In a manufacturing environment, inventory isn’t just a list of parts or a few pallets sitting in storage—it’s the lifeblood of your production. Whether it’s raw materials, components, or finished goods, managing inventory well can be the difference between smooth operations and costly bottlenecks.

Unfortunately, inventory mismanagement is a quiet killer in manufacturing. It leads to overstocking, unexpected shortages, production delays, higher operating costs, and frustrated teams. And in today’s lean, demand-driven environment, there’s little room for error.

This guide walks through field-tested inventory optimization strategies tailored specifically for manufacturing plants. These aren’t abstract ideas—they’re practical, actionable steps that plant and inventory managers can implement to drive real results.

1. Get Total Visibility: Know What You Have, Where It Is, and What It’s Worth

If you don’t have full visibility, everything else is just guesswork.

Common problems:

- Parts stored in incorrect locations

- Production delays due to “missing” materials that were never recorded

- Overstock because items are duplicated in multiple systems

Solutions:

1. Integrate your inventory system with production and procurement tools

2. Implement a real-time inventory tracking system using barcodes, RFID, or smart sensors

3. Build a virtual inventory map of your plant, showing exact item locations by zone or department

Manufacturing example:

At a medium-sized electronics assembly plant, the lack of real-time visibility led to frequent delays as workers waited for parts that were “on the shelf” but couldn’t be located. After switching to a location-based cloud system with barcode scanning, they reduced these delays by over 30% in two months.

2. Use ABC Analysis to Prioritize What Matters Most

Trying to give every item equal attention is a recipe for inefficiency. In reality, some inventory items are more critical than others.

ABC classification:

- A-items: High value, low volume. Disruptive if missing (e.g., proprietary chips, engine blocks)

- B-items: Moderate value and frequency. Important, but replaceable.

- C-items: Low value, high volume. Often basic supplies like fasteners or cleaning solvents.

Actionable tips:

- Audit your inventory list and assign categories

- Review A-items weekly, B-items monthly, and C-items quarterly

- Use automation for C-item reordering (e.g., pre-set min/max levels)

Why it works:

ABC analysis helps you allocate your attention, resources, and storage space where they deliver the most impact.

3. Forecast Demand Based on Real Production Trends

Many manufacturers struggle because they order inventory based on outdated assumptions or manual guesses. That leads to either excess inventory or mid-production shortages

Smarter forecasting:

Factor in lead times and supplier reliability

Analyze historical production data and consumption rates

Build forecasts based on seasonality, customer contracts, and sales orders

Advanced move:

Use demand forecasting tools or AI-enhanced platforms to detect demand trends and adjust inventory levels dynamically.

Manufacturing tip:

Avoid treating all products the same. Forecast raw materials differently for made-to-order vs. make-to-stock workflows.

4. Automate Reorders and Standardize Restocking Rules

Manual inventory checks and reorder decisions are inconsistent, time-consuming, and often reactive.

Streamline it:

- Set reorder points (ROP) and safety stock thresholds for every SKU

- Automate purchase orders when stock drops below a threshold

- Sync with your suppliers for real-time purchasing integration

Scenario:

A plant using aluminum castings for industrial machinery production set automated restocking alerts based on real-time consumption data. This eliminated emergency supplier calls and reduced last-minute shipping fees by over 40%.

5. Minimize Work-in-Progress (WIP) and Excess Material

WIP inventory is one of the hardest categories to control. Excess WIP clutters the floor, hides inefficiencies, and inflates inventory value.

Lean strategies:

- Use visual controls (kanban boards, digital dashboards) to monitor WIP in real time

- Break production into smaller batches to reduce queues

- Review stage-by-stage WIP holding times and eliminate delays

Best practice:

Limit WIP to what can be completed in the next 24–48 hours. If there’s more than that, it’s a red flag.

Extra tip:

Coordinate WIP visibility with maintenance and quality teams. WIP backlogs often hide defect issues.

6. Implement Cycle Counting Instead of Annual Physical Counts

Annual inventory counts are time-consuming, error-prone, and disruptive. Cycle counting offers a better path.

Cycle counting best practices:

- Focus on A and B items more frequently (weekly/monthly)

- Create a schedule that covers your entire inventory monthly or quarterly

- Use mobile scanners and software that update records instantly

Result:

One automotive component supplier saw a 95% reduction in audit errors after replacing annual counts with daily 20-minute cycle counts.

