Imagine a concrete pour grinding to a halt because the rebar delivery never arrived, or a crew standing idle waiting for a specific tool to be found on a chaotic site. Scenarios like these are all too familiar in construction projects. Having the right materials and equipment at the right time is vital to keeping projects on schedule and within budget. Yet many construction teams struggle with either shortages of critical items that delay work, or piles of excess materials that tie up cash and clutter the site. Striking the perfect balance — ensuring you have exactly what you need, when you need it, without overstocking — is the goal of effective construction inventory management.

One proven technique to achieve this balance is ABC analysis. ABC analysis is an inventory categorization method that helps you identify the most important items in your inventory and prioritize them above less critical ones. Instead of giving equal attention to every screw and steel beam, ABC analysis lets you focus your time, budget, and energy on the materials that matter most to your project’s success. In this guide, we’ll explain what ABC analysis is, how to apply it to construction materials management, and step-by-step instructions to implement it. Along the way, we’ll also discuss how modern tools can complement ABC analysis to bring your construction inventory management to the next level.

What is ABC Analysis?

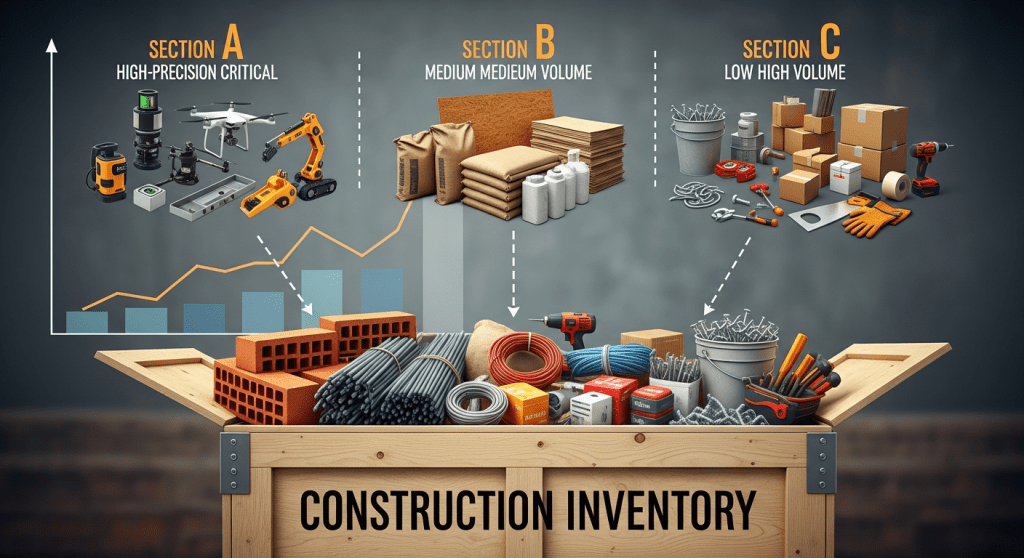

ABC analysis (also known as ABC classification, or “Always Better Control”) is a time-tested inventory management strategy for categorizing stock items based on their importance. The technique is rooted in the Pareto Principle (the “80/20 rule”), which in inventory terms means that a small fraction of items often accounts for the majority of the inventory value or impact. In an ABC classification:

- Category A items are the most important: typically about 20% of your items that make up around 80% of the total value or consumption. These are high-value or critical-impact materials that warrant the most attention.

- Category B items are moderately important: roughly 30% of items accounting for about 15% of value. These are of middling value or importance – not as vital as A’s, but more significant than routine consumables.

- Category C items are the least important: often around 50% of items but only ~5% of overall value. These are low-value, plentiful items that require minimal management effort.

The exact percentages aren’t rigid rules, but the general idea is clear: a small core of items (A) are disproportionately critical, a middle group (B) is of medium importance, and a long tail of many minor items (C) have minimal impact. By classifying your inventory this way, you can apply “always better control” to Category A, moderate control to B, and basic control to C – hence the name ABC.

