Effective inventory control is the backbone of any successful industrial construction project. In massive builds like power plants, refineries, or manufacturing facilities, material costs often run into the tens or hundreds of millions, and even a small inventory mistake can delay progress and drive up expenses.

Industrial construction sites deal with specialized equipment, heavy machinery, and thousands of components that must all come together at the right time. If bolts, steel beams, or electrical panels are misallocated, a critical project milestone can quickly derail.

Operations teams and project managers in this field know that inventory issues in construction have huge ripple effects on efficiency, schedule, and the bottom line.

Whether you’re overseeing a sprawling oil refinery build or a cutting-edge power plant installation, mastering inventory logistics is key to keeping the project lean, the crew productive, and the budget in check. Read on to discover the most critical obstacles on the industrial construction inventory front and how to solve them with smarter planning, innovative processes, and the right tools for the job.

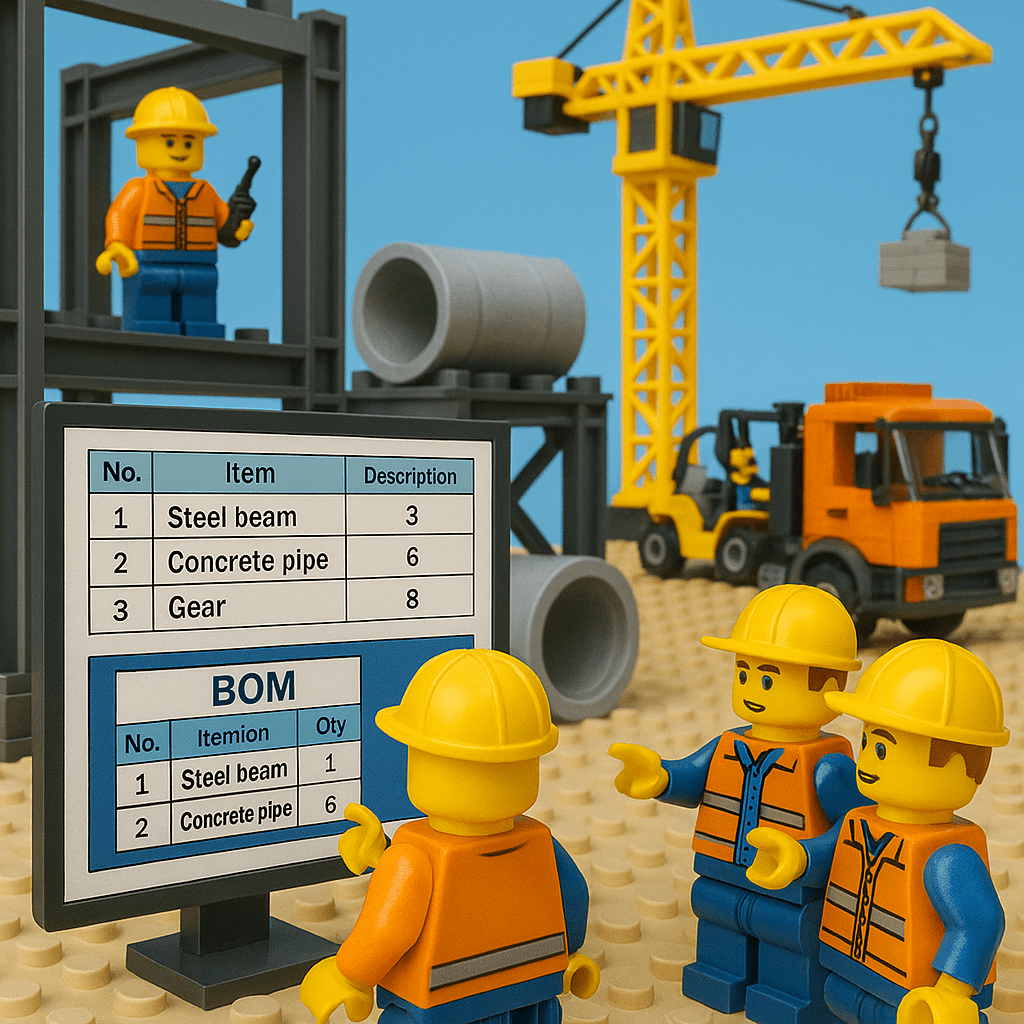

1. Bulk Material Handling and Storage

Industrial construction projects often involve gigantic materials—steel beams spanning dozens of feet, massive concrete pipes, and specialized equipment weighing tons. These bulky inventory items need heavy-duty cranes, forklifts, and trucks to move, and they eat up space in laydown yards and warehouses.

The challenge is not only in moving these large items, but also in storing them safely without causing bottlenecks or site congestion. A misplaced 50-foot steel girder or an incorrectly logged transformer can stall work quickly.

This problem is unique to industrial builds because of the scale and weight of materials involved. Unlike a residential project where a pallet of bricks is a big load, an industrial site might handle entire shipping containers of machinery or prebuilt modular sections. These oversized items make standard inventory procedures impractical. You can’t simply slide a 100-ton component onto a shelf or forklift it like a box of nails. Managing crane schedules, designated lift paths, and secure stacking zones becomes critical to keep the project moving.

Solution:

- Strategic site layout with designated storage areas.

- Use of color-coded markings, GPS tags, and scheduled crane management.

- Just-in-time (JIT) deliveries and off-site prefabrication.

Establish a strategic layout plan for heavy materials before they arrive on site. Designate specific drop zones and storage areas on a site map so every crew member knows exactly where bulky items are kept.

Use color-coded markings, GPS tags, or flagging tape to speed up locating these items. Coordinate deliveries precisely and stagger the arrival of oversize shipments to avoid crane conflicts.

