Managing hazardous materials inventory on industrial sites is a critical task that ties directly into workplace safety, regulatory compliance, and operational efficiency. Industrial facilities such as factories, plants, construction sites, and warehouses often handle a variety of hazardous substances – from chemicals and fuels to solvents, gases, and other dangerous materials.

Keeping strict control and oversight of these materials isn’t just an administrative headache; it’s an essential practice to prevent accidents, protect employee health, ensure environmental safety, and comply with laws.

Why Hazardous Materials Inventory Management Matters

Safety is on the line. Hazardous materials by definition pose risks – they might be flammable, toxic, corrosive, reactive, or otherwise dangerous. If these materials are not managed properly, the probability of accidents and injuries increases dramatically. For example, imagine a scenario where a pallet of chemical drums is stored haphazardly in a factory. Without inventory control, incompatible chemicals could end up next to each other or a flammable solvent might be unknowingly placed near a heat source. The results could be fires, explosions, or release of toxic fumes, putting workers and the facility in danger. Even seemingly minor lapses – like an unlabeled container or a missing Safety Data Sheet – can lead to workers not understanding the hazards they’re dealing with, which in turn can cause improper handling or emergency response mistakes. Proper hazardous materials inventory management ensures everything hazardous is clearly identified, stored correctly, and handled with the right precautions, thereby preventing workplace accidents and health incidents.

Regulatory compliance is another major reason this topic matters. Around the world, industrial sites are subject to strict laws and regulations regarding hazardous chemicals and materials. For instance, the OSHA Hazard Communication Standard (in the US) requires employers to maintain an up-to-date inventory of all hazardous chemicals on site, along with corresponding Safety Data Sheets (SDS) and proper labeling. Many countries have similar regulations because authorities want to make sure companies know what dangers are present in their facilities. Additionally, environmental regulations often mandate reporting the quantities of certain hazardous substances stored or used (such as the Tier II chemical inventory reports in the US that emergency planners use). Failing to keep an accurate inventory can result in non-compliance, which may lead to hefty fines, legal liabilities, or even shutdown orders. Regulators expect that if you have hazardous materials, you’ll track them meticulously and be ready to produce inventory records, storage details, and safety documentation on demand. Thus, robust inventory management is essentially the backbone of staying compliant with environmental health and safety (EHS) laws and avoiding penalties.

Environmental protection is closely tied to managing hazardous inventories. Industrial sites that handle hazardous materials carry a risk of spills, leaks, or uncontrolled emissions if materials are not stored and monitored properly. A single leaking drum of a toxic chemical in your inventory, if overlooked, could contaminate soil or water, harm wildlife, or require expensive cleanup and reporting. By keeping a tight inventory – knowing container conditions, quantities, and storage locations – you are better positioned to prevent environmental releases or catch them early. In case of any incident, an accurate inventory will help environmental response teams assess what substances might be involved and respond appropriately. In short, protecting the environment starts with knowing exactly what hazardous substances you have and managing them responsibly.

Moreover, good hazardous materials inventory management contributes to operational efficiency and cost control. It might not be immediately obvious, but consider how disorganization affects productivity: If critical raw materials (say, a special adhesive or cleaning solvent) aren’t where they’re supposed to be or have run out unexpectedly because of poor tracking, it can halt production lines or construction work. Conversely, keeping excess hazardous stock “just in case” without realizing it can tie up capital, take up valuable storage space, and even increase risk (more quantity = more potential hazard). By systematically tracking hazardous materials, companies ensure they have exactly what they need when they need it – no more, no less. This reduces downtime from missing materials and avoids waste from materials expiring unused on a back shelf. It also means better decision-making: purchasing can be done based on real data (avoiding over-ordering chemicals you already have), and you can implement lean inventory strategies confidently without fear of stockouts of safety-critical items (like running out of coolant chemicals or spill response supplies). Thus, effective inventory management makes the operation more reliable and efficient, saving money in the long run.

Finally, consider the stakeholder trust and corporate responsibility aspect. Clients, employees, and the surrounding community all have a vested interest in how safely an industrial site handles hazardous substances. If you can demonstrate that your facility keeps a tight grip on its hazardous materials – with clear records, well-kept storage, and quick access to information – it builds trust. Employees feel safer knowing that their managers have accounted for all the chemicals and provided the necessary protective measures. Neighbors and local authorities feel reassured that the site is less likely to have a catastrophic incident. In industries like manufacturing or construction, having a reputation for strong safety and compliance practices (which includes hazardous materials management) can even become a competitive advantage, helping you win contracts or maintain certifications. In summary, hazardous materials inventory management matters because it underpins safety, legal compliance, environmental stewardship, operational smoothness, and the overall credibility of the business.

