Real-Time Tracking vs. Annual Counts – it’s a debate many warehouse managers and operations leaders face when evaluating their inventory audit practices. Should you stick with the traditional annual physical inventory count or embrace real-time inventory tracking for continuous accuracy?

In this comprehensive guide, we’ll compare these two approaches and show how modern methods (like cycle counting and real-time tools) are revolutionizing inventory audits. By the end, you’ll understand the benefits of each, how to implement real-time tracking in your operation, and why modernizing your inventory audits can be a game-changer for operational efficiency.

The Traditional Annual Inventory Count (and Its Challenges)

Most businesses are familiar with the annual inventory audit – that big once-a-year event where everything in the warehouse gets counted and reconciled. For decades, this annual physical count has been the standard way to ensure inventory records match reality. Typically scheduled at year-end or during a slow season, an annual count involves pausing normal operations, deploying staff (or hiring auditors) to count every last nut and bolt, and comparing those numbers against the books.

Why Annual Counts Exist?

Annual inventory audits originated from accounting needs and practical limitations. Companies need an accurate inventory valuation for financial statements and tax purposes at least once per year. Before digital tools, continuously tracking every stock movement in real time was impractical. So, businesses did a yearly “reset” by counting everything to catch errors like miscounts, shrinkage, or data entry mistakes that accumulated over the year.

How an Annual Audit Works?

In an annual count, the warehouse often has to shut down or severely limit operations for a day (or even several days) so that workers can focus on counting without new stock coming in or out. All items are counted, usually manually with pen-and-paper tallies or spreadsheets, then cross-checked against inventory records. Discrepancies are noted and investigated after the count. This process is labor-intensive: managers may bring in extra staff or pay overtime, and regular order processing or production might halt during the count.

While annual counts do provide a full snapshot of inventory, they come with significant challenges:

- Disruption to Operations: Halting shipping, receiving, and production to count inventory is costly. A day (or weekend) of downtime can delay orders and affect customers. The larger the operation, the bigger the disruption. Some companies try to conduct counts overnight or during holidays, but it still often means lost productivity.

- Labor-Intensive and Stressful: Counting an entire warehouse in one go is exhausting for staff. It often involves long hours of tedious work, which can lead to fatigue – and fatigued people make mistakes. Managers also face pressure to finish counts quickly to resume normal operations.

- Error-Prone Snapshots: Ironically, the massive effort of an annual count can still yield errors. Humans miscount or miss items, especially when rushing. If mistakes happen (e.g., two people count the same shelf differently), recounts are needed, further extending the process. And if the warehouse layout or labeling isn’t perfectly organized, items can be overlooked.

- Infrequent Corrections: Perhaps the biggest issue – you only get this comprehensive accuracy check once a year. Any discrepancies found mean that for some part of the past year your inventory records were wrong. Maybe items were stolen or lost months ago and you only discover it now. Maybe receiving mistakes in March led to stockouts in August that went unexplained until the annual audit revealed the record inaccuracies. An annual audit is like shining a light in a dark room infrequently; a lot of “unknown unknowns” can lurk in the interim.

- Financial Impact: Inventory variances discovered at year-end might require significant write-offs or adjustments. For example, if the count finds less stock on hand than recorded, the business takes a loss to adjust the books. These surprises can hurt financial results. Moreover, running without accurate inventory data for long stretches can lead to overstocking (tying up capital in stock you don’t actually need) or stockouts (losing sales or halting production because you thought you had materials that aren’t actually there).

Annual physical counts are a necessary evil in many organizations – necessary for accounting and basic control, but “evil” in the sense of being disruptive and reactive. They give a backward-looking report card on your inventory accuracy, often too late to fix operational problems caused by inaccuracies earlier in the year.

In today’s fast-paced environment, relying solely on a yearly inventory snapshot is increasingly seen as inadequate. Businesses need more frequent insight to meet customer demands and avoid costly mistakes. This is where real-time tracking and continuous inventory auditing practices come in, aiming to modernize inventory audits from a once-a-year ordeal to a seamless part of daily operations.

The Rise of Real-Time Inventory Tracking

Imagine knowing exactly what’s in your warehouse (or on your job sites) at any given moment – without having to shut down operations or do a marathon count. Real-time inventory tracking makes this possible. In a real-time tracking system (often called a perpetual inventory system), inventory records are updated continuously as transactions happen. Every time a part is used in production, a product is sold or shipped, or new stock arrives, the system immediately reflects that change in inventory levels. The result is an always up-to-date view of stock on hand.

How Real-Time Tracking Works?

Modern inventory management software and systems (often part of a Warehouse Management System or dedicated inventory platform) use technology to log inventory changes instantly. Common components of real-time inventory tracking include:

- Barcoding and Scanning: Each item or SKU is labeled with a barcode (or QR code/RFID tag). When items are received, moved, or issued, staff scan them with handheld scanners or mobile devices. The scan instantly adds or subtracts the item from inventory in the system. This way, every transaction (sale, transfer, use, return) is recorded in real time. For example, a warehouse picker scans a widget as he pulls it from shelf A for an order, and the system immediately knows one less widget is in shelf A.

- Integrated Software Systems: Many companies integrate inventory tracking with sales and purchasing. For instance, a point-of-sale (POS) system in a retail context will automatically adjust inventory levels when a sale is made. Similarly, when a purchase order is received and logged, inventory counts increase right away. These integrations ensure that as business events occur, inventory data doesn’t wait to be updated. In a manufacturing setting, a materials management system might deduct parts as they are issued to a work order.

- Cloud-Based, Real-Time Databases: With the cloud and sensor devices, inventory data can sync across multiple locations instantaneously. If you have several warehouses or stock across job sites, a cloud-based inventory system will update centrally. So if Warehouse A ships 10 items to Warehouse B and scans them out, Warehouse B can see those items scanned in (in transit or upon receipt) all in real time.

