Imagine this: You’re a manufacturing operations manager gearing up for the dreaded annual stock check. Production grinds to a halt, teams spend days (or nights) combing through every bin and shelf, and everyone’s stressed—armed with clipboards, barcode scanners, and a truckload of coffee. Sound familiar? If you’re an inventory specialist or operations director, you know exactly what this scenario feels like. The yearly physical inventory count has long been seen as a necessary evil to ensure inventory accuracy for financial records and planning.

But what if there’s a better way to keep track of stock without the chaos and downtime? Enter cycle counting: a smarter, leaner approach to inventory control that is rapidly replacing those massive annual stocktakes. Cycle counting in manufacturing involves counting small sections of inventory on a rotating schedule throughout the year, instead of doing one big stock audit at year-end. It’s like breaking a monumental task into bite-sized pieces. This method offers a stocktaking alternative that promises to maintain high inventory accuracy continuously without bringing your factory or warehouse to a standstill.

Cycle Counting vs. Annual Stock Checks: Which is Right for You?

Let’s get one thing straight: the goal of any inventory counting method is to achieve accurate stock figures. How you get there—either through an annual physical inventory or through continuous cycle counts, can make a world of difference in your day-to-day operations.

To understand why more manufacturers are shifting to cycle counting, let’s compare these two approaches head-to-head on several key factors.

What’s the basic difference?

An Annual Stock check (a.k.a. annual physical inventory count or stocktake) means pausing normal operations once a year to count everything in the warehouse or stockroom. It provides a comprehensive snapshot of inventory at that point in time, often for financial reporting or auditing. However, it’s labor-intensive and often requires overtime or full shutdowns.

Cycle Counting, on the other hand, is a repeated process of counting select subsets of inventory on a rotating schedule (daily, weekly, etc.) without stopping operations. Instead of one big bang, you’re continuously auditing your inventory in small chunks.

Both methods aim for inventory accuracy, but their impacts on efficiency, business continuity, and cost differ drastically. Below, we break down the comparison in terms of efficiency, accuracy, operational disruption, and cost.

Efficiency: Small Bites vs. Big Feasts

When it comes to efficiency, cycle counting follows the philosophy of “less is more, done often.” Annual stock checks are like throwing a huge feast—you need a ton of preparation, a big team, and you’ll likely feel “stuffed” (exhausted) afterwards. In contrast, cycle counts are like having small, frequent meals—much easier to digest.

- Annual Stock Check Efficiency: Once-a-year counts consume massive effort in a short burst. Think of the planning: weeks of preparation, labeling, and organizing inventory beforehand. Then the count itself might take an entire day or weekend of concentrated work. Because it’s such a heavy lift, people often rush to get it done, which can lead to mistakes or corners cut. After the big count, there’s typically a scramble to reconcile differences and update records. For a few weeks, you might breathe easier knowing the numbers are updated—but that feeling doesn’t last long as normal operations resume and the data begins to drift again.

- Cycle Counting Efficiency: Cycle counting spreads the workload out. Instead of 100% of inventory in one go, you might count 2% of your inventory every day (or some manageable chunk periodically). Over a month or quarter, you’ve covered everything with far less stress on any given day. This continuous approach is inherently more efficient in terms of labor management: you can use one or two people for short counting sessions integrated into their regular shift, rather than mobilizing your entire staff for a marathon count. Also, by focusing on smaller sets of items, counters can be more thorough and attentive, catching errors on the spot. It’s the difference between trying to sprint a marathon versus doing daily jogs—you maintain a steady pace without burning out. In lean manufacturing inventory control, this kind of steady, incremental work is preferred because it eliminates the waste associated with big batch processes (like overtime hours and shutdowns for annual counts).

Accuracy: Continuous Correction vs. Annual Surprises

Accuracy is the name of the game in inventory management. If annual counts are a one-time report card, cycle counting is like continuous homework that keeps you prepared.

- Annual Stock Check Accuracy: Right after an annual count, your records are likely very accurate—possibly the most accurate they’ll be all year. That’s a plus for annual stocktakes: they reset the system to “true” stock levels (identifying discrepancies that accumulated over the year). However, consider what happens between those annual events. Twelve months is a long time in a busy factory or warehouse. Errors, misplacements, and shrinkage (loss/theft) can quietly build up. By the time you do your next yearly count, you might uncover some nasty surprises: significant variances that have been impacting production or order fulfillment without anyone realizing the extent. In short, accuracy under the annual system tends to be peaks and valleys—high right after the count, then gradually degrading until the next big check.