Many teams find that just-in-time deliveries and off-site prefabrication of large assemblies (like welding equipment onto modular skids) can greatly reduce on-site storage needs. For example, pre-assembling a machine off-site means one big delivery instead of many small parts. By treating your materials yard like a mini-warehouse – with clearly marked locations and scheduled handling – crews spend less time searching and more time building.

2. Complex Bills of Materials (BOM) and Component Tracking

Industrial projects require thousands of individual parts – flanges, valves, sensors, cables, fasteners, and more – to build complex systems.

The bill of materials (BOM) for a power plant or refinery can run into the tens of thousands of line items, each with specific part numbers, grades, and suppliers.

Tracking every component through cutting, welding, calibration, and delivery is a massive challenge. It’s easy for parts to slip through the cracks: a mislabeled valve or a missing gasket might not be discovered until hours of installation work are wasted.

This challenge is unique to industrial construction because of the sheer scale and specificity of the equipment involved. A small residential build might only need generic lumber and nails, but a chemical plant or power station uses highly specialized instruments and materials. Many parts are custom-made or have tight tolerances, so substitutions are often not possible. Managing this many unique items – and ensuring they all arrive on schedule and fit together – is far more complex than the simple supply lists of smaller projects.

Solution:

- Centralized digital inventory system linked to BOM.

- QR codes, barcodes, RFID labels for precise tracking.

- Regular audits and reconciliation by dedicated materials coordinators.

Adopt a centralized inventory management system that ties into your project’s BOM.

Tag each component with QR codes, barcodes, or RFID labels, and scan them at every stage – receiving, storage, and installation. This creates a digital trail so teams always know how many of each part are available and where they’re located. Integrate this system with your design or ERP software so that any change in the BOM automatically updates inventory counts.

Finally, assign a dedicated materials coordinator or engineer to reconcile orders with actual usage during regular audits. By closely monitoring the BOM and keeping real-time records, you reduce over-ordering, prevent downtime from missing parts, and streamline each assembly step.

3. Extended Lead Times for Specialized Components

Industrial builds often rely on highly specialized equipment and materials that have long manufacturing lead times. If you need a custom heat exchanger, a high-voltage transformer, or a unique alloy piping section, you may wait weeks or even months for production and delivery.