- Continuous Reconciliation: Real-time systems often have built-in checks to flag discrepancies as they occur. For example, if an item’s count goes negative (meaning more were shipped than recorded as in stock), the system can alert managers immediately. Alerts and dashboards provide a continuous “audit” of inventory health, highlighting issues like unusual usage patterns or low stock that needs restocking. Essentially, the system is always auditing itself.

Benefits of Real-Time Inventory Tracking

Embracing real-time tracking yields numerous advantages over periodic annual counts:

- Always Accurate Data: Because every transaction updates the records, your inventory database reflects reality (or very close to it) at all times. You don’t have year-long gaps where errors accumulate. This means day-to-day operations (sales, purchasing, production planning) can trust the inventory numbers. You can make informed decisions with confidence. For example, a production planner can see in real time if a critical component stock is low and reorder before it runs out – rather than discovering the shortage in an audit after production has already been delayed.

- Reduced Stockouts and Overstock: With up-to-date counts, companies avoid the common problem of thinking they have more stock than they actually do (which causes stockouts and disappointed customers), or the opposite, over-ordering because the system under-reported stock. Real-time visibility helps maintain optimal stock levels, improving fulfillment rates and reducing excess inventory carrying costs.

- Early Detection of Discrepancies: If something goes missing or an error is made, a real-time system will catch it much sooner. For instance, if an item is stolen from inventory, the next cycle count or transaction involving that item will flag a discrepancy, prompting an investigation. You’re not waiting months to discover the theft or mistake. This early detection helps clamp down on problems like theft, fraud, or process errors, minimizing their impact.

- Continuous Auditing (Peace of Mind): Essentially, real-time tracking turns inventory auditing from a once-yearly scramble into a continuous process. Every day, every transaction is a mini-audit verifying that “what just happened” aligns with the records. Managers can run reports any time to see accuracy metrics. By the time you do need an official audit (say for end-of-year financials), there should be far fewer surprises – it’s mostly confirming what you already know.

- Less Operational Disruption: Unlike a full physical count requiring downtime, real-time tracking operates in the flow of normal work. Workers scan items as part of their picking or stocking tasks; software quietly updates counts in the background. There’s no need to halt everything for a grand count. Operations keep humming, and inventory stays accurate in parallel.

- Labor Efficiency: While setting up a real-time tracking system takes effort (we’ll discuss implementation later), day-to-day it can actually reduce labor. Scanning an item into stock or out to a shipment is quick – quicker and more accurate than writing on a count sheet. There is less need for large teams to do remedial counting sessions, because small corrections happen continuously. Employees spend more time moving and managing stock, and less time double-checking or searching for errors.

- Better Visibility and Decision Making: Real-time inventory data provides valuable insights. Managers can monitor trends like how quickly certain items turn over, which locations use inventory fastest, or which items often show discrepancies. With such visibility, you can optimize warehouse layout (for example, placing fast-moving goods in easier-to-pick locations), adjust reordering strategies, or preempt problems (like identifying a pattern of damage or loss in a certain area). In short, real-time tracking informs smarter decisions up and down the supply chain.

- Customer Satisfaction and Responsiveness: In industries like retail and e-commerce (and increasingly in B2B as well), customers expect accurate stock information and quick delivery. Real-time inventory systems enable features like up-to-the-minute online stock levels (preventing selling something you don’t actually have) and efficient fulfillment (since you know exactly where an item is when an order comes in). Even in manufacturing or construction, having real-time stock info means less downtime waiting for parts, which translates to projects staying on schedule and clients being served on time.

It’s important to note that adopting real-time tracking doesn’t necessarily eliminate the need for physical counts entirely. Many organizations still perform a periodic audit (quarterly or annually) as a fail-safe or for compliance with accounting standards. However, when you have a robust real-time system, those counts become far easier and mostly confirmatory. Instead of discovering thousands of discrepancies, you’re fine-tuning minor variances. Essentially, the heavy lifting of accuracy is done proactively throughout the year, rather than reactively in one big push.

Cycle Counting: The Bridge Between Annual and Real-Time Audits

In discussing real-time tracking vs. annual counts, we have to talk about cycle counting. Cycle counting is a practice that often accompanies real-time inventory systems and serves as a bridge between continuous tracking and formal audits. It’s one of the key techniques for modernizing inventory audits.

What is Cycle Counting?

Cycle counting is a strategy where you count a subset of your inventory on a regular, rotating schedule, instead of counting everything at once. For example, instead of one yearly count of 10,000 items, you might count 200 different items every week on a rolling basis. Over time (say quarterly or annually), you’ve counted all items, but in manageable chunks. Cycle counts are usually done daily, weekly, or monthly, depending on the size of inventory and resources.

Key characteristics of cycle counting:

- You focus on a portion of inventory each time (e.g., by location, by product category, or by highest value items).

- Counts are done more frequently (continuous throughout the year).

- Regular operations can continue around the counting (you might cordon off one aisle to count, rather than shutting the whole warehouse).

- It leverages the 80/20 rule often: Many businesses use ABC analysis – counting “A” items (high value or fast-moving) very frequently, “B” items regularly, and “C” items (low value or slow-moving) less often. This ensures critical items are audited more often for accuracy.

- Each cycle count is effectively a mini-audit. Discrepancies found can be immediately corrected in the system and, more importantly, investigated to find root causes.

Cycle counting shines in companies that use a perpetual inventory system (continuous updates). The system might indicate which items to count on a given day based on last count date or known risk factors. Workers then count those items (often still using barcode scanners or mobile devices) to verify that the physical count matches the system count. If there’s a mismatch, the system can prompt an adjustment and log it, and a manager can look into why it happened (e.g., was there an unrecorded transaction, theft, or a receiving error?).