In practice, the “importance” of an item for ABC analysis is often measured by its annual usage value (sometimes called annual consumption value) – calculated as the item’s cost multiplied by the quantity used in a year. Items with the highest monetary usage (cost × usage volume) rise to the top as Category A. However, importance can also be defined by other factors depending on context. We’ll discuss that more when we tailor ABC analysis to construction. First, let’s see why ABC analysis is so useful in a construction setting.

Why ABC Analysis Matters for Construction Inventory Management

Construction projects involve thousands of different materials and tools, from expensive heavy equipment components to everyday nuts and bolts. Not all of these items are equally critical to the project’s outcome. ABC analysis helps construction managers separate the vital few from the trivial many. Here are key reasons ABC analysis is especially valuable for construction inventory management:

- Focus on Critical Materials: Construction schedules often depend on a handful of critical materials. For example, steel beams for structural work or a specialized component for an HVAC system might be make-or-break items – if they’re missing, the whole project can stall. By identifying these as Category A, you ensure they get top priority in planning and tracking. You’ll place orders early, expedite delivery if needed, and double-check they’re on hand before work starts. In short, ABC analysis flags which materials must not run out so you can proactively prevent stockouts and delays.

- Improved Project Scheduling: When you know which inventory items are critical (A items), you can align them with your project schedule more effectively. For instance, if concrete and rebar are Category A for your project’s foundation phase, you’ll make sure they arrive well before the pour date. Aligning inventory with scheduling prevents those costly moments where crews are standing around waiting for materials. (Ever seen an entire crew idle because a $50 part was missing? It happens – and ABC analysis aims to eliminate such hiccups.)

- Cost Control and Budget Adherence: Materials often represent a large portion of construction costs (sometimes 30–60% of a project’s budget), so managing them wisely has a big financial impact. ABC analysis helps avoid tying up too much money in inventory. You might decide that Category C items (like inexpensive fasteners or paint) can be ordered on-the-fly or in bulk infrequently, rather than holding large stock. Meanwhile, you invest your budget in maintaining healthy stock of Category A items where it counts. This prioritized spending ensures critical needs are covered while minimizing waste on excess stock of low-value items.

- Efficient Use of Storage Space: On many job sites, space is at a premium. You can’t afford to clutter trailers or laydown yards with huge quantities of every single item. ABC classification guides you to allocate space smartly. High-priority (A) materials might be stored closest to the work area for quick access (and perhaps in more secure containers), whereas C items can be tucked away in a corner or brought in only as needed. By organizing storage based on ABC categories, you keep the job site lean and organized, focusing prime space on what’s truly needed.

- Reduced Loss and Theft: Unfortunately, pilferage and loss of materials/tools can be a problem in construction. Typically, the items most likely to “go missing” are those that are valuable (which often coincide with Category A). By being aware of which inventory is high-value, you can implement stricter controls for A items – such as tool check-out logs, locked storage, or GPS tags – while not over-burdening staff with paperwork for every little C-category item. This targeted security helps protect expensive assets without creating unnecessary red tape for everything on site.

- Streamlined Inventory Audits: Without ABC analysis, a project manager might try to count and monitor everything equally, which is inefficient. ABC categorization lets you audit more often what matters most. For example, you might decide to do a quick count of A items (say, the generator fuel or the supply of steel plates) every week, B items monthly, and C items only before major project milestones. This ensures accuracy where it has the biggest impact on project continuity. It also saves time – your team isn’t spending hours tracking every box of nails when they could be focusing on critical stock.

In essence, ABC analysis brings focus and prioritization to construction inventory management. It acknowledges that not all materials are created equal. By doing so, it helps prevent the big headaches – like work stoppages due to missing items – and cuts down on the subtle inefficiencies (like money tied up in excess stock or time wasted hunting for tools).

Did you know? Studies have found that the average construction worker may spend up to 10 minutes a day searching for tools or materials that aren’t where they should be. That adds up to about a full workweek of lost time per person each year! This startling statistic underscores how poor inventory organization can drain productivity. Using ABC analysis in conjunction with good inventory practices can significantly reduce these losses by keeping the most needed items well-organized and easy to locate.