Challenges in Managing Hazardous Materials Inventory

While the importance is clear, managing hazardous materials inventory on an industrial site is no small feat. It comes with unique challenges that organizations must confront:

- Wide Range of Materials and Hazards: Industrial facilities often deal with dozens or even hundreds of different hazardous substances, each with its own properties and risks. One storage room might contain flammable liquids, another holds corrosives, elsewhere there are gas cylinders under high pressure. Keeping track of all these and understanding their distinct handling requirements is challenging. There is also the complexity of hazard classifications (flammable, oxidizer, toxic, etc.) and ensuring incompatible materials are not stored together. Managing such variety demands careful organization and deep knowledge of the materials.

- Regulatory Complexity: Compliance requirements for hazardous materials can be complex and come from multiple angles. For example, occupational safety regulations require employee right-to-know and proper labeling, environmental laws might require reporting quantities on site, fire codes limit how much of certain chemicals can be stored in one area, and transportation rules govern how hazardous materials are shipped in/out. Keeping the inventory in line with all these regulations can feel like navigating a maze. Each chemical might have a threshold quantity that if exceeded, triggers additional rules (such as needing a special permit or a different type of storage cabinet). Ensuring your inventory stays within allowable limits and that all paperwork (permits, reports, SDS documentation) is up to date is an ongoing challenge.

- Inaccurate or Outdated Inventory Data: One of the most common issues is simply knowing exactly what you have on hand at any given moment. If you’re relying on manual logs or sporadic spreadsheets, it’s easy for records to fall out of sync with reality. Perhaps a technician took a container of solvent and didn’t log it, or new chemicals arrived but the central list wasn’t updated promptly. These data gaps lead to discrepancies: you might think you have 10 barrels of a cleaning agent when only 6 are actually in the warehouse, or vice versa. Inaccurate inventory data is dangerous with hazardous materials – thinking you have less than you do might lead to accidentally exceeding storage limits or failing to report something, while thinking you have more could mean running out of a critical chemical when needed for a safety process (like water treatment chemicals for your scrubbers). Maintaining accurate, real-time inventory counts is tough, especially across multiple storage locations or busy sites where materials move frequently.

- Multiple Storage Locations and Silos: On industrial sites, hazardous materials might not be confined to one central warehouse. They could be spread across various departments, satellite storage rooms, outdoor yard areas, or jobsite trailers. Different departments might manage their “own” chemical stash, sometimes with inconsistent practices. This decentralized situation leads to informational silos – one department might not know what the other has, and the overall EHS manager struggles to piece together a holistic inventory. If each team uses a different method to track (or not track) their hazardous materials, creating a unified view is challenging. For example, a maintenance team could have a cabinet of lubricants and paints, the lab has reagents, production has cleaning chemicals – all in separate logs. The challenge is unifying these into one coherent inventory system so nothing falls through the cracks.

- Human Error and Training Gaps: Humans are prone to error, and when handling inventory tasks amid a busy industrial environment, mistakes happen. Labels fall off or fade, containers get moved and not put back in the right place, someone forgets to update a log, or uses the wrong chemical because of a mix-up. Additionally, if employees are not adequately trained, they may not understand the importance of strict inventory management. For instance, a worker might think “it’s just one bottle, no need to record it” or might dispose of a chemical without informing anyone. Creating a culture where every hazardous material transaction is properly recorded and every container is handled with protocol requires continuous training and vigilance. Overcoming complacency and reinforcing procedures is a constant battle for supervisors and EHS professionals.

- Emergency Situations and Lack of Preparedness: A tricky moment for hazardous materials management is when an emergency strikes (like a fire, spill, or natural disaster). In the chaos of an incident, if you don’t have instant access to what hazardous materials are present and where they are, the situation can escalate. Responders need to know, for example, if there are propane cylinders in a warehouse that’s on fire, or if floodwaters could reach a storage area with pesticides. One challenge is ensuring that inventory information is not only accurate, but also readily accessible under emergency conditions. Facilities sometimes struggle with keeping backup copies of inventory lists, updating emergency plans with current inventory data, and communicating that information quickly when needed. If your inventory management is disorganized during normal times, it certainly won’t magically become organized during a crisis.

- Disposal and Waste Management: Part of managing hazardous materials inventory is dealing with the end of their life cycle – expired chemicals, used solvents, contaminated rags, and so on. These often become regulated hazardous waste. A challenge here is making sure that hazardous materials don’t quietly accumulate beyond their useful life. Expired chemicals might become unstable or more hazardous over time. Also, holding onto waste without proper tracking can lead to violations of hazardous waste regulations (which often require waste to be labeled, dated, and removed within certain time frames). Managing the inventory means also knowing when to dispose of or recycle substances and doing so through licensed waste haulers. Overburdened staff might procrastinate on disposal, leading to cluttered waste storage areas and potential compliance issues.