Benefits of Cycle Counting vs. Annual Counts

- Less Disruption: Because you’re only counting small sections at a time, you rarely need to shut down operations. You might schedule cycle counts during slow periods of the day or have one staff member counting while others continue regular work. No more all-hands-on-deck shutdown days – cycle counts are part of normal routine.

- Ongoing Accuracy Improvements: Cycle counts greatly improve accuracy by catching errors throughout the year. If an item is miscounted or misplaced, you likely catch it within weeks rather than at year-end. This continuous correction keeps your inventory records tight. Many companies find that with diligent cycle counting, their inventory accuracy can exceed 95–99%, compared to maybe 70–85% accuracy when they only did annual counts and let errors accumulate.

- Reduced Errors and Shrinkage: When you count smaller batches of inventory, people tend to make fewer mistakes versus a marathon count of everything. It’s easier to concentrate on 50 items in one aisle than 5,000 items in a warehouse at once. Also, by counting more often, you identify and correct the sources of error (like a certain item consistently off, indicating maybe a packaging issue or a training issue with how it’s being logged). If theft is occurring, frequent counts of high-value items will alert you before huge losses accrue. Essentially, cycle counting acts as an early-warning system for inventory problems.

- Timelier Data for Purchasing & Planning: With parts of your inventory being verified regularly, your purchasing team can trust that those records are accurate when reordering. For example, if a cycle count shows that widget A is actually lower in stock than thought, you can replenish now, not discover the shortfall later when fulfilling an order. This means fewer emergency rush orders or production surprises.

- Less Year-End Pressure: Come year-end or audit time, if you’ve been cycle counting, you may not need to do a full count at all. Or if you do (perhaps due to a financial audit requirement), it’s much quicker and smoother because your counts are mostly right. It might just be a validation step instead of a discovery mission. Staff won’t dread the annual inventory day as much (if it even exists) because there are no huge unknowns – you’ve been keeping up all along.

- Better Resource Allocation: Cycle counting spreads the workload throughout the year. You might dedicate an hour a day or a couple of hours a week to counting, which is easier to fit in than trying to pull off a 16-hour counting marathon. It uses resources more evenly and avoids that big spike of labor cost and overtime for an annual count.

- Audit and Compliance Benefits: Many businesses still need an annual count for auditors or regulators. If you can show that you maintain inventory accuracy via regular cycle counts (with documented adjustments and audit trails), auditors are often impressed by the robust controls. It demonstrates proactive inventory management. Some businesses in fact only do cycle counts and forego a traditional annual stocktake, because the continuous records suffice for their accountants (though requirements vary by jurisdiction and company policy). Even if an external audit requires a year-end verification, your cycle count records make that process more straightforward.

In practice, cycle counting and real-time tracking go hand in hand. Real-time systems make cycle counting easier (since you’re scanning items anyway, a cycle count might just be scanning a few items and comparing to the system count). Conversely, cycle counting ensures the real-time system stays accurate (as it catches any transactions that might have been missed or any drift in data). Together, they form a modern approach to inventory auditing: always on, always improving.

To illustrate, think of annual vs. cycle counting like maintaining a car: Annual counting is like taking your car for service once a year and discovering a bunch of issues to fix; cycle counting is like doing small check-ups and maintenance regularly so the car stays in good condition continuously. The latter prevents breakdowns; the former might leave you stranded if you ignore things until that one service appointment.

Real-Time vs. Annual Counts: A Side-by-Side Comparison

Let’s distill the differences between an annual inventory count approach and a real-time (perpetual) inventory tracking approach. Both aim to keep inventory records accurate, but they do so in fundamentally different ways.

Here’s a quick comparison of key factors:

| Category | Annual Count | Real-Time Tracking |

|---|---|---|

| Frequency of Counts | Once a year (or at best, a few times a year) full physical inventory. | Continuous updates with every transaction; supplemental cycle counts regularly (daily/weekly) for verification. |

| Data Accuracy | Inventory records can drift over time and might be inaccurate for months until the next count. You get a snapshot of accuracy only on count day. | Inventory records are accurate in near real-time. Discrepancies are corrected quickly, maintaining consistent accuracy. |

| Operational Impact | High disruption. Operations may stop or slow down. Often requires off-hours or shutdown periods. | Minimal disruption. Counting is integrated into daily workflows and done in small sections without halting operations. |

| Labor & Resource Use | Intense labor needed during count period. Possible overtime and temp workers. Repetitive tasks increase risk of errors. | Labor spread over time. Staff integrate scanning/counting into normal duties. Less stressful, more efficient, and fewer errors. |

| Timing of Error Detection | Errors and theft may go unnoticed for months. Detection is reactive—often too late. | Issues are detected quickly and corrected as they happen. Enables a proactive, preventative approach. |

| Technology Requirements | Can be performed manually with spreadsheets or pen and paper. Barcode scanners can help but aren’t required. | Requires tech infrastructure—inventory software, barcode/RFID, scanners. Needs upfront investment and training but brings automation and real-time visibility. |

| Cost Considerations | May seem cheaper upfront due to low tech use, but hidden costs include lost productivity, potential revenue loss, and major inventory write-offs. | Ongoing investment in systems and tools, but gains efficiency, reduces emergency fixes, and avoids overstocking. Long-term savings often outweigh initial costs. |

| Scalability | Difficult to scale. As operations grow, counts take longer and become more complex and disruptive. | Highly scalable. New SKUs, locations, and warehouses integrate smoothly. Real-time systems provide unified enterprise-wide visibility without increasing operational burden. |

In summary, annual counts provide a static picture, whereas real-time tracking offers a dynamic movie of your inventory. The static picture can be out-of-date and costly to produce, while the dynamic movie, once set up, keeps you informed and agile.

