Imagine this scenario: an assembly line is buzzing with activity when suddenly everything comes to a halt. The cause? A tiny component is missing – even though your inventory system claimed it was in stock.

For manufacturing managers, situations like these are all too familiar. Inventory errors in manufacturing might seem small on paper, but they can snowball into major production headaches.

In today’s fast-paced, lean manufacturing environment, there’s little room for mistakes. Yet, many factories still struggle with miscounts, misplaced parts, or inaccurate records that throw off their entire operation.

Modern manufacturing relies on precision and timing. Assembly lines, whether in automotive, electronics, or consumer goods, depend on every part being available at the right place and time. A single inventory discrepancy – like a phantom stock (recorded inventory that isn’t actually there) or a missing batch of components – can disrupt the whole sequence.

The result? Production delays, idle workers, and emergency scrambles to find or reorder parts. Not only is this stressful, but it’s also expensive. Industry estimates suggest that inventory errors can eat up a significant chunk of revenue – some studies put it at 10–30% of annual profits lost due to issues like stockouts, overstock, and other inventory mishaps. For any manufacturing manager focused on operational efficiency, that’s a wake-up call.

Understanding Inventory Errors in Manufacturing

Inventory errors refer to any inaccuracies or mistakes in tracking stock levels and locations. In a manufacturing context, this isn’t just about finished product inventory, it includes raw materials, components, work-in-progress items, and spare parts. An error could mean the system says you have 50 units of a part but only 45 are actually on the shelf. It could also mean items are stored in the wrong location, or a shipment was recorded incorrectly. Essentially, what you think you have doesn’t match reality.

These discrepancies are more common than one might think. Manufacturing managers often juggle thousands of parts and materials, and many still use manual or outdated methods for inventory control. Picture a busy warehouse where staff count parts by hand or update spreadsheets at the end of the day. Human error is inevitable – a flipped digit here, a missed entry there – and those small mistakes accumulate. Over time, you might end up with “hidden” shortages (where the system looks fine until you suddenly run out) or phantom surpluses (where the database shows stock that isn’t actually available).

Why do these errors happen?

Isolated systems and ineffective communication. If your purchasing, warehouse, and production teams use separate systems or don’t communicate changes, inventory info falls through the cracks. For example, if procurement delays a delivery but the inventory system isn’t alerted, production might schedule as if materials were available – until they discover the shelves are empty.

No routine audits or cycle counts: Some factories only do a full inventory count once a year. In the 12 months between, small errors add up unchecked. Without regular cycle counting (periodically counting sections of inventory), discrepancies can grow rampant without anyone noticing until a major problem erupts.

Inventory errors stem from both human factors and system shortcomings. For manufacturing managers, recognizing these root causes is the first step toward fixing them.

How Inventory Errors Disrupt Assembly Line Operations

Assembly lines are finely tuned systems. Each station depends on a steady supply of the right parts. When inventory errors occur, that harmony breaks. Here’s how these inaccuracies directly disrupt assembly lines:

- Unplanned Line Stoppages: This is the nightmare scenario. Production has to stop because a required part isn’t available when needed. Often, this happens because the inventory system overstated what was on hand. The entire line grinds to a halt while the team scrambles to get the missing parts. Every minute of downtime is expensive – some automotive manufacturers estimate losses of tens of thousands of dollars per minute. Even in smaller operations, a halted line means paying workers and running equipment with no output.

- Bottlenecks and Slowdowns: Not all inventory errors cause a full stop, sometimes, they create a bottleneck. One station might have to slow down because a needed part is in short supply. Workers spend extra time hunting for a component that “should” be in its bin but isn’t. These hiccups break the line’s synchronized rhythm – downstream stations may sit idle while upstream issues get sorted out, cutting overall throughput.

- Last-Minute Firefighting: Inventory errors often force managers into firefighting mode. Instead of focusing on optimizing operations, you’re urgently reallocating parts, calling suppliers for rush deliveries, or jury-rigging a temporary fix. This reactive scrambling can keep production going, but it’s inefficient and stressful. It also diverts your team’s attention from other important tasks, like quality control or process improvement, because everyone is busy putting out inventory-related fires.

