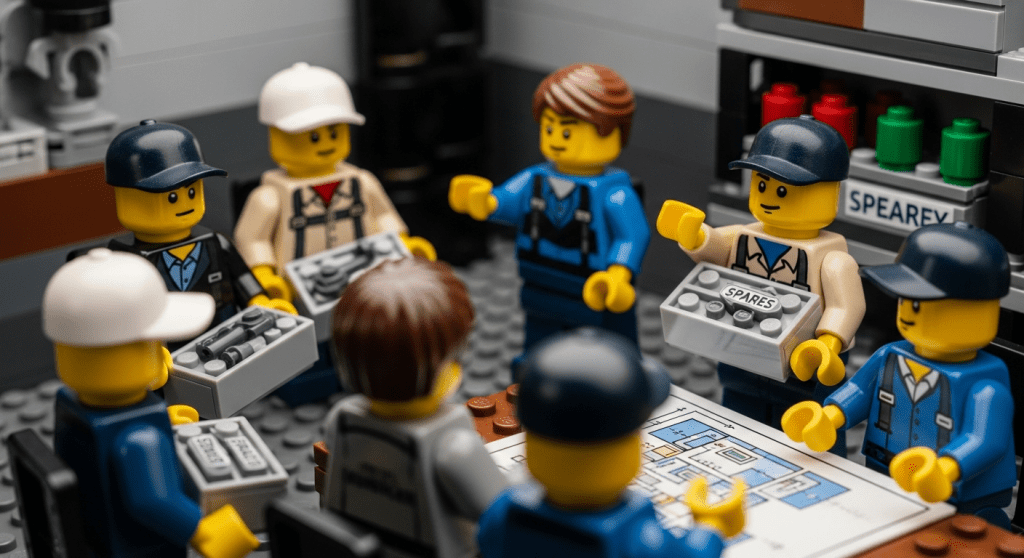

Project commissioning is the final critical phase of a construction or engineering project, where the focus shifts from building to making sure everything is ready for operation. An often overlooked but essential part of this phase is the inventory handover – transferring all spare parts, extra materials, and consumables from the project team to the owner or operations team.

Proper project commissioning inventory handover ensures that the client has everything needed to operate and maintain the facility from day one. Imagine finishing a complex project only to realize that no one knows where the spare filters, replacement valves, or extra tiles are stored – or worse, that they were never handed over at all. Avoiding such scenarios requires careful planning and execution.

What Is Inventory Handover in Project Commissioning?

Inventory handover refers to the process of transferring all project-related stock – including spare parts, extra materials, and consumables – to the owner or operations team at the end of a project. During commissioning (the final phase when systems are tested and the project is prepared for operation), contractors are typically required to provide the client with certain spares and materials as part of project closeout. These items may include:

- Equipment Spare Parts: Replacement components for installed machinery and systems (e.g. pumps, motors, filters, belts, gaskets). Vendors often recommend a list of critical spares to have on hand for the first couple of years of operation.

- Attic Stock Materials: Extra building materials and finishes kept for future repairs or maintenance. For example, a percentage of floor tiles, carpet, paint, ceiling tiles, and other consumables are commonly turned over to the owner. This ensures that if a small area needs repair, identical materials are available.

- Consumables and Supplies: Items like lubricants, filters, light bulbs, fuses, or chemicals that will be used during initial operation and maintenance. These might be provided to give the owner a startup supply.

- Tools or Specialized Equipment: In some cases, special tools or devices supplied under the contract (for maintaining equipment) are handed over as well.

- Documentation and Accessories: Along with physical items, the handover includes related documentation such as operation manuals, warranty information, and inventory lists describing the spares.

During project commissioning, systems are tested and any issues are fixed. It’s also the period when ownership of the facility is transferred. A successful inventory handover means the client receives not just a functioning building or plant, but also all the pieces necessary to keep it running smoothly. This process is typically formalized – many contracts require a detailed inventory list and a sign-off from the owner acknowledging receipt of all specified spares and materials.

In essence, inventory handover is about leaving the owner equipped and informed. The operations and maintenance (O&M) team should walk away knowing what each spare part is, where it is stored, and how it will be used or replaced when needed. It bridges the gap between construction and ongoing maintenance, ensuring that there are no loose ends. Next, we’ll discuss why careful management of this inventory is so important and then outline how to do it step by step.

Why Managing Spares and Materials at Handover Matters

Turning over spare parts and materials isn’t just a box-ticking exercise – it’s a critical practice that carries significant benefits and prevents future problems. Here are a few key reasons why effective management of spares during handover matters:

✅ Preventing Operational Downtime: The initial months of operating a new facility can bring unexpected maintenance needs. Having the recommended spare parts on hand (and knowing their locations) means that if a pump fails or a light fixture breaks, the replacement is immediately available. This quick access can avoid costly downtime and keep the facility running without interruption. In industries like manufacturing or utilities, a missing critical spare could halt operations. Proper handover ensures the new owner isn’t scrambling to source parts that should have been provided.