For modern warehouse managers – especially in sectors like industrial manufacturing and construction where projects move fast and delays are expensive – the ability to see and trust your inventory status in real time is incredibly valuable. It transforms inventory from a source of uncertainty (and yearly headaches) into a well-controlled asset that actively supports the business’s efficiency and goals.

Technology’s Role in Modernizing Inventory Audits

Making the leap from annual counts to real-time tracking wouldn’t be possible without technology. If you’re considering modernizing your inventory audit process, understanding the tools and tech that enable this is key. Here’s how technology underpins real-time inventory management and continuous auditing:

- Inventory Management Software (IMS/WMS): At the heart of real-time tracking is robust software. This could be a dedicated Inventory Management System or a module within a broader ERP/Warehouse Management System. The software acts as the central brain, recording all transactions, storing the data, and often providing user-friendly interfaces (like dashboards or maps) to visualize inventory. Modern systems are cloud-based, meaning your data syncs in real time and is accessible anywhere. They often include features like user permissions (controlling who can adjust inventory), automated alerts (for low stock or discrepancies), and reporting tools (for audit trails, usage history, etc.). When evaluating software, look for one that supports multi-location tracking, barcoding, and real-time updates (not all inventory software is truly real-time – some cheaper solutions still function like glorified ledgers that require manual updates).

- Barcoding and QR Codes: These are the workhorses of real-time inventory tracking. Assigning a unique barcode or QR code to every product (and often to every location, shelf, or bin) allows quick scanning. Scanning is much faster and far more accurate than manually typing SKU numbers or counting without aid. With barcodes, a warehouse associate can scan an item and instantly update quantity as they add or remove it from stock. Barcoding systems involve printing labels and using barcode scanner devices (which can range from dedicated industrial scanners to smartphone apps, depending on the system). QR codes can encode more info or be used for location tags that link to the inventory system. The end result is reducing human error – the system knows exactly which item and how many were moved with each scan.

- RFID (Radio-Frequency Identification): RFID takes scanning a step further by allowing multiple items to be detected and updated without line-of-sight. RFID tags on products can be read by an RFID reader as items pass through a doorway or are near a scanner, updating counts automatically. This technology can dramatically speed up counts (some retailers use RFID to count an entire store’s inventory in minutes by simply walking around with a reader wand). However, RFID is more expensive and complex to implement than basic barcodes, so it’s often used for high-value goods or very large operations that need rapid counting. In manufacturing and construction, RFID might be used for tracking expensive tools or components.

- Sensors and Automation: In some cutting-edge operations, sensor devices track inventory movement. For example, weight sensors on bins can report stock levels (e.g., a bin of bolts on an assembly line signals when it’s running low). Automated guided vehicles (AGVs) or conveyor systems might automatically log items as they move. Drones have even been tested to fly through warehouses and scan inventory on shelves! While these advanced technologies might not be mainstream yet for all warehouses, they are part of the future of real-time inventory auditing – essentially automating not just the record-keeping but the actual counting process continuously.

- Mobile Access and Apps: Modern inventory platforms usually offer mobile applications or web portals that work on tablets and smartphones. This is crucial for real-time use on the warehouse floor or out at field locations. A mobile interface lets workers log transactions on the spot – for instance, a field technician can record using a part at a job site through a mobile app, updating central inventory records immediately. Or a warehouse cycle counter can walk to a bin, count it, and input any corrections on a tablet, all in real time. Mobile access makes the system much more flexible and ensures data gets captured at the point of activity. (Note: Even if a platform doesn’t have a native mobile app, cloud-based systems can usually be accessed via a mobile web browser. The key is being able to use it on portable devices easily.)

- Integrations (Systems Talking to Each Other): Real-time accuracy is amplified when your inventory system connects with other systems: e.g., your purchasing system, sales order system, manufacturing system, etc. If a sales order entry automatically deducts inventory or a production system logs parts usage directly to inventory, it removes the delay and double-entry that could cause errors. For example, integrating inventory software with an e-commerce platform means when a product sells online, the inventory is instantly decremented, preventing overselling. In a construction context, integrating an inventory system with project management software might automatically reserve materials for a project when scheduled, so inventory reflects what’s truly available vs. allocated. While full integration might require APIs or built-in connectors (which some inventory platforms provide), even simple import/export of data regularly can help keep systems in sync. The ultimate goal is one source of truth for inventory that all processes feed into or draw from.

- Reporting and Analytics: Modern tools provide far better reporting than a manual count can. You can generate inventory audit reports that detail all adjustments made, all transactions, who performed them, and when. This creates accountability (deterring theft, since you can trace issues to individuals) and makes external audits easier (you can show auditors a log of every inventory movement). Analytics can identify patterns – like “shrinkage rate by month” or “most frequently adjusted items” – which help target areas for improvement. These insights are something you simply don’t get from an annual count beyond a yes/no of was it right or not.

