Imagine wrapping up a long workday on a busy construction site, only to realize that a high-end power drill has gone missing. You retrace your steps through the tool crib, check the back of the work truck, and quiz your crew – but it’s nowhere to be found. Missing tools and equipment are an all-too-common scenario in industrial construction, leading to panic searches, unexpected expenses, and project delays. Tool loss and shrinkage (the gradual loss of inventory due to theft or misplacement) have become persistent headaches for jobsite managers and warehouse teams worldwide. In fact, tool theft and loss are so widespread that they’re often accepted as “part of the job” – but it doesn’t have to be this way.

Effective tool loss prevention in construction is possible with the right strategies and tools. By understanding why tools go missing and implementing robust tracking and management practices, construction companies can save thousands of dollars, keep projects on schedule, and reduce a lot of needless frustration.

The Scope of Tool Loss and Shrinkage on Industrial Job Sites

Tool loss on industrial job sites is more than just an occasional nuisance – it’s a significant drain on resources and productivity across the construction industry. Studies have estimated that construction site theft (including tools, equipment, and materials) costs contractors billions of dollars every year. Tools are actually the number one category of items stolen from construction sites, often making up nearly half of all reported theft incidents. Why? Because tools are typically small, portable, and easy to resell, making them a prime target for opportunistic thieves.

However, not all missing tools are a result of outside theft. On hectic job sites, inventory shrinkage can also happen due to simple disorganization and oversight.

A cordless drill might get left behind in a ceiling crawlspace during a rushed installation, or a set of expensive wrenches might be buried under debris and accidentally tossed out. When crews are juggling multiple tasks in a fast-paced environment, it’s easy for items to “walk off” or disappear into the chaos.

Over time, these losses add up. A few missing power tools each month may not seem like much, but multiply that across several job sites or over a full year, and the financial impact becomes eye-opening.

Almost every construction manager or warehouse supervisor has a story about “the case of the disappearing tools.” You’re not alone – surveys of tradespeople indicate that a large majority have experienced tool theft or loss on the job. It’s a global issue that affects big and small contractors alike. From commercial building sites in major cities to remote industrial projects, tool shrinkage erodes profit margins and undermines efficiency everywhere. The good news is that awareness of the problem is rising, and so are the solutions available to combat it.

Before we jump into solutions, let’s take a closer look at exactly what’s going missing on job sites and why. Understanding the scope of lost items and the common causes of shrinkage is the first step toward crafting a prevention plan.

The Usual Suspects: Commonly Lost or Stolen Tools and Equipment

Not all tools are equally likely to go missing. There are certain tools and pieces of equipment that tend to “grow legs” more often than others on construction sites. Knowing what these are can help you put extra precautions in place. Here are some of the most commonly lost or stolen items on industrial job sites:

- Power Tools (Drills, Saws, Nail Guns) – Portable power tools are top targets for theft. They’re essential, valuable, easy to hide, and quick to resell. They’re also often misplaced during busy workdays if left unattended.

- Hand Tools and Small Equipment – Items like hammers, screwdrivers, pliers, and tape measures frequently go missing. Though cheap individually, frequent replacements add up. Small gear like batteries and laser levels are easily overlooked and lost.

- Heavy Equipment Parts and Accessories – Thieves often steal detachable items like copper cables, blades, drill bits, and fuel cans. Smaller units like compressors and generators are also targeted when left unsecured.

- Electronics and Specialized Gear – High-value items like GPS units, radios, tablets, and even PPE (like premium helmets) are vulnerable to both theft and misplacement on busy job sites.

Any item that is valuable, portable, and in-demand is at risk. Thieves know that construction tools are often branded, high-quality, and easily pawned or sold online. Even within the team, a worker might “borrow” a tool for a home project and conveniently forget to bring it back. By recognizing these usual suspects, jobsite managers can identify which assets need the tightest controls and tracking.