- Production Delays and Missed Deadlines: When assembly is interrupted or slowed, the effects ripple outward. Final products don’t get finished on time, meaning missed shipping deadlines and delays in downstream processes. One small inventory mistake can cascade into a big scheduling mess, causing you to miss customer commitments.

When these disruptions happen frequently, the assembly line’s efficiency and reliability take a hit. Workers get frustrated by constant holdups, supervisors are in crisis mode rather than improving the process, and the company’s ability to meet production targets becomes shaky. Next, let’s examine the broader ripple effects and costs associated with inventory errors.

The Hidden Costs of Inventory Errors

Beyond the immediate chaos on the shop floor, inventory inaccuracies quietly drain resources and money in other ways. Manufacturing managers might notice the obvious downtime, but what about the less visible costs? Understanding these can strengthen the case for investing in better inventory control.

- Idle Labor and Overtime: When a line stops, you’re still paying workers who aren’t producing anything. Later, you might pay overtime to catch up to the schedule. Both idle time and overtime directly hit your labor budget without adding any value.

- Expedited Shipping and Procurement Costs: If a critical component runs out due to an inventory mistake, you often have to order replacements urgently. Expedited shipping fees or rush-order premiums can be steep, and those emergency expenses cut into your margins. These last-minute costs wouldn’t be necessary with proper inventory accuracy and planning.

- High Inventory Carrying Costs: On the flip side of stockouts is the tendency to hoard inventory as a safety net. Excess inventory comes with carrying costs – storage space, insurance, potential spoilage or obsolescence. If your records are unreliable, you might over-purchase “just in case,” only to have piles of unused stock consuming space and capital. Essentially, money that could be invested elsewhere is stuck on shelves gathering dust.

- Loss of Trust and Team Morale: If the inventory system is frequently wrong, workers and managers lose trust in the data. They start double-checking everything “just to be sure,” which means extra work and frustration. Constantly dealing with avoidable problems hurts morale and can even lead to higher turnover over time.

- Customer Satisfaction and Reputation: Ultimately, manufacturing is about delivering on time and in full. Inventory errors that delay production often lead to late shipments or stockouts for customers. Whether you’re supplying components just-in-time to another manufacturer or shipping finished goods to end customers, reliability matters. A single missed delivery due to an unexpected stockout can make customers question your dependability. In competitive markets, too many of these slip-ups can seriously tarnish your reputation.

In essence, inventory errors act like a leak in the manufacturing operation. Some leaks are obvious (like a halted line), but others quietly drain resources out of sight. Plugging these leaks through better inventory control doesn’t just prevent headaches – it directly improves the bottom line and frees up your team to focus on productive work.

Preventing Inventory Errors: Strategies for Smooth Assembly Lines

By now it’s clear that inventory errors in manufacturing are a serious liability. The good news is that these problems are preventable. With the right strategies and tools, you can greatly enhance inventory accuracy and keep your assembly lines running like clockwork. Here are several proven approaches to inventory control that boost accuracy and efficiency:

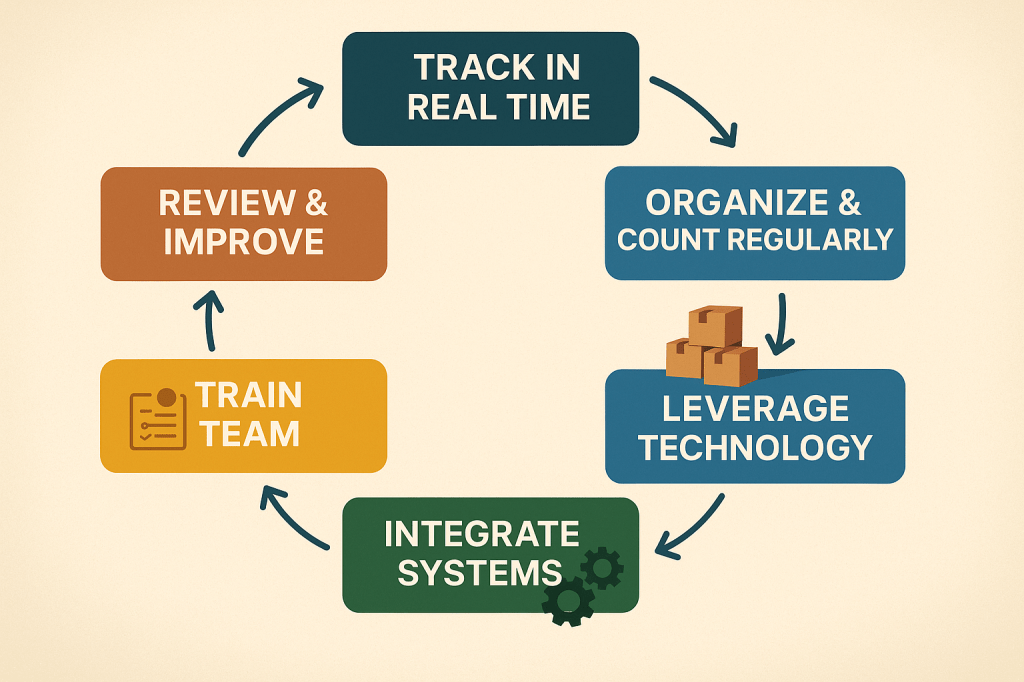

Implement Real-Time Inventory Tracking

Moving away from paper logs or infrequent updates to a real-time system is a game-changer. This could mean using barcode scanners or RFID tags so that every part’s movement (receiving, storage, picking for production) is recorded instantly. Real-time tracking ensures that your inventory data is always up-to-date. For example, when a worker pulls 100 screws for the line, scanning them out immediately deducts it from the system. This way, anyone looking at stock levels sees the truth, not last night’s numbers.

Adopt a Robust Inventory Management System

Spreadsheets and manual logs just can’t keep up with modern manufacturing needs. Dedicated inventory management software provides a centralized platform for all inventory data. The best systems are cloud-based (updating live and accessible anywhere) and integrate with production schedules and purchase orders. They can issue alerts when stock is low or when mismatches are detected. Modern solutions even use visual tools like an inventory map to give clear visibility of what’s where. Whatever system you choose, the goal is to have one source of truth that everyone – from warehouse staff to production planners – can rely on.

Regular Cycle Counts and Audits

Instead of waiting for a yearly inventory overhaul, successful manufacturers conduct frequent mini-counts. Cycle counting means counting a subset of inventory on a rotating schedule (for instance, audit a few items every week on a rolling basis). This continuous checking catches discrepancies early before they snowball. If any significant mismatch is found, you can investigate and correct the root cause (be it a process issue or a training need) right away. Regular audits reinforce accuracy and keep the inventory database honest.

Train and Empower Your Team

People are a critical part of the inventory accuracy equation. Ensure that all staff involved in inventory – from receiving clerks to assembly line stock runners – are well-trained in the processes and understand why accuracy matters. Create standard operating procedures (SOPs) for key tasks like receiving shipments, issuing parts to production, and recording scrap or waste. Encourage a culture where employees double-check unusual figures and feel comfortable reporting a potential error. Sometimes the folks on the ground notice issues (like labels that are often misread or a system quirk that causes confusion) – tapping into their insight can lead to simple fixes that prevent mistakes.

Organize and Label for Clarity

If your storage areas are neat and clearly labeled, it’s much harder to lose track of parts. Implement 5S principles in the stockroom: Sort, Set in order, Shine, Standardize, Sustain. That means keeping only necessary items, arranging them logically (perhaps by part number or production usage frequency), labeling everything, and maintaining the order through audits. When every bin has a designated item and every item has a labeled home, misplacement errors drop dramatically. Plus, workers can pick parts faster, which also reduces picking errors and speeds up assembly line replenishment.