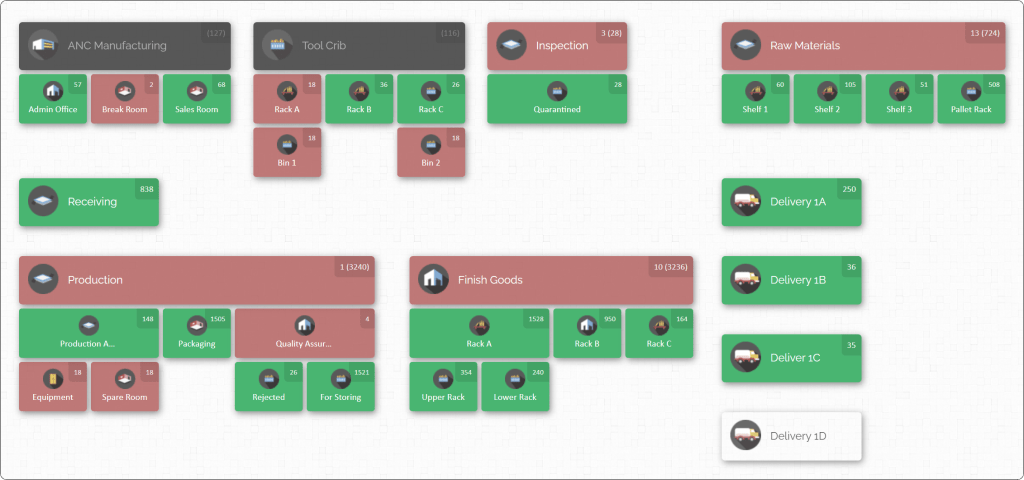

- Visual Mapping: A unique and user-friendly innovation in some modern inventory systems (like CyberStockroom, which we’ll discuss next) is visual inventory mapping. This means representing your warehouse or storage locations on a digital map so you can literally see where items are in a graphical layout. It might sound cosmetic, but visual maps greatly enhance understanding and speed. A warehouse manager can glance at a map and see stock levels in different rooms or bins (often color-coded or with quantities displayed) without reading through long location lists. For multi-site operations, mapping can show an overview of inventory across all sites on one screen. This visual approach simplifies the audit process too – you can virtually “walk through” your warehouse via the map to verify everything is where it should be. It’s much more intuitive than scrolling through rows on a spreadsheet, and it helps pinpoint discrepancies (e.g., an empty spot on a shelf pops out visually).

- Security and Control: As you modernize, controlling access and tracking changes becomes vital. Good systems allow setting user roles (so not everyone can, say, delete inventory records or make adjustments without approval). Every change in inventory should be recorded with a user and timestamp (an audit trail). If an item count is adjusted, you know who did it and why. These controls prevent unauthorized “fixing” of numbers and make audits trustworthy. Compare this to a paper count sheet where someone could easily pencil-whip a number to make it reconcile without anyone knowing – modern systems leave a trail for accountability.

Overall, technology turns inventory auditing from a brute-force manual task into an integrated, automated part of operations. It shifts the emphasis from counting to managing. Instead of spending time counting products, your team spends time investigating the occasional discrepancy and continuously improving processes. The tech handles the repetitive parts, and humans handle the exceptions and strategy.

However, it’s not all or nothing – adopting technology can be gradual. Some businesses start by using mobile scanners and software for their annual counts to ease the pain, then evolve into doing cycle counts, and eventually reach a fully real-time integrated system. The key is to identify which tools will address your biggest pain points (be it errors, theft, or inefficiency) and make a plan to implement them.

Next, let’s look at a specific modern solution as an example of how technology facilitates real-time inventory audits and management.

CyberStockroom: Bringing Inventory Audits into Real-Time

As warehouse managers and operations leaders consider moving to real-time inventory tracking, choosing the right software platform is crucial. CyberStockroom is one such modern tool that exemplifies how technology can make inventory management intuitive, visual, and real-time – ultimately simplifying audits and boosting efficiency. In this section, we’ll discuss CyberStockroom’s approach and features, and how they directly address the challenges of annual counts with a fresh, innovative solution.

What is CyberStockroom?

CyberStockroom is a cloud-based inventory management software with a unique twist: it uses an interactive inventory map as the interface for managing and tracking stock. Instead of just tables or lists of items, CyberStockroom lets you build a visual map of all your locations (warehouses, stockrooms, job sites, trucks, storage bins – whatever your business uses) and then place inventory items within that map.

This visual-first approach helps you literally see what you have and where it is, in real time. For industries like industrial manufacturing and construction, which often have inventory spread across multiple sites or moving between warehouses and job locations, this map view provides instant clarity that a spreadsheet can’t match.

Real-Time Visibility Across Locations: One of CyberStockroom’s core benefits is real-time inventory visibility. The software updates stock levels immediately as you perform transactions (like adding incoming inventory, moving items from one location to another, or checking out items for use). For example, a construction company using CyberStockroom can track materials and tools across all active job sites and the central warehouse. If a power drill is moved from the main warehouse to Job Site A, a simple drag-and-drop on the map (or a quick barcode scan and transfer action) will update its new location on the map instantly. Managers can glance at the dashboard and see current counts at each site without making calls or waiting for nightly reports. This effectively eliminates the guesswork and lag that often plague annual inventory systems. Audit readiness becomes a constant state – at any time, you can verify what you have.

Interactive Inventory Map (Visual Auditing): CyberStockroom’s map isn’t just a pretty picture; it’s a working dashboard. Each location icon or area on the map is clickable to show what’s inside. If you click the “Warehouse” on your map, you might see it break down into sub-locations like Aisle 1, Aisle 2, or Mezzanine, and further into shelves or bins, each with item counts. It’s like a digital twin of your physical storage. This visual hierarchy makes it easy to conduct spot audits. Say you want to audit Aisle 1 today – you can physically go to Aisle 1, count a few items, and compare to what the map shows for those items. If something is off, you update it on the spot. The map interface also makes training new staff easier – they can understand the layout quickly and see the context of inventory, rather than dealing with cryptic location codes in a database.

Drag & Drop Transfers and Updates: A standout feature relevant to efficient inventory audits is CyberStockroom’s drag-and-drop functionality. Need to move 50 units of Part X from Warehouse to a Field Truck? Simply drag the icon of Part X from the Warehouse on the map and drop it onto the Truck location. The system will prompt for quantity and complete the transfer, updating counts in both places immediately. This quick method encourages employees to record movements as they happen (because it’s so easy), instead of postponing updates or forgetting. That means your records stay accurate in real time, and any audit process sees the truth. Also, performing cycle counts is straightforward: if you want to adjust a count for a bin, you locate that bin on the map, count the actual items, and then update the quantity field for that bin in CyberStockroom. The system logs that adjustment (with time and user stamp), serving as an audit trail.