7. Track Inventory Across Multiple Departments and Facilities

Most manufacturers don’t store all their inventory in one place. Materials might flow between storage, production, QA, and shipping—or even between locations.

What to do:

Track movement history to identify bottlenecks or frequent relocations

Set up virtual locations inside your inventory system (e.g., “Line 3,” “QA Hold,” “Maintenance Room”)

Use check-in/check-out logs for tools and shared parts

Why it matters:

You need visibility across every transfer, not just storage. If one item sits too long at QA, production can stall.

8. Optimize Inventory Layout for Workflow Efficiency

Inventory optimization isn’t just about quantity—it’s also about accessibility.

Tactics:

Reorganize shelves using FIFO (First-In, First-Out) principles

Place high-turnover items near the production line

Group commonly used items together to reduce walking time

Real result:

A packaging plant reduced operator walk time by 22% simply by relocating fast-moving SKUs closer to the assembly zone.

9. Use Inventory Data to Improve Supplier Relationships

Inventory optimization doesn’t stop inside your walls. Your suppliers play a huge role.

How to collaborate better:

- Share consumption and forecast data with key suppliers

- Set up vendor-managed inventory (VMI) agreements

- Monitor supplier performance (delivery lead time, order accuracy)

Why it works:

Fewer surprises for you means fewer surprises for your vendors—leading to smoother workflows on both sides.

10. Inventory Optimization Is Ongoing—Set KPIs to Track Progress

You can’t improve what you don’t measure. Track KPIs that tie inventory management to production outcomes.

Suggested KPIs:

- Inventory Turnover Ratio

- Stockout Rate

- Carrying Cost of Inventory

- Order Cycle Time

- Inventory Accuracy %

Tip:

Visualize KPIs in dashboards and review them weekly in production meetings.

Final Thoughts: Start Small, Think Big — and Use the Right Tools

Inventory optimization isn’t a one-time fix—it’s an ongoing process of visibility, analysis, and adjustment. But the payoff is huge: less waste, fewer delays, smoother production, and more profit.

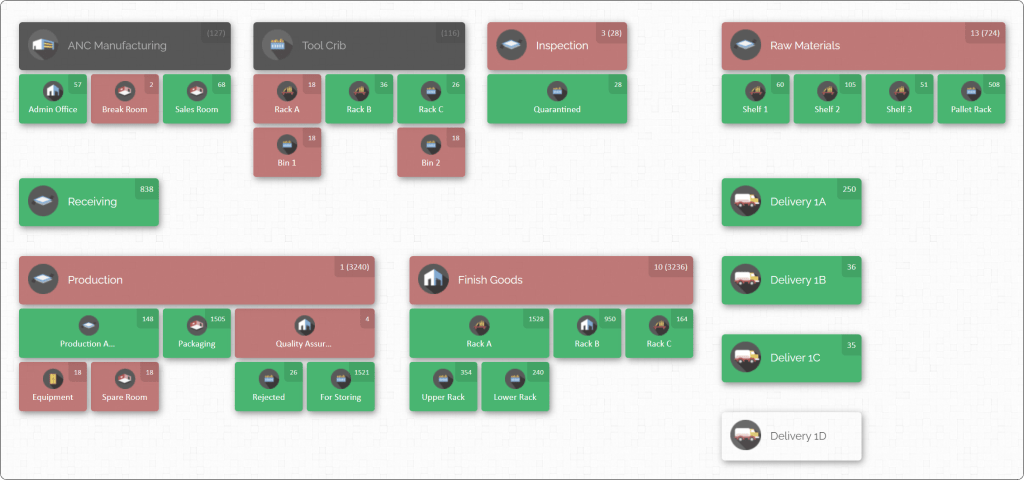

And you don’t have to do it alone. Tools like CyberStockroom are built specifically for businesses that want to improve the way they manage inventory—especially in complex environments like manufacturing plants. With CyberStockroom, you can:

- Create a visual map of your plant that shows where every item is stored

- Track inventory in real time across multiple locations, departments, or even mobile units

- Set expiration dates, and stock thresholds

- Use barcode scanning and check-in/check-out systems to boost accountability and avoid human error.

- Automate cycle counts and review activity reports to catch issues early

Manufacturing is complex enough. With the right tools and strategies in place, your inventory doesn’t have to be.

Leave a comment