Why Do Tools Go Missing? Root Causes of Tool Loss and Shrinkage

If tool loss were just about “bad guys” stealing from the site, the solution would simply be better security guards. In reality, the causes of tool loss and shrinkage are both external and internal, and often preventable with better practices. Understanding why tools go missing in the first place will help you address those issues directly. Here are some of the primary causes:

1. Jobsite Disorganization: Construction sites are hectic by nature – with multiple trades working simultaneously, equipment moving around, and constant pressure to stay on schedule. In a disorganized site, tools don’t have a designated “home” or proper storage. Workers may leave equipment wherever it’s last used, expecting to grab it later. Without an orderly system, tools get buried under supplies or debris, left in random places, or thrown into the wrong gang box. Chaos is a breeding ground for loss. Simply put, if you set a tool down in a random spot on a sprawling jobsite, there’s a fair chance you won’t find that exact spot again easily!

2. Lack of Tracking and Accountability: Many crews still operate on the honor system – a tool is taken out of the storage shed or tool crib, used, and hopefully returned by day’s end. But without any checkout logs or inventory tracking, it’s easy for items to go missing without immediate detection. No one notices the cordless drill is gone until someone needs it next week, and by then any trail of responsibility is cold. A lack of accountability or clear assignment (knowing who has what tool) means tools “walk off” because people assume someone else has it or nobody realizes it’s gone. In short, what isn’t tracked will not be missed until it’s too late.

3. Opportunistic Theft by Outsiders: Construction sites can be targets for thieves – especially after hours. A site with minimal security, fencing, or surveillance invites trouble. Thieves may sneak in at night or blend in as contractors during the day, walking off with valuable tools. Since tools are easy to conceal and carry, a few missing drills or saws might not even be noticed immediately. Opportunistic thieves also target work trucks or vans; if tools are left in vehicles or trailers overnight without proper locks, they might disappear by morning. In many regions, organized crews specifically target construction equipment due to the high resale value of tools and scrap materials.

4. Internal Theft or Misuse: While it’s uncomfortable to think about, not all losses are from unknown third parties. Crew members or subcontractors sometimes take tools for personal use or side jobs, figuring it won’t be missed. This could range from “borrowing” a hammer or battery (and forgetting to return it) to outright theft of expensive equipment. A lack of a strong accountability culture can enable this behavior. Additionally, tools can be misplaced when workers move between sites or teams – an employee might leave a company tool in their personal truck or at another jobsite.

5. Inefficient Tool Management Practices: Sometimes the very process (or lack thereof) for managing tools causes shrinkage. This could include anything from not keeping an up-to-date inventory list, to failing to mark tools with identifiable labels or serial numbers, to not training workers on proper tool handling. Without regular audits, missing tools might go unnoticed for months. If tools aren’t clearly labeled as company property, they’re easier for a thief to pass off or for another crew to accidentally pick up. And if employees aren’t trained to treat tools with care (because “the company will just buy more”), then tools won’t be handled or stored diligently.

6. Project Pressure and Human Error: Construction schedules are tight. Under the pressure of deadlines, workers might rush from one task to another. In the hustle, tools get left behind. Maybe the crew is pouring concrete at one end of the site and forgets a set of tools on the other end as they race to the next pour. Maybe an electrician in a hurry leaves a drill on a ladder and someone else tidies up not realizing it’s up there. Human error is inevitable, but a culture that emphasizes taking a moment to account for tools can help mitigate it.

All these factors contribute to a perfect storm where tools and equipment can easily slip through the cracks. The first step in prevention is awareness – by identifying these root causes on your jobsite, you can start plugging the leaks.

Next, we’ll explore just how these losses impact your bottom line and operations, and then dive into strategies to prevent tool loss in the first place.

The Real Cost: Financial and Operational Impacts of Tool Loss

Losing a $300 drill isn’t just a $300 problem. The impact of tool loss and shrinkage cascades through a construction project and business in ways that aren’t immediately obvious when you notice something missing. Here are some of the major financial and operational impacts that uncontrolled tool loss can have:

- Direct Replacement Costs: First and foremost, lost tools need to be replaced. Over the course of a year, a company might lose dozens of tools – from power saws to handheld GPS units – resulting in thousands of dollars spent on buying replacements. These unplanned costs eat directly into profit margins. Money spent replacing a lost laser level is money that could have gone to new equipment or hires. In an industry with tight budgets, every dollar counts.