✅ Fulfilling Contractual Obligations: Most construction and engineering contracts specify the spare parts and attic stock to be delivered at project completion. These might be defined as “two years’ operating spares” or a certain percentage of materials. Managing this inventory carefully is necessary to meet contractual requirements and pass final inspections. Failure to deliver the agreed spares can delay project closeout, payment (as clients may withhold final payment), or even lead to disputes. A well-documented inventory handover protects both the contractor and client by clearly showing that all obligations have been met.

✅ Smooth Transition to Maintenance: A new building or plant often transitions to a facilities management or maintenance team after commissioning. Those teams rely on the spare parts and information handed over to support the asset. If the inventory is organized and clearly documented, the maintenance staff can hit the ground running. They’ll know exactly where to find that box of filters or which type of lubricant is on the shelf. This boosts the owner’s confidence in taking over the project and demonstrates the contractor’s professionalism. It’s much easier for the owner’s team to assume responsibility when they are handed a tidy package of parts, materials, and records (rather than a chaotic pile of “extra stuff” with no explanation).

✅ Cost and Efficiency Benefits: Proper inventory handover can translate to cost savings for the owner. They don’t need to immediately purchase spare parts or materials that were already budgeted and provided in the project. Moreover, when inventory is documented and accounted for, it’s less likely to be wasted or lost. Without a clear handover, valuable items might go missing (either misplaced or taken), forcing the owner to buy replacements later. By tracking every spare, you also reduce the chance of duplicating orders or holding excess stock that ties up capital unnecessarily. In short, good inventory management at closeout sets the stage for efficient maintenance budgeting and stocking.

✅ Quality Assurance and Warranty Protection: Often the spare parts supplied are those recommended by equipment manufacturers to keep systems in warranty compliance. For example, using the correct type of oil filter or gasket can be important for warranty conditions. When the correct spares are handed over and their usage is tracked, the owner is more likely to perform maintenance that meets warranty requirements, protecting their investment. Additionally, providing spare parts that match installed equipment (and documenting their source and specs) helps maintain the quality and integrity of repairs. If a part fails, the owner can quickly produce the spare and show it’s the approved component, avoiding any blame on maintenance for using wrong parts.

In summary, managing spares and materials during project commissioning is critical to ensure a seamless handoff, satisfied client, and trouble-free startup of the facility. It’s a mark of a thorough project closeout. Conversely, poor inventory handover can lead to immediate frustrations: imagine a facility manager discovering that no spare fuses or filters were delivered, or that the extra floor tiles for repairs can’t be located. Such oversights reflect badly on the project team and can sour the client relationship. By understanding the importance of inventory handover, project teams can prioritize it appropriately in the commissioning checklist.

Common Challenges in Inventory Handover

Despite its importance, inventory handover can be challenging. Knowing what hurdles to watch for will help you mitigate them. Some common challenges include:

- Last-Minute Scramble: It’s not uncommon for spare parts procurement and organization to be left until the tail end of the project. The team may be rushing to finish construction and address punch list items, and suddenly someone realizes the spare parts need to be gathered. Rushing at the last minute increases the risk of missing items, incomplete documentation, or haphazard packing that leads to confusion later.

- Poor Tracking and Lost Items: On a busy construction site, spare materials and parts might be scattered across laydown yards, storage containers, or subcontractors’ workshops. Without a tracking system, items can get lost or misplaced. For example, a box of valve kits might have been delivered and then moved during site cleanup. If inventory isn’t tracked, the contractor might think it was handed over, while the owner never actually receives it. Ensuring everything is accounted for as it moves is crucial.

- Lack of Labeling and Identification: Spare parts range from large assemblies to tiny components. If they aren’t clearly labeled, the owner’s team might not know what they are or which equipment they belong to. In some cases, small parts or specialty tools have been handed over in unmarked boxes – effectively useless because no one realizes their purpose. The challenge is to label and document each item in a way that’s understandable to someone not intimately involved in the construction.

- Multiple Stakeholders Providing Spares: On complex projects, different subcontractors or vendors might be responsible for supplying spare parts for their portion of work. For example, the mechanical contractor provides HVAC spares, the electrical supplier provides spare breakers, and so on. Coordinating all these inputs into one coherent handover package can be challenging. If there isn’t a single point of coordination, some spares might be forgotten or duplicated. There is also a risk that each party provides documentation in a different format or quality, making it hard for the client to use.

- Storage and Preservation Issues: Spares and attic stock need proper storage, even during the handover process. Sensitive parts might require climate control or protective packaging. If these items are not stored correctly (e.g., electronic components left in a humid trailer, or paint not kept in proper temperature), they could deteriorate by the time the owner tries to use them. A challenge is ensuring that handover materials remain in good condition and are stored appropriately until they officially change hands.

- Inadequate Documentation: Creating a thorough inventory list takes effort. Some teams struggle with how much detail to include. Too little detail (e.g., “Box of bolts – 1 each”) is not helpful, while too much might be time-consuming. Getting the right level of detail – item name, model/part number, quantity, location, and any notes – is a balancing act. Additionally, assembling related documents (like manuals, datasheets, or warranties for those spares) can be tedious. However, without adequate documentation, the value of the physical spares is greatly diminished for the end user.

