.g., “Keep X and Y for touch-ups, send Z and W to next project, return A and B to vendor by next week”). This proactive wrap-up can significantly cut down waste.

Ultimately, reducing material waste is a win-win: it saves money and it’s better for the environment. By focusing on optimization and reuse, industrial construction firms can turn what used to be heaps of junk at project end into either cost recoveries or productive assets for the next job. Plus, a lean project that uses just what it needs (and no more) is a hallmark of efficient management and sustainability – something increasingly important in our industry.

Challenge 8: Adopting New Technology and Training the Team

We’d be remiss not to mention a human-centric challenge: even when the solutions to these inventory issues are known (like “use this great software” or “implement that new process”), getting a construction team to actually adopt them can be easier said than done. The construction industry has a reputation (sometimes unfairly generalized, but often true) for being slower to adopt new technology compared to other sectors. Many field personnel have been doing things a certain way for decades – say, keeping notes in a notebook or doing daily checklists on paper – and changing those habits requires effort. Resistance to change and lack of training can be a major barrier when implementing improved inventory management practices or systems.

You might introduce a fancy inventory app, but if half the team doesn’t use it properly (or at all), you won’t see the benefits. Or you roll out a new barcode system, but the barcode scanner sits on a shelf because nobody was comfortable with it or it’s seen as “too much work.” Additionally, without proper training, even well-intentioned staff might use a system incorrectly, leading to new errors (for instance, entering wrong data because they weren’t clear on the process). There’s also the issue of initial productivity dip – adopting any new tool or process has a learning curve, and construction schedules are unforgiving. If workers feel the new system slows them down at first, they might abandon it unless they see the long-term value.

How to solve it?

Successful adoption of inventory management improvements requires a mix of the right tool selection, good training, and change management. Here are some pointers:

- Choose user-friendly solutions: When selecting any new inventory management tool or software, prioritize ease of use. In the construction context, that often means the system should be intuitive, visual, and not require advanced tech skills. For example, a tool that has a simple mobile interface or a map-based visualization (rather than complex tables) can be more readily adopted by field crews who might be less tech-savvy. The less intimidating and more “just makes sense” the tool is, the easier it will be to get your team on board.

- Provide hands-on training (and retraining): Don’t just throw a new system at the team and expect them to figure it out. Conduct brief training sessions, ideally hands-on where they can practice, in how to use the new inventory process or device. Show practical examples relevant to their day: like “Here’s how you’d check out a tool using the new app” or “Watch how we receive a delivery in the system with a quick barcode scan.” People learn by doing – so if possible, train in a real or simulated jobsite environment. Additionally, offer refreshers or quick reference guides, since not everyone will remember everything from a one-time training. Make sure there is also support (an IT help line or a designated “power user” on site) to help colleagues when they stumble.

- Explain the “why” and show the benefits: Change is much easier to swallow when people understand why it’s necessary and what’s in it for them. Take time to communicate to the crew how these new inventory measures will actually make their lives easier: “If we all use this system, we’ll spend way less time hunting for stuff or waiting around, and more time getting work done (which means we go home on time and hit our bonuses).” Or, “This new process might seem extra work, but it will prevent those frustrating moments when a tool you need is missing.” Often, field teams will embrace a change if they see that management is investing to solve the pain points they’ve been complaining about (like never having the right part when needed). So connect the dots for them.

- Start small and build confidence: If you’re implementing a major change, you don’t have to deploy it 100% on all sites overnight. You might start with a pilot project or a single department to work out kinks and gather success stories. When others see that, for example, the crew on Project X cut their inventory costs and stress by using the new system, they’ll be more willing to try it too. Early wins create positive buzz. Also, identify champions – those tech-savvy or enthusiastic crew members who can advocate to their peers (“I’ve been using the barcode scanner, it’s actually pretty slick and saves me time”). Peer influence can be more effective than top-down orders.

- Make it part of the routine: Finally, ensure the new processes are integrated into daily routines and project workflows. If it’s treated as optional or an “extra task,” people will drop it when things get busy. Instead, build it in: e.g., daily inventory check updates as part of end-of-day duties, or the rule that “no tool leaves the yard without a scan.” When everyone sees it’s the new normal and not just a trial, it will become habit over time.

Bringing a construction team up to speed with new inventory management practices might take some effort, but it’s absolutely worth it. Once the crew sees that the tools work and actually reduce chaos on the job, they often wonder how they lived without them. The key is to support your team through the transition. Remember, the best system is one that people actually use. So invest in your team’s buy-in and skills – the returns will be a smoother-running operation with far fewer inventory headaches.

CyberStockroom: A Modern Solution for Industrial Construction Inventory Challenges

In discussing these challenges and solutions, we’ve frequently touched on the role of technology and good systems. One such modern solution worth highlighting is CyberStockroom – an inventory management platform designed with many of these construction-specific hurdles in mind.