During this time, other site work often grinds to a halt because that component is critical to the schedule. A missed shipment date for a custom pump can force crews to shuffle tasks and idle large teams on site.

This challenge is unique to industrial construction because many components are engineered specifically for one project. Manufacturers have long queues for custom parts, and even standard equipment is often built-to-order. Unlike a home renovation where you can pop into a local supplier for off-the-shelf materials, industrial projects must coordinate global sourcing, customs, and freight. Delays in overseas factories or in transit hit industrial schedules much harder than in smaller projects.

Solution:

- Advanced procurement planning and early vendor collaboration.

- Vendor-managed inventories or blanket purchase agreements.

- Flexibility in schedules to accommodate delays.

Plan procurement far in advance. Work closely with vendors to lock in delivery dates and milestones as soon as designs are firm. In many cases, placing orders as soon as engineering drawings are complete is critical.

Consider vendor-managed inventory or blanket purchase agreements – for example, a supplier might fabricate parts and park them at a nearby facility so they’re ready when needed. Where possible, identify alternative or local suppliers to reduce shipping time.

If delays still occur, adjust project schedules by front-loading tasks that don’t depend on the late items. This way, the yard stays productive while you wait, and expensive equipment isn’t sitting idle in storage.

4. Coordination Across Multiple Sites and Warehouses

Large industrial projects often have multiple job sites, yards, and warehouses in different regions or even countries. For example, one phase might happen on a coastal shipyard while another is inland or off-site. Each location may have its own stock of parts and materials.

The challenge is keeping an accurate, unified view of inventory across all these locations. Without coordination, one site might over-order while another site runs out, causing waste or delays. Miscommunication on inventory transfers or shipment arrivals can shut down work until clarity is restored.

This challenge is unique because industrial projects are commonly divided into distinct segments, each with its own logistical base. Residential projects rarely involve dozens of simultaneous laydown yards. In industrial construction, separate teams (civil, mechanical, electrical, etc.) might each maintain their own storeroom, yet their schedules overlap. Shipping materials between distant sites requires extra planning and travel time, complicating the supply chain further.

Solution:

- Implement multi-location inventory systems with cloud-based dashboards.

- Real-time tracking and transfer capabilities.

- Frequent cross-site audits for accuracy.

Implement a multi-location inventory system that links all stockrooms in real time. With cloud-based software, you can view inventories at every warehouse or site from a single dashboard.

Transfer orders between sites should be visible to all stakeholders. For example, if Site A is low on a sensor, the system can alert managers to ship some from Site B’s warehouse.

Regular cross-site audits help reconcile any discrepancies. By treating multiple yards as a networked warehouse, you cut down on duplicate orders and ensure the right materials flow to wherever they’re needed most.

5. Balancing Just-In-Time Delivery with On-Site Inventory

Industrial teams want to reduce on-site inventory clutter – but they can’t wait too long to receive critical materials either. Just-in-time (JIT) delivery is ideal for saving storage space and capital, but unpredictable supply chains and transportation for oversized industrial materials make pure JIT risky.

If a late shipment arrives even a day late, it can halt a major subsystem of the plant. Conversely, stocking too much on-site means clogged yards, material damage, and increased overhead.

This dilemma is unique in industrial construction because of the enormous volume of materials and remote locations involved. A small contractor might leave extra pipes at home, but an oil refinery project might have hundreds of truckloads of pipe on site. Some sites even rent extra land just to store incoming materials. Weather or customs delays can turn a standard two-week delivery into a two-month problem – something smaller projects rarely encounter.

Solution:

- Flexible inventory strategies blending JIT and lean buffer stocks.

- Off-site modular construction and pre-assembly.

- Small safety stock on-site for critical items.

Use a flexible inventory strategy. Map out your project schedule and sequence deliveries accordingly; for example, order long-lead items months ahead and reserve tighter timing for standard goods.

Employ modular construction and pre-assembly off-site to minimize on-site stock. Maintain a small safety stock of critical high-use items (gaskets, fasteners, spare filters) in secure, weather-protected storage on site to bridge minor delays.