Awareness of these challenges underscores why a structured approach is necessary. Next, we’ll outline a step-by-step guide to manage inventory handover effectively, addressing these common issues. By following a clear process, you can avoid the last-minute panic and ensure nothing falls through the cracks.

How to Manage Inventory Handover: Step-by-Step Guide

Organizing a smooth inventory handover involves several stages, from early planning to the final transfer. Below is a step-by-step guide with best practices at each stage. Following these steps will help you tackle the challenges discussed above and deliver a professional, complete package of spares and materials to your client.

1. Identify Spare Parts Requirements Early

The process starts long before the project is in its final days. Plan for spare parts and attic stock early – ideally during the project planning or procurement phase. Begin by reviewing the project specifications and contract documents to understand what spares or extra materials are required to be handed over. Contracts often include specific clauses for spare parts (e.g., “contractor shall provide a list of recommended two-year operational spares for all major equipment and deliver these to the Owner”) or attic stock allowances (e.g., “provide 2% of all floor tile and paint as attic stock”). Make a checklist of all these requirements up front.

Next, gather input from key stakeholders:

Equipment Vendors: As part of commissioning, vendors usually supply Operations & Maintenance (O&M) manuals that contain recommended spare parts lists for their equipment. Obtain these lists early. Discuss with vendors which parts are critical to have on hand (often those with long lead times or high wear-and-tear).

Maintenance/Facility Team: If possible, involve the owner’s maintenance team early on. They can provide insight into what spares they consider crucial or any preferences (for instance, the facility team might want a stock of air filters for HVAC units because they know they’ll replace them monthly). Early collaboration ensures the handover inventory aligns with the end-user’s expectations.

Project Team & Subcontractors: Communicate with subcontractors about spare parts deliverables. Each trade should know what they are expected to turn over. For example, the electrical subcontractor might be tasked with providing a set of spare light fixtures, breakers, and fuses. Integrate these into their scope and ensure purchase orders account for these additional quantities.

By identifying requirements early, you can procure the spares in a timely manner. Build spare parts procurement into the project schedule so that these items arrive on site with enough time for inspection and organization. Early planning also allows budgeting for spares – important for both contractor (if it’s their cost) and owner (if they’re paying via the contract). Essentially, treat spare parts as their own deliverable within the project, not an afterthought.

Additionally, assign responsibility within your team for managing the inventory handover. On larger projects, some companies appoint a “Spare Parts Coordinator” or materials manager who keeps track of all spares from day one. This person can maintain the master spare parts list, follow up with vendors, and ensure everything is ready by commissioning time. Even on smaller projects, having one person or a small team accountable for spares tracking can greatly improve organization.

2. Gather and Itemize All Spares & Materials

As the project nears completion, collect all the spare parts and attic stock items that need to be handed over and itemize them in an inventory list. This step is about physically gathering everything in one place and verifying what you have.

Start by creating an Inventory Register – a master list (spreadsheet or database) of all spare parts and materials that will be handed over. For each item, record key information such as:

- Item Name/Description: e.g., “Pump Motor – 5 HP for Chilled Water Pump P-7” or “Ceiling Tiles – 24×24 inch acoustic tiles”.

- Part/Model Number: if applicable, note the manufacturer’s part number or model. This will help the owner reorder in future.

- Quantity: how many of each are being provided (e.g., 2 units, 10 boxes, 5 liters, etc.).

- Associated Equipment or System: link the spare to the system it belongs to (e.g., pump motor for Pump P-7, or spare tiles for Building A lobby ceiling). This context is very useful to maintenance staff.

- Storage Location: where the item is being stored on site for handover (we’ll organize locations in the next step, but you can pre-fill this if known).

Now, commence the collection of items:

- Retrieve spare parts from subcontractors or vendors as they arrive. Sometimes vendors ship spares separately from the main equipment – track these shipments diligently. As items arrive, tag them and secure them in a designated area.

- Round up attic stock materials, which might be left over from installation (like extra boxes of tiles or paint). Ensure these are unused, in good condition, and appropriately packaged. Often, attic stock is the surplus from bulk orders (contractors intentionally order a bit extra for closeout). Verify the quantities match what’s required (for example, if contract says 2% of installed material, calculate that amount and make sure you have at least that on hand).

- Check off each required item against your early planning checklist. If anything is missing or short, take action immediately: order the missing parts, or communicate with the supplier to send the balance. It’s much easier to expedite missing spares now than to explain the absence to the client later.

As you itemize, it can be helpful to categorize the inventory logically. Categories might include Mechanical Spares, Electrical Spares, Plumbing, HVAC, Consumables, Extra Building Materials, etc. Grouping items will make it easier to package and present them in an organized way (and also helps if different team members are responsible for different categories).

This is also a good stage to inspect what you’ve received. Open boxes to verify the content (you don’t want to hand over a crate supposedly containing a pump motor, only for the owner to find something else inside). Check for any obvious damages. If a part arrived broken or defective, get a replacement now. Make note of any items that have special handling needs (e.g., “keep in cool dry place” or “fragile – contains glass”). You’ll address storage in the next step, but awareness now helps prevent accidental damage.

