Managing construction consumables inventory may not always be the first thing on a contractor’s mind, but it plays a critical role in keeping projects on track. Think about it – a multi-million dollar construction project could be halted by something as small as a missing box of nails or an out-of-stock adhesive. These little parts have a big impact on timelines, budgets, and productivity.

What Are Construction Consumables?

In the context of construction, consumables are the supplies and materials that get used up during the course of a project. They are typically inexpensive individual items that you don’t expect to retrieve once issued – they get consumed in use. These include everyday construction supplies such as nails, screws, nuts, bolts, washers, drill bits, welding rods, caulking, adhesives, tapes, sandpaper, sealants, and solvents. Even personal protective equipment (PPE) like gloves, dust masks, and earplugs can be considered consumables because they often need frequent replacement.

Consumables differ from durable tools or equipment in that they have a short lifespan – they might last for only one or a few uses before needing replenishment. For example, a diamond saw blade may be used on a few jobs but will wear out relatively quickly and require replacement. Or a canister of industrial adhesive might be emptied in a single large task. Because of this, consumables are purchased in bulk quantities and stored as inventory to be drawn upon continuously as work progresses.It’s easy to overlook consumables in favor of big-ticket items like power tools or heavy machinery when thinking about inventory. However, consumables are essential for daily operations on a job site. A project literally cannot move forward if workers don’t have the right fasteners, cutting blades, or safety supplies on hand. They are the nuts and bolts (often literally) of the construction process.

Managing these items requires careful attention, even though each item individually might seem minor. In fact, tracking consumables is a key part of overall construction inventory management – alongside managing major building materials and equipment – because it ensures the team always has the required small parts to do their jobs.

Little Parts, Big Impact: Why Managing Consumables Matters

Small items can cause big problems (or big wins) depending on how well they’re managed. Why are consumables so critical to control on construction sites? There are several compelling reasons:

- Preventing Cost Overruns: Individually, consumable parts are low-cost, but their usage adds up quickly. For example, a contractor might invest $500 in a power drill, but over its life they could spend several times that amount on drill bits and anchors for various projects. Without tracking, these ongoing expenses can silently erode profit margins. By managing consumable inventory and usage, companies can bulk purchase more efficiently, avoid overpriced last-minute buys, and understand the true cost of projects. Effective management reduces waste and ensures money isn’t leaking out through unchecked consumption of supplies.

- Avoiding Delays and Downtime: One of the biggest impacts of running out of a consumable is the risk of work stoppages. Imagine a scenario where a crew is ready to install drywall but the specific screws required have run out on site. Work might have to pause while someone rushes to procure more – causing idle crew time and potentially pushing back project timelines. In construction, delays are expensive; labor is left waiting and project milestones slip. By keeping a well-monitored stock of consumables and replenishing them proactively, site managers can prevent these “small” shortages from snowballing into major schedule impacts. Little parts can thus have a huge effect on keeping the project timeline intact.

- Improving Productivity: Even short of an outright stockout, poor consumable management can hurt productivity. Crews might spend extra time searching for scattered materials or improvising if the right item isn’t at hand. For instance, using the wrong size fastener because the correct one is missing can compromise work quality or require rework later. Organized consumables management means everything is where it should be and available when needed. Workers can grab what they need quickly and keep moving. This streamlines workflow and maintains momentum on site.

- Enhanced Safety and Compliance: Many consumables relate to safety (like PPE or materials needed to secure sites). If these aren’t available, workers might take risks or jobs might proceed unsafely. Ensuring critical safety consumables (like gloves, goggles, first aid supplies, etc.) are always stocked and replaced prevents dangerous situations and helps meet safety regulations. In addition, having the proper materials (e.g. the right kind of anchors or supports) prevents corners from being cut. Good inventory practices for consumables thus also support a safer, more compliant job site.

- Accountability and Transparency: When consumables are not tracked, it can lead to finger-pointing or uncertainty about where supplies went. Did someone take a box of screws for personal use? Was a batch of copper wiring misplaced or stolen? It’s hard to tell if there’s no record. By managing consumables with an inventory system, every item’s usage can be traced to a project, location, or team member. This creates a culture of accountability – workers know that materials are being monitored, which can deter casual theft or misuse. It also provides transparency when investigating cost overruns or losses; managers can see, for example, that a particular project used an unusually high number of a certain item and then dig into why.

In short, consumables management directly affects the bottom line and the success of construction projects. Contractors who take the time to manage these little parts will avoid unnecessary headaches and expenses. They’ll keep their crews productive and their projects on schedule, rather than stalled while waiting for another delivery of something as simple as nails or welding rods. Now that we’ve established why it’s so important to manage construction consumables inventory, let’s look at some of the challenges involved and how to overcome them.

