The Hidden Costs of Tool Waste in Construction

In the world of industrial construction, managing tools and supplies effectively can be a significant challenge. Tools are lost, misused, or misplaced from hammers to power drills, leading to wasted time and costly delays. The consequences are not just financial – they also impact project timelines, productivity, and overall site safety. Here’s how:

Why Tools Disappear: Common Causes

- Decentralized Job Sites: With multiple job sites and crews working simultaneously, tools get scattered across locations. This makes tracking them a nightmare.

- Lack of Visibility: Tools are often checked out manually with no system in place to track where they are or who is using them.

- Theft & Misplacement: Job sites are chaotic, and tools can be easily stolen or misplaced without anyone noticing.

- Overstocking & Wasting: Contractors may purchase more tools than necessary because they can’t find what they already have, leading to excess inventory and waste.

- Poor Record Keeping: Tools aren’t always checked in and out properly, leaving no accountability for missing or damaged items.

This leads to wasted time, increased costs, and a frustrated workforce.

How Tool Waste Affects Your Bottom Line

In construction, tool waste has several far-reaching consequences, including:

- Lost Productivity: Teams waste valuable hours searching for missing tools. It’s estimated that workers lose up to 90 minutes a day searching for misplaced items.

- Increased Costs: Missing tools need to be replaced, and this quickly adds up to hundreds of thousands of dollars each year.

- Project Delays: Without the right tools at the right time, projects are delayed, and workers are forced to wait. Delays like these cost money and extend project timelines.

- Decreased Profit Margins: With tools being lost or wasted, businesses face a continual cycle of replacing missing items and wasting resources, cutting into their profits.

Impact of Tool Loss

Here’s a breakdown of how much missing tools cost a typical construction company over a year:

| Tools and Machineries | Estimated Loss |

| Missing Hand Tools (e.g., hammers, drills) | $10,000+ annually |

| Power Tool Losses (e.g., saws, grinders) | $25,000+ annually |

| Heavy Equipment Theft (e.g., forklifts, cranes) | $300M annually across the industry |

Tools Most Commonly Wasted in Industrial Construction

Some tools are more likely to be misplaced or wasted than others. These include:

- Hand Tools: Hammers, screwdrivers, and wrenches

- Power Tools: Drills, grinders, and saws

- Heavy Equipment: Forklifts, bulldozers, and cranes

- Small Equipment & Consumables: Levels, safety gear, fasteners, and adhesives

All of these tools are essential for day-to-day operations but are often subject to misplacement or theft. They represent a significant chunk of the equipment wasted on construction sites.

Smart Inventory Solutions: Addressing the Problem

Now that we know the problem, let’s talk about how to solve it. Fortunately, modern inventory management solutions are helping industrial construction firms reduce tool waste, improve visibility, and streamline operations. Here’s how:

Effective Strategies to Manage Tools and Supplies

- Real-Time Tracking:

- Technology: Use barcodes, QR codes, or RFID tags to track tools and materials. Each item is assigned a unique identifier that can be scanned as it moves between sites.

- Benefits: You’ll know exactly where your tools are, who is using them, and when they were last checked in.

- Technology: Use barcodes, QR codes, or RFID tags to track tools and materials. Each item is assigned a unique identifier that can be scanned as it moves between sites.

- Tool Assignment Systems:

- Solution: Assign tools to specific crew members for each shift or project.

- Benefits: With accountability, it’s clear who has which tool, and it’s easier to track usage and avoid losses.

- Solution: Assign tools to specific crew members for each shift or project.

- Mobile Inventory Management:

- Technology: Use mobile apps that allow workers to check out tools using their smartphones, reducing the need for manual logging.

- Benefits: This improves the accuracy and efficiency of tool tracking and makes real-time updates possible.

- Technology: Use mobile apps that allow workers to check out tools using their smartphones, reducing the need for manual logging.