Now that we understand the value of ABC analysis, let’s get into the practical steps of applying ABC analysis to your construction inventory.

How to Implement ABC Analysis for Construction Materials

Applying ABC analysis in a construction context involves a series of logical steps – from gathering data about your materials to putting the right controls in place for each category. It’s essentially a focused way of doing inventory management. Let’s walk through a step-by-step process:

1. Inventory Data Gathering and List All Materials

Begin by listing all inventory items that you manage for your construction project or business. This list should include every significant material, part, or tool that is stored and tracked – for example, lumber, cement bags, rebar bundles, plumbing fittings, electrical cable spools, drywall sheets, paint cans, excavator attachments, and so on. Alongside each item, gather the following key data:

- Annual usage quantity – How many units of this item do you typically use in a year? (If you’re doing this analysis for a single large project, you might use the total quantity required for the project instead of annual usage.)

- Unit cost or value – How much does one unit of the item cost? For owned equipment or tools, you might use their estimated value or rental cost. For consumables, use purchase price per unit.

Total annual usage value – This is simply usage quantity × unit cost. It represents how much money’s worth of each item you consume over a year (or in the project). This figure will be crucial in ranking items by importance.

Tip: If you have historical inventory records, pull data from the last year to estimate usage. If not, use project estimates or procurement plans to gauge quantities. Be sure to include materials from all warehouses, laydown yards, and job sites under your management.

2. Calculate Usage Value and Rank Items

With your data in hand, calculate the annual usage value for each item (if you haven’t already done so). For example, if you use 1,000 bags of cement a year and each costs $10, the annual usage value for cement is $10,000. Do this for every item on your list.

Next, rank the items in descending order by their usage value (highest to lowest). This ranked list will show you which materials consume the most money over the year. Typically, you’ll see a small number of items at the top that account for a very large portion of the total spend, while a long tail of items at the bottom contribute only a tiny fraction. This is the Pareto Principle revealing itself in your data.

For example, you might find that the top 10 items on your list make up, say, 75% or 80% of your total annual material expenditure. These could be things like structural steel, ready-mix concrete, lumber, rebar, and heavy equipment rentals – big-ticket necessities for your projects. Lower down the list, you’ll have dozens of small items (tapes, fasteners, sealants, etc.) that individually are very low-cost.

3. Determine Cumulative Percentages and Category Breaks

Once items are ranked by usage value, it’s helpful to compute cumulative percentages. Go down your ordered list and add up each item’s percentage of the total value as you go. For instance, item #1 might be 25% of total value, items #1–3 together might make up 60%, and so on until all items sum to 100%. Also note the cumulative percentage of the number of items. This will let you see, for example, “the top 15% of items account for 80% of value.”

Now decide on the thresholds for your A, B, and C categories. In classic ABC analysis, a common split is:

- Category A – items that cumulatively account for around ~80% of the total value (this often turns out to be about 15–20% of the items, depending on your data distribution).

- Category B – items that together account for the next ~15% of value (often around the next 20–30% of items). Typically, by the time you include A + B, you’re covering ~95% of value.

- Category C – the remaining items that make up the last ~5% or so of value (usually a large number of items, often 50% or more of the item count).

These thresholds aren’t set in stone – you might adjust them slightly based on natural breakpoints in your list. For instance, if you see a big drop-off in usage value after the 12th item, you might decide everything above that is A even if it’s only 78% of value, and so on. The goal is to group logically into high, medium, and low importance bands.

By the end of this step, every item in your inventory list is classified as A, B, or C. It can be useful to mark this on a spreadsheet or inventory management system for reference.

Example – Categorizing Construction Inventory:

To make this concrete, let’s illustrate with a simplified example. Imagine a construction company uses the following materials in a year with these usage values:

- Steel I-beams – $150,000 per year

- Ready-mix concrete – $120,000 per year

- Diesel fuel (for machinery) – $80,000 per year

- Lumber (framing wood) – $50,000 per year

- Copper electrical wire – $30,000 per year

- PVC piping and fittings – $20,000 per year

- Paint and finishes – $15,000 per year

- Miscellaneous hardware (nails, screws, brackets) – $8,000 per year

- Safety equipment (PPE like gloves, hard hats) – $5,000 per year

Total annual inventory spend in this example is around $478,000. Now, sorting by value: steel, concrete, and diesel are the top three. Let’s see how they accumulate:

- Steel + Concrete + Fuel: $350k total, which is ~73% of the total value, and these are 3 items out of 9 (~33% of item count).