- Cycle Counting Accuracy: Cycle counting keeps the accuracy dial turned up consistently. Because you’re auditing sections of inventory regularly, errors get caught and corrected much sooner. For example, if a certain part or material is off, you might catch it within days or weeks rather than a year later. This continuous correction means your inventory records stay much closer to reality all the time. Over the long run, companies that implement cycle counts often see their overall inventory accuracy improve dramatically. There’s even a ripple effect: knowing that counts happen frequently tends to make staff more mindful in their daily inventory handling (since any mistakes will be noticed relatively soon). The bottom line is you avoid the huge year-end reconciliations because discrepancies never get the chance to snowball. Many organizations report that after adopting cycle counting, they maintain accuracy rates of 95–99% throughout the year, rather than a brief spike to 100% after an annual count followed by a decline.

Disruption: Keeping the Lines Running

In manufacturing, time is money—downtime is the enemy. This might be where cycle counting shines the brightest in comparison to annual stock checks.

- Annual Stock Check Disruption: An annual physical inventory often requires either a slowdown or full stop in operations. You might schedule it over a holiday or weekend to minimize the impact, but it’s still a disruption. Production lines might need to empty out material and halt, warehouse shipping might pause, and all hands are diverted to counting tasks. This disruption can result in delayed orders, idle machines, and an operational headache. For many businesses, the cost of shutting down for a day or two goes beyond just paying people to count—it’s lost production, late shipments, and general frustration. It’s a bit like stopping a busy highway to count all the cars; everything behind you comes to a standstill. And if any issues are found (say a critical component count is way off), you might then scramble to adjust production plans or expedite purchases after the fact, compounding the disruption.

- Cycle Counting Disruption (or Lack Thereof): Cycle counting integrates into business-as-usual with minimal fuss. Instead of a giant roadblock once a year, you’re doing rolling lane closures that hardly slow the traffic. A well-planned cycle count program checks inventory in small sections at times that won’t interfere with production. For instance, you could schedule a daily count of one shelf or one product category early in the morning or during a shift change. Operations continue around these micro-counts. There’s no need to halt all shipping or manufacturing—only the specific items or area being counted is momentarily paused. This means no large-scale stoppages. The rest of the facility can keep humming, with most people barely noticing that “inventory auditing” is happening in the background. This continuous flow approach aligns with lean practices by avoiding the waste of large-scale downtime. Your team maintains momentum, and you can say goodbye to the dread of planning that big count day each year.

Cost: Overtime vs. Ongoing Investment

Every manager has an eye on the budget, so how do these methods compare in terms of cost?

- Annual Stock Check Costs: At first glance, doing one inventory count a year might seem cost-effective—you’re only devoting resources once. However, annual counts often carry hidden (and not-so-hidden) costs. Obvious ones include overtime pay (since counts often happen after hours or on weekends) and possibly hiring temporary workers to help. Then consider the cost of stopping production or halting order fulfillment: lost revenue from downtime can be substantial. Additionally, big variances discovered late might have already caused financial impact (e.g., stockouts leading to missed sales, or excess stock tying up capital) that went unaddressed for months. And if mistakes are made during the rushed big count, there could be costs in correcting inventory records or expediting emergency orders to cover stock discrepancies.

- Cycle Counting Costs: Cycle counting is more of an ongoing operational expense, but one that usually turns out lower overall. You might dedicate a small fraction of staff time each week to counting tasks. There’s some training involved, and possibly investment in tools (like barcode scanners or software if you don’t already have them) to facilitate the process. But you largely avoid the huge spikes in cost associated with the annual event. There’s no need for an army of counters on overtime or a crew of temporary workers. Moreover, by catching issues early, cycle counts help prevent cost surprises. For example, if you find a discrepancy in raw materials inventory via a cycle count, you can correct it and avoid an unexpected production stoppage down the line (which would cost a lot more). Many companies find that the continuous approach saves money in the long run by smoothing out labor costs and preventing the inefficiencies and errors that accumulate between yearly counts. Plus, the improved accuracy can reduce safety stock levels (since you can trust your numbers more), directly saving on inventory carrying costs.