All these challenges underscore why a thoughtful, systematic approach to hazardous materials inventory management is necessary. It’s not an easy job – but with the right strategies and tools, it can be done effectively.

Best Practices for Hazardous Materials Inventory Management

To overcome the challenges above and achieve a safe, compliant operation, industrial sites should implement a combination of organizational strategies and practical procedures. Here are key steps and best practices for effective hazardous materials inventory management:

Identify and Catalog All Hazardous Materials

Start with a comprehensive audit of your site’s hazardous substances. This means walking through every area – maintenance closets, chemical storage rooms, production lines, tool cribs, etc. – and documenting each hazardous material present. Include raw materials, process chemicals, cleaning agents, paints, fuels, gases, and even ancillary items like aerosol cans or batteries that might be classified as hazardous. For each item, record important details such as the exact product name, chemical name or formula (if applicable), the manufacturer, and the quantity on hand. It’s vital to capture the product identifier exactly as it appears on its label and Safety Data Sheet, because consistency is required for compliance (the name on your inventory list should match the name on the SDS).

Don’t overlook “hidden” hazards – for example, a welding area might have cylinders of acetylene and oxygen (fire/explosion hazards), or a janitor’s closet might store bleach and ammonia (which can create toxic gas if mixed). This initial identification process can be time-consuming, but it lays the foundation for everything else. Once you have a master list of hazardous materials, you’ll want to keep it current by updating it whenever new materials are purchased or old ones are used up or removed.

Maintain Proper Labeling and Documentation

Every hazardous material should be clearly labeled and accompanied by documentation that explains its hazards. As a best practice, implement a rule that no container of hazardous substance is ever unlabeled, even secondary containers. Use durable labels (with hazard symbols if appropriate) that won’t fade or fall off. At the same time, establish an SDS library that includes an up-to-date Safety Data Sheet for each hazardous material in your inventory. Many regulations worldwide, including OSHA’s HazCom standard, require that employees have access to the hazard information on an SDS for each chemical. Ensure that your SDS collection is complete and readily accessible (for example, in a binders in work areas or digitally through an inventory management system). Tie this back to the inventory list: for each entry on your inventory, have a notation of where the SDS is (or link to it, if digital). If your inventory is segmented by area, keep a hazardous materials register in each work area listing the materials present there, so workers and emergency responders can quickly see what’s nearby. By rigorously maintaining labels and SDS documentation, you not only stay compliant with hazard communication rules, but you also empower your workers to handle materials safely (since they can identify contents and read hazard info at any time).

Design Safe Storage and Segregation

Organizing your hazardous materials storage is a critical step. Safe storage means storing chemicals in a manner that reduces risk – both to people and from chemical reactions. Begin by segregating incompatible materials. For instance, store acids away from bases, and flammables away from oxidizers or ignition sources. You might use dedicated flammable liquid cabinets for paints and solvents, corrosive cabinets for acids, and gas cylinder cages that secure compressed gases upright. Mark each storage location clearly (shelving units, cabinets, racks) and ideally designate specific shelves or sections for specific hazard classes. This way, anyone looking for “where do I put this new drum of oil?” has an obvious, labeled spot for it. Use secondary containment like spill trays for liquids, so if a container leaks, it’s caught safely.

Limit the storage quantity in any given area according to guidelines – for example, don’t exceed the recommended volume of flammables in one cabinet as per fire codes. Part of inventory management is knowing not just how much you have, but ensuring it’s distributed in a safe manner. If you have multiple stock rooms, consider spreading out high-hazard materials so that no single area holds an excessive concentration (this can help minimize the impact if an incident occurs). Also, maintain orderliness: keep aisles clear, do not stack heavy or unstable containers too high, and post signs indicating hazards (like “Corrosive Storage – Acid, use face shield”). By designing the storage layout thoughtfully, you reduce the chance of accidents such as spills, fires, or chemical reactions, and you make it easier to count and find items during inventory checks.

Implement an Inventory Tracking System

To really keep on top of your hazardous materials, move away from paper logs and static spreadsheets and embrace an inventory tracking system – ideally a digital one that updates in real time. Modern inventory management software can be a game-changer. At minimum, use a centralized database (even if it’s a simple spreadsheet on a shared drive, though dedicated software is better) where all hazardous material transactions are recorded. Each time a new shipment of a hazardous product comes in, log it into the system; each time something is used up or disposed of, deduct it. Better yet, use barcoding on containers and storage locations: employees can scan items whenever they are moved or used, automatically updating the inventory count. This reduces the errors associated with manual data entry and ensures that the inventory list is always up-to-date.