These would clearly be Category A due to their heavy impact on cost and project operations. - Lumber + Wire + PVC: Together these three add $100k, reaching ~94% of total value (and items #4–6, roughly another 33% of items). These would fall into Category B – significant but not as critical as A.

- Paint + Hardware + PPE: The last 3 items add up to $28k, which is just ~6% of total value (and they comprise the remaining 34% of the item count). These are Category C, the low-value items.

In this example, Category A (steel, concrete, fuel) are vital materials – expensive and essential – so they demand tight control. Category B (lumber, wiring, PVC) are important everyday materials but individually have a more modest share of cost; they need regular oversight, not extreme measures. Category C (paint, small hardware, basic PPE) are cheap, plentiful items that you don’t need to micromanage.

4. Apply Inventory Controls According to Categories

Now comes the action: using the ABC categories to manage each group differently. The whole point of ABC analysis is to prioritize effort where it matters. Here’s how you can manage each category in a construction context:

- Managing Category A (High Priority Items): These items should get the most rigorous management. For all A items, consider implementing strict inventory control policies. For example: maintain minimum stock levels and reorder points (never let an A item stock fall below a certain threshold without triggering a reorder); perform frequent inventory checks or cycle counts (e.g. weekly) to ensure counts are accurate; use secure or special storage (lock up valuable tools, keep high-value materials in a guarded yard); and possibly arrange backup suppliers or rush order agreements for A items in case your primary supply runs into issues. In construction, A items might also merit on-site spares – for instance, if a critical piece of equipment part is an A item, you might keep a spare on site despite the cost. Treat A items as mission-critical. Delays or losses involving these items can severely impact your project, so invest time and resources to manage them closely.

- Managing Category B (Moderate Priority Items): B items require management but not to an overbearing degree. You’ll still want reasonable controls: maybe check B stock levels monthly; set reorder points, but perhaps with a bit more leeway or higher safety stock since they’re not as expensive; store them accessibly but they don’t necessarily need the tight security of A items. If an item is on the border of A and B, lean towards managing it like A. Otherwise, for most B’s, a standard inventory review process is fine. You pay attention to them, but you won’t check them daily. For example, you might schedule material deliveries for B items just in time for each phase of the project (to avoid clutter) but you won’t spend as much effort as you do managing A item logistics. If a B item runs low unexpectedly it might be an inconvenience, but usually not a project-ending event – still, you plan to avoid that scenario through regular monitoring.

- Managing Category C (Low Priority Items): C items can be managed with the simplest, low-touch system. These are often bulk materials or inexpensive consumables (like packs of nails, buckets of paint, spare bolts, etc.). You might not even assign formal reorder points for every C item; instead, you could use a more reactive or periodic restocking approach (e.g., just check the stock of C items before starting a new project phase or monthly, and reorder in bulk if needed). Some companies use a two-bin or kanban system for C items: e.g., keep two bins of an item, and when one is empty, reorder that bin – this way you always have one bin in use and one on order. The idea is to minimize the time spent managing C items. They’re low cost, and a shortage of them, while annoying, is usually easy to resolve quickly (you can run to the hardware store or order from a supplier on short notice without much financial pain). Don’t let C items distract you from the A and B oversight. Many construction teams also give more responsibility to field crews or warehouse staff to manage C items (since it’s straightforward), freeing up project managers and procurement officers to focus on the A and B categories.