- Project Delays and Downtime: The moment you realize a critical tool is missing often coincides with the moment you need it most. If a specialized tool like a crimping tool or a concrete mixer attachment is nowhere to be found when crews are ready to work, that task might come to a halt. Workers stand idle (while still on the clock) until a replacement is found or a backup arrives. Even a short delay can throw off a tightly coordinated construction schedule. Multiply that by multiple incidents and you get significant timeline overruns. In construction, delays often translate to monetary penalties or overtime costs. One missing tool in the wrong moment can literally hold up an entire crew.

- Lost Productivity and Wasted Time: Even when missing tools don’t stop work entirely, they waste precious time. Think about the hours crews spend searching for misplaced tools each week – walking around the site, checking gang boxes, or driving back to the last site hoping they left it there. It’s estimated that workers can spend a surprising chunk of their day just looking for tools or materials. All that time is unproductive labor expense. Additionally, if a worker doesn’t have the right tool at hand, they might improvise with a less suitable tool, working slower or with more difficulty. This lowers efficiency and can even impact work quality.

- Increased Safety Risks: A lack of the proper tools can lead workers to take unsafe shortcuts. If the only grounded extension cord is missing, someone might use a damaged one. If a ladder is gone, they might stand on an unstable surface to get the job done. Missing PPE or safety equipment is even more directly dangerous. Tool loss, therefore, isn’t just a budget issue – it can create safety hazards and liabilities by forcing improvisation or delaying critical maintenance of equipment.

- Higher Operational Costs and Insurance: Frequent theft and losses may drive up insurance premiums for construction equipment coverage. If you’re making frequent claims or showing a pattern of poor asset management, insurers see you as a higher risk. Alternatively, if losses aren’t claimed, they still come out-of-pocket. Some companies also overspend by over-purchasing “just in case” backups for tools they suspect will go missing. That means carrying more inventory than needed, tying up capital in spare tools sitting on shelves.

- Morale and Trust Issues: While harder to quantify, constant tool loss can create morale problems. Workers get frustrated if they can never find the equipment they need, or if they feel someone’s stealing from the team. Trust between management and crews can suffer if employees feel they’re unfairly suspected, or if management fails to address known theft problems. A well-organized, secure system for managing tools actually shows the team that the company cares about providing what they need to do their jobs – which can boost morale and productivity.

- Client Perception and Professionalism: Imagine having to tell a client that a job is delayed because “we lost a tool.” It’s not a conversation any contractor wants to have. Repeated delays or visible disorganization can harm your company’s reputation. On the flip side, a well-organized jobsite where everything is accounted for signals professionalism. Preventing shrinkage contributes to smoother operations that clients will notice (or, importantly, not notice because things simply go as planned).

Tool shrinkage quietly drains money and efficiency from construction operations. It’s a hidden cost that can accumulate to significant proportions, affecting everything from the day’s work plan to a project’s profit margin. By quantifying these impacts – even roughly – you can make a strong case to your team (and upper management) that investing time and resources in tool loss prevention is absolutely worth it. Now, with the problem clearly defined, let’s move on to proactive solutions that can stop this bleed and improve your bottom line.

Best Practices for Tool Tracking and Inventory Management

Preventing tool loss and shrinkage isn’t a one-time fix – it requires consistent habits and systems built into your daily operations. The good news is that many best practices for tool management are simple to implement and low-cost. It’s all about organization, accountability, and a bit of technology.

Below are some tried-and-true best practices that industrial job sites around the world use to keep their tools under control:

1. Centralize and Organize Tool Storage

One fundamental step is to give every tool a designated home. Whether it’s a dedicated tool crib, a locked Conex container, a mobile tool trailer, or even just clearly labeled shelving in a warehouse – create a central place for tools to return to. Within that space, organize tools by category (electrical, carpentry, plumbing, etc.) and use shadow boards or labeled bins so anyone can see what goes where.

When a worker checks out a tool, they know exactly where to put it back. Centralized storage cuts down on the “I left it somewhere on Site A” problem, because tools shouldn’t be left lying around – they belong in their home when not in use. It also makes end-of-day cleanup easier: a quick scan of the storage area will reveal if any item is still out on the site.