Integrate Systems for Visibility

Inventory management shouldn’t happen in isolation. If possible, integrate your inventory system with purchasing, production planning (ERP/MRP systems), and even supplier systems. This connectivity means if a delivery is late or a production schedule changes, the inventory counts and projections adjust accordingly. An integrated setup can automatically trigger reorders, send alerts for anomalies, or update the production schedule if inventory won’t meet demand. This holistic visibility ensures that one hand always knows what the other is doing, eliminating those communication-related discrepancies.

Each of these strategies reinforces the others. For instance, a good inventory management system makes real-time tracking easier; training employees helps them use that system correctly; regular cycle counts verify that the process is working, and so on. By implementing these measures, you’re essentially bulletproofing your assembly line against the most common inventory slip-ups.

CyberStockroom: A Smarter Way to Manage Inventory

In the realm of modern inventory management tools, CyberStockroom stands out as an innovative solution tailored to make inventory control easier and more visual. So, what is CyberStockroom? It’s a cloud-based inventory management software designed to give you a real-time, bird’s-eye view of all your stock across locations – using a unique map-based interface. For manufacturing managers grappling with assembly line disruptions, CyberStockroom offers features that directly address those pain points.

How CyberStockroom Helps Resolve Inventory Issues:

- Visual Inventory Mapping: Instead of sifting through spreadsheets or textual lists, CyberStockroom lets you create a virtual map of your operation. You can lay out your warehouse zones, production floor, storage rooms, whatever makes sense for your business – and see inventory levels in each area at a glance. This visual approach reduces confusion. For example, if a part is supposed to be at “Station A” and isn’t, you can quickly see if it’s sitting in “Bulk Storage” or another sub-location.

- Real-Time Updates and Tracking: CyberStockroom is cloud-based and supports barcode scanning, meaning the moment something is moved or used, your team can update it instantly. The live nature of the system means everyone from the storeroom to the assembly line is looking at current data. This prevents the classic scenario of production thinking stock is available when it was actually consumed earlier in the day. As soon as parts are pulled for production or new stock is received, the system updates the counts instantly. Real-time accuracy is maintained effortlessly.

- Easy Transfers and Adjustments: The software features a drag-and-drop interface for moving inventory between locations on the map. Say you transfer 50 units of a part from the central warehouse to the assembly line feeder station – you can literally drag that item icon from one location to the other on the map, and inventory counts update accordingly. This simplicity encourages teams to actually record movements (one of the biggest issues in inventory errors is forgetting to log a move). Because it’s so easy, employees consistently record movements and your records stay accurate.

From Errors to Efficiency

Inventory errors might be common, but they are far from harmless – as we’ve seen, they can disrupt assembly lines and undermine an entire manufacturing operation. The key takeaway for any manufacturing manager is that accuracy and visibility in inventory management are directly linked to production reliability. When you eliminate the inventory blind spots and inconsistencies, you empower your assembly lines to run without unexpected interruptions. The result is a smoother operation, happier customers, and a healthier bottom line.

Achieving this level of control isn’t an overnight task, but it’s absolutely achievable with a combination of smart strategies and modern tools. By enforcing good practices (like organized storage, regular cycle counts, and cross-department communication) and leveraging technology (like real-time tracking and platforms such as CyberStockroom), you build a robust inventory control system.

Manufacturing is challenging enough without self-inflicted problems. Inventory errors are one area where proactive effort pays off massively. No more pausing an assembly line for a part that “was supposed to be there.” No more costly rush orders or overstocking just to cover for data flaws. Instead, you can respond to demand changes confidently, maintain lean inventory without fear, and devote your energy to improving processes rather than fighting fires.

In the end, minimizing inventory errors means maximizing operational efficiency. It’s about transforming inventory management from a weak link into a competitive strength. So take a moment to assess your own operation: Are inventory inaccuracies causing drag on your assembly lines? If yes, now is the time to act. Strengthen your procedures, bring in the right tools, and cultivate a culture of accuracy. Your assembly lines will thank you – by staying productive and profitable day in and day out.

Leave a comment