By the end of this step, you should have a complete inventory list and all physical items gathered. The contractor’s team should have full visibility of what will be turned over. Think of it as doing your own internal audit: everything the owner expects to get is accounted for on your list and is present in your storage area.

3. Organize and Label the Inventory for Easy Access

Once all spares and materials are gathered and listed, the next step is to organize them neatly and label everything clearly. This is crucial to make the handover user-friendly for the owner. The goal is that any maintenance person later can look at the inventory and quickly understand what each item is and where it is.

Plan the storage layout: Decide where the inventory will be stored leading up to and during handover. It could be a dedicated room or container on site, a corner of the main equipment room, or a warehouse area. Wherever it is, make it orderly:

- Group similar items together. For example, keep all electrical spare parts in one set of bins or shelves, mechanical spares in another, and consumables in another area. Within those, sub-group by equipment or system if possible (all parts for the generator in one pallet, all HVAC belts and filters in one box, etc.).

- Use shelves, bins, or pallets as needed to separate items. Avoid a scenario where everything is thrown into one big crate. If the owner has to dig through a mixed box of parts, the organization effort has failed. Instead, consider providing multiple smaller containers that are logically sorted (and preferably not too heavy to move).

Label every item and container: Each spare part or material package should have a label or tag that matches the description on your inventory list. Include on the label:

- A clear name/description (e.g., “Spare Fan Motor – 1 HP, for EF-2”).

- The quantity in that package (e.g., “Contains 2 units” if a box has two pieces).

- Optionally, reference an item number from your list if you have one. Numbering items on the inventory list and putting corresponding numbers on labels can help cross-reference quickly.

- If the item is small or in bulk (like fasteners or gaskets), label the container they’re in (e.g., a bag or bin) rather than each piece.

Also label the storage locations or containers themselves. For example, you might place large labels like “Shelf 1: Electrical Spares” or “Pallet A: Attic Stock Materials”. This way, when you hand over, you can literally point the owner’s team to “those three shelves contain all your spare parts, labeled by system.”

Provide protective packaging as needed: Ensure that spares are preserved in good condition. If you have electronics or delicate parts, keep them in original packaging with anti-static bags or cushioning. Keep chemicals sealed and in appropriate containers. For paints or liquids, check lids for tightness and mark them clearly (including color codes or product codes). The owner will appreciate receiving materials that are clean and well-kept, not dusty or leaking. If some parts have a shelf-life or expiration date (certain chemicals or filters), mark those dates on the package so the owner knows how long they’re good for.

It’s often helpful to create a “Spare Parts Corner” or area that you can show during the final walkthrough. Some contractors even stage the spares in a visually appealing way (lined up neatly, with printed labels) – it sends a message of thoroughness. During handover, you might walk the client’s representative through this area, explaining what each group of items is. An organized presentation can leave a strong positive impression.

In summary, this step is about making the inventory accessible and self-explanatory. When done right, the owner’s maintenance team later won’t have to call you to ask “we found a box labeled X, what is it for?” because you have already clearly labeled it as, say, a pump seal kit for a specific pump. A little effort in organization now saves a lot of potential confusion later.

4. Prepare Detailed Inventory Documentation

With the physical items organized and labeled, turn your attention to the documentation that will accompany the handover. This includes the inventory list itself (to be given to the client) and any supporting documents like manuals, warranties, and certificates related to those spares and materials.

Finalize the Inventory List: Your itemized register from step 2 should now be refined and verified. Ensure it includes all relevant details for each item. It’s often useful to include the location or container ID where each item is stored (e.g., “Spare Drive Belt for AHU-1 – Qty: 2 – Location: Mechanical Room shelf B”). Organize the list logically, perhaps grouped by system or category, similar to how you physically organized them. This list will be handed to the owner as the official record of what was delivered. Make it clear and easy to read: tables or spreadsheets can be printed and placed in a binder, and also shared electronically for their records.

Include Reference Documents: For each major piece of equipment’s spares, attach or include references to the O&M manuals. Typically, O&M manuals (which are part of project closeout documents) have sections listing spare parts and maintenance procedures. You can cross-reference the manual sections in your inventory list (e.g., “See O&M Manual section 5 for vendor’s spare parts list and maintenance guidelines for this pump.”). In some cases, you might print out the spare parts page from the manual and include it in an appendix. The idea is to give context – not just “here are parts” but also “here’s what they’re for and how to use them.”

Warranties and Certificates: If any spare parts themselves carry a warranty (for instance, a spare motor might have its own warranty from manufacturer starting at delivery), include those warranty documents. Also, if relevant, include material certificates or test certificates for things like spare pressure valves, etc., if they were provided by vendors. This level of thoroughness ensures the owner has all necessary paperwork if they need to make a warranty claim on a spare part in the future.