2. Use a Check-Out/Check-In System

Establish a simple tool tracking system to log who has each tool. This can be as basic as a clipboard sign-out sheet in the tool crib or as advanced as a barcode scanning app – the key is to record whenever a tool leaves or returns to storage. For example, if John from Crew A takes out the laser level on Monday, have him sign it out (or scan it out) and be responsible for returning it. This introduces accountability; tools are far less likely to vanish when there’s a name attached to them. Some companies assign specific tool kits or sets to each crew or supervisor, so it’s clear who oversees them. Others use digital asset management systems that let workers check tools in and out via a smartphone. Choose a method that fits your team’s size and tech comfort, but make it routine.

3. Label and Tag Everything

It’s much harder for a tool to slip into someone’s personal stash or get mixed up with another crew’s gear if it’s clearly labeled as yours. Mark your tools with unique identifiers – this could be a company code engraved or stamped onto metal tools, brightly colored paint markings, or durable barcode/QR code stickers that link to an inventory system. Labels not only deter casual theft (a pawn shop might hesitate to buy a drill engraved with “XYZ Construction Co.”), but they also help honest mix-ups. If two crews are working in the same area, a distinct marking ensures everyone knows which nail gun belongs to which company. Modern tagging systems even let you scan a code on the tool to instantly see what it is and who is responsible for it (more on that in the technology section).

4. Perform Regular Inventory Audits

Don’t wait until something is urgently needed to discover it’s missing. Schedule regular inventory counts of your tools and equipment – for instance, a quick weekly check and a more thorough monthly audit. This can be as simple as having the warehouse manager or foreman verify that all items on the “master tool list” are present and accounted for. Regular audits will quickly highlight if anything has walked away in the last few days, allowing you to investigate sooner rather than months later. It also keeps your inventory list up-to-date. If you combine audits with maintenance checks (inspecting tools for damage and scheduling repairs or replacements), you’ll extend the life of the tools you do have.

5. Train Your Crew and Set Expectations

Even the best system will fail if people don’t use it. Take time to train your team on new tool management procedures and explain why they matter. Emphasize that preventing tool loss isn’t about micromanaging or mistrust – it’s about ensuring everyone can do their job effectively and safely with the tools they need. Set clear expectations, such as: “At the end of the day, every tool must be returned to its storage and signed back in – no exceptions.” Encourage a culture of accountability where crew members look out for the company’s equipment. Sometimes, instituting a simple end-of-day routine (like a toolbox talk or a brief huddle to confirm all tools are back) can ingrain good habits. Some companies even implement reward systems (like a quarterly pizza party if no tools go missing for three months) to positively reinforce mindful tool handling.

6. Secure the Jobsite After Hours

Organizational practices during work hours need to be paired with good security practices off-hours. Ensure that all tools and valuable equipment are secured in locked storage when crews leave for the day. Invest in sturdy locks, consider steel job boxes for smaller tools, and use well-lit, fenced storage areas or containers that are difficult to break into. If feasible, use security cameras or even periodic security patrols, especially in theft-prone areas. Even simple measures like posting signage about surveillance or uniquely marking tools can dissuade thieves. The goal is to make it as hard as possible for unauthorized people to get to your tools, and to remove the easy “quick grab” opportunities.

7. Limit Access and Assign Responsibility

Along with physical security, think about controlled access to tools. Not every crew member needs free rein to every piece of equipment. You might assign a tool custodian (or several, on bigger sites) who holds the keys to the storage and manages the log. Alternatively, if you use an electronic tracking system, give access only to trusted individuals to authorize check-outs. The idea is to have a clear chain of custody. When everyone knows that tool usage is monitored, there’s less temptation for mischief. Assigning responsibility for tool management to a specific role (like the warehouse manager, site coordinator, or a rotating crew lead) also ensures someone has ownership of the process.

By adopting these best practices, you create an environment where it’s actually difficult to lose a tool without someone noticing. Yes, it takes a bit of effort and a change in routine, but the payoff is huge: fewer lost tools, less money spent on replacements, and smoother, more professional operations.

Many of these practices cost little to nothing to implement – they’re about process and mindset. In the next section, we’ll look at how technology can supercharge these efforts and provide even more robust protection against tool loss.

High-Tech Solutions: Emerging Technologies for Tool Loss Prevention

While good habits and organization go a long way, modern technology can take tool loss prevention to the next level. In recent years, the construction industry has seen a wave of new tools (pun intended) designed to keep track of equipment automatically and digitally. These emerging technologies offer advanced ways to monitor your assets, often in real time. Here are some of the high-tech solutions making a big impact on construction sites:

RFID Tracking

RFID tags let you track tools automatically. Readers at site entrances or handheld scanners can instantly log items in or out without manual counting. This saves time and helps prevent theft by flagging unauthorized removals.