For medium to large manufacturers or any operation where inventory is complex and critical, cycle counting tends to win out across these categories. It provides a path to leaner inventory management: continuous improvement, less waste (time and effort), and more reliable data. That said, implementing cycle counting does require planning and the right tools. Speaking of tools, let’s talk about how technology can turbocharge your cycle counting efforts—specifically, how CyberStockroom’s unique features align with the benefits we just discussed.

CyberStockroom’s Inventory Map: A Lean Machine for Cycle Counters

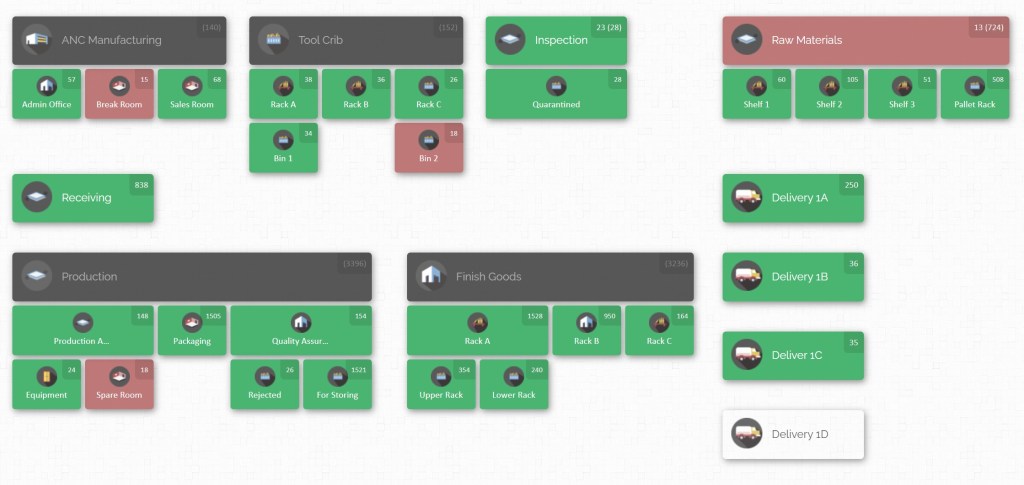

Every new process benefits from the right technology, and cycle counting is no exception. CyberStockroom is an inventory management platform designed to enhance visibility and ease-of-use—two things that make cycle counting much easier. Its flagship feature is the Inventory Map we previewed above, and it brings a visual, intuitive twist to managing stock.

Here’s how CyberStockroom supports a cycle counting program:

- A Visual Inventory: Just as GPS in your car helps you navigate to a destination efficiently, CyberStockroom’s visual map helps your team navigate inventory counts. When it’s time to cycle count, you can easily identify which area or item to count next by looking at the map. For instance, suppose you plan to cycle count all “A” category items (high-value or fast-moving stock) this week. With the map, you can see exactly where those items are located in the facility. This eliminates wasted time wandering around or searching through spreadsheets to figure out what to count and where. It also helps divide counting tasks logically (e.g., count one room or one shelf at a time) because you have a clear picture of your storage layout.

- Real-Time Data Updates: CyberStockroom’s system updates inventory data in real time. When you conduct a cycle count and enter adjustments (say you expected 50 units but counted 48, so you correct it), the system immediately reflects that change across the platform. This real-time inventory tracking is crucial for maintaining accuracy. It means that other departments—purchasing, production planning, sales—are always looking at up-to-date numbers. You’re essentially performing continuous inventory verification, reducing the reliance on any annual physical inventory. The benefit is twofold: you catch discrepancies instantly and your whole team trusts the inventory data at any given moment.

- Barcode Scanning Integration: Counting is faster and less error-prone with barcode scanners, especially when you have thousands of parts. CyberStockroom integrates with barcode scanning devices, so your team can scan item labels or locations during cycle counts for instant identification and quantity entry. This ties in with the real-time updates—scan the location, scan the product, enter the count, and the database updates on the spot. The result: quicker counts and fewer manual entry mistakes.

