In modern industrial operations, knowing exactly what you have and where it’s located is no longer a luxury—it’s a necessity. Poor inventory visibility leads to problems like lost parts, surprise stockouts, production delays, and bloated carrying costs. In fact, nearly half of businesses cite inventory management as their top day-to-day challenge. The solution? Adopting inventory visibility best practices that make your operations more transparent, efficient, and responsive.

An effective inventory visibility strategy empowers warehouse managers and supply chain executives to make fast, informed decisions. Imagine being able to instantly pinpoint a critical component’s location or see stock levels at all sites with a glance. In this post, we’ll explore the top 10 best practices to achieve that level of clarity and control over your inventory. These practices blend technology and process improvements to ensure you always have the answer to the key question: “How many of what do we have, and where is it?”

1. Centralize Inventory Information with a Unified System

The foundation of inventory visibility is a single source of truth. Centralize all inventory data by using a unified inventory management system (IMS) or warehouse management system (WMS) that spans your entire operation. Instead of traditional spreadsheets or separate databases at each site, consolidate information so that every product, part, or material is tracked in one platform. This unified approach means that when a shipment arrives or a part is used on the production line, the system updates immediately and all stakeholders see the same data.

A cloud-based inventory system is especially powerful for industrial operations spread across multiple locations. It allows real-time inventory visibility from anywhere.

For example, a supply chain executive can check stock levels across regional warehouses in one dashboard, while a warehouse manager on-site updates counts via a mobile device. When all locations and departments log inventory movements in one system, you eliminate blind spots. This prevents scenarios like one warehouse overstocking because it didn’t know another facility had surplus. Centralizing data ensures that everyone from procurement to fulfillment, makes decisions based on accurate, up-to-date inventory information.

2. Use Real-Time Tracking Technology

Inventory data is only as good as the speed and accuracy with which it’s updated. Implement real-time tracking technologies to automatically capture inventory movements and status changes. Barcodes and QR codes are ubiquitous tools: workers can scan items during receiving, transfers, and shipping, instantly updating quantities in the system. This reduces manual data entry errors and ensures stock levels reflect reality throughout the day.

For even greater automation, many industrial operations turn to RFID (Radio Frequency Identification) tags. RFID tags on pallets or high-value items enable you to record movements without direct line-of-sight scanning — a reader can detect all tagged items moving through a doorway or zone. This is invaluable for busy warehouses or yard environments where scanning each item individually isn’t feasible. Additionally, Sensors and GPS trackers can extend visibility to assets in transit or stored in remote sites.

The table below highlights a few technologies and how each improves inventory visibility:

| Technology | How It Improves Inventory Visibility |

|---|---|

| Barcode/QR codes | Enables quick, accurate scanning of items at each touchpoint (receiving, picking, shipping), ensuring immediate updates to stock records. |

| RFID tagging | Allows automatic, bulk identification of items as they move through checkpoints, providing live location data without manual scanning. |

| Sensors and GPS trackers | Monitors inventory conditions and locations in real time (e.g. GPS on containers, temperature/humidity sensors for sensitive goods), extending visibility beyond the warehouse. |

Real-time tracking creates a continuous flow of inventory data. The moment a pallet moves or a part is consumed, the system updates accordingly. This immediacy is crucial for preventing discrepancies and keeping operations running smoothly.

3. Standardize Labeling and Processes

Technology alone won’t solve inventory visibility if your identification and processes are chaotic. Standardize how you label inventory and manage it across the organization. That means every product should have a unique identifier (SKU or part number) and barcode, and every storage location (racks, bins, rooms, vehicles) should also be clearly labeled. When locations have identifiers, workers can scan “from” and “to” locations during moves, so the system always knows exactly where an item resides.

Equally important is establishing standard operating procedures for all inventory transactions. Define a clear process for receiving goods, moving them into storage, picking for orders or production, and shipping out. For instance, your receiving procedure might dictate that each delivery is checked against purchase orders, barcoded, and entered into the system before it goes on the shelf. Standardizing this ensures nothing skips the tracking system. Likewise, require that any time an item is moved or used, the change is recorded immediately via the system (using mobile scanners or terminals).

