In today’s manufacturing environment, it’s typical for businesses to run several plants, warehouses, or production sites. Effectively managing inventory across these various locations is essential, yet can be extremely difficult when using outdated or isolated systems.

Many manufacturers, particularly smaller ones, continue to depend on basic tools like spreadsheets to monitor their stock. This often leads to a disjointed perspective on inventory: one site may have an abundance of raw materials while another struggles with shortages, often without anyone being aware in a timely manner.

Cloud inventory systems have emerged as a powerful solution to these problems. By leveraging cloud technology, manufacturers of all sizes – from small job shops to global enterprises – can gain a centralized, real-time view of inventory across every site.

Challenges in Managing Inventory Across Multiple Sites

Operating multiple manufacturing sites or warehouses introduces several inventory management challenges that single-site operations may not face:

Lack of Visibility: Each facility might maintain its own inventory records. Without a unified system, there’s no single source of truth. Data from different sites has to be manually consolidated (often via emails or spreadsheets), which is slow and error-prone. This silo effect means managers can’t easily see what overall stock the company has in real time – they only see their piece of the puzzle. If Site A runs low on a component, they might not know that Site B has a surplus that could be reallocated.

Out-of-Date Information: When inventory data is tracked separately at each site, by the time reports get to headquarters the information may be days or weeks old. Fast-moving production environments suffer when decisions are based on stale data. This often leads to surprises like discovering a stock shortage only when it’s about to halt a production line.

Inconsistent Processes: Different sites might use different methods or software to track inventory (one might use an ERP system module, another uses spreadsheets, etc.). This inconsistency makes it hard to standardize training, reporting, and best practices. It also increases IT complexity and costs if maintaining multiple systems.

Overstock and Stockouts: Perhaps the biggest consequence of poor multi-site visibility is the tendency for some locations to hold excess safety stock “just in case,” while others unintentionally run dry. Lack of coordination can cause overstock (tying up capital and storage space) at one site and stockouts (and costly downtime) at another. For example, a factory might order more raw material than needed because they don’t realize another plant has plenty to spare. This imbalance drives up carrying costs and can lead to waste (e.g. materials expiring on a shelf at Site A that Site B could have used).

High Administrative and IT Burden: Managing separate inventory systems at multiple sites means updates and audits have to be performed site-by-site. The IT team might need to maintain servers or software installations in several locations. Such decentralized management is inefficient and costly compared to a single centralized system. It’s also harder to enforce security and backup protocols uniformly across sites.

These challenges can significantly impact a manufacturer’s agility and cost efficiency. Without a clear, up-to-date picture of inventory across the entire operation, it’s difficult to optimize production schedules, forecast accurately, or respond swiftly to supply chain disruptions. This is where cloud inventory systems come in – they are specifically designed to address these multi-site pain points.

Benefits of Cloud Inventory Systems in Manufacturing

Adopting a cloud-based inventory system provides a unified platform to manage stock across all locations, delivering numerous benefits to both small/medium businesses (SMBs) and large enterprises:

Enhanced Inventory Visibility & Real-Time Tracking

Cloud inventory systems create a central data repository that all sites connect to. Instead of information sitting in local silos, everything is updated to the cloud in real time as transactions happen. This means a plant manager in one location can instantly see if another warehouse across the country received a new shipment or used up certain parts. Everyone has access to the same up-to-the-minute data.

This real-time visibility is transformative – it allows proactive decision-making. For instance, if inventory of a critical component is running low at Factory X, managers elsewhere see this and can either rush replenishment or redistribute stock from another facility before it becomes a crisis.

Cloud platforms often provide dashboards that show inventory levels by location, so you can monitor stock anywhere in the world at a glance. In short, it eliminates blind spots. (As an illustration, cloud software like Zoho Inventory touts that managing multiple warehouses is made easy with a unified system to “track and manage” stock across all locations.)