If your operation is large, consider a cloud-based inventory software that multiple people (across departments or sites) can access simultaneously. This ensures everyone works off the same real-time information and eliminates confusion from multiple versions of a list. The goal is to achieve real-time visibility – at any given moment, you should be able to query the system and know “we have 25 gallons of epoxy resin in Warehouse A and 5 more gallons at Site B, batch numbers X, Y, Z.” An effective tracking system will also timestamp transactions and possibly record who performed them (useful for accountability). By implementing technology for inventory tracking, you minimize the chance of “mystery stock” appearing or disappearing and can trust your data when making decisions.

Train Employees and Establish Procedures

Even the best system will fail without people following the rules. Make hazardous material inventory management an integral part of your standard operating procedures (SOPs) and training programs. Develop clear procedures for how materials are received, stored, issued, and disposed of, and embed inventory steps into each of those processes. For example, have an SOP that when a chemical shipment arrives, the receiving personnel must immediately update the inventory database and ensure the new material is labeled and placed in the correct storage. Likewise, when a worker takes out a container for use, there should be a check-out process (signing a log or scanning) so that you keep track of where that material is going. Conduct regular training sessions for all staff who handle hazardous materials, emphasizing why these inventory procedures matter for their safety and for compliance. It’s helpful to train employees on reading labels and SDS information too, so they appreciate the hazards behind the names.

Foster a culture of accountability: perhaps assign area custodians or “chemical champions” in each department responsible for double-checking that inventory in their area is managed right. Make it easy for workers to do the right thing – for instance, have inventory forms or barcode scanners readily available at the point of use, so it’s not a hassle to log usage. When everyone understands that keeping accurate inventory is a non-negotiable part of the job (just like wearing PPE or locking out equipment), compliance with these practices becomes much higher. And importantly, management should enforce and audit these procedures – if someone bypasses the system (“I was in a rush, so I didn’t log it”), there should be follow-ups to reinforce the process. Over time, consistent training and enforcement will engrain good inventory habits into the daily routine.

Monitor Inventory Levels, Usage Rates, and Expiration Dates

Inventory management isn’t just about knowing what you have; it’s also about knowing how that inventory changes over time. Keep an eye on usage rates of each hazardous material – how fast do you consume certain chemicals? This helps in planning purchases and also in identifying anomalies (if suddenly a solvent is being used up twice as fast, was there a spill or misuse?). Establish minimum and maximum stock levels for each item if applicable: for example, decide that you should always have at least 10 spare ammonia sensors (if that’s a hazardous item critical for safety) but no more than 50 gallons of a particular solvent in storage to limit risk. By tracking levels, you can set reorder points to replenish before you run out of something essential (like ingredients for a process or safety supplies such as fire suppressants). Conversely, monitoring levels prevents you from overstocking hazardous materials unnecessarily. This is important because surplus hazardous materials not only increase potential risk but could also expire before use. Which brings us to expiration monitoring: a lot of chemicals have shelf lives or degrade over time (think of reagents, certain fuels, or epoxy components).

Include expiration dates in your inventory records and implement a system (even just a monthly review) to check for any item nearing expiration. Some inventory software can flag expiring chemicals for you. For each item, use a “first-in, first-out (FIFO)” policy – use the oldest stock first so nothing goes bad sitting in the back. If something will expire soon and you won’t use it in time, plan for its disposal or see if it can be used elsewhere instead of letting it become waste. Keeping on top of this prevents the accumulation of old, possibly more hazardous, chemicals and reduces waste. It also ensures the effectiveness and quality of the materials you do use (using a chemical within its recommended shelf life can be important for it to work properly, which ties into quality control in your processes). In summary, continuously monitor and manage inventory levels with an eye on both safety (not too much, not too little) and efficiency.

Plan for Proper Disposal and Waste Handling

Part of managing hazardous materials is dealing with when they are no longer needed or become waste. Develop a protocol for hazardous waste management that dovetails with your inventory system. For example, when a chemical is identified as expired or a batch is no longer usable, mark it in the inventory as “pending disposal” and move it to a designated waste accumulation area (which should be another mapped location in your inventory system). Label waste containers clearly with contents and accumulation start dates, as required by regulation. Keep inventory of hazardous waste, too – don’t just forget about chemicals once they’re waste, because they are often even more regulated at that point. Arrange for regular disposal pickups through licensed hazardous waste contractors so that waste doesn’t linger on site beyond allowed time limits. Track the volumes of waste generated, as this can sometimes trigger regulatory reporting (and also gives you insight into how efficiently materials are being used; lots of waste might mean over-purchasing or process issues).