Attic Stock Transmittal Form: Many owners, especially institutional ones, have a standard form for attic stock/spare parts handover. It usually lists each item, quantity, and has a sign-off for the owner to acknowledge receipt. If the client provided such a form, fill it out completely. If not, you can create a simple sign-off sheet yourself: essentially a summary of the inventory list where both parties (contractor and owner rep) will sign and date at handover. This document is a formal record that “X items were delivered on Y date” and is often included in the closeout package.

Digital Copies: In addition to hard copies in binders, provide digital copies of the inventory list and related documents. A spreadsheet of the spares list can be extremely useful for the owner – they might import it into their maintenance management software or use it for future inventory audits. Ensure the digital files are well-organized (e.g., one folder containing the inventory spreadsheet and subfolders of manuals and warranties). Label files clearly (for example, “ProjectX_Spare_Parts_List.xlsx” rather than just “Book1.xlsx”).

Quality documentation is as important as the physical items themselves. Think about the future maintenance personnel who might not have been around during the project – the documentation should be detailed enough that it “tells the story” of what was handed over. For instance, a year later, someone should be able to read the inventory list and understand that a certain filter corresponds to a certain piece of equipment because you included that info.

By preparing thorough documentation, you enable traceability of the inventory. If there’s ever a question like “did the contractor give us part X?”, the answer is readily available in the records. This builds trust and transparency. It also protects you as the contractor – you’ll have proof of exactly what was delivered and accepted.

5. Conduct a Thorough Inventory Audit and Verification

Before the official handover to the client, it’s wise to perform an internal audit or verification of the inventory. Essentially, double-check everything: quantities, labeling, documentation accuracy, and condition of items. This step is about quality control – catching and correcting any discrepancies before the client is involved.

Cross-Check the List vs. Physical Inventory: Take your final inventory list and physically verify each item against it. It can be helpful to have two people for this task – one person reads off the list, the other locates the item and confirms. Verify that:

- Every item on the list is present in the storage area, in the quantity stated.

- Every item present is indeed on the list (if you find something lying around that somehow wasn’t recorded, now is the time to fix that).

- Labels on items match the descriptions on the list. If you labeled a box “Spare bearings for motor X” but the list calls them “Spare bearing set model 123,” consider aligning the terminology so there’s no confusion – consistency matters.

- Check that no required item is missing. If something is missing, determine why – was it never ordered, did it not arrive, or was it misplaced? Urgently resolve any missing pieces: this might mean quickly procuring a replacement or tracking down where the item went. It’s better to delay the handover slightly to get everything right than to hand over incomplete inventory.

Inspect Item Condition: As you audit, inspect each spare part again for condition. Confirm that nothing has been damaged during storage and that perishable items are still within their shelf life. For example, if you promised a spare battery with the equipment, ensure the battery is still charged or within expiry, or note its expiration date to the owner. If any item looks sub-par, swap it out if possible. You want to hand over parts that are in new, ready-to-use condition.

Verify Documentation Completeness: Ensure all the paperwork is ready. If you referenced documents in the inventory list, check those documents are included. Double-check that quantities on the transmittal forms match the physical count. If you have a colleague or team member who wasn’t involved in preparing the docs, have them do a quick review – a fresh set of eyes might catch a typo or omission. It’s easy to, say, list “10 filters” in one place and “12 filters” in another by mistake, so consistency check is helpful.

Simulate the Handover: One effective technique is to do a mini “practice handover” within your team. Imagine you are explaining and delivering the spares to the client – walk through the storage area with your inventory list and speak out what each item is, checking off as you go. This simulation can reveal if anything is unclear or if you have difficulty identifying something based on your own list (if you struggle, certainly the new owner will). It also prepares you for the actual meeting so you can be confident and efficient.

Performing this audit demonstrates diligence. When it comes time for the real handover, you’ll be well-prepared and unlikely to encounter surprises. Additionally, if the client or their representative wants to count or verify some items during handover (and sometimes they do), you can be confident everything checks out. You might even invite the owner’s maintenance rep to join your internal check if they’re available; this openness can build trust.

In summary, verify, verify, verify. It might feel like extra work to count and inspect items you think you’ve already handled, but it’s a safeguard that ensures you truly deliver what was promised. This thoroughness can differentiate a great closeout from a mediocre one.