Cost Savings and Efficiency Gains

Better visibility and accuracy directly translate to cost savings. When you know exactly what’s on hand across your entire operation, you can avoid over-purchasing and holding excessive inventory buffers.

Companies often find they can reduce overall inventory levels once they have a cloud system, because they no longer need a redundant safety stock at each site – the cloud system makes it possible to share inventory between sites effectively. This reduction in stockholding frees up working capital and lowers carrying costs (which include storage, insurance, and obsolescence of unused stock). Likewise, preventing stockouts avoids the heavy costs associated with line stoppages, rush shipping of parts, or disappointed customers.

There are IT cost savings as well: a cloud solution means you don’t need on-premise servers and maintenance at each location, since the software is hosted by the provider. Updates and backups are handled centrally by the vendor, reducing the burden on your IT staff. For a small or mid-sized manufacturer, this can be a huge benefit – you get sophisticated inventory management without needing a large IT department or expensive infrastructure. Overall, more efficient inventory management leads to leaner operations and less waste.

Scalability and Flexibility (for SMBs and Enterprises)

A cloud inventory system can scale with your business. This is crucial for growing companies and also beneficial for large enterprises with dynamic operations. For SMBs, cloud solutions often operate on subscription models – you can start with the features or capacity you need and expand as your business grows or you add new sites. You avoid the massive upfront investment of traditional enterprise software.

If you open a new warehouse or launch a new production facility, you simply add it to your cloud platform and it’s immediately integrated into your inventory network – no need to install separate software at that site. For large enterprises, cloud systems provide the flexibility to quickly onboard acquisitions or new locations and to connect with suppliers or partners in the supply chain. The cloud can usually handle spikes in usage (for example, a seasonal surge in transactions) better than an older on-premise system constrained by fixed hardware. In terms of user access, cloud inventory tools typically offer web-based or mobile access, so whether a worker is on the factory floor with a tablet or a regional manager is checking on inventory from the corporate office, they can all use the system simultaneously from anywhere.

This anywhere-access was particularly valuable during recent times when remote work and travel restrictions made it harder for central teams to be on-site – with cloud access, they could still audit and supervise inventory virtually.

Improved Accuracy and Traceability

Cloud inventory systems often incorporate barcode scanning, RFID, or IoT device integration to log inventory movements automatically. When an employee at any site performs a transaction (like receiving materials, consuming parts in production, or shipping finished goods), scanning an item updates the cloud record instantly.

This level of automation greatly improves inventory accuracy by removing manual data entry (and its associated errors). Over time, organizations see higher inventory record accuracy – often 95-99% accuracy – meaning the data in the system matches the physical stock on shelves almost perfectly.

Moreover, every change is logged with a timestamp and user, so it’s easy to trace when, where, and who moved something. This traceability is important for quality control and compliance (for example, tracking lot numbers or serial numbers across multiple facilities if there’s a recall or audit).

Centralized Control with Local Empowerment

With a cloud platform, headquarters can maintain standard definitions (like one consistent product catalog, SKU codes, units of measure, etc.) and company-wide inventory policies (min/max levels, reordering rules) that apply across all sites. This ensures consistency in how inventory is managed. At the same time, local teams at each site still have the flexibility to manage day-to-day operations – they can view and update their location’s data, place local orders or transfers (with appropriate permissions), and so on.

The cloud system essentially balances central oversight with local autonomy, which is ideal for multi-site operations. Management can run aggregate reports (e.g., total finished goods across all warehouses) or drill down into a specific location’s status, all within the same system.

Better Collaboration & Decision-Making

When everyone from procurement, to production planners, to warehouse managers is looking at the same real-time inventory information, it fosters collaboration. A sales planner can check if stock is available in any warehouse to fulfill a customer order, or a factory manager can signal others through the system that they have surplus materials up for grabs. Cloud systems can also integrate with other enterprise systems (like ERP, MRP, or sales platforms) to provide inventory data wherever it’s needed. This integration means your production schedules and procurement plans are always based on the latest inventory status.