5. Communicate the Priorities to Your Team

ABC analysis shouldn’t exist only in your notebook – communicate these priorities to those involved in inventory handling. Project managers, site supervisors, storekeepers, and procurement officers should all understand which items are Category A, B, C and what that means. For instance, the site supervisor should know that “Category A items must never stock out – if we’re running low on structural steel or diesel, escalate it immediately.” Likewise, storekeepers can be instructed that “Category C items like consumables don’t need immediate reordering the second they run low; focus on A’s first.” By educating the team, you ensure everyone aligns their efforts with the ABC priorities. This can reduce friction too – for example, if field personnel know an item is Category A, they’ll likely treat it with more care (like returning a costly laser level to its case and secure storage after use, rather than leaving it lying around).

6. Review and Adjust Regularly

ABC classification is not a one-and-done task, especially in construction, where project requirements evolve. Make it a habit to review your ABC categories periodically. On long projects, the consumption of materials may change over time – what was Category A in the early phase (e.g. concrete during foundation work) might not even be used in later phases; meanwhile, finish materials (like flooring or fixtures) might become the big spend in later stages. So you may want to update the classification as a project moves from phase to phase, or when starting a new project. Also, prices can change – if lumber prices spike one year, lumber might move from B to A category in terms of value impact.

Regular review could be quarterly or at major project milestones. Check if any new items have entered your inventory that need classification, and if any items’ usage patterns have shifted enough to warrant a category change. Keep the ABC analysis dynamic and relevant. This ensures you’re always focusing on the true current priorities.

Additionally, analyze how the ABC-based approach is working. Are you achieving fewer stockouts of A items? Is the overall inventory value carrying cost down? If not, dig in and see if categories were chosen correctly or if procedures for each category need tweaking. ABC analysis is a tool – it still requires sound execution to deliver results.

By following these steps, you’ll have implemented ABC analysis for your construction inventory. You’ve essentially created a segmented inventory strategy: intensive care for the critical items, standard care for the mid-range, and minimal care for the trivial many. Next, let’s explore how you can take this a step further by leveraging technology (like CyberStockroom’s platform) to manage these categories and your inventory more efficiently.

Leveraging Technology (CyberStockroom) to Enhance Inventory Management

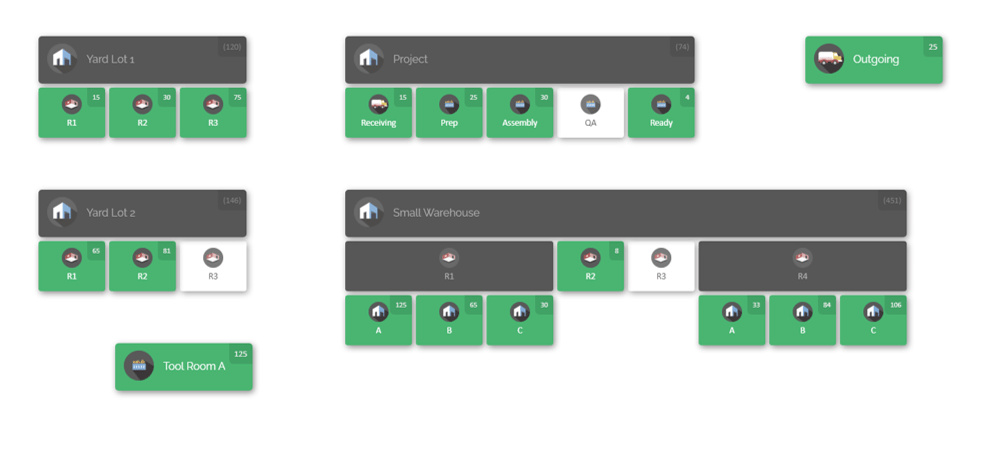

Implementing ABC analysis manually – perhaps using spreadsheets and periodic manual counts – is a great start. But in large or fast-moving construction projects, keeping tabs on all your Category A, B, and C items can become challenging. This is where modern inventory management software comes into play. One such tool is CyberStockroom, a cloud-based inventory management platform with a unique map-based approach. Let’s discuss how CyberStockroom (and similar solutions) can support and streamline your ABC inventory strategy in construction:

Visual Inventory Mapping

CyberStockroom introduces the concept of an inventory map – a visual representation of all your inventory across various locations (warehouses, job sites, storage yards, vehicles, etc.). Instead of viewing inventory as abstract lines in a spreadsheet, you see a bird’s-eye view of your operations. For a construction manager dealing with multiple job sites or storage areas, this is a game-changer. You can instantly see where each item is. For example, suppose steel beams are a Category A item; with a map-based system you could zoom in and see that you have 20 beams at the main yard and 10 on Site A. If Site B needs some urgently, you know exactly where to pull from. This level of inventory visibility ensures your A items are in the right place at the right time. It complements ABC analysis by not only prioritizing what to monitor, but also giving you tools to monitor where everything is in real time.

Real-Time Updates and Accessibility

As a cloud-based platform, CyberStockroom allows all stakeholders – from the office procurement team to the field supervisors – to be on the same page. When a delivery arrives or when materials are issued out to the site, the inventory can be updated immediately in the system. This means your ABC analysis data (like stock levels of A, B, C items) is always current. No more guessing or working off last week’s spreadsheet. And because it’s accessible from any device via a web browser, a project manager can check critical item levels from the site on a tablet or from the home office on a PC. Real-time information reduces the chance of nasty surprises, like discovering too late that you’re out of a critical material. It also means you can respond faster – if an A item’s quantity dips below the threshold, you see it and act at once.

Drag-and-Drop Transfers & Location Management

Construction inventory is always on the move – tools move from the warehouse to trucks to sites, materials get distributed to different crews, leftovers return to storage. CyberStockroom’s interface allows users to simply drag and drop items on the map to reflect transfers between locations. This intuitive feature makes it easy to record movements of inventory. From an ABC perspective, it’s especially useful for keeping an audit trail of where your Category A items are at all times. Say you have an expensive surveying instrument (Category A tool) – you can track that it moved from the main office to Jobsite X, and who is responsible for it. If needed, you can drag it to another location on the map when it’s transferred. Having such a systematized yet simple way to log transfers helps prevent loss and misplacement, particularly for high-value items.

Barcoding and Fast Check-Ins/Outs

CyberStockroom supports barcoding, meaning you can tag your materials and equipment with barcode or QR code labels and use scanners to check items in and out or update counts. On a busy site, this is far quicker and more accurate than pen-and-paper logs. How does this help with ABC? Well, you might choose to barcode at least all your A and B category items. Then, whenever an important item is taken or moved, a quick scan updates the system. For example, when loading a pallet of copper pipes (Category B) onto a truck for delivery to the site, scanning the code can deduct it from warehouse stock and assign it to that site in the system. This ensures that your inventory records remain accurate without burdensome data entry. It’s easier to maintain tight control on A items when the process to record transactions is streamlined and user-friendly.

Custom Fields and Categorization

In CyberStockroom, you can often set up custom fields or tags for items. You could create a field in the system for “ABC Category” and label each item as A, B, or C. This way, you can filter or search your inventory by category. For instance, before doing a cycle count you might filter to show only A items and quickly run through those first. Or if a director asks, “What are our most critical materials on hand right now?” you could filter to Category A and instantly generate a report of those items, their quantities, and locations. The software essentially can serve as a living, dynamic ABC analysis database that’s always up to date. And because it’s visual, you might even color-code or visually mark the map for critical item locations (e.g., flag where all A items are stored).

Loss and Theft Reduction

We touched on how ABC analysis encourages tighter security for expensive items. CyberStockroom facilitates this by keeping a historical log of inventory transactions. Each time something is moved, checked out, or in, there’s a record (and you can often include who performed the transaction). This creates accountability. If a valuable tool goes missing, you can look up when and where it was last recorded and who had it. Over time, this discourages casual theft or mishandling because there’s transparency. For materials, if quantities don’t match up with what was used in construction, it flags a potential issue (did some materials “walk away” or were they wasted?). Having a solid digital paper trail means your Category A items are watched over without needing a manager physically counting them daily.