6. Leverage Inventory Management Software for a Streamlined Handover

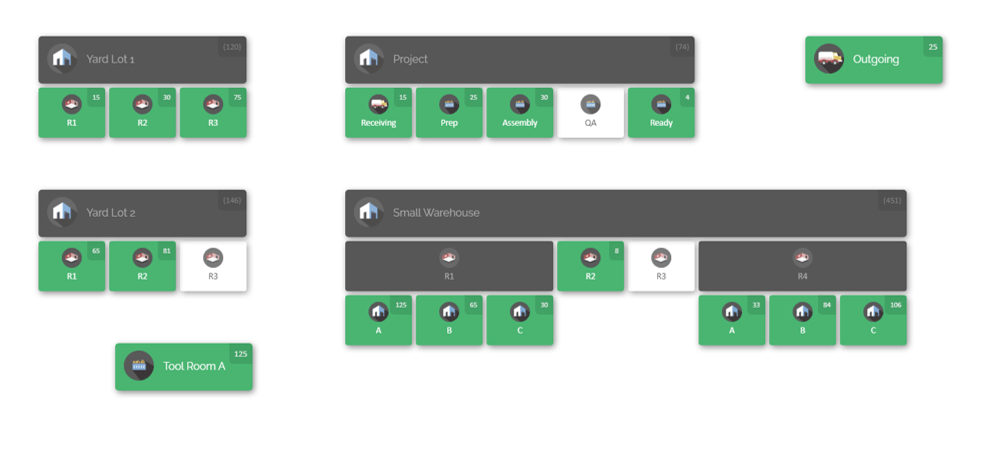

While managing inventory handover can be done with spreadsheets and manual effort, using a modern inventory management software can dramatically simplify the process and reduce errors. A tool like CyberStockroom, for example, is tailored to track inventory across multiple locations with a visual map interface – which is ideal for construction projects with various storage areas. Let’s see how leveraging such technology can benefit the inventory handover process:

Real-Time Tracking and Visibility

Throughout the project, CyberStockroom allows you to create a virtual map of all your inventory locations – think of locations like the main warehouse, on-site storage room, mechanical room, and even contractor trucks if needed. As spare parts and materials arrive, you can log them into the system and assign them to their storage location on the map. This provides instant visibility of where each item is.

For instance, you could pull up the project’s inventory map and see that you have 5 spare valves sitting in the laydown yard container and another 3 in the mechanical room cabinet. By the time of handover, you’ll have an accurate, up-to-date account of all items without having to comb through multiple spreadsheets or purchase orders. Every time an item was used or moved during construction, the system would update – preventing the common problem of lost or untracked spares.

Visual Organization

The map-based approach of CyberStockroom is especially useful when organizing spares on a site. Instead of relying purely on textual descriptions, you have a visual dashboard of the inventory. For example, you can visually break down the site into sub-locations (warehouse, storage shed A, electrical room shelves, etc.) on a map. When preparing for handover, you might arrange all attic stock in one area and label it on the map, all mechanical spares in another, and so on. The software can display product quantities at each location, giving you a bird’s-eye view of how items are distributed. This visual clarity makes it easier to explain to the client – you could even share a snapshot of the inventory map to show how items are organized, which reinforces confidence that nothing is hidden or missing.

Ease of Barcode Scanning and Labeling

CyberStockroom supports barcoding, meaning you can tag each item or box with a barcode label and quickly check items in or out by scanning. During commissioning, if someone needed to temporarily use a spare or relocate it, a quick scan updates the system. This minimizes manual data entry mistakes. When it’s time to label your inventory for handover, the software can generate labels with item names and barcodes that align with the database. Later, the owner’s team can use those same labels if they continue with the system, or at least benefit from the clarity of professional labels. No indecipherable handwriting or inconsistent naming – everything matches the digital inventory list.

Centralized Information and Reporting

All the details about each spare part can be stored in the system – including part numbers, photos, supplier info, and even attachment files (like manuals or datasheets). Think how powerful it is to hand over not just a physical part, but a digital record of that part. With CyberStockroom, you could provide the owner a login or an exported report that shows every item, complete with details and even a picture.

Collaboration and Accountability

Cloud-based inventory tools like CyberStockroom allow multiple team members to update and view the inventory concurrently. So your procurement team, site supervisors, and project manager all stay on the same page regarding spare parts status. Each transaction (addition, move, removal of an item) can be logged with a timestamp and user. This creates an audit trail – you can see, for example, that “User A checked out 1 spare fuse on March 1 to replace a blown fuse during testing.” Such a log is invaluable if questions arise. It also instills a sense of accountability in the team handling spares: knowing that usage is being tracked tends to reduce any casual “borrowing” or loss of items. When prepping for handover, you can review the activity history to ensure, for example, that any used spares were replenished or noted.

Smooth Handover and Continuity

Perhaps one of the biggest advantages of using an inventory system is the ease of transferring knowledge to the owner. Instead of handing the client a stack of papers and trying to verbally explain what’s where, you can present a structured digital inventory. With CyberStockroom’s map, you might even give a live demonstration: “Here’s a map of your facility in our system; as you can see, clicking this storeroom shows all the spare parts inside it.” Even if the owner’s team is not going to adopt the same software, this presentation makes a strong impact. You can then hand over an export of the data, which they can import into their own maintenance management system. The continuity means they’re not starting from scratch – they have an established inventory baseline in a digital form.

Incorporating software does require some setup early in the project (inputting locations and items), but the payoff is significant in the commissioning phase. It reduces manual errors, saves time in organization, and results in a very polished handover.

CyberStockroom, in particular, with its intuitive visual interface, is well-suited for construction inventory management. It can handle the dynamic nature of project sites where inventory moves around, and it presents data in a way that’s easy to grasp for both technical and non-technical stakeholders.

By leveraging inventory management software, you essentially bring your spare parts handover into the digital age – increasing accuracy, transparency, and professionalism. It transforms a potentially chaotic process into a well-orchestrated one. Many headaches of manual tracking simply disappear, and you can focus on higher-level management knowing the details are being handled by the system.