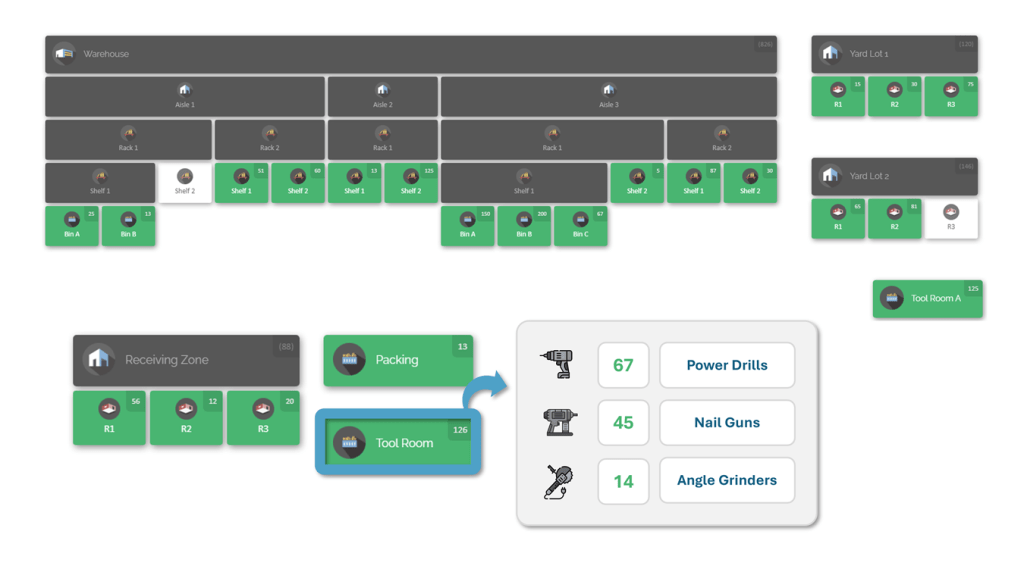

CyberStockroom takes a unique visual approach to managing inventory, using interactive maps to give you a bird’s-eye view of all your stuff across warehouses, laydown yards, and jobsites. Let’s take a look at how a tool like CyberStockroom can directly address the challenges we’ve listed:

- Visual Inventory Map for Full Visibility: CyberStockroom’s signature feature is its interactive inventory map. Instead of static lists, you get a customizable map of all your locations – whether it’s multiple project sites, storage yards, on-site containers, or even individual trucks. You can visually place inventory items on the map where they physically reside (e.g. Warehouse -> Aisle 4 -> Bin B, or Site Alpha -> Container 2 -> “Pipes Section”). This makes it immediately clear where everything is. For a manager dealing with multi-location chaos (Challenge 3), this is a game-changer. With a quick glance at the map, you can see, for example, that Site A has 20 steel beams and Site B has 5, and that a certain compressor is currently assigned to Truck #7 on the road. No more guesswork or calling around – the map puts all locations in one view.

- Real-Time Tracking and Updates (Cloud-Based): CyberStockroom is cloud-based and updates instantly as inventory moves or changes. Team members in the field or at the warehouse can use any internet-connected device (laptop, tablet, smartphone) to check items in or out, record a usage, or transfer items between locations. The system supports barcoding, so when, say, a pallet of cement is delivered, a quick scan can add it to inventory at the “Main Yard” location; when that pallet (or part of it) is sent to a jobsite, another scan transfers it on the map to “Site X”. These immediate updates help eliminate inaccurate data (addressing Challenge 1) because every transaction is captured in the moment rather than on a delay. It also means everyone sees the same up-to-date information (solving Challenge 6): if a crew member out in the field logs that they took 5 units of something, the office knows about it right away.

- Multi-Location Coordination Made Easy: Because the platform consolidates all locations, it inherently helps solve the multi-location management issue. But beyond just seeing where things are, CyberStockroom allows easy transfers and requests between sites. A site supervisor can literally drag-and-drop an item on the map from one location to another to indicate “I need this moved”, which the warehouse manager or logistics person can then act on. This level of coordination means less double purchasing and more reallocation of what you already have. It also accounts for mobile inventory – you can assign items to moving entities like trucks or crews. For example, if Crew #3 has a set of specialized tools assigned to them, the map will show those tools under Crew #3’s icon until they are returned or reassigned. This way, even “roaming” assets are tracked (addressing Challenges 3 and 6 together).

- Loss & Theft Prevention Features: CyberStockroom includes features specifically aimed at preventing loss. You can assign items to people or teams (just like checking out tools), and the system keeps an audit trail of who had what, when. If John checked out a laser level, the system will note that until it’s checked back in, so there’s clear responsibility. The map also timestamps moves and can be configured to alert if something odd happens (e.g., an item’s count drops unexpectedly or an expensive asset is moved outside a designated area). By maintaining this digital paper trail, it becomes much harder for items to simply vanish without notice – greatly addressing Challenge 4 (theft and loss). Many CyberStockroom users conduct quick inventory spot-checks using the system’s reports: if the software says 5 generators should be on Site Y and you only find 4 during a physical walk, you know exactly there’s an issue to investigate and you have a log of who last handled them.