Barcode Scanning Support: While the interface allows manual updates, CyberStockroom also integrates barcoding for even faster operations. You can use barcode scanners or even a smartphone to scan product barcodes and do things like check items in or out, or add to a location. For example, if you’re issuing components to the manufacturing floor, scanning each component’s barcode into a “Production” location on the map will decrement stock in the main warehouse. These scans update the map in real time. During audit checks, scanning can be used to quickly verify inventory. CyberStockroom supports printing barcode labels for products and locations, so everything can be coded. This brings the speed and accuracy of scanning into your inventory audits – no more manual tally sheets.

Multi-User, Cloud-Based Collaboration: Because CyberStockroom is cloud-based, your whole team can work together in it simultaneously from anywhere. Warehouse staff might be updating counts in the warehouse, while project managers at a job site are checking material availability on their tablets, and a procurement officer at HQ is watching inventory levels to reorder supplies – all at the same time, all seeing the same up-to-date data. For auditing, this means different teams could be counting different sites or sections concurrently, all feeding into one system. You don’t have to consolidate spreadsheets from each site; CyberStockroom becomes the single source of truth. Plus, managers can monitor the activity via the cloud – if someone makes an adjustment or transfer, it’s logged and visible immediately. This greatly enhances accountability. If an auditor or supervisor wants to review inventory activity, they can pull up the activity history log and see every transaction (who moved what, when). This kind of visibility is invaluable compared to an annual count where you might know something is off but have no clue when it happened or who last touched it.

Loss and Theft Prevention (Audit Trail): Speaking of activity history – CyberStockroom includes robust audit tools to combat shrinkage. Every inventory movement recorded is stored in an activity history, which can be filtered by user, date, location, or action type. If an item goes missing, you can quickly check the history to see the last recorded movement of that item (e.g., “User Jane transferred 5 units from Main Warehouse to Van 3 on July 10”). This audit trail helps identify if it was a procedural error or potential theft. Knowing that everything is tracked also acts as a deterrent to intentional mischief. Traditional annual counts might tell you something is gone, but not when or how. CyberStockroom gives you the timeline, which is a modern approach to inventory auditing – continuous surveillance of stock integrity. In other words, inventory control isn’t just about knowing quantities, but also knowing the chain of custody, and CyberStockroom provides that.

Tailored for Operations Efficiency: For the target audience (warehouse managers in manufacturing/construction), CyberStockroom has features that directly improve operational efficiency:

- Job Site & Mobile Inventory Management: You can map not only fixed warehouses but also mobile units (like construction trailers, service trucks, or tool cribs in the field). Tracking inventory in these moving or temporary locations in real time is a huge benefit. Instead of waiting for each crew to report back tool usage weekly (or worse, finding out at project end that several drills are missing), central managers see field inventory status instantly. CyberStockroom even allows assigning items to people or teams, so accountability is clear. This reduces loss and ensures critical equipment is where it’s needed. In effect, it turns what might have been an occasional “field inventory audit” (chasing down who has what equipment) into a smooth daily process.

- Preventing Project Delays: By giving real-time visibility, CyberStockroom helps avoid project slowdowns. For example, if a construction site is running low on a certain material, the manager sees that and can transfer or reorder before it halts work. In an annual count regime, the site might have run out unknowingly until someone physically checks, causing a scramble. The software can be a proactive tool for keeping projects on schedule.

- Ease of Use and Adoption: A fancy system is only as good as its adoption by the team. CyberStockroom’s conversational, visual interface reduces training time. Warehouse crews and field workers don’t need deep technical skills to use it – if you can recognize locations on a map and click or drag icons, you can use the system. This is important because a system that’s too complex often gets bypassed, leading to inaccurate data. CyberStockroom’s design encourages usage, which in turn means inventory data stays complete and accurate. The tone of the software (and the company, from its help guides) is professional but approachable, which aligns with how the blog should come across – not heavy jargon, but clear benefits.

- Job Site & Mobile Inventory Management: You can map not only fixed warehouses but also mobile units (like construction trailers, service trucks, or tool cribs in the field). Tracking inventory in these moving or temporary locations in real time is a huge benefit. Instead of waiting for each crew to report back tool usage weekly (or worse, finding out at project end that several drills are missing), central managers see field inventory status instantly. CyberStockroom even allows assigning items to people or teams, so accountability is clear. This reduces loss and ensures critical equipment is where it’s needed. In effect, it turns what might have been an occasional “field inventory audit” (chasing down who has what equipment) into a smooth daily process.

No More “Spreadsheet Shuffle”: To illustrate the contrast: many manufacturing and construction companies still use Excel or manual methods for inventory. Perhaps they have a yearly stocktake and then try to update their spreadsheets, only for the data to become stale a month later when parts start moving around. With CyberStockroom, the spreadsheet phase is eliminated. Instead of juggling rows and columns, managers see a living map. Updates are not an occasional painful project, but a natural part of daily work. This shift dramatically cuts down time spent on inventory admin. One CyberStockroom user in a case study noted they saved hours each week that used to be spent reconciling inventory lists, and they drastically reduced instances of missing equipment across job sites.

In summary, CyberStockroom serves as a prime example of how modern software can enable the transition from annual counts to real-time tracking:

- It provides real-time updates, so your inventory audit is essentially happening every second.

- It offers an audit trail and history, replacing blind spots with accountability.

- It simplifies cycle counting and adjustments through intuitive design, making it easy to maintain accuracy continuously.

- It caters to multiple locations and moving inventory, which is critical for industries like construction and multi-warehouse manufacturing.

- It focuses on operational efficiency and ease of use, ensuring that the system actually gets used consistently (which is half the battle in inventory management).

By leveraging a tool like CyberStockroom, companies can modernize their inventory audits practically overnight. The dreaded annual inventory day can become a thing of the past, replaced by ongoing, low-stress inventory management that keeps the business running smoothly year-round.