Multi-Project and Multi-Location Coordination

Construction companies often juggle multiple projects simultaneously, and inventory might be shared or shuffled between them. A map-based system like CyberStockroom offers a consolidated view. You can see all your inventory across projects or warehouses on one screen. This birds-eye view is incredibly useful for decision-making. Let’s say one project’s site has surplus Category A materials that another project site urgently needs – you can identify that quickly and coordinate a transfer. Without such visibility, each project might over-order “just in case.” CyberStockroom helps optimize inventory levels by enabling resource sharing decisions, ultimately saving money and avoiding redundancies. It’s the perfect companion to ABC analysis: you know what’s important, and the software shows you where it is and where it’s needed.

In summary, CyberStockroom supports the ABC approach by providing the tools to execute it flawlessly. ABC analysis tells you what to prioritize; CyberStockroom gives you the means to monitor and manage those priorities in real time. The result is a more proactive, efficient inventory management process. Instead of reactively putting out fires (like surprise stockouts or missing equipment), you’ll have a handle on your critical materials at all times. The combination of a smart strategy (ABC) and a smart system (inventory mapping software) can dramatically improve how you manage construction inventory.

Best Practices and Tips for ABC Analysis in Construction

Before we wrap up, let’s consolidate some best practices for using ABC analysis effectively in construction projects, along with a few extra tips to get the most out of this approach:

- Use Multi-Criteria if Needed: Classic ABC analysis uses annual spend as the sole criterion. In construction, however, criticality isn’t always reflected by cost alone. There may be inexpensive items that could halt work if unavailable (for example, a particular $5 fastener required to assemble a structure, or a specific permit or document if we consider broad “inventory”). If you identify such items, feel free to treat them as higher category than their cost suggests. Some construction managers use a multi-criteria approach – considering factors like lead time and usage criticality in addition to cost. For instance, an item that is cheap but has a very long lead time (special-order component) might be managed as an A item because you can’t quickly replace it if it runs out. Keep an eye out for these exceptions and adjust your ABC classifications accordingly.

- Integrate ABC Analysis with Project Planning: Make ABC inventory review a part of your project planning and scheduling routine. For example, when planning a new phase of work, review Category A items for that phase to ensure procurement is aligned with the schedule. Include inventory status as a line item in project meetings: e.g., “Are all A category materials for the upcoming tasks on site or on track for delivery?” This ensures that inventory considerations are not siloed away from project management – they become a core part of risk management for the project timeline.

- Train Your Team on Inventory Procedures: A system is only as good as its users. If you’ve implemented ABC policies , invest time in training the relevant team members. Everyone from the warehouse manager who receives deliveries to the foreman who requests materials should understand the logic. They don’t need to know the financial details of A vs C, but they should know, for example, that “we count the generator fuel and steel stock every Friday” or “these high-value tools must be signed out/in on the app when taken.” Create simple Standard Operating Procedures (SOPs) around your ABC controls so that it becomes part of daily/weekly routines.

- Avoid Over-Classification Paralysis: While ABC is useful, don’t complicate it further by trying to create too many sub-categories or exceptions. The power of ABC is its simplicity (three categories). Some managers get carried away and want A1, A2, B+, B-, C categories, etc. Be cautious – the goal is to streamline your focus, not create a new bureaucracy. If you find a need for a finer distinction, perhaps the multi-criteria approach mentioned is better (like tagging an item as “critical” separately). But generally stick to the A, B, C buckets for decisions. It will keep communication clear (“this is an A item, treat it as such” is straightforward).

- Leverage Reporting and KPIs: Over time, track some key performance indicators for your inventory. For instance, stockout frequency for A items, inventory turnover rates, carrying cost for each category, etc. If you’re using software like CyberStockroom, you might be able to pull reports on these. These metrics will help you continuously improve. If you still experience stockouts on an A item, that’s a red flag to tighten controls or reassess the usage estimates. If you find you never ever use a certain C item that’s sitting in inventory, maybe it’s not needed at all (could even be offloaded). Use ABC as a framework to clean up inefficiencies. Some companies even set targets like “0 stockouts on A items, reduce inventory value of C items by 20% this year,” and then use ABC analysis to guide actions toward those targets.