Consistency is key. When all team members follow the same playbook, you prevent lapses where inventory “falls off the radar” due to a missed scan or a handwritten note that never gets digitized. Standard labels and processes also make training easier and operations more scalable. New employees or temporary workers can quickly learn how to identify items and update inventory because the method is uniform throughout the facility (and even across facilities). In short, make inventory management a disciplined routine — every item, every movement, every time.

4. Conduct Routine Cycle Counts and Audits

Even with the best systems, inventory accuracy can drift over time due to losses, misplacements, or entry errors. That’s why performing regular cycle counts is a best practice to maintain visibility. Cycle counting means counting a subset of your inventory on a rotating schedule rather than doing a rare full warehouse count. For example, you might count a different product category or storage area each week such that you cover all items over a month or quarter. By cycling through continuous mini-audits, discrepancies are caught early and corrected in the system.

Establish a cycle count program that prioritizes your most valuable or fastest-moving items for more frequent counts (an ABC inventory approach). Team members should compare the system’s recorded quantity versus the physical count and investigate any mismatch immediately. Is there a procedural gap that led to the error (e.g. items not scanned during a rush)? Solving these root causes helps prevent repeat issues.

In addition to cycle counts, schedule periodic full audits of critical locations or before peak seasons. Regular auditing boosts confidence that the “digital twin” of your inventory (what’s in the software) truly reflects the physical reality on the warehouse floor. This accuracy is foundational for visibility — it’s not enough to see data in real time if that data is wrong. When your counts are reliable, managers and automated systems alike can trust the inventory information to make decisions, from reordering stock to committing to a customer’s order. Accurate inventory is visible inventory.

5. Visualize Inventory with Maps and Dashboards

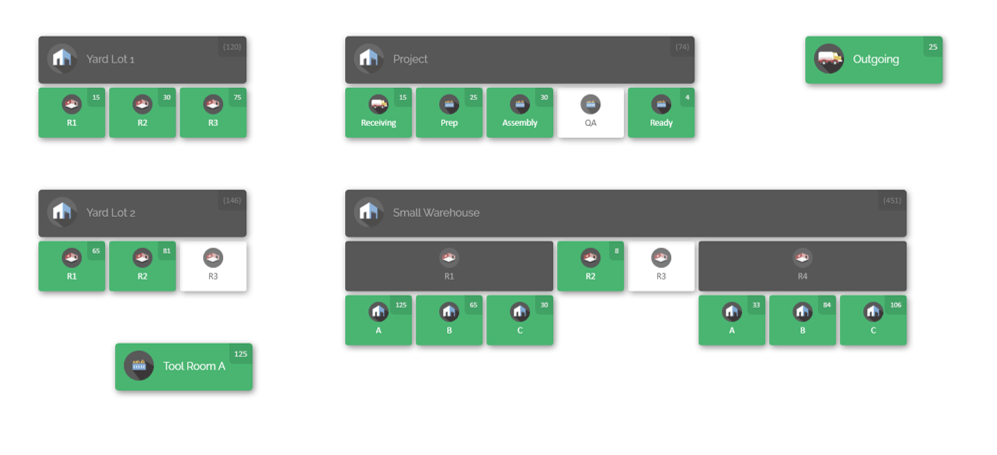

It’s much easier to grasp your inventory situation when you can see it rather than just read rows on a spreadsheet. Implement tools that visualize inventory data, such as a map-based inventory dashboard or interactive floor plan of your facilities. A visual inventory map gives you a bird’s-eye view of stock across all areas — you can glance at an on-screen layout of your warehouse or plant and immediately spot where items are located and how many are there.

For example, an interactive map could show your facility divided into zones (receiving, storage, production, etc.) with color-coded indicators for inventory levels. Clicking a specific room or bin reveals which products are there and in what quantity. This kind of visual dashboard makes it easy for teams to find what they need and quickly spot discrepancies.

Many modern inventory management solutions offer customizable dashboards, and some (like CyberStockroom) specialize in map-based inventory management. These visuals help bridge the gap between digital data and the physical layout of your operation. Instead of paging through reports, managers can literally see the state of the warehouse in real time, which greatly speeds up decision-making. When evaluating tools, look for those that allow floor plan mapping or at least rich visual reporting. An investment in visualization is an investment in clarity — one glance can convey what might take dozens of spreadsheet lines to understand.