Additionally, have a procedure for spill management: ensure spill kits are available for each type of chemical and that their contents (neutralizers, absorbents) are themselves tracked and replenished as inventory items. If a spill occurs and some inventory is released, account for that loss in your records. Essentially, the goal is cradle-to-grave management of hazardous materials – from the moment they arrive to the moment they leave (either used in product, emitted in controlled ways, or disposed as waste), you have an eye on them. This comprehensive approach not only meets the cradle-to-grave principle in environmental regulations (like RCRA in the US for hazardous waste), but also closes the loop so you aren’t left with unknown “legacy” chemicals in a corner of the warehouse.

Conduct Regular Audits and Continuous Improvement

Inventory management is not a one-and-done project, but an ongoing process. Schedule regular audits of your hazardous materials inventory. For instance, perform a quarterly (or at least annual) comprehensive inventory count where someone physically verifies each item and quantity against the records. Many organizations use cycle counting, where you spot-check certain categories or storage areas on a rotating basis (e.g., check all flammables this week, all toxics next week). These audits will catch discrepancies and allow you to investigate their causes (maybe a procedure wasn’t followed, or a label fell off and was logged incorrectly). Additionally, audits should check compliance aspects: verify that every material present has a label and an SDS, that storage is appropriate, and that nothing unauthorized has crept in. Use findings from audits to drive continuous improvement – update your procedures or training to address any gaps found. It’s also wise to stay informed about changes in regulations or best practices. Perhaps a new law requires tracking an additional detail, or perhaps you discover a new technology (like RFID tracking or improved software features) that could enhance your system. EHS managers and compliance officers should review the inventory management program periodically to ensure it remains effective and up-to-date with current standards. By continuously monitoring and refining your hazardous materials inventory practices, you maintain a high level of safety and compliance and adapt to any new challenges that arise.

Following these best practices creates a robust framework for hazardous materials inventory management. It transforms what could be a chaotic aspect of operations into a well-controlled process that protects people and supports the business.