7. Execute the Formal Handover to the Owner

Now comes the culmination of all your preparation: the formal handover meeting or process where you transfer the inventory of spares and materials to the owner. This typically occurs alongside other commissioning handover activities (like transferring keys, documentation, and training the owner on systems). Here’s how to execute the inventory handover smoothly and professionproject manager on the client side) for a dedicated session to review and accept the spare parts and materials. It’s best done on-site where the items are located. Ensure all relevant people are present: this may include the general contractor’s project manager, the person who managed the inventory (if not the PM), and the owner’s facilities or maintenance supervisor. If the project is large or complex, having the architect or commissioning agent present can also be helpful, but usually the focus here is on maintenance personnel.

Present the Documentation First: Begin by providing the owner with the inventory list and any transmittal forms for signature. Walk them through the document, explaining the structure (for example, “Items are grouped by system, with location indicated. We have a total of 50 line items of spares and materials detailed here.”). Highlight any particularly important or high-value spares on the list. This gives the owner a clear roadmap of what they’re about to see and receive.

Physical Inspection of Items: Next, tour the storage area together. This is where your organized “spare parts corner” shines. Take the owner through each section:

- Point out each group of items, using your labels and list as a guide. For instance: “Here we have three spare pump motors (you can see the tags on them). These correspond to line 5 on the inventory list – spares for Pump P-7 and P-8. Next, on this shelf, we have the electrical spares: you’ll find a box of circuit breakers, some spare light fixtures, and fuses – all labeled and listed in the document.”

- For attic stock like tiles, carpet, or paint, show how they are packaged. For example: “These four boxes are attic stock tiles for the lobby and offices. Each is labeled with the area and color. Over here are 2 cans of the paint used in the corridors for touch-ups, labeled with the paint code.”

- Encourage the owally:

- Schedule a Walkthrough and Handover Meeting: Coordinate with the owner’s representative (often a facilities manager or ner’s rep to check or count anything they wish. Since you’ve audited everything, you should be confident. They might randomly open a box or count a few items. Assist them in doing so – open packages to show contents if requested. This transparency helps build their trust that everything is indeed as stated.

Discuss Storage and Security: Officially, once handed over, these items become the owner’s property and responsibility. It’s wise to discuss with them how and where they will keep these spares moving forward. Perhaps the spares will remain in the same room or maybe they plan to move them to a central warehouse. Offer suggestions if appropriate: for example, “We recommend keeping the smaller parts in this cabinet and maybe moving the larger motors to your main maintenance shop for long-term storage.” If any item requires special storage conditions (temperature, humidity, etc.), remind them at this time and ensure it’s noted in documentation. This conversation shows that you care about the preservation of the parts, not just the hand-off.

Obtain Formal Sign-off: Once the owner is satisfied that all items are present and in order, execute the paperwork. This usually involves:

- Signing the inventory list or transmittal form to acknowledge receipt of the listed items in good order. Both the owner’s rep and your side should sign, each keeping a copy.

- If there were any minor discrepancies discovered and resolved on the spot (for example, an item was initially mislabeled but clarified during the walkthrough), note those on the document before signing, to avoid confusion later.

- Also have them sign any related closeout documents like a general project handover certificate that might mention that all spare parts and attic stock have been delivered per contract.

Provide Keys or Access (if relevant): In some cases, spare parts might be handed over in locked cabinets or storage rooms that will now belong to the owner. Ensure you give them the keys to these or access codes as needed. For example, if you set up a locked cage for spares in a mechanical room, turn over the key at this time.

Offer a Q&A Opportunity: Ask the owner’s team if they have any questions about the spares – usage, installation, future procurement, etc. They might ask, “How often do we need these filters?” or “What’s the lead time if we need to order another one of these pumps?” Answer to the best of your ability (much of this should be in the O&M manuals, so you can reference those). If you used an inventory system like CyberStockroom and the owner is interested in continuing with it, this is a good time to discuss handing over digital access or data exports as well.

Emphasize Support and Contact Info: Let the owner know that although the project is ending, you are providing them with all info needed. If appropriate, point out where in the documentation your contact or the vendor contacts are listed in case they need assistance finding or ordering replacement parts in the future. For instance, “We’ve included the supplier’s contact on the inventory sheet for the water pumps in case down the line you need more of these parts, you can reach out to them directly. Of course, you can also contact us if anything urgent comes up during the warranty period.” This reassures the owner that they’re not being left high-and-dry with a pile of parts they don’t understand.

Completing the formal handover is a significant milestone. It not only fulfills your obligations but also represents one of the last interactions of the project. By handling it professionally – being organized, transparent, and helpful – you leave a strong final impression. Many clients cite the closeout phase as a big factor in their overall satisfaction with a project. Handing over a well-organized inventory of spares, accompanied by clear records, shows diligence and adds to the client’s confidence in the quality of your work.