Challenges in Tracking Construction Consumables

If managing consumables were easy, more companies would have already perfected it. The reality is that tracking hundreds of small, fast-moving items across one or multiple job sites can get complicated. Here are some common challenges that construction teams face with consumables inventory:

- High Volume of Items: Unlike major equipment (which might be tracked individually), consumables often consist of many different SKUs and quantities. A single project might require dozens of types of screws, nails in various lengths, different adhesives and tapes for different tasks, etc. Keeping an accurate count of everything – often numbering in the thousands of units – is a daunting task, especially if done manually. It’s easy for counts to be off when items are constantly taken out of stock throughout the day.

- Frequent Usage and Replenishment: Consumables are used continuously, which means stock levels can change rapidly. Materials might be drawn from the inventory multiple times a day by different crew members. Traditional methods like weekly stock checks might be too slow to catch shortages in time. The fast turnover rate demands a more continual tracking approach, otherwise you risk discovering too late that you’re out of something essential.

- Distributed Storage Locations: On a construction project, consumables might be stored in various places – a main warehouse or storage trailer, individual gang boxes on different floors, tool cribs, or even in workers’ trucks. For companies running multiple projects, each job site has its own mini-inventory of consumables. This distributed nature makes it hard to maintain visibility. One site could be overstocked on a supply that another site urgently needs, but without good communication or a centralized view, that insight is lost. Managing consumables effectively means coordinating across locations and consolidating information.

- Lack of Dedicated Inventory Personnel: Large warehouses have inventory managers or storekeepers, but on a job site, often the task of tracking materials falls to the site manager or foreman as a secondary responsibility. Busy with overseeing construction work, they may not have the bandwidth to meticulously update counts or watch over consumables all day. As a result, inventory control can become an afterthought and discrepancies go unnoticed until they cause a problem.

- Informal Checkout/Usage: Many small materials get taken as needed without a formal requisition process. A carpenter might grab a handful of screws or a tube of caulk and not log it anywhere, especially if the culture doesn’t enforce that. These “invisible” usages accumulate, and the inventory records (if any) become inaccurate. Without a simple system to check items in and out, tracking relies purely on trust and memory, which is prone to error.

- Shrinkage and Waste: Consumables are easy to misplace, damage, or even pilfer because they’re small and not serialized. A box of expensive copper wire connectors might “walk off” from the site, or packs of epoxy might spoil because they were left in the rain or beyond their shelf life. Small losses like these often go unreported. Over time, this shrinkage can be significant in value. It’s also common to see excess materials left over from a job (surplus inventory) that may end up forgotten in a storage room, effectively wasted if not reused. Managing consumables well means keeping an eye on these potential loss points – ensuring items are stored securely and used in a first-in, first-out manner so older stock is used before it expires.

Given these challenges, it becomes clear that a haphazard approach to consumable inventory won’t cut it. Construction businesses need a structured strategy and the right tools to tackle the complexity. Let’s delve into best practices for overcoming these obstacles and maintaining control over your consumable inventory.

Best Practices for Managing Construction Consumables Inventory

To successfully manage construction consumables, you should combine good planning, organized processes, and the help of technology. Here are some best practices that general contractors, site managers, and procurement officers can implement to stay on top of those little parts:

1. Plan Ahead for Consumable Needs

Anticipating demand is the first step to avoiding shortages. Before a project starts (and continuously as it progresses), review the plans and scope to forecast which consumables will be needed and in what quantities.

Look at the bill of materials and phases of work – for example, a flooring installation phase will require plenty of adhesives and leveling compound, while a concrete pour will need form ties and curing blankets. Use data from past projects and input from field supervisors to estimate usage rates. If on a previous similar job you went through 20 boxes of masonry anchors, that’s a cue for how many to have on hand this time (perhaps a bit extra as a buffer).

Planning ahead also means engaging procurement early. Secure your orders for consumables with suppliers in advance, especially for any specialty items or those that have longer lead times. This helps you avoid last-minute scrambling or paying premium prices due to rush orders. Another aspect of planning is setting aside contingency stock: identify which consumables are absolutely critical (those that could halt work if unavailable) and maintain a safety reserve of those. For instance, even if you normally use 100 drill bits in a month, having an extra cushion on site (say 120 or 150) can save the day if usage spikes or deliveries are delayed. Essentially, proactive planning ensures that consumables supply aligns with the project schedule and reduces the reliance on “firefighting” to get materials at the 11th hour.

2. Keep an Organized Inventory Catalog

It’s important to know exactly what you have in stock. Create a detailed inventory list or catalog of all consumables your company uses. This list should include every type of item, along with relevant details that help in managing them. Key information to record for each consumable might include: item name and description, category (e.g. fasteners, electrical parts, PPE), the unit of measure (e.g. pounds, pieces, boxes), current quantity on hand, minimum quantity to keep on hand (reorder threshold), supplier or brand, cost per unit, and where it’s stored. Assigning unique identifiers or SKUs to each item is highly recommended – it standardizes how everyone refers to that item and avoids confusion (so that one person’s “lag bolt 3/8″” isn’t someone else’s “bolt L”, for instance).