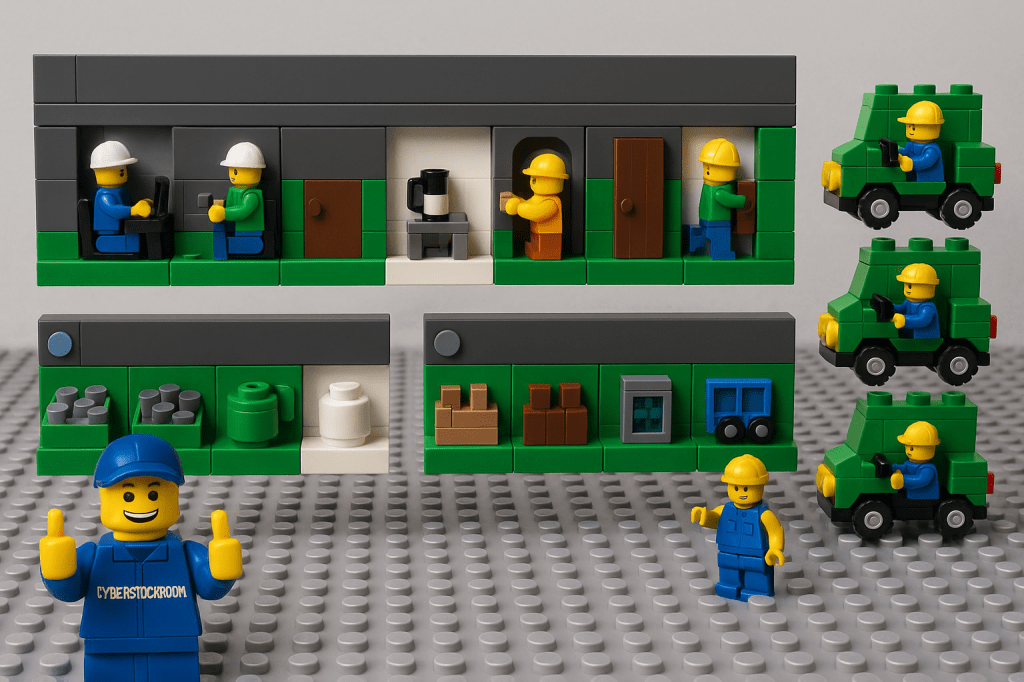

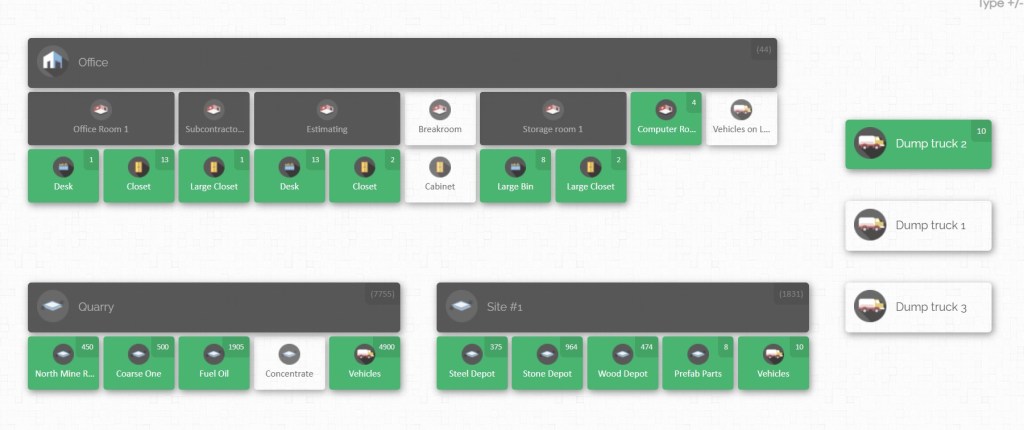

- Centralized Digital Platforms:

- Solution: Implement cloud-based platforms to track inventory across all job sites. These platforms allow managers to view tool availability, locations, and usage from anywhere.

- Benefits: Instant visibility and a comprehensive view of all inventory in real time.

- Solution: Implement cloud-based platforms to track inventory across all job sites. These platforms allow managers to view tool availability, locations, and usage from anywhere.

- Tool Transfers and Location Updates:

- Technology: Use systems that allow tools to be easily transferred between locations with a simple click or drag-and-drop action on a digital map.

- Benefits: This keeps records up to date and prevents confusion when tools move between job sites.

- Technology: Use systems that allow tools to be easily transferred between locations with a simple click or drag-and-drop action on a digital map.

- Routine Audits and Reconciliation:

- Solution: Conduct regular audits to ensure your inventory matches what’s physically on-site.

- Benefits: Regular checks prevent discrepancies and alert you to any missing or damaged tools before it becomes a bigger problem.

- Solution: Conduct regular audits to ensure your inventory matches what’s physically on-site.

How Cyberstockroom Solves Tool Waste in Construction

Cyberstockroom provides a powerful inventory management solution designed specifically for industries like construction. It tackles tool waste through its cloud-based system and real-time tracking features. Here’s how Cyberstockroom can help:

Key Features of Cyberstockroom for Construction Inventory

| Feature | How It Helps |

| Real-Time Tracking | Tracks tools with barcodes and the visual inventory map, giving instant visibility into location and usage. |

| Mobile-View | Allows crews to check out tools using smartphones or tablets browser apps. |

| Drag-and-Drop Transfers | Tools and supplies can be easily moved between job sites and updates are made instantly in the system. |

| Cloud-Based System | Managers can view inventory from any device, anywhere – ensuring full visibility across all job sites. |

| Tool Assignment & Accountability | Assign tools to specific workers or teams, ensuring accountability for each item. |

| Customizable Fields | Attach documents, maintenance records, and user manuals to each tool, ensuring proper usage and upkeep. |

| Inventory History Logs | Keep track of each tool’s usage, including who checked it out and when it was returned. |

Benefits for Construction Sites

- Improved Visibility: Cyberstockroom’s real-time tracking ensures that tools are always accounted for and in the right place.

- Fewer Tool Losses: Tool assignment and accountability features reduce the chances of tools going missing.

- Reduced Wasted Time: With mobile check-in/check-out and location tracking, workers spend less time searching for tools and more time working.

- Increased Efficiency: Cloud-based inventory management provides a clear, updated picture of what’s available, helping to avoid overstocking and unnecessary purchases.

How to Implement Cyberstockroom on Your Construction Sites

Construction Site Demo MapTo take control of your inventory and stop wasting tools, Cyberstockroom is the solution. Here’s how you can get started:

- Assess Your Needs: Determine the number of tools and materials to track across your job sites.

- Tag Tools: Attach barcodes, QR codes, or RFID tags to your tools.

- Train Your Crew: Get your team up to speed on the mobile app and inventory platform.

- Start Tracking: Begin using the system for tool check-ins, check-outs, and transfers.

- Monitor & Adjust: Use the system’s reports and logs to fine-tune your processes and inventory strategy.

Final Thoughts

Tool waste in construction is a huge issue, but with the right tools (pun intended), it’s possible to bring order to the chaos. By adopting modern inventory tracking technologies and accountability systems, you can reduce tool losses, streamline your processes, and ultimately save time and money. Cyberstockroom’s powerful features provide the visibility and control you need to stop wasting tools and materials, empowering your team to work smarter, not harder.

Ready to Take Control of Your Tools?

Get started with Cyberstockroom today to ensure your tools are always in the right place at the right time!

Leave a comment