Work with suppliers who offer expedited shipping or local stocking for quick turnaround. By combining careful JIT planning with lean buffer stocks, you minimize wasted space while keeping crews supplied exactly when they need it.

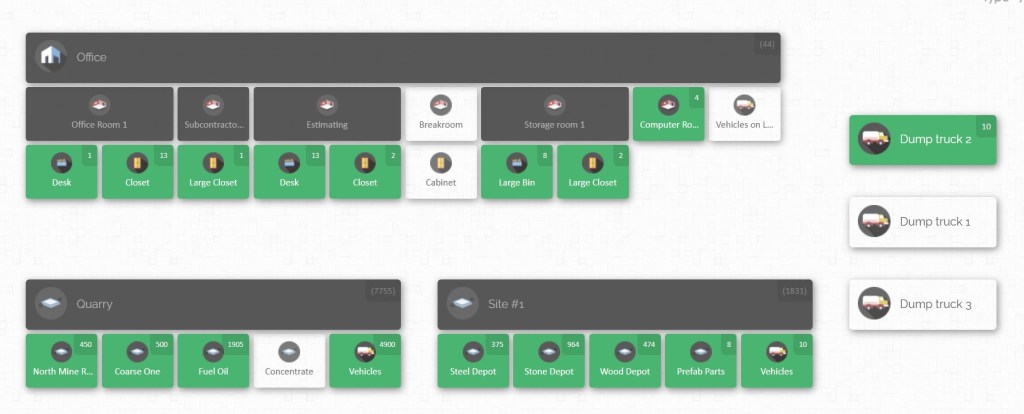

Spotlight: CyberStockroom – Modern Inventory Management

CyberStockroom is a visual, real-time inventory platform built for exactly these kinds of complex construction environments. It combines a map-based interface with real-time tracking and multi-location support to give operations teams total visibility over every part and material.

Key features of CyberStockroom include:

- Visual Site Mapping: Users upload site plans or warehouse layouts and place inventory items on a digital map. This way, crews immediately know the exact location of each asset or material. If the site layout changes, the map can be updated in real time so everyone stays on the same page.

- Real-Time Tracking: Every time a part is received, consumed, or moved, the system records it immediately. Scanning of barcodes keeps the digital inventory in sync with reality, eliminating the guesswork. Managers always know exactly what’s in stock and what’s running low, preventing unnecessary orders and project delays.

- Multi-Location Support: CyberStockroom links inventory across multiple yards, warehouses, or projects. A central dashboard shows stock levels by location, and managers can initiate transfers between sites with a few clicks. This prevents shortages by letting one site borrow from another quickly.

- Mobile Access: The software works on smartphones and tablets internet browsers. Teams can use their devices to count or move stock right on the construction floor. All updates sync to the cloud, keeping headquarters in the loop and maintaining accurate records.

By leveraging these capabilities, CyberStockroom directly addresses many of the earlier challenges. The visual map solves the layout and bulky materials problem. Real-time counts eliminate the mystery of “where did that part go.” Multi-location features keep decentralized stock coordinated.

In short, operations teams spend less time searching for parts, avoid ordering duplicates, and keep the project running smoothly and efficiently.

6. Regulatory Compliance and Material Traceability

Industrial construction often involves hazardous materials, specialized alloys, and safety-critical components that must meet strict regulations and standards.

You may need to track mill test certificates for every batch of steel, prove pressure vessels are certified, or document the chain of custody for hazardous waste removal. Failing a materials inspection or not having required documentation on hand can halt progress and trigger costly rework.

This challenge is unique because of the heavy compliance burden in industries like oil & gas, power, and chemical processing. For example, pressure piping often requires third-party certification at every welding stage. A small commercial or residential project doesn’t demand this level of traceability. Industrial teams must manage detailed records — what lot of raw material was used, who performed each weld, which inspector signed off. Not keeping tight control isn’t just a schedule delay; it can threaten worker safety and regulatory approval.