Data analytics across the consolidated inventory data can reveal usage trends, faster turnover at one site versus another, or opportunities to streamline supply chain logistics (for example, maybe two sites can coordinate to share a nearby distribution center). Overall, decisions become more data-driven. A survey of manufacturers showed that improving inventory visibility was a top priority because it directly improves forecasting and responsiveness – cloud systems are a key enabler of that visibility.

How Cloud Systems Address Multi-Site Inventory Problems

It’s helpful to directly connect the challenges to the solutions enabled by cloud inventory technology. The table below summarizes how a cloud system tackles common multi-site inventory management issues:

| Challenge | Solution via Cloud Inventory |

| Siloed data across sites | Centralized cloud database accessible by all sites ensures a single source of truth for inventory data. Every location logs into the same system, so data is unified and up-to-date company-wide. |

| Delayed, out-of-sync updates | Real-time synchronization: as soon as stock is added, moved, or used at any site, the cloud record updates instantly. No need to wait for end-of-day or weekly reports – everyone sees changes as they happen. |

| Manual reconciliation & errors | Automated data capture (via barcode scanners, IoT sensors, etc.) feeds the cloud system, minimizing manual entry. This reduces errors and the time spent reconciling records from different locations. |

| Stock imbalances (overstock/stockouts) | Full visibility allows inventory balancing across sites. Surplus at one warehouse can be identified and transferred to another that’s low. Cloud systems also enable setting company-wide reorder points that consider total inventory, preventing over-ordering. |

| High IT and maintenance costs | The cloud provider handles the infrastructure, security updates, and software maintenance. Companies no longer need separate servers or IT teams at each location for inventory software, lowering overhead. Users just need an internet connection and device to access. |

| Scaling to new sites is slow | Rapid scalability: new locations can be added to the cloud platform with minimal effort. Since there’s no complex on-prem install, a new plant or warehouse can come online in the system quickly and start reporting inventory immediately. |

| Inconsistent methods | A cloud system standardizes inventory management processes across all sites. Everyone uses the same interface, follows the same workflows for receiving, issuing, counting, etc., which improves consistency and compliance with company procedures. |

| Limited oversight and analytics | Cloud platforms often include reporting and analytics tools that aggregate data from all locations. Managers get enterprise-wide KPIs (like total inventory turns, fill rates, shrinkage) and can drill down by site. This holistic insight is impossible to obtain easily when using disconnected local systems. |

As shown above, cloud inventory systems directly solve the core problems that plague multi-site operations. They provide a foundation for visibility, efficiency, and agility that simply isn’t achievable with manual methods or isolated on-premise tools.

Cloud Inventory Success

Many manufacturers have already reaped the benefits of switching to cloud-based inventory management, whether through comprehensive ERP systems or specialized inventory platforms. Here are a couple of illustrative examples:

- Mid-Sized Manufacturer (Electronics Industry): A mid-sized electronics manufacturer with three production plants found it hard to coordinate inventory. They often had one factory expedite orders for parts that another factory had in excess. After implementing a cloud inventory system, they achieved a unified view of component stock across all facilities. Almost immediately, they spotted opportunities to redistribute components internally instead of buying new stock. Over the first year, the company reduced its overall inventory levels by about 15% by eliminating this redundant stock holding. Perhaps more importantly, stockouts of critical components went down to near-zero – if any site started running low, the system would alert managers in time to transfer stock from a sister plant or rush-order from a supplier. The real-time nature of the new system also saved countless hours of manual inventory reporting. One manager remarked that before the cloud system, their inventory data was always a week behind; now it’s live, enabling them to make faster decisions to keep production on track.