Barcodes and QR Codes

A low-cost, easy way to track tools. Workers scan labels with a phone to check items in and out. It logs who used what, where it is, and when it’s due for maintenance. Great for teams already using smartphones.

GPS and Bluetooth Trackers

Use GPS for tracking large equipment across job sites. Bluetooth tags help locate tools nearby using a smartphone. Some tools now have built-in trackers, making it easy to find misplaced gear.

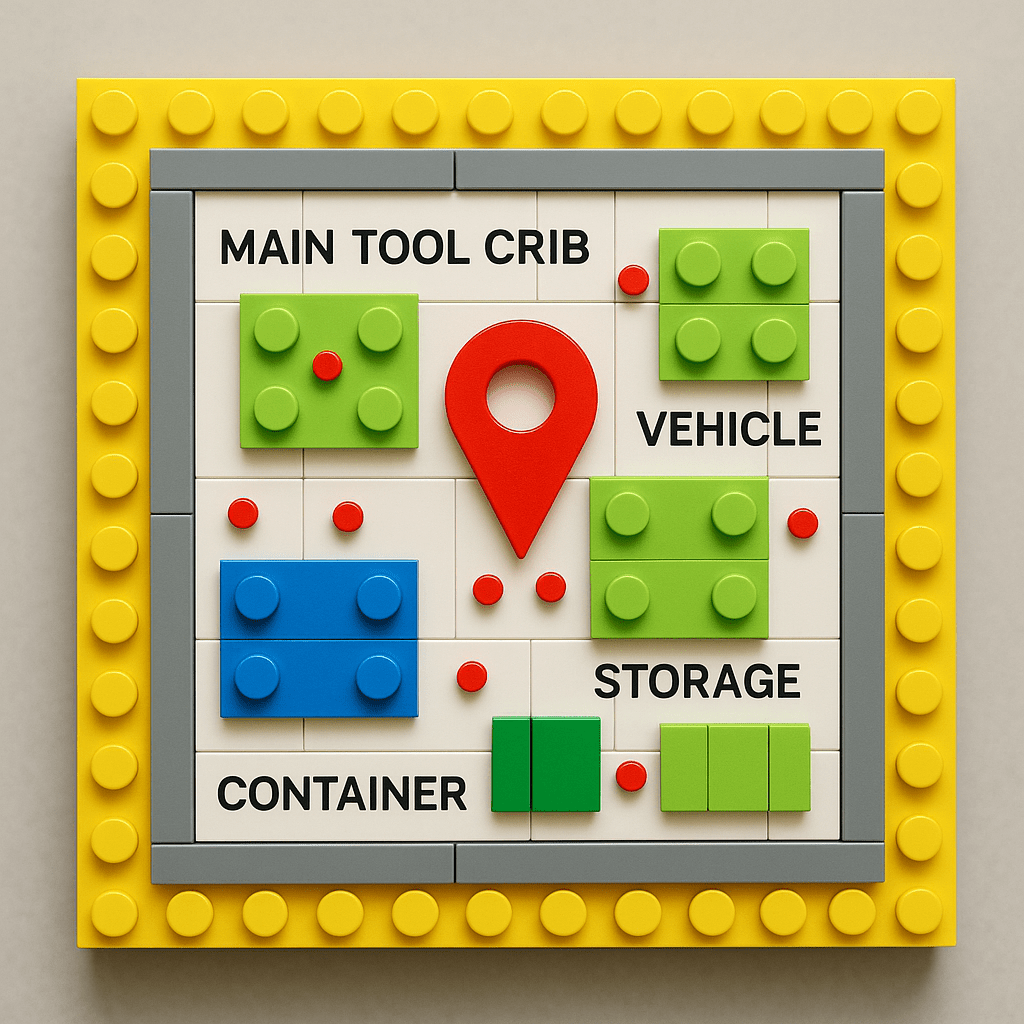

Digital Inventory Maps

Visually track where tools are stored—trailers, floors, trucks—using a map of your site. Updates happen with a quick scan, reducing search time and giving you a clear view of tool locations at all times.