- Activity Logs and Reporting: Remember we mentioned how cycle counting catches discrepancies early? CyberStockroom enhances this by maintaining detailed activity logs and reports. Every adjustment made from a cycle count is recorded. You can run reports to see trends, like which items frequently show variances or which locations often have count issues. This insight is incredibly valuable for continuous improvement. It might reveal, for instance, that a certain component stored in Area B often has shortages—prompting you to investigate (maybe there’s unrecorded usage or a theft issue). With robust reporting, you turn cycle counts from a purely corrective measure into a preventive strategy, strengthening overall inventory control.

CyberStockroom acts as a force multiplier for cycle counting. It embodies the principles of lean manufacturing inventory control by making inventory information visual, immediate, and actionable. Instead of cycle counting in a vacuum, you have a holistic view of your operations.

The Inventory Map and related tools ensure that when you decide to ditch the annual stock check in favor of cycle counts, you’re not doing it with pen-and-paper in the dark—you’re doing it with a real-time map and intelligent software guiding the way.

Next, let’s shift from “why” and “with what” to “how.” How can you successfully implement cycle counting in a manufacturing environment? The following section provides a step-by-step guide to get you started on the right foot.

How to Implement Cycle Counting in Manufacturing (Step-by-Step Guide)

Switching from annual counts to cycle counting is a strategic move, but it won’t happen overnight. It requires a bit of planning, training, and process adjustment. The good news is that many have done it before, and there are proven best practices to follow. Here’s a straightforward roadmap to implementing a cycle count program in your manufacturing operation:

- Set the Foundation with a Baseline Count: Before you begin regular cycle counts, ensure your starting inventory records are accurate. Ideally, perform one last comprehensive inventory check (yes, possibly an “annual” count or a one-time full audit) to correct any major discrepancies. This baseline gives you a clean slate. If a full count isn’t feasible, at least audit your most critical items. The goal is to kick off cycle counting with confidence that your data is reasonably trustworthy. It’s much easier to maintain accuracy than to attain it, so start from as solid a point as possible.

- Categorize Inventory (ABC Analysis): Not all items are equal. Divide your inventory into categories based on importance, usage, or value. A common approach is ABC classification: “A” items are high-value or high-turnover goods (the top 20% that account for the bulk of value or movement), “B” are moderate, and “C” are low-value or slow-moving items. This categorization helps you prioritize. Plan to count “A” items most frequently (e.g., weekly or bi-weekly), “B” items regularly (maybe monthly), and “C” items less often (perhaps quarterly). This way, you’re focusing efforts where inaccuracies would hurt the most. In a manufacturing context, your “A” items might include key raw materials or fasteners that would halt production if missing, whereas “C” items might be rarely used MRO supplies. ABC analysis ensures your cycle counting program is risk-based and efficient.

- Develop a Cycle Count Schedule: Create a schedule that covers who, what, and when for counting. Decide how many items or locations you’ll count in a given interval. For example, you might schedule a small count each workday (which over a month would cover your whole inventory). Assign responsible persons or teams for each count. Many companies schedule counts by day or shift—perhaps one category per day, or one warehouse zone per week. The key is consistency; treat these counts as non-negotiable routine tasks. Using a calendar or your inventory system’s scheduling feature (like CyberStockroom’s reminders) helps keep everyone on track. Also, plan around your production cycle: avoid counting a particular area when it’s super busy. Coordinate with production supervisors so that, say, you count the assembly line stock after the day’s production, not during a rush.

- Train Your Team and Set Procedures: Cycle counting should be part of your standard work, so everyone involved needs to know the drill. Train your inventory staff (or anyone who will perform counts) on the proper procedures. This includes how to count accurately (e.g., handling package quantities correctly—if five bolts come in a pack, does that count as 1 or 5 units?), how to use the tools (like scanning devices or software to enter counts), and what steps to take if numbers don’t match. It’s also important to communicate why cycle counting is being adopted, to get buy-in. Explain to your team and other departments that this will lead to fewer fire drills and more reliable inventory for everyone. When people understand the benefit (like “we won’t have to shut down for two days at year-end anymore!”), they’re more likely to support the new process. Also, establish clear on-the-floor procedures for during a count: for instance, if you’re counting a particular shelf, you might temporarily rope it off or flag it so no one removes or adds items until you’re done. Little standard practices like that go a long way in ensuring accuracy.