Solution:

- Digital certification and traceability processes.

- Barcode/RFID systems linked with compliance documentation.

- Automated tracking integrated with QA databases.

Digitize your certificate and traceability process. From the moment materials arrive on site, log batch numbers and attach any test certificates to those items in your inventory system.

Use barcode/RFID scanning in the field so installers can instantly retrieve compliance documentation. Keep a real-time log of hazardous or controlled materials moving on and off site. Many teams link their inventory software with quality databases so that inspections go smoothly.

By automating compliance tracking (linking inventory to permit systems or QA logs), you avoid paperwork headaches and fines, and keep projects on schedule.

7. Inventory Security and Theft Prevention

Industrial construction sites can span hundreds of acres and often operate around the clock, making them targets for theft and unauthorized use of materials.

Expensive items like copper wiring, precision tools, and even heavy machinery attachments can vanish if not closely monitored. The risk is unique because industrial sites frequently have lots of equipment and many contractors coming and going; keeping track of who has moved what part is challenging.

Unlike a small build that can be secured easily, industrial projects may have multiple entry points, temporary fencing, and off-hours work. A missing generator or a pallet of specialty valves can cost thousands to replace. A lack of inventory controls in such an environment leads to silent losses that erode margins over time.

Solution:

- Secure storage areas and surveillance systems.

- Check-in/check-out accountability procedures.

- Frequent audits and RFID tagging for tracking.

Combine physical security with accountability systems. Store valuable items in lockable containers or cages and install surveillance cameras in key areas. Limit yard access to authorized personnel only.

Implement a check-in/check-out system for tools and parts: workers scan items when taking them for a task and scan them back when done.

Conduct frequent inventory audits (daily or weekly for high-value items) to catch any shrinkage early. Many teams also mark or RFID-tag tools and components so they can’t be easily resold, and link each item in the inventory system to the worker or crew using it. Together, technology and robust processes help deter theft and ensure that materials stay put, protecting both the project timeline and the budget.

8. Weather and Environmental Impact on Materials

Industrial projects frequently span months or years in outdoor environments, exposing inventory to harsh conditions. Long-term exposure to rain, salt air, extreme heat, or cold can damage materials if not properly stored.

For example, untreated steel left outside will rust, electrical components may fail if moisture seeps in, and chemicals might lose potency in sunlight. Unexpected events like heavy rains or storms can also flood laydown yards or wash materials away.

This challenge is especially acute for industrial construction because of the sheer volume of outdoor inventory. Even a small commercial project can bring materials indoors overnight; an oil plant construction site might have miles of piping and large equipment sitting in the elements. Materials that degrade under weather pressure can no longer be used safely, forcing expensive reorders or onsite repairs. Replacing rusted parts can delay work for weeks.

Solution:

- Protective storage and weather-resistant containers.

- FIFO (First In, First Out) inventory management.

- Strategic scheduling and proactive weather monitoring.

Store materials under protective cover and in weather-rated containers whenever possible. Use tarps, covered sheds, or sealed warehouses for sensitive items.

Implement an inventory practice of “first in, first out” for outdoor stock to minimize time exposed. Track installation schedules and avoid leaving critical materials on site long before they will be used.

Also, build weather monitoring into your planning: if a major storm is coming, secure inventory in advance. By adapting storage and handling practices to local climate conditions, teams preserve material quality and avoid the costly damage caused by the elements.

9. Skilled Workforce and Training Gaps in Inventory Control

Even the best systems fail without people who know how to use them. On large industrial sites, dozens of subcontractors and crews arrive with different skills and priorities. Many workers are experts in welding or electrical work – not inventory management. If teams aren’t trained to record material use or follow inventory protocols, you end up with data gaps and guesswork. This problem becomes acute with high turnover or rotating shifts, making it hard to keep everyone aligned on the same procedures.

This issue is unique to industrial construction because the scale magnifies it. When a warehouse is small, any worker can quickly learn to count screws or lumber. But with multiple massive storerooms or laydown yards, you need dedicated inventory personnel and standardized training. Without that, different crews might count or label materials differently, leading to conflicting records and wasted time reconciling them.