Cloud-Based Tool Management

Cloud platforms bring everything together: barcodes, RFID, maps, and reports. Everyone on the team sees the same info in real time, helping prevent losses and making tool management seamless.

These technologies might sound high-tech, but many are designed to be user-friendly and scalable for companies of all sizes. You don’t have to implement everything at once; even one or two tech upgrades can significantly strengthen your tool loss prevention. For instance, you might start by labeling everything with QR codes and using a basic app, then gradually add RFID for the most expensive items later.

Next, let’s look at a real-world example of how one such technology – an inventory mapping software called CyberStockroom – can tie all these ideas together and make tool tracking virtually foolproof on a busy jobsite.

CyberStockroom: A Map-Based Solution for Tool Tracking and Loss Prevention

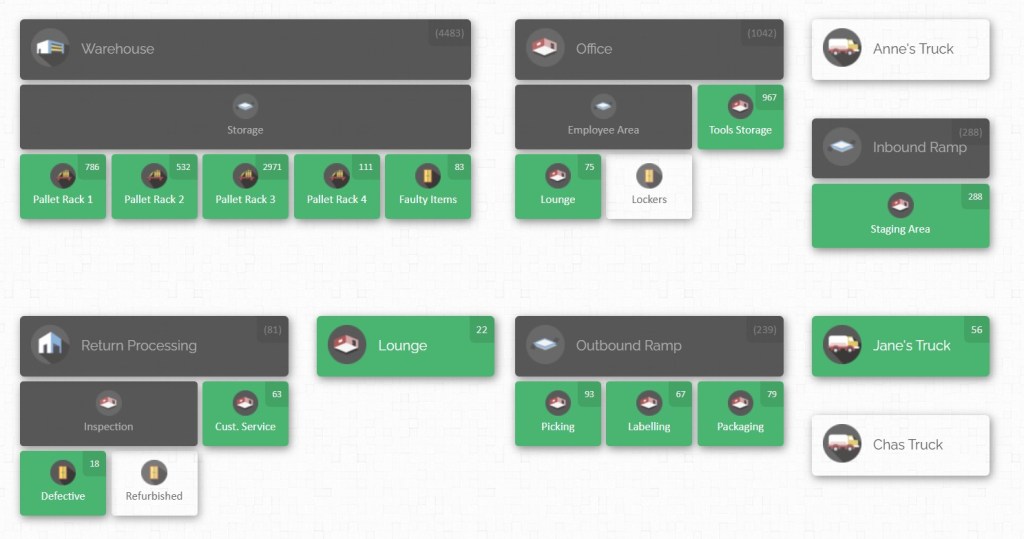

One of the emerging leaders in high-tech tool management is CyberStockroom, an inventory management platform that takes a unique map-based approach to tracking tools and equipment.

If you’re struggling with tool loss and disorganization, CyberStockroom is a solution worth considering. Let’s break down how it works and why it’s particularly suited for industrial construction environments:

Interactive Inventory Map

At the heart of CyberStockroom is an interactive inventory map that mirrors your actual operations. You start by creating a virtual map of your jobsite and related locations – for example, you can map out your main warehouse, each jobsite, the storage containers on those sites, the vehicles, even specific zones within a site (like “Building A – 2nd Floor” or “North Tool Crib”).

This map isn’t just a static image; it’s a functional interface. Every tool and piece of equipment in your inventory is represented on this map at its current location. So if that compressor is on Truck #5 heading to Site B, that’s where it shows up. If three drills are in the Site A tool crib and one is currently with Crew X on the third floor, the map reflects that.

Real-Time Visibility

Because CyberStockroom is cloud-based and updates in real time, it gives instant visibility across all your active sites. It’s like having a live feed of where everything is. Jobsite managers, warehouse teams, and procurement officers can all see the same updated info. If someone transfers a batch of power tools from the central warehouse to a jobsite, the system updates. If a crew member checks out a tool for the day, the map shows it assigned to that person or location.

This real-time tracking means no more guessing or making phone calls to locate a piece of equipment – you can simply look at the dashboard and know.

Easy Tool Assignment and Movement Tracking

CyberStockroom makes it simple to record movements of tools. It often uses a drag-and-drop interface on the map: need to move an item from Warehouse to Site? Just drag its icon over, or select a transfer. This can be combined with barcode scanning – scan a tool’s code and select its new location from a list or map.