Implementing Real-Time Tracking (How to Modernize Your Inventory Audits)

Transitioning from a traditional annual count approach to a modern real-time system is a significant change, but it’s absolutely achievable with a structured plan.

Here are some how-to tips and best practices for implementing real-time inventory tracking and continuous auditing in your organization:

- Assess Your Current Process and Pain Points: Start by identifying exactly what makes your current inventory audits painful or inefficient. Is it the downtime during counts? Frequent discrepancies? Lack of visibility between counts? High shrinkage? Understanding the biggest pain points will help prioritize what to tackle first and what features to look for in a system (e.g., if theft is a big issue, focus on audit trail and accountability features; if multi-location confusion is a problem, focus on a system with strong multi-site support).

- Get Buy-In from Stakeholders: Modernizing inventory management often requires investing in technology and changing people’s routines. Secure support from management by building the case: highlight the costs of the current approach (lay out any losses from inaccuracies, labor costs of annual counts, customer impacts, etc.) and the expected benefits (efficiency, cost savings, improved service). Also get buy-in from the warehouse and field teams by involving them early – explain how it will make their jobs easier (less firefighting when stock is wrong, less drudgery in long counts, etc.). People are more likely to embrace changes when they see personal benefits, like not having to stay until midnight counting pallets once a year!

- Choose the Right Inventory System: Research and select an inventory management software that fits your business size and needs. Key features to look for for real-time auditing include: real-time updating (perpetual inventory capability), barcode/RFID support, multi-location tracking, user-friendly interface (maps or visual cues help), robust reporting and audit trails, and cloud accessibility. Consider solutions like CyberStockroom (with its visual map and real-time ethos) or other proven WMS/IMS systems. If possible, take advantage of free trials or demos – load some of your data and see how it works in practice. Ensure it can handle your industry specifics (e.g., does it handle batch/lot numbers if you need that, or tool/equipment assignment if that’s relevant?).

- Inventory Data Setup and Cleanup: Before going live, you’ll need to input your existing inventory data into the new system. This is a great opportunity to clean up data. For example, standardize your item naming/SKU conventions, eliminate obsolete items, and validate current stock levels. It might involve a one-time full count to establish a baseline if your records are currently unreliable (think of it as the last “big count” you’ll ever do, to start the new system on the right foot). Many systems allow importing data from spreadsheets to speed up initial setup. Also map out your locations in the system (create the digital map or hierarchy of your warehouse and sites). Doing this groundwork ensures a smooth start with accurate data.

- Implement Barcoding (or Improve Labeling): If you’re not already using barcodes, now is the time. Decide on a labeling scheme for your products and locations. You might print barcode labels for every shelf/bin and every product type. Invest in a couple of good scanners (wired or wireless). Train staff on scanning items in/out. If you already have barcodes (e.g., manufacturer barcodes on products), your chosen system should be able to use those to identify items. Test scanning workflows to make sure they integrate with the software properly. A small pilot in one area of the warehouse can help iron out kinks.

- Start with a Pilot (if applicable): It can be wise to roll out the new process in a limited scope initially – for example, one department, one location, or one category of items – before scaling up to the whole operation. This way, you can troubleshoot issues, adjust configuration, and build confidence. During the pilot, closely monitor inventory accuracy. Compare what the system says vs. what’s physically there frequently, and address any differences immediately to find out what caused them. This tight feedback loop will help refine processes (maybe staff need more training on recording certain transactions, or maybe you’ll discover a particular workflow that needs adjusting).

- Train Your Team: Proper training is critical. Even the best system will fail if people don’t use it correctly. Provide hands-on training sessions for all users – warehouse staff, stockroom clerks, site managers, anyone who interacts with inventory. Training should cover how to perform daily transactions (receiving stock, issuing stock, moving items, etc.) in the new system, how to do cycle counts or adjustments when needed, and how to interpret the system’s data (like reading the inventory map or dashboards). Emphasize the “why” as well – explain to the team how these new practices make everyone’s life easier in the long run (less chaos, fewer urgent searches for missing items, etc.). Get feedback and questions; often the people on the ground will have insight into how to best integrate the system into the workflow.

- Establish New Standard Operating Procedures (SOPs): To truly modernize your inventory audits, you need to bake the new practices into daily operations. Develop clear SOPs that outline how inventory transactions are handled. For example: “All shipments received must be logged in the system by end of day with barcode scanning,” or “If any stock is moved from one site to another, it must be recorded via the system before departure,” or “Cycle counts will be performed every Friday on 5 SKUs in each category and results logged.” Make these procedures part of everyone’s responsibilities. Over time, following these SOPs will create a culture where real-time inventory maintenance is second nature.

- Implement a Cycle Counting Program: Even with real-time tracking, plan for regular cycle counts to verify and maintain accuracy. Use the system’s features to schedule or randomly prompt counts. For instance, you might decide that every item gets a physical verification at least once a quarter. The system can generate a count list or you can manually set one up. Assign those counts to team members as a routine task. When discrepancies are found, investigate immediately: Was it a transactional mistake, theft, or an operational issue? Fix the record and address the root cause (e.g., retrain staff on proper scanning, or improve security for high-value items, etc.). The goal is to continuously tighten the accuracy so that cycle count discrepancies shrink over time.

- Monitor Performance and Adjust: After implementation, keep an eye on key metrics. Inventory accuracy percentage is one (e.g., what fraction of items counted match the system exactly?). Also look at metrics like frequency of stockouts, amount of emergency orders, shrinkage value, and the labor hours spent on inventory tasks. Ideally, you’ll see accuracy go up and the negatives go down. Share these wins with the team – it’s motivating to see improvement. But if something isn’t improving (say, discrepancies persist in a certain area), use the system’s data to diagnose it. Maybe that area has a process gap or someone needs more training or there’s an underlying issue (like a supplier consistently short-shipping items). Real-time tracking will surface these issues, but it’s up to you to act on them. Be ready to tweak procedures or provide refresher training as needed. Modernizing is an ongoing journey, not a one-time switch to flip.