- Global Enterprise (Automotive Supply Chain): A large automotive parts manufacturer operating multiple factories and distribution centers worldwide migrated from disparate legacy inventory systems at each site to a single cloud-based platform. This enterprise integration was a big project, but it paid off: they now have end-to-end visibility of parts from manufacturing through regional warehouses. For example, if a European warehouse is running low on a particular part, they can see if any U.S. or Asian location has a surplus, and initiate an inter-company transfer or adjust production plans accordingly. The cloud system also interfaces with their assembly plants’ production systems, so as cars are built and parts are consumed, inventory levels update instantly. The company reported significant improvements – inventory accuracy rose into the high 90% range, audit times were cut dramatically (since all records are digital and centralized), and they managed to reduce backorders by proactively reallocating stock globally. This kind of agility was crucial during recent supply chain disruptions; because data from every site was in one place, the firm could navigate component shortages by diverting inventory from one region to another in a timely fashion.

These examples demonstrate the tangible improvements cloud inventory management can deliver: lower costs tied up in inventory, fewer production delays, and more streamlined operations across multiple locations. Whether it’s a small business or a Fortune 500 enterprise, the principles remain the same – connectivity and real-time data lead to smarter inventory decisions.

How Cyberstockroom Can Help Solve Inventory Problems

To make the discussion concrete, let’s consider Cyberstockroom as an example of a cloud inventory system and how it can directly address the challenges we outlined.

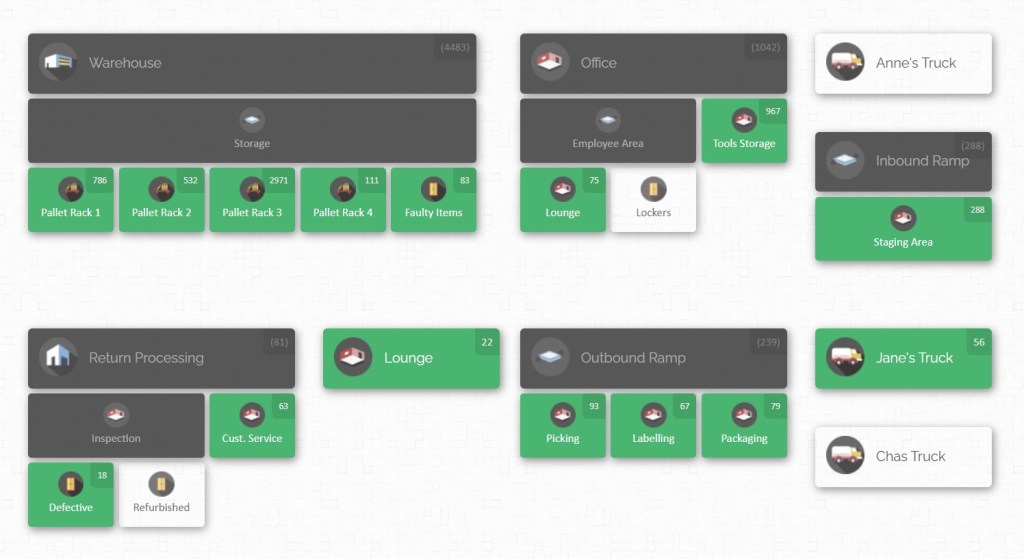

Cyberstockroom is an online inventory tracking solution that is particularly known for its intuitive, visual approach to managing inventory. Users can create a map of all the locations in their business and populate it with their products. This means if you have, say, five warehouses and two factories, Cyberstockroom lets you visually map those sites (and even different rooms or areas within them) and see what inventory is stored where on the map.

What benefits does this bring to a multi-site operation?

- Visual Inventory Visibility: The map-based interface gives a bird’s-eye view of inventory distribution. Rather than scrolling through spreadsheets or lists, you can literally see your entire operation’s inventory layout. For example, Warehouse A and Warehouse B might be represented on the map – clicking on each location shows the products and quantities there. This makes it very easy to spot imbalances (maybe one location is showing a lot of a certain item while another is nearly empty). Cyberstockroom essentially combines the real-time data of the cloud with a user-friendly visual representation, so that anyone – even non-technical staff – can quickly understand the inventory situation across sites.