- Combine ABC with Other Techniques: ABC analysis can work hand in hand with other inventory management methods. For example, you could apply Just-In-Time (JIT) delivery for certain Category A items to ensure freshness or reduce on-site storage (common for things like concrete or perishable materials), but you’d only do that if you have absolute confidence in supplier reliability for those A items. Or use safety stock calculations for A and B items to determine the optimal buffer to keep. The point is, ABC doesn’t have to exist in isolation – it enhances other practices by providing focus. You might still do regular cycle counting, but focusing cycle counts on A and B items first (as opposed to random counts). You might employ vendor management strategies, focusing effort on negotiating better terms for A item suppliers. Look at ABC as part of a holistic inventory control strategy.

- Document and Iterate: Finally, document the outcomes of your ABC analysis and decisions made. For instance, keep a log or spreadsheet of what items are in each category and why (especially for any that you subjectively bumped up due to criticality). This documentation is useful for transparency and for onboarding new team members (“here’s why we treat the welding rods as A category – they’re inexpensive but without them our steelwork stops, and they have a 2-week lead time”). Revisit this document when doing your periodic review to update it. Over successive projects, you’ll build a knowledge base of material management. Your ABC analyses from past projects can inform new ones (you might find the same materials consistently end up as A – those are your core critical materials across projects).

By following these best practices, you’ll ensure that ABC analysis truly delivers on its promise: lower costs, higher efficiency, and fewer last-minute crises on the job site.

Conclusion: Prioritizing What Matters Most

In the fast-paced world of construction, managing inventory can feel like a high-wire act. There are so many components to juggle, and the stakes are high – one missing delivery or an overlooked order can throw a project off schedule and blow the budget. ABC analysis offers a welcome safety net. By categorizing your construction inventory into A, B, and C groups, you create a clear roadmap of what to safeguard closely and what can be managed with a lighter touch. This focused approach helps ensure that critical materials are always available when needed, while optimizing resources spent on less critical stock.

We explored how to implement ABC analysis step by step, turning raw data into actionable categories and policies. When applied diligently, this method leads to tangible benefits: fewer costly delays, less capital tied up in unused inventory, and a more organized, responsive supply chain at your job sites. The example of categorizing materials like steel, lumber, and nails shows just how differently we should treat high-impact items versus everyday supplies.

Moreover, we discussed amplifying the power of ABC analysis with modern tools like CyberStockroom’s map-based inventory software. Embracing technology can take your inventory management from reactive to proactive. With real-time visibility and easy tracking, you can practically watch over your Category A items like a hawk, without breaking a sweat. The synergy of a solid strategy (ABC) and a supportive system (inventory management software) means you’re not only prioritizing what matters, but also actively monitoring and controlling those priorities in the field.

Ultimately, effective construction inventory management comes down to prioritization and planning. ABC analysis is all about prioritization – it shines a spotlight on the materials that truly drive your project’s success. When your team internalizes this and your processes are built around it, inventory management stops being a scramble and becomes a strategic asset. You’ll find your projects run smoother: crews have what they need, when they need it; procurement is spending smartly; and there’s less “fire-fighting” over missing parts or gluts of excess materials.

As you apply ABC analysis in your construction operations, remember that continuous improvement is part of the journey. Learn from each project and refine your categories and methods. Over time, you’ll develop an almost instinctive understanding of your critical materials and the best ways to manage them.

In conclusion, prioritizing critical materials using ABC analysis can transform your construction inventory management from a headache into a well-choreographed component of project success. By always focusing on the “vital few” and not getting bogged down by the “trivial many,” you keep your projects on track and your resources optimally utilized. So whether you’re a project manager ensuring the next build goes off without a hitch, a site supervisor wanting more control over site supplies, or a procurement officer aiming to stretch the budget, ABC analysis is a powerful ally. Combine it with the right tools and teamwork, and you’ll build a foundation for inventory excellence that supports every project you undertake.Empower your team to focus on what matters most, and watch as better inventory control leads to smoother projects, stronger bottom lines, and clients that come back with confidence for your well-managed execution. Happy building, and happy inventory organizing!

Leave a comment