- Maintain System Discipline: Over the long term, consistency is key. Avoid falling back into bad habits, like allowing “ghost” transactions (items moving without being recorded). One way to enforce this is by periodic audits – for example, a manager can randomly pick a few items each month and verify counts and activity logs, essentially auditing the system’s use. If any discrepancies are found, have a policy to follow up. Holding everyone accountable to using the system properly will ensure the accuracy remains high. Remember, the technology is a tool, but it’s human adherence that truly modernizes the audit process.

- Leverage Insights for Efficiency Gains: Once the real-time system is stable, use the rich data it provides to optimize operations. Perhaps you discover certain slow-moving inventory that could be reduced to free up space (because now you have clear visibility into inventory turnover). Or you might identify that one location always seems to run short and could use a larger par level. Maybe the data shows a pattern of discrepancies at a certain time of day – indicating a process gap in a shift handover. Modern inventory systems can yield such insights via reports and even AI-driven analysis. By acting on these insights, you can achieve leaner inventory, faster throughput, and better overall efficiency, which is the ultimate aim of the content pillar (Operations Efficiency).

Implementing real-time tracking and cycle counting does require effort and change management, but businesses that have done it often say they could never go back. It transforms inventory from a periodic headache into a well-managed, transparent part of operations.

If you’re in industrial manufacturing or construction, modernizing inventory audits can also give you a competitive edge. You’ll be more agile in responding to project needs or production changes, and you’ll likely save money by reducing surplus stock and avoiding project delays. Plus, consider the peace of mind: knowing that you always have a handle on your inventory means one less major worry on your plate.

Conclusion: Embrace Continuous Inventory Auditing for Efficiency and Peace of Mind

The bottom line is clear – real-time inventory tracking and continuous auditing methods are rapidly making annual counts obsolete in forward-thinking organizations. In the battle of Real-Time Tracking vs. Annual Counts, the scales tip heavily in favor of real-time for most scenarios. By modernizing your inventory audit process, you’re not just adopting a new tool, you’re fostering a proactive culture of accuracy and efficiency.

Let’s recap the key takeaways:

- Annual inventory audits, while traditional and sometimes necessary for financial reasons, come with high costs: operational downtime, intense labor, and the risk of prolonged inaccuracies. They provide a backward-looking snapshot and often reveal problems only after they’ve impacted the business.

- Real-time inventory tracking offers a living, breathing picture of stock levels. With each transaction recorded as it happens, your inventory data stays current. This approach, especially when paired with cycle counting, means inventory accuracy becomes a continuous attribute of your operations, not an annual project. The result is fewer surprises, lower shrinkage, and better decision-making throughout the year.

- Cycle counting is a powerful practice that spreads out the work of auditing and embeds it into daily/weekly routines. It significantly reduces errors and operational disruption, acting as the glue that holds a perpetual inventory system together. If annual counts are like cramming for a test, cycle counts are like regular studying – much healthier and more effective.

- Technology is the enabler of modern inventory audits. Tools like CyberStockroom illustrate how features such as visual mapping, instant updates, barcode scanning, and comprehensive audit logs can simplify what used to be complicated. Investing in a good system and integrating it into your processes pays off in accuracy, efficiency, and time savings. In today’s digital age, even industries that once relied on clipboards and year-end reconciliations (like construction sites or manufacturing shop floors) are seeing the value of going digital and real-time.

- Operational efficiency gains are a major reward of modernizing your inventory approach. When your inventory is accurate and visible, you prevent the costly ripple effects of bad data: production stoppages, emergency shipping of parts, lost sales, or overstocked warehouses eating up capital. Instead, you run leaner and respond faster. Warehouse managers can allocate labor better (no more all-weekend counts), and teams can focus on value-adding activities rather than constant firefighting of inventory issues.

- Improved morale and accountability: Though it might not be as quantifiable, there’s a morale boost when a previously dreaded task (the annual inventory count) becomes a non-issue. Your staff no longer has to dread the year-end chaos; instead, inventory control is just part of the daily rhythm. Furthermore, with clear records of who handled what inventory when, accountability improves. Team members take inventory movements more seriously when they know it’s tracked, which further boosts accuracy and care.

For warehouse managers and operations professionals in industrial manufacturing, construction, or any field dealing with significant inventory, the message is: don’t wait for the pain of the next annual audit to make a change. The tools and techniques for real-time inventory management are mature and accessible. Transitioning to them can start small and grow, but the key is to start. Each step toward real-time tracking – be it introducing cycle counts or implementing a new software – will yield improvements.

Modernizing inventory audits is like upgrading from a paper map to GPS navigation. The old paper map (annual count) works, but it’s static and requires you to do a lot of work to figure out where you are. GPS (real-time tracking) gives you live updates, redirects you when there’s an obstacle (discrepancy), and generally makes the journey smoother. Once you’ve experienced it, you wonder how you managed before.

In conclusion, embracing real-time inventory tracking and continuous audit practices is an investment in the resilience and efficiency of your operations. It reduces risk, saves time, and provides confidence that you know the state of your inventory at all times. Whether you’re keeping a manufacturing line fed with parts or ensuring a construction site has all the materials it needs, having accurate inventory information in real time is crucial to delivering on schedule and on budget. By leaving behind the once-a-year audit mindset and adopting a culture of continuous inventory awareness, you’re better equipped to adapt in a competitive and fast-moving business environment.

So, take the step to modernize: explore the technology, involve your team, and turn inventory audits from a yearly headache into a daily strength. Your future self – and your bottom line – will thank you.

Leave a comment