CyberStockroom: A Map-Based Solution for Inventory Visibility

In the midst of these best practices, it’s worth highlighting how technology can tie them together. CyberStockroom is a prime example of an inventory management platform built to enhance visibility through a unique map-based approach. It allows businesses to create a digital twin of their operations, mapping out every warehouse, stockroom, truck, or yard as locations on a visual dashboard. This means that rather than sifting through lists, you can navigate an intuitive map to see where items are and how many are at each spot.

CyberStockroom centralizes your inventory data in the cloud and supports real-time updates via barcode scanning or RFID. Its user-friendly drag-and-drop interface makes following standard inventory procedures easy — you can literally drag an item from one location to another on the screen, and the system records the transfer.

At the heart of CyberStockroom is the visual inventory map. It provides a clear picture of your operations — a manager can zoom into a zone on the map and immediately see what’s on each shelf or in each room, and how much is there. If something’s running low, it stands out at a glance so you know to restock or investigate. The map is fully customizable to mirror your actual layout and locations, whether you operate one site or many around the globe.

Because it’s cloud-based, everyone on your team — from floor staff to executives — can access the same live inventory map on any device. This keeps all departments on the same page with up-to-date information. CyberStockroom also offers built-in reports and alerts linked to the map, helping you proactively manage low stock or other exceptions. In short, adopting the right tool like CyberStockroom can supercharge your inventory visibility efforts, turning these best practices into everyday routine.

6. Integrate Inventory Data Across the Supply Chain

Inventory visibility shouldn’t end at your warehouse door. To truly optimize, make sure your inventory systems integrate with other systems and partners across your supply chain. Within your organization, this means connecting your inventory management or WMS with your purchasing/procurement system, order management or ERP, and sales platforms. When these systems talk to each other, you gain end-to-end visibility: you can see inbound supply in transit, current stock on hand, and outbound demand in one coherent flow of information.

For example, integrating with suppliers allows you to track raw materials from the moment they ship out. Likewise, linking your WMS with customer order systems lets you see which products are already committed to orders versus truly available. If your company runs multiple warehouses or plants, make sure they all feed data into the central system so you can view multi-location inventory in one place. This prevents one facility from scrambling for stock while another location has a surplus.Integration isn’t limited to your four walls. It can extend to logistics and in-transit inventory by connecting to shipping and tracking systems, giving you visibility into stock that’s on the move.

The ultimate goal is a seamless flow of inventory information from supplier to customer — true end-to-end visibility. While achieving this may require some IT investment and partner collaboration, the payoff is huge: fewer surprises, faster responses to disruptions, and a more agile supply chain.

7. Leverage Data Analytics and Forecasting

Having a lot of inventory data is great, but using that data effectively is what sets leading operations apart. Leverage analytics to extract insights and forecast future needs, which directly improves visibility by making it predictive rather than just reactive. Some crucial ones include inventory accuracy and order fill rate. Tracking these KPIs over time highlights trends and problem areas.

For example, if your inventory accuracy is slipping, there might be process errors to correct. If an important item’s fill rate is low, you may need to adjust forecasts or stock levels to better meet demand. Modern inventory systems provide many reports by default, and you can also export data to business intelligence tools for deeper analysis. The insights gained will inform smarter planning — you can adjust reorder points, relocate stock, or take other actions based on real patterns, not guesswork.

The table below highlights a few key metrics and why each matters for inventory visibility:

| Metric | Why It Matters |

|---|---|

| Inventory Accuracy (% matching records) | Reflects the reliability of your data. High accuracy means the system’s stock records match reality, enabling sound decisions. |

| Order Fill Rate (% orders fulfilled from stock) | A high fill rate means you’re meeting customer demand from stock. A low fill rate suggests frequent stockouts or forecasting issues. |

By pairing vigilant analysis with forecasting, you turn visibility from a static snapshot into a dynamic foresight tool. Instead of only knowing where things are now, you’ll anticipate where they will be needed and adjust proactively. In this way, your inventory stays aligned with business needs, and you experience far fewer surprises in operations.