- Use the Right Tools: Equip your team with tools that make cycle counting easier and more accurate. This includes physical tools like barcode scanners or mobile devices for entering data as you count, and software tools like a robust inventory management system that supports cycle counts. If you’re using CyberStockroom, for example, leverage the inventory map, real-time tracking, and count scheduling features to streamline the process (as discussed earlier). If your system allows, have counters enter their counts directly into the system on the spot rather than jotting numbers on paper to input later—this reduces errors from transcription and speeds up reconciliation. Other helpful tools might include digital count sheets, mobile apps for inventory counting, or even RFID technologies for quick scans. Investing in these tools pays off by saving time and preventing mistakes.

- Execute Counts and Reconcile Discrepancies: Now for the core activity: doing the counts. Follow your schedule diligently. When counting, consider having a second person verify counts for critical items or locations (a quick double-check can catch simple mistakes). If you find a discrepancy between what’s on the shelf and what the record says, investigate immediately. Check if there was a recent transaction not recorded, or if the item was misplaced. CyberStockroom’s activity log, for instance, can show recent movements of that item. After investigating, update the inventory records to the correct number (and document the adjustment or its reason if required by your audit rules). The cycle count isn’t finished until the physical count and the system record agree. Reconciliation is where the improvement happens—you fix the errors so your accuracy stays high. Over time, you’ll likely notice fewer and smaller discrepancies if your process is working well. But maintaining vigilance is key: this step ensures that inventory accuracy — that magic phrase again — remains high perpetually, not just at one point in time.

- Monitor, Report, and Improve: The process doesn’t end once you’ve cycled through all your items. Continuous improvement is a big part of success. Track metrics like your inventory accuracy percentage over time or the frequency of discrepancies in certain categories. Use your system’s reporting (or even simple Excel charts) to identify patterns: Are certain items always off? Is a particular storage area prone to errors? These insights can drive further action — maybe additional staff training, better labeling, or changes in how items are organized. Also, periodically review your cycle count schedule itself. You might find that you initially overestimated how often some items need counting, or conversely, that some “B” items are critical enough to treat as “A” and count more frequently. Adjust the plan as needed. Keep management and stakeholders informed of progress: for instance, celebrate that your inventory accuracy improved from 92% to 98% after six months of cycle counting. This helps maintain organizational support and motivation. Essentially, treat the cycle counting program as an ongoing, evolving part of operations. The mantra is “set, measure, learn, adjust, repeat.”

By following these steps, you’ll build a robust cycle counting program that fits your manufacturing operation. It may take a few weeks or months to fully cycle through your inventory and work out any kinks, but once the rhythm is established, most managers wonder why they didn’t start cycle counting sooner. The payoff is clear: fewer surprises, a smoother running supply chain, and a lot less stress when someone asks, “What’s our inventory situation?” — because now you’ll always have an up-to-date answer.

Conclusion: Goodbye Annual Headaches, Hello Lean Inventory Control

The days of treating inventory accuracy like a once-yearly cram session are fading. Manufacturing companies are increasingly saying “goodbye” to the huge annual stock check and “hello” to continuous inventory assurance through cycle counting. It’s not hard to see why.

Cycle counting brings lean manufacturing inventory control to life by embedding inventory checks into regular operations — no more all-nighters in the warehouse or costly shutdowns just to count parts. Instead, you get a steady drumbeat of verification that keeps your data reliable every day.

By replacing the big-bang stocktake with a well-oiled cycle count program, you’re also fostering a culture of ongoing diligence and improvement. Operators become more inventory-conscious, finance gets more timely accurate numbers, and customers face fewer stock-related hiccups. It’s a win for every department.

Remember, success with cycle counting doesn’t happen by magic. It takes planning, the right tools, and commitment from the team. But with the guide above, you have a solid starting point. And tools like CyberStockroom are there to make the journey easier, giving you visibility and control that aligns perfectly with these modern practices.

So if you’re a still bracing for the next annual inventory ordeal, now is the time to rethink that approach. Shifting to cycle counting can save your sanity, your budget, and quite possibly your customer satisfaction levels. In the end, maintaining inventory accuracy is not just an accounting exercise — it’s central to running an efficient, responsive, and profitable operation. Cycle counting is your ticket to get there with less pain and more gain. Happy counting!

Leave a comment