- Real-Time Updates and Accessibility: Being a cloud system, Cyberstockroom is accessible from any location. Teams at each site can log in through a web browser to update inventory movements (receiving shipments, using parts, transferring items, etc.), and those updates are reflected instantly for everyone. If a field technician with a tablet removes a part from inventory in one location, it will show up on the system immediately, so colleagues at other sites know that part’s stock went down. This real-time aspect ensures that decisions are always based on the latest information. Managers at headquarters can monitor all locations without calling or emailing for updates – they just check Cyberstockroom. It’s also handy for remote or traveling managers who need to check inventory on the go.

- Simplified Multi-Site Management for SMBs: Cyberstockroom is particularly well-suited for small to mid-sized companies that have outgrown spreadsheets but don’t want a complex, heavy enterprise system. It focuses on core inventory tracking features with an easy learning curve. Setting up multiple locations in the system is straightforward – you add your warehouses/stores/work sites, and you can drag-and-drop products onto locations in the map interface. This simplicity means even a business without a dedicated IT department can get up and running quickly. And as the business grows (say you add a new warehouse), you can simply add that new location to the map and start managing inventory there immediately. The system scales with you without a lot of overhead. (In a sense, it provides SMBs the kind of multi-warehouse management capabilities that were once available only to big firms with expensive software. Now, a cloud tool can offer it as an affordable service.)

- Reduction of Errors and Stock Discrepancies: Cyberstockroom supports features like check-in/check-out of products to specific locations (one of their YouTube tutorials even demonstrates checking products into a location). By enforcing a simple process for moving inventory (you always log where an item is going), it keeps the records accurate. This helps avoid the classic scenario of “Where did those 50 units go? One site says we have them, the other site doesn’t.” With everyone using the same system, those kinds of mysteries are reduced. All transactions are tracked, so reconciliation is easier. If something seems off, you can trace back in the system to see the last recorded movements of that item.

- Collaboration and Sharing: Because Cyberstockroom is cloud-based, all team members – whether they sit in the warehouse or in the main office – are looking at the same data. This transparency encourages teams to work together. If the sales team in the office needs to know if a product can ship from a particular warehouse, they can check availability in Cyberstockroom without having to call the warehouse manager. Conversely, if a warehouse is overstocked, they can flag it in the system so others know that inventory is available to meet needs elsewhere. It essentially breaks down the communication barriers between sites. Many cloud inventory tools, Cyberstockroom included, also allow role-based access control, meaning you can finely tune who sees or edits what (e.g., a store manager might only see their store’s inventory, while a regional manager sees all stores in their region). This way, people get the information relevant to them while top management can oversee everything.

Conclusion

Multi-site manufacturers have a lot to gain from cloud inventory systems. By moving inventory management to the cloud, organizations create a single, reliable view of stock across all factories and warehouses – enabling better decisions, leaner inventories, and faster response to demand changes. The benefits range from very practical (e.g. preventing stockouts and surplus stock) to strategic (supporting growth and supply chain agility). We’ve seen that both small businesses and large enterprises can leverage these systems: the cloud makes advanced inventory management accessible to the little guys, while giving the big players the global oversight they need.

Of course, adopting a new system requires change management – companies need to train staff and possibly rework some processes to fit a centralized approach. But the effort is well worth the payoff when you eliminate the headaches of chasing down inventory information from multiple sources. The success stories in the industry show clear improvements in efficiency and cost savings once a cloud inventory solution is in place.

In an era where manufacturing supply chains are increasingly complex and distributed, having real-time visibility and control is no longer a luxury – it’s becoming a necessity. Cloud inventory systems provide the tools to achieve that. Whether it’s a platform like Cyberstockroom with a friendly interface for mapping your stock, or a larger-scale cloud ERP inventory module, the core idea is the same: connect your sites, see your inventory, and manage it proactively.

By doing so, multi-site operations can operate with the confidence of knowing exactly what they have and where they have it, at any time, which ultimately leads to a more resilient and responsive manufacturing operation.

Leave a comment