Using CyberStockroom for Hazardous Materials Inventory Management

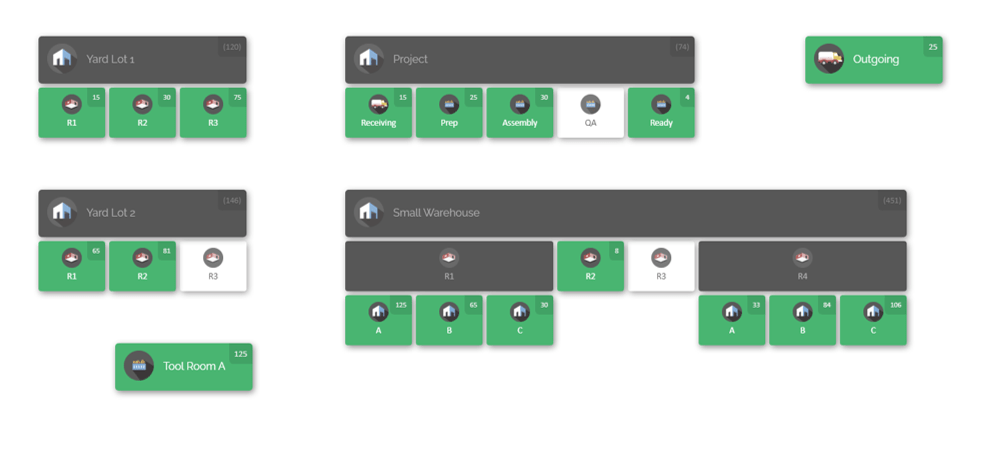

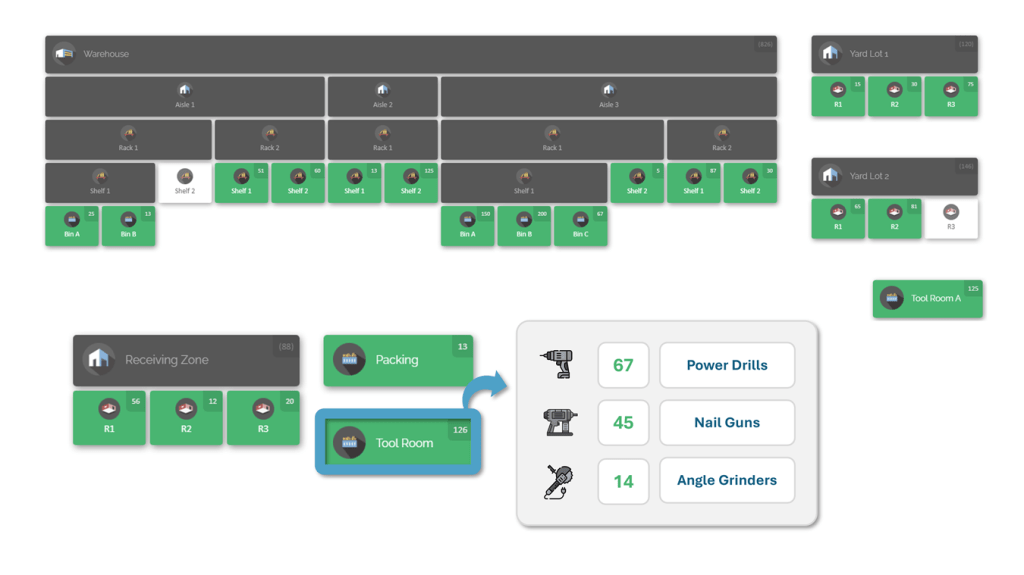

Modern problems require modern solutions. As outlined, technology can significantly improve how you manage hazardous materials inventory – and one such technological solution is CyberStockroom. CyberStockroom is an inventory management platform that uses a unique visual map-based approach to help businesses track their inventory across various locations. In the context of hazardous materials on industrial sites, CyberStockroom’s features can directly address many of the challenges we discussed and streamline the best practices we outlined. Here’s how CyberStockroom can support and enhance hazardous materials inventory management:

- Visual Inventory Maps for “Hazardous Materials at a Glance”: CyberStockroom’s signature feature is the ability to create a visual map of your facilities and plot your inventory onto it. For an industrial site with hazardous materials, this means you can have a digital floor plan or site map where each storage location (warehouse sections, chemical cabinets, fuel storage areas, etc.) is represented. In daily use, the visual format makes it easier for staff to find materials without rummaging (reducing the temptation to leave things lying around or the risk of knocking things over). CyberStockroom’s inventory map approach makes managing hazardous materials more intuitive – it’s like having a living diagram of your chemical storage, which greatly enhances oversight and safety.

- Real-Time Tracking and Updates: CyberStockroom is a cloud-based system, meaning all changes to inventory are updated in real time and can be accessed from anywhere by authorized users. When dealing with hazardous materials, real-time accuracy is paramount. If someone uses a chemical or moves it, CyberStockroom allows that transaction to be recorded immediately – for example, by scanning a barcode or updating the quantity on the map – so that the inventory count is always current. This helps avoid the classic problem of “the system says we have 5 barrels, but we only see 3 on the shelf” because any removal should have been logged as it happened. Furthermore, because it’s cloud-based, managers can check inventory status remotely. An EHS manager or compliance officer could verify the latest inventory even if they’re at a different location or working from home, which is useful for multi-site companies. Everyone from the warehouse manager to a safety engineer can be on the same page, looking at the same live data. By using CyberStockroom to maintain live tracking, you eliminate information silos and lag, ensuring that decisions are made based on up-to-the-minute information.

- Drag-and-Drop Simplicity and User-Friendly Interface: One aspect that sets CyberStockroom apart is its emphasis on ease of use. Managing inventory can sometimes be seen as tedious, but CyberStockroom’s interface is designed to be visual and interactive. Users can literally drag and drop items on the inventory map to reflect a move – for example, if a drum of chemical is transferred from the main warehouse to a satellite storage, you could drag its icon from one location to another on the map. This instantly updates its location in the system without a bunch of manual data entry. Such a feature is very handy in dynamic industrial environments where materials move around frequently. The drag-and-drop metaphor is easy for staff to understand, reducing training time and increasing adoption of the system. When everyone finds the inventory system simple to use, they are more likely to consistently use it, which means better data integrity. CyberStockroom also allows customization of fields and items, so you can tailor the system to your hazardous materials context – for example, adding a custom field for “Hazard Class” or “Expiration Date” for each item. The combination of user-friendly design and customization means that the platform can be adapted to your specific processes (rather than forcing you to adapt to it), supporting the goal that inventory management becomes part of the everyday routine rather than an afterthought.

- Accountability through Check-Out and Assignments: Hazardous materials are sometimes not just sitting on shelves; they might be in use or checked out to certain personnel (like a maintenance worker signing out a container of solvent for a repair job). CyberStockroom supports check-in/check-out functionality and the assignment of items to people or projects. This means you can record when a particular item leaves its storage location and who is responsible for it. For example, if a technician checks out a gas detector calibration gas cylinder, the system can note that “John Doe from the Instrumentation team has this cylinder.” This fosters accountability – individuals know that the system is tracking who has what, so they are more likely to return materials and containers properly and report usage. In terms of safety, this feature can ensure that only authorized or trained personnel handle certain hazardous items. You could configure the system such that only users with certain roles or permissions can check out particularly dangerous equipment or chemicals. That way, you prevent unauthorized use (no untrained intern should be signing out the hydrofluoric acid, for instance). By tying inventory to user identity, CyberStockroom helps create a culture where hazardous materials are treated with due responsibility, and any misuse or loss can be quickly traced.