8. Train and Empower Your Team

The best processes and tools won’t deliver results if the people using them aren’t on board. Training staff and fostering an inventory-conscious culture is a fundamental best practice. Start with comprehensive training on any inventory system, scanners, or devices your team will use. Warehouse operatives should know, for example, how to properly receive and barcode new stock, how to execute transfers in the system, and the importance of timing (e.g. not letting a pallet get shelved without scanning it in). Periodic refresher courses can help reinforce these practices.

Beyond the technical know-how, emphasize to employees why inventory visibility matters. When staff understand that accurate inventory data prevents over-ordering, rush freight, or line stoppages, they will follow procedures more diligently. Encourage a sense of ownership among staff: empower them to flag issues (e.g. a bin missing a barcode label or a discrepancy found during counting) and suggest improvements. Often, the people working with inventory daily have valuable insights into where visibility might be breaking down.

You can also assign specific accountability, such as an “inventory champion” on each shift or in each department who helps ensure processes are followed. Recognize and reward good practices, like a quarter with high inventory accuracy or zero missing items. By building a culture of accuracy and accountability, you ensure that the technology and processes (practices 1–7) are executed correctly. In summary, well-trained and engaged employees are the glue that holds your inventory visibility strategy together.

9. Set Reorder Points and Automated Alerts

Proactive management is a key part of visibility. One proven practice is to set clear reorder points for your key items. A reorder point is a stock level that triggers replenishment. For example, if you set a reorder point of 100 units for a component, the system can flag or auto-create a purchase order when inventory dips to that level. These triggers give you visibility into low-stock situations before they turn into stockouts.

In tandem with reorder points, use automated alerts to stay on top of critical inventory changes. You can set up notifications for scenarios like:

- An item’s quantity dropping below its safety stock level (time to expedite a restock).

- Inventory exceeding a maximum level (potential overstock or receiving error).

- (Removed bullet: expiration date alert, as needed)

- (Removed bullet: dead stock alert, as needed)

Alerts act as extra eyes and ears for your inventory. Rather than discovering a stockout when it’s too late, you’ll be notified at the critical moment and can act in time. In essence, accurate data combined with well-configured alerts and reorder points keeps your operations running smoothly — production lines stay supplied and customer orders get filled because you were proactive instead of reactive.

10. Continuously Review and Improve

Industrial operations are dynamic, and continuous improvement should be the mantra for inventory visibility. What works for your warehouse today might need refinement tomorrow as product lines change, volumes grow, or new technologies emerge. Regularly review your inventory processes, tools, and performance metrics to find areas for improvement. Consider a quarterly inventory review meeting to go over KPIs and any incidents (like stockouts or discrepancies). If certain patterns emerge — say a particular item often shows count errors — you can pinpoint the cause and take corrective action (such as adjusting a process or providing extra training).

Stay aware of new technologies and methods in supply chain management. For example, solutions like drones for counting inventory or AI-based forecasting are emerging. Evaluate any innovation with a critical eye: will it solve a visibility pain point or boost efficiency for your operation? Adopting the right new tool — say a mobile RFID scanner or an advanced analytics platform — can keep your approach cutting-edge.

Finally, involve your team in this improvement loop. Front-line employees often have practical suggestions to streamline workflows or enhance system use. Remember, improvement is not a one-time project but an ongoing mindset. By continuously fine-tuning your inventory practices, you ensure they evolve with your business as it grows and changes. The most adaptable organizations respond faster to market changes, avoid compounding errors, and maintain a consistently efficient operation.

Conclusion

Achieving top-notch inventory visibility is an ongoing journey, but the benefits are well worth the effort. By implementing these best practices — from centralizing data and leveraging real-time tech to training your team and visualizing stock — you build a system where every part, product, or pallet is accounted for. The payoff is smoother operations, lower costs, and the agility to meet demand without last-minute scrambling.

For warehouse managers and supply chain executives alike, one thing is clear: investing in visibility is investing in efficiency and reliability. When you know how many of each item you have and exactly where it is, you remove uncertainty from daily work. Stockouts and lost items become rare, because you can catch issues early and even capitalize on shifting demand when opportunities arise.

In today’s era of complex supply chains and high customer expectations, mastering inventory visibility isn’t just good practice — it’s a competitive necessity. By following the steps outlined above and leveraging modern tools (like CyberStockroom’s map-based platform) to fit your operation, you can turn inventory management from a constant challenge into a strategic advantage for your business.

Leave a comment