8. Support Ongoing Spare Parts Management and Replenishment

After the handover, the owner’s team will take over responsibility for the inventory. However, your role in setting them up for success can extend slightly beyond the handover event. It’s good practice to provide guidance for ongoing management of those spares and ensure a smooth transition into the maintenance phase. Consider the following post-handover support steps:

Orient the Maintenance Team: If the actual maintenance technicians were not present during the handover walkthrough, you might offer to do a short orientation for them later. This could be as simple as walking the facility manager or lead technician through the spares storage one more time, explaining what’s there. You could also prepare a brief summary document: “Spare Parts Quick Reference,” listing critical spares and their locations in a concise format for easy reference. While not always necessary, this extra step can be very helpful if the handover meeting only involved project managers and not the hands-on maintenance crew.

Emphasize the Importance of Tracking Usage: Encourage the owner to track the usage of the spare parts going forward. If they continue with an inventory system, they’ll have tools for this. If they prefer a manual method, suggest they keep a log or spreadsheet whenever a spare is taken and used. The reason is to maintain the benefit – if they use spares without tracking, in a year they might not know what’s left. Emphasize how a small effort in logging will pay off in preventing future shortages.

Recommend Reorder Points: Since you’re handing over a finite stock of parts, eventually some will get used up. It’s helpful to give the owner guidelines on when to reorder critical items. For example, if you provided 10 replacement air filters and you know the facility uses 2 per month, advise them that when they get down to say 2 or 3 filters remaining, they should reorder a new batch. For unique expensive parts (like a spare pump or motor), they might not reorder immediately after use due to cost, but at least they should plan for lead time. If you have insights (maybe from vendors) on approximate lead times, share that: “These drive belts have a 8-week lead time from the supplier, so don’t wait until the last one to order more.” This kind of advice helps the maintenance team keep the operation running smoothly long after your project team is gone.

Schedule Warranty Period Check-ins (if applicable): Many projects have a warranty period (say 12 months after handover) where the contractor remains obligated to fix defects. During that period, spare parts usage might occur for warranty repairs. Coordinate with the owner that if they do use any of the spares for warranty fixes, how that will be handled. Often, if a part is used to replace a failed component under warranty, the contractor or vendor might replenish that part or at least note it. While this goes slightly beyond basic handover, it’s part of the aftercare – you don’t want the owner feeling shortchanged if they had to consume a spare due to a construction defect. Clarify that process. For example, “If the facility ends up using the spare pump we provided because the installed one had an issue, we will replace that spare under warranty so you’re not left with none.” This kind of promise should be in line with your contract terms, of course, but mentioning it reassures the owner that using a spare now won’t leave them deficient later.

Follow-Up Communication: A few weeks after handover, it can be good to follow up with a friendly note: “Just checking in to ensure you found all the spare parts documentation clear and if your team has any questions about the materials we turned over.” This opens the door for the owner to ask any minor questions they might have had after digging into the inventory. Often, owners are impressed with such proactiveness. It shows that you stand by your work and care about their operational success.

Finally, take the opportunity to learn lessons for future projects. Internally, review how the inventory handover went. Were there any hiccups? Did the owner ask for information you hadn’t prepared? Use that to improve your process next time. Perhaps you realize that having a digital inventory from the start (step 6) was a huge time saver, or conversely that you needed more contingency time to gather spares. Continuous improvement in this area will make each subsequent project commissioning even smoother.

With the owner now fully in charge of the spare parts inventory, your job is essentially done. You’ve given them not just a building, but the tools to maintain it. A well-managed inventory handover means the facility begins its life on a strong footing – maintenance staff are empowered with parts and knowledge, and the client feels they got everything they paid for (and more). This level of care can turn over a project with zero loose ends, greatly increasing the likelihood of positive referrals and repeat business.

Conclusion

Inventory handover is a critical component of project commissioning that ensures the long-term success and maintainability of a project. By diligently managing the spares and materials handover process – from early identification of requirements to careful organization, documentation, and formal transfer – project teams can prevent operational hiccups and exceed client expectations. It transforms the handover from a chaotic afterthought into a well-structured deliverable in its own right.

Throughout this guide, we highlighted the importance of planning ahead, keeping meticulous records, and embracing tools like CyberStockroom to bring efficiency and clarity to inventory management. With a visual, real-time inventory system in place, both contractors and owners benefit from transparency and accuracy. The commissioning phase is already a busy time, but investing effort in a smooth inventory handover pays dividends: the owner steps into their new facility with confidence, armed with spare parts and knowledge to address any early maintenance needs.

For construction and project professionals, mastering inventory handover is part of delivering quality. It reduces the chances of emergency calls from a panicked client who can’t find a critical part, and it demonstrates thoroughness that differentiates you from competitors. In the global construction industry where projects are becoming ever more complex, such attention to detail in closeout processes builds a reputation for reliability.

In summary, treat your project commissioning inventory handover with the same seriousness as any other deliverable. Organize spares systematically, leverage modern inventory management practices, and communicate clearly with the owner’s team. When done right, inventory handover becomes a seamless bridge from construction to operation – ensuring that your project not only gets built on time and on budget, but also operates smoothly from day one. The spare parts on the shelf today are the insurance for the facility’s tomorrow, and managing that handover well is a mark of true project success.

Leave a comment