- Cloud-Based Accessibility and Collaboration: Because CyberStockroom is cloud-based, it enables multi-user access and collaboration. Different members of your team – warehouse staff, EHS managers, quality control, etc. – can all access the inventory system through their web browser (whether on a desktop in the office, a tablet on the factory floor, or a laptop at home). There is no need for everyone to be physically present or to trade paper files to verify inventory. This widespread accessibility ensures that, for example, a plant supervisor on night shift can update a chemical usage, and by the next morning the day shift and management see those changes without delay. It also means if you have multiple sites or departments, they’re all working in one unified system. A global view is possible – you could see hazardous material inventory across all your plant locations worldwide on one platform (with maps for each site). This is very useful for corporate EHS leaders tracking compliance across facilities, or for moving materials between sites. Additionally, cloud data is usually backed up and secure, reducing the risk that a local disaster (like a computer crash or fire) would wipe out your inventory records. CyberStockroom’s approach fits well with the reality of industrial operations today, where teams may be spread out and need to collaborate in real time on safety and inventory matters.

In summary, CyberStockroom aids hazardous materials inventory management by making it visual, real-time, and user-friendly. It automates a lot of the tedious parts of tracking, helps enforce good practices (through accountability features), and centralizes information needed for safe handling and compliance. By correlating CyberStockroom’s capabilities with our earlier best practices: it helps identify and locate materials easily (mapping), maintain accurate counts (real-time updates), ensure proper controls (permissions and custom fields), and simplify audits (reporting and visibility). For any industrial operation grappling with the question “How do we keep on top of all these hazardous materials?”, adopting a tool like CyberStockroom can be a transformative step forward. It embodies the principle that better inventory management leads to better safety and compliance – and it provides the practical means to achieve that on the ground.

Aligning Inventory Management with Safety and Compliance Goals

It’s worth explicitly connecting how robust hazardous materials inventory management aligns with overarching safety and compliance goals. Many industrial organizations have high-level targets such as “zero accidents,” “100% regulatory compliance,” or ISO-certified safety management systems. How does keeping a good inventory help achieve these?

First, workplace safety programs (like OSHA’s Process Safety Management for high-hazard chemicals, or general occupational safety plans) often require hazard assessments and controls. A current inventory is the foundation of a hazard assessment – you can’t evaluate the risk of what you don’t know exists. When you have a constantly updated inventory, you can systematically review each material for associated risks and ensure controls (proper storage, PPE, training) are in place. Essentially, inventory management is preventative medicine for safety: it brings potential hazards to light so you can mitigate them before they cause harm. It also makes safety audits smoother. If an inspector visits your facility, one of the first things they might ask is “Show me your chemical inventory and how you manage these materials.” Being able to pull out a well-organized inventory list or, better yet, show a live inventory system with all details, demonstrates your safety diligence. It helps you pass safety inspections and audits with flying colors, because it shows you have control over the hazards on site.

In terms of regulatory compliance, maintaining an accurate inventory feeds into many required activities. For example, completing regulatory reports (annual emissions reports, chemical inventory reports, fire department hazardous substance registrations, etc.) becomes straightforward because you can compile the needed data from your records rather than guesstimating. Compliance officers often need to ensure that the facility does not exceed certain storage limits without additional safety measures (like if you store above a threshold of propane, you need higher fire protection, or if you have more than a threshold of an Extremely Hazardous Substance, you need an emergency plan filed). By aligning inventory tracking with those threshold values, you can set internal alarms before you inadvertently cross a regulatory line. It’s far better to manage your inventory so you stay within compliance bounds than to discover during an inspection that you’ve been over the limit for months. In this way, inventory management serves as a continuous compliance check.

Quality management systems (like ISO 9001 or industry-specific standards) also benefit. If your production or research processes use hazardous materials as inputs, inventory control ensures the right materials (correct grade, not expired) are used, which affects product quality. Also, quality systems emphasize traceability – being able to trace what materials went into which batch of product. A good inventory system can help with that by logging lot numbers or batches of chemicals and their usage. In case of any quality issue, you can quickly trace back to see if a particular chemical lot was a culprit. Although quality might seem separate from safety, in practice, a well-organized inventory that keeps materials in good condition (not degraded or contaminated) and available when needed can improve process reliability and output quality. For instance, using a degraded solvent because it was stored too long or ran out of the preferred chemical and substituting a less appropriate one can lead to defects. So by managing inventory, you indirectly support consistent quality outcomes in production.