Every movement is logged automatically, creating an audit trail. If a tool goes missing, you can trace the last known location and who handled it last. That audit trail is gold when investigating shrinkage or just keeping people accountable. Crew leaders can assign tools to individuals or teams within the system, so there’s clarity on responsibility.

Loss Prevention and Alerts

By having all your assets mapped out, you can quickly spot if something is out of place. The location-based visibility acts as a deterrent; employees know that every tool is being tracked, and if something disappears, the system will point out when and where it was last seen. It’s much harder for tools to quietly vanish when a system like this shines a spotlight on their whereabouts.

Integration with Crew Management

Industrial job sites often have multiple teams and subcontractors working in parallel. CyberStockroom is designed to handle that complexity. You can assign inventory to specific people, crews, or even to a contractor company. For instance, if subcontractor ABC is using your company’s equipment, you can assign those tools to ABC on the map. This way, everyone is clear on who is responsible for what.

When they’re done, the tools can be checked back in and reassigned or returned to storage. This level of accountability is crucial for preventing the “not my problem” syndrome where tools fall through the cracks between different groups.

User-Friendly and Visual

Perhaps one of the biggest advantages is user adoption. Many of us have experienced software that, while powerful, is just too cumbersome or unintuitive for the field teams to actually use consistently. CyberStockroom’s visual map approach means even those who are not tech-savvy can literally see and interact with a representation of the site. It’s as easy as looking at a floorplan and seeing icons for tools – very little training is required to get the basic idea.

The platform can replace clunky spreadsheets with a map that feels almost like a simplified video game of your inventory. This visual approach reduces miscommunication significantly – when everyone sees the same information presented clearly, there’s less chance of confusion over where something went.

Preventing Shrinkage Without Extra Work

One hesitation managers might have is, “Will this create a lot of extra work for my team?” CyberStockroom is designed to minimize additional effort. The drag-and-drop updates and scanning are quick tasks, not lengthy data entries. And by automating logs and inventories, it actually saves time that would otherwise be spent on manual counts or searching. It turns what used to be reactive fire-fighting (trying to find or replace lost items) into a smooth, proactive management process.

In practice, adopting a system like CyberStockroom can dramatically reduce tool loss. Companies report improved accountability and significantly fewer instances of missing equipment once everything is being tracked on the map. Plus, when losses do occur, investigations are easier – you can often pinpoint what happened, which helps recover the item or at least learn from the incident.

Actionable Tips to Implement Your Tool Loss Prevention Strategy

By now we’ve covered a lot of ground: the scale of tool loss, why it happens, how it hurts your business, and what best practices and tech solutions can help. It’s time to turn that knowledge into action.

Here’s a recap of key steps and actionable tips you can take to build an effective tool loss prevention strategy on your job sites:

- Audit Your Current Situation – Take inventory of all tools and note what’s missing. Look for patterns—certain items, sites, or crews might be repeat offenders. This helps focus your efforts.

- Organize and Secure Storage – Set up centralized, lockable tool storage. Make sure everything has a designated spot and restrict access to trusted personnel. Lock up valuable items daily.

- Start Tracking Immediately – Use a simple check-in/check-out system—paper or spreadsheet to start. Upgrade to barcodes or digital apps over time. The key is to build accountability early.

- Label Your Tools – Clearly mark tools with your company name or ID number. Durable labels or engravings help deter theft. Barcodes or QR codes can link to your tracking system.

- Use Technology for Problem Areas – Pilot RFID or Bluetooth trackers on high-value or frequently lost items. A small test run can show real results and help your team adjust to new tools.

- Train and Involve Your Team – Introduce changes positively. Train staff on the new system, assign a tool-tracking lead, and welcome suggestions. Engaged teams are more likely to follow through.

- Monitor and Improve Watch for results and make adjustments. If losses drop or someone prevents an issue, celebrate it. Recognition reinforces the importance of tool care.

- Consider an All-in-One Solution – Platforms like CyberStockroom combine labeling, tracking, mapping, and reporting in one system. A free trial can quickly show if it fits your needs. Even small reductions in loss often cover the cost.

Leave a comment