It is critical for aviation companies to navigate the complex world of aerospace inventory management. It is about more than just keeping track of parts, it is also about assuring safety and increasing operational efficiency.

- Aerospace Inventory Management Overview

- CyberStockroom’s Role in Aerospace Inventory Management

- Take the Next Step in Enhancing Your Aerospace Inventory Management

Aerospace Inventory Management Overview

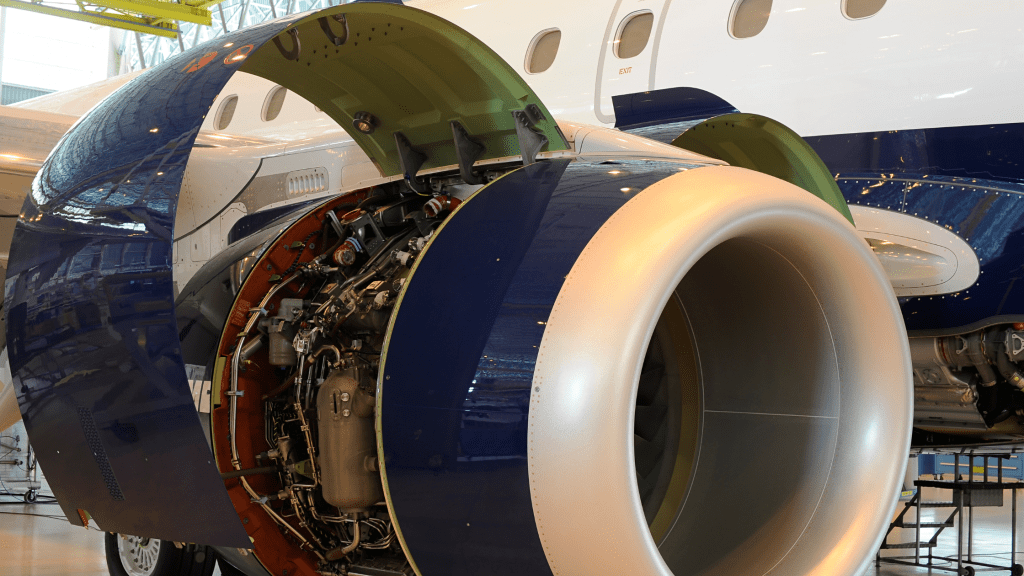

Aerospace inventory management is about rigorous management and control of aircraft parts. Precision, attention to detail, and strategic thinking are all required. This process is important for maintaining the greatest levels of safety and efficiency in an industry where even little mistakes can have serious effects.

Inventory management in the dynamic context of aerospace goes beyond simply tracking items. It requires a proactive strategy for predicting demands, managing inventory life cycles, and assuring the timely availability of essential parts.

This level of control is crucial in limiting aircraft downtime and avoiding the ripple effects of delays throughout the aviation network.

Furthermore, aerospace inventory management involves more than just having the right parts in the proper quantities. It’s also important to understand the interplay of numerous components, their compatibility with various aircraft models, and the ever-changing technological landscape. This knowledge allows for more informed judgments concerning stock levels, future purchases, and the retirement of obsolete parts.

Staying on top of technical improvements and business trends is also essential for effective inventory management in aircraft. This involves integrating advanced inventory management systems that improve inventory tracking and data analysis. Adopting digital transformation in inventory processes contributes to more transparency, fewer errors, and faster response times in supply chain operations.

Best Practices for Aerospace Inventory Management

The following are the best practices that are redefining how the industry maintains its inventory.

From advanced control strategies to accurate part tracking and effective shelf life management, these practices are critical to preserving efficiency and safety in aircraft operations.

Revolutionizing Inventory Control– Traditional inventory systems are no longer sustainable in the aircraft industry. Parts and components’ complexity and variety require dynamic, advanced solutions. Modern management of inventory in aerospace is now based on technological approaches. Real-time tracking systems, advanced analytics for predictive maintenance, and automated restocking systems are examples of these methods. Aerospace operations become much safer and more efficient by adopting these innovative technologies. Real-time data enables quick decision-making, while predictive analytics aid in anticipating and preventing potential problems before they arise, hence improving operational safety.Mastering Aircraft Parts Inventory– Managing aircraft components inventory entails more than merely keeping track of what’s in stock. It is about understanding and forecasting the demand for diverse components. Aerospace operations can prevent the costly delays associated with part shortages by properly forecasting which parts will be required and when. Techniques such as data-driven demand forecasting and trend analysis are critical. This not only ensures the availability of necessary parts but also aids in the maintenance of a lean inventory, minimizing excessive hoarding expenses.Ensuring Parts Traceability– Losing track of components or spare parts is unimaginable in aircraft, where safety is crucial. As a result, the industry adopts modern traceability techniques. Part serialization, as well as the usage of RFID (Radio-Frequency Identification) and GPS tracking systems, are all widespread procedures. These systems enable component tracking throughout its lifecycle, from production to installation and maintenance. Such traceability is critical for inventory management, regulatory compliance, and safety in the aerospace industry.Managing Spare Parts Shelf Life– Shelf life management is crucial for aerospace spare parts. Effective management strategies include regular monitoring and updating of inventory systems to reflect the current status of every part. This involves keeping track of expiration dates and creating a first-in-first-out (FIFO) system to ensure that items are used in the order they were received, allowing for timely replacement or disposal. Such thorough monitoring guarantees that all parts utilized are in their operational prime, hence preserving the highest standards of safety and reliability.