Emergency preparedness and response plans also rely on inventory information. Sites usually have emergency plans for scenarios like chemical spills, fires, or releases. These plans should reference what hazardous materials are present and where. When your inventory is well-managed, your emergency team can develop more effective response strategies (they know exactly what might be involved in a worst-case scenario). It also facilitates communication with local emergency services – many fire departments love when a facility can hand them an up-to-date hazardous material inventory during a fire response, so they know what they’re dealing with. This partnership and transparency with responders improve the safety of everyone. In some regions, providing such information isn’t just a courtesy; it’s required under community right-to-know regulations. Thus, your inventory practices can directly contribute to community safety and regulatory fulfillment in emergency planning.

To align inventory management with these goals, it’s helpful to integrate it into the broader EHS management system of the company. Treat maintaining the hazardous materials inventory as a key performance indicator (KPI) for safety and compliance. For example, measure “% of inventory reconciliations completed on schedule” or “number of discrepancies found in monthly inventory vs resolved.” Management can include these metrics in safety committee meetings or management review meetings. By doing so, you signal that hazardous inventory control is as important as incident rates or audit scores – which indeed it is, because it influences those outcomes.

In summary, effective hazardous materials inventory management is a linchpin that holds together safety protocols, legal compliance, and even product quality assurance on industrial sites. It turns what could be a chaotic management problem into a proactive strategy for risk reduction. Companies that prioritize this alignment often find that not only do they avoid accidents and fines, but they also run a tighter ship operationally. Less downtime, less waste, and better preparedness are the rewards of marrying inventory management with safety and compliance objectives.

Conclusion

Managing hazardous materials inventory on an industrial site is a complex responsibility, but it’s one that yields significant benefits when done right. By knowing exactly what hazardous substances are on your site, where they are, and in what quantities, you create a foundation of knowledge that supports every aspect of safety and compliance. In this guide, we’ve highlighted the importance of diligent inventory management – from preventing accidents like spills, fires, and exposures, to staying on the right side of regulations and avoiding costly penalties. We’ve examined the challenges that can trip up even well-intentioned organizations, and provided a step-by-step framework of best practices to systematically tackle those challenges. From conducting initial audits and labeling everything, to leveraging technology for real-time tracking, training your people, and continually auditing your process – each piece of the puzzle is vital.

We also explored how tools like CyberStockroom’s inventory mapping software can make this job easier and more effective. The ability to visualize your hazardous materials across a site, update inventory data instantly, and coordinate among teams transforms inventory management from a tedious chore into a streamlined workflow. Technology, combined with strong procedures, helps ensure that nothing falls through the cracks – that missing chemical bottles, inaccurate logs, or forgotten drums become problems of the past.

For EHS managers, plant supervisors, compliance officers, and warehouse managers, adopting these practices means peace of mind. It means when you walk through your facility, you aren’t seeing mystery containers and wondering “what’s that and who put it here?” – instead, you have confidence that everything is accounted for and in its proper place. It means if an inspector arrives or an emergency strikes, you’re prepared with answers and information at your fingertips. It means workers can do their jobs more safely, not having to worry that an invisible hazard is lurking due to someone’s oversight.

In the big picture, robust hazardous materials inventory management is about creating a culture of safety, responsibility, and continuous improvement. It’s one of those behind-the-scenes efforts that, when done well, might not be obviously noticed on a daily basis – because things are running smoothly. And that’s the point: by preventing incidents and ensuring compliance, you avoid negative events and keep operations productive. The true mark of success might be that nothing dramatic happens – no accidents, no violations – which is exactly what we want when dealing with dangerous materials.

As you implement or refine your hazardous materials inventory management program, remember that it’s an ongoing journey. Keep engaging your team, keep leveraging better tools and training, and keep the information flowing. Over time, you’ll likely find additional efficiencies or improvements tailored to your specific operation. Embrace those tweaks and stay adaptive.

In conclusion, inventory management for hazardous materials is both an art and a science: it requires meticulous attention to detail (the science of tracking, data, and regulations) and smart organizational skills (the art of integrating people, processes, and tools). By applying the guidance in this how-to guide, you’ll be well on your way to mastering that art and science. The payoff is a safer workplace, a compliant operation, and a stronger, more resilient industrial site that can handle its hazardous materials with confidence and control. Your employees, your community, and your bottom line will all thank you for it. Stay safe, stay organized, and never lose sight of “what’s where” when it comes to hazardous inventory – it’s the cornerstone of quality and compliance in industrial operations.

Leave a comment