- Ease of Use and Team Adoption: Knowing that adoption can be a hurdle (Challenge 8), CyberStockroom is designed to be intuitive and visual for end-users. The map interface tends to be more engaging and easier to grasp for folks who aren’t keen on spreadsheets. Drag-and-drop functionality (for moving items on the map) makes sense to anyone who can use a smartphone. The system doesn’t require extensive training or technical know-how – field crews often pick it up quickly because it mirrors the real world (you see a representation of your site or warehouse, and you interact with it). CyberStockroom’s team also offers onboarding support to help train your staff and get your inventory data imported, etc. The easier and more pain-free the tool is, the more likely your team will actually use it day in and day out, cementing those good inventory habits.

- Real-Life Scenario – How it all comes together: Imagine a typical day using CyberStockroom on a construction project. In the morning meeting, the site supervisor pulls up the inventory map on a tablet. They can instantly verify that all materials needed for today’s tasks are on site because the map shows, for instance, that the 8 rolls of insulation needed are already in the storage container on level 2. They also notice the map is showing only 2 HVAC filters left on site (and a little alert indicates that’s below the recommended level), so they quickly create a transfer request to get more from the central warehouse by tomorrow – preventing a work stoppage. Later in the day, a crew member needs a specific power drill but can’t find it in the tool crib; they check the map and see it’s actually marked as currently with Crew B on the third floor. A quick radio call to Crew B saves half an hour of searching. As work wraps up, tools are scanned back into the site’s storage, updating their status on the map so nothing gets left behind overnight. Meanwhile, the project manager at the office opens CyberStockroom and spots that Site X has a surplus of rebar coils (they finished a phase under budget) while Site Y will need rebar next week – so a reallocation is arranged in the system, shifting inventory to where it’s needed and avoiding a redundant purchase. Throughout the day, everyone was working off the same real-time inventory information, and a bunch of potential problems were averted by that visibility and coordination. This kind of smooth operation is exactly what CyberStockroom is built to enable.

While CyberStockroom is one solution, the broader point is this: the right inventory management software can be a game-changer for industrial construction projects. It brings together all the best practices we’ve discussed – real-time data, multi-site visibility, accountability, forecasting aids, theft prevention, and ease of use – into one coherent system. By leveraging a tool like this, construction professionals can transform inventory management from a constant headache into a streamlined, proactive process. It’s about working smarter, not harder: letting technology handle the heavy lifting of tracking and coordinating, so you and your team can focus on building and delivering successful projects.

Conclusion

Inventory management may not be the most glamorous part of industrial construction, but it is absolutely foundational to project success. As we’ve explored, the challenges are numerous: from simply keeping counts accurate and avoiding data errors, to predicting what materials you’ll need in a volatile environment, to juggling inventory across multiple jobsites and warehouses, protecting it from theft, navigating supply chain hiccups, reducing waste, and getting your whole team on board with better practices. These issues can plague any construction project, yet they are far from insurmountable.

The solutions boil down to a mix of smart process and smart tools. By implementing strategies like regular cycle counts, better forecasting methods, clear check-out systems, and contingency planning for supplies, you tackle the procedural side of things. By embracing technology – whether it’s a comprehensive platform like CyberStockroom or even simple steps like using barcode scanners and cloud-based spreadsheets – you empower your team with real-time information and automation that humans alone can’t achieve at scale. Crucially, fostering a culture that values inventory management (training your crew, communicating the benefits, and holding everyone accountable) ties it all together.

The payoff for overcoming these inventory challenges is huge. Projects stay on schedule because materials are where they need to be. Budgets are maintained (or improved) because you’re not bleeding cash on rush orders, lost items, or overstocked surpluses. Crews are more productive because they spend less time searching for stuff and more time installing it. And let’s not forget safety and quality – when the right tools and materials are on hand, work is done right and without dangerous makeshift solutions.

In the end, managing construction inventory effectively is about visibility, control, and foresight. Industrial construction projects have a lot of moving parts, but with the right approach, you can bring order to that chaos. By identifying these unique challenges and addressing them head-on with the strategies we discussed, your team can ensure that inventory issues never derail your project. Instead of reacting to problems, you’ll be preventing them – keeping your jobsites humming, your warehouses organized, and your projects profitable. That’s the power of good inventory management in construction: it turns a potential weak link into one of the strongest drivers of success. Now, it’s up to us as construction professionals to put these solutions into practice and build a future where missing materials and surprise shortages are a thing of the past. Happy building – with full shelves and clear plans ahead!

Leave a comment