Navigating Aerospace Inventory Challenges

Managing inventories in aerospace is like solving a complicated puzzle. Every component – whether it’s a part or a regulation – needs to fit properly to keep everything working smoothly and safely.

In this section, we look into the common challenges of managing parts and the importance of following safety rules, showing how careful planning and up-to-date systems are key to overcoming these challenges.

Overcoming Parts Management Hurdles– Stockouts, surplus, and obsolete items have a substantial impact on operations in aerospace inventory management. Stockouts can create delays and stop flights, jeopardizing both safety and revenue. Surplus inventory, on the other hand, ties up resources and might result in financial loss as technology develops. Strategic forecasting and real-time inventory visibility are required for the effective management of these concerns. This ensures that operations run smoothly and that the proper parts are available when needed.Staying Compliant with Safety Regulations– Meeting safety rules in the aerospace industry is crucial and is linked to inventory management. Compliance involves guaranteeing that all parts are certified, stored appropriately, and have verifiable histories. Advanced tracking and reporting systems are critical for ensuring compliance. They give precise, up-to-date inventory records, which simplifies audits and allows them to respond promptly to regulatory changes. Thus, effective inventory management is critical to complying with safety standards and sustaining reliable, safe aircraft operations.

CyberStockroom’s Role in Aerospace Inventory Management

CyberStockroom is a game changer in the management of aircraft supplies. Let’s look into its primary features and functions and the significant benefits they provide:

Achieving True Inventory Visibility

CyberStockroom provides a comprehensive map of the entire inventory. This kind of insight helps a lot in the aerospace industry, where maintaining essential investments with precision is critical. It enables teams to track every item precisely, ensuring that no detail is overlooked.

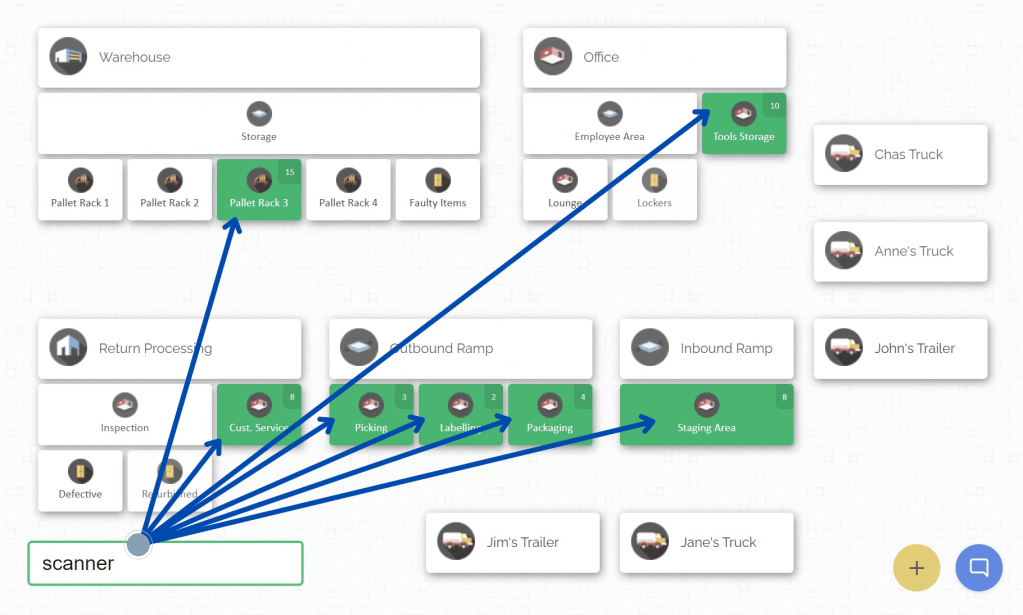

It offers a bird’s-eye view of the complete inventory landscape and categorizes inventory into locations and sub-locations, resulting in a clear and detailed picture.

Simplifying Transfers and Adjustments

Moving products between places is simple with CyberStockroom, thanks to its drag-and-drop feature. This is especially important in the aerospace industry, as speedy transfers and relocation of parts to different storage, locations, or aircraft is a common requirement. This ease of transfer aids in keeping processes running smoothly.

Streamlining Inventory Handling

CyberStockroom is intended to improve and streamline inventory management. Users can label things with photos, barcodes, and custom fields, making it easier to locate and retrieve specific aviation parts. In the aircraft business, where time is critical, this means faster access to the necessary parts, which helps to keep maintenance and operations on track.

Advanced Product Distribution Tracking

One of the most cutting-edge features CyberStockroom has to offer is the ability for users to scan or choose any inventory item and instantaneously view its distribution across many locations.

This means that aerospace businesses must be able to properly manage and track component distribution, ensuring that every part is precisely where it needs to be. This level of supervision and control assures that no part is ever missing or unavailable during critical maintenance or assembly.

Take the Next Step in Enhancing Your Aerospace Inventory Management

Adopting the proper tools and strategies is critical in an industry where precision and reliability are not just aspirations but necessity. Don’t let your inventory management fall behind the times. Explore cutting-edge technologies such as CyberStockroom and transform your inventory management system now. Your path to more effective, compliant, and long-term aerospace inventory management begins here. Reach out, learn more, and take the critical step toward excellence and innovation in your aerospace operations.

Leave a comment