Solution:

- Comprehensive inventory management training.

- Standardized, easy-to-use inventory tools.

- Dedicated inventory coordinators to maintain oversight.

Invest in training and clear procedures. Make sure every team knows how to check materials in and out – for instance, require workers to scan barcodes or sign a log before using parts. Designate inventory coordinators or stock clerks at each site to oversee counts and audits.

Use user-friendly application on tablets or phones so workers can update stocks with minimal hassle. Some companies even gamify or incentivize accurate inventory reporting.

By building a culture of accountability – rewarding crews that keep accurate records and making inventory a shared responsibility – teams drastically reduce lost time chasing missing materials.

10. Manual Tracking and Lack of Real-Time Visibility

In many industrial projects, inventory is still tracked through spreadsheets, paper logs, or even memory. These manual methods are slow and error-prone.

If a site manager relies on weekly counts or phone calls to know stock levels, the information is always outdated. Crews may order parts they don’t actually need, or assume something is out of stock when it’s hiding in a corner of the warehouse. The result? Lost time, redundant orders, and confused workflows.

This challenge is particularly magnified in industrial construction because job sites are large and activity is constant. By the time a foreman sends someone to physically check a material store and reports back, the inventory might have changed again. Without an automated system, it’s nearly impossible to keep accurate, up-to-date inventories at scale.

Solution:

- Transition to automated, real-time digital inventory systems.

- Mobile scanning and instant data updates.

- Real-time dashboards accessible by all stakeholders.

Move away from paper and static spreadsheets. Implement a cloud-based inventory system with real-time updates.

Give teams mobile devices or scanners so that every transaction – receiving, moving, or using a part – is recorded instantly. With up-to-date dashboards, supervisors can check stock levels anytime and anywhere. This digital transparency eliminates guesswork and ensures materials are used efficiently.

Over time, it also enables data-driven planning: by analyzing usage trends, teams can forecast needs more accurately and avoid over-ordering. Shifting to real-time visibility is a leap toward leaner operations and faster project execution.

11. Vendor and Subcontractor Coordination

Industrial projects rely on dozens of suppliers and subcontractors, each responsible for different parts of the build. This creates a coordination challenge. For example, the electrical contractor might order fixtures on one timeline, while the civil team needs rebar on another. Without centralized oversight, these parallel streams can clash: materials may arrive too early and sit unused, or too late, leaving crews waiting. This complexity is unique because an industrial site is like a mini city of vendors with varied schedules and processes.

Miscommunication can easily lead to delays. A change order from one subcontractor that isn’t shared with others can mean duplicate materials or missing items. Unlike smaller projects where one contractor manages everything, industrial construction requires orchestrating a web of suppliers with different lead times and ordering systems.

Solution:

- Integrated procurement and vendor communication channels.

- Shared material plans and centralized tracking dashboards.

- Regular coordination meetings and push notification systems for updates.

Streamline procurement through integrated communication channels. Establish a clear material plan shared with all subcontractors. Hold regular coordination meetings or use a shared dashboard to update everyone on material status. Use software to issue purchase orders centrally and track them by project phase. When a change arises, push notifications can alert affected parties immediately. Some companies also use vendor portals where suppliers update delivery dates directly. By keeping all stakeholders synced on what’s ordered and when, projects avoid costly overlaps and gaps in their supply chain.

Conclusion

Facing these challenges head-on with proactive planning and the right technology is key to improving operations efficiency. The strategies above – from organized storage layouts to digital tracking systems – all aim to save time, cut costs, and optimize resources. By addressing the unique inventory issues of industrial construction, project managers can avoid delays and budget overruns.

Modern solutions like CyberStockroom, along with smart processes and well-trained teams, turn inventory management from a liability into a competitive advantage. When the right material is in the right place at the right time, projects run smoother, crews stay productive, and the entire construction workflow is leaner and more reliable.

Leave a comment