Having a centralized, up-to-date record of this information is invaluable. It allows anyone looking for a part to quickly determine if it’s available or needs reordering. Moreover, maintaining an organized catalog helps in analysis later – you can review which consumables are used the most, which rarely move, or how consumption patterns change seasonally or by project type. To keep the catalog accurate, designate responsibility for updating it. For example, a warehouse manager or site coordinator can update the spreadsheet or system whenever new stock is received or issued. In modern practice, many firms migrate this catalog to an inventory management software, which can simplify updates and make the data easily accessible to the whole team (more on that shortly). The bottom line: know your consumables by name, quantity, and location – you can’t manage what you don’t measure.

3. Optimize Storage and Labeling On Site

How you store consumables on the job site or in the warehouse has a big influence on how easily they can be tracked and accessed. A best practice is to set up a dedicated, well-organized storage area for consumables, whether it’s a section of the site warehouse, a supply room, or a mobile storage container brought to the site. Within that space, group similar items together and clearly label everything. For example, have bins or shelves for different categories: all types of nails in one section, electrical connectors in another, adhesives and sealants on a specific shelf, safety gear in its own area, and so on. Use labels or color coding so that anyone can find items and return them to the correct spot. This might seem like simple housekeeping, but it greatly reduces the chance of misplacing stock or overlooking an item until it’s all gone.

Storage optimization also means considering protection and accessibility. Ensure that materials are stored in conditions that won’t degrade them – keep boxes of screws dry to prevent rust, store glues or paints at appropriate temperatures, and secure any high-value consumables in a locked cabinet if theft is a concern. Position fast-moving consumables in easily reachable areas to speed up retrieval, while slower-moving or bulk reserve stock can be in upper or rear shelves. A neat trick is to implement a two-bin system for critical items: each item has two containers, and when one is emptied (used up), it triggers a reorder while the second bin supplies the ongoing work. This way you always have a backup supply and a clear signal to replenish.

Finally, assign someone to maintain the orderliness of the consumables storage, at least periodically. It could be part of a site manager’s weekly routine to straighten up the inventory area, or a specific crew member responsible for checking that things are in their place. An orderly storage system not only makes counting easier during audits (since items aren’t all over the place), but it also psychologically encourages workers to respect the inventory and return things to where they belong. In summary, a well-organized “construction stockroom” on site keeps chaos at bay – anyone can find what they need quickly, and you can visually notice when supplies are running low.

4. Establish Standard Procedures and Accountability

Standardizing how your team handles consumables is crucial. If everyone follows a different process (or no process at all) for using and reporting inventory, you’ll inevitably have confusion and errors.

Develop a simple Standard Operating Procedure (SOP) for consumable inventory management and make sure all employees are aware of it.

This SOP might outline steps like: how to request or sign out consumables from storage, how to log when items are taken), who to notify if stock is low, and how often inventory counts will be done. Keep the process as straightforward as possible – if it’s too burdensome, people will bypass it. For example, you might implement a rule that at the end of each day, crew leads report any consumable that they used the last of, so it can be reordered. Or if using an app or software, require that scanning an item’s barcode is part of the checkout when taking new supplies.

Training the team on these procedures is just as important as writing them down. Take time to explain to field workers why tracking these materials matters (refer back to the “little parts, big impact” points to give them context). When employees understand that keeping inventory updated prevents delays and helps the project, they’re more likely to comply. Provide hands-on training for any tools they need to use – for instance, if there’s an inventory spreadsheet or a mobile device for scanning, show them how to use it. Designate specific people who are accountable for inventory accuracy at each site. This could be the site foreman or a storekeeper; essentially someone who takes ownership of making sure the SOP is followed. That person can do spot checks, remind others to log usage, and act as the point person to communicate with the procurement office for reorders.

Accountability can also be reinforced by tracking usage per project or per person. When feasible, assign consumables to a project code or to an individual when dispensed. This doesn’t mean micromanaging every nail, but for bulk issues you could note “issued 1000 nails to Crew A for Building 2 framing on Project X.” If later the project’s consumable costs seem high, you have data to investigate which phase or team used more than expected. This level of tracking creates responsibility – crews are less likely to waste materials if they know the usage is being logged and reviewed. Celebrate or positively reinforce teams that manage their consumables well (for instance, “Crew B stayed within their consumables budget this quarter due to careful usage – great job!”). In summary, make consumable management a routine part of everyone’s job on the site through clear procedures, training, and a culture of accountability.

5. Leverage a Visual Inventory Management System

One of the smartest moves you can make is to utilize modern inventory management software to track your construction consumables. While spreadsheets and paper logs can work, they often struggle to keep up with the dynamic nature of construction inventory. This is where a tool like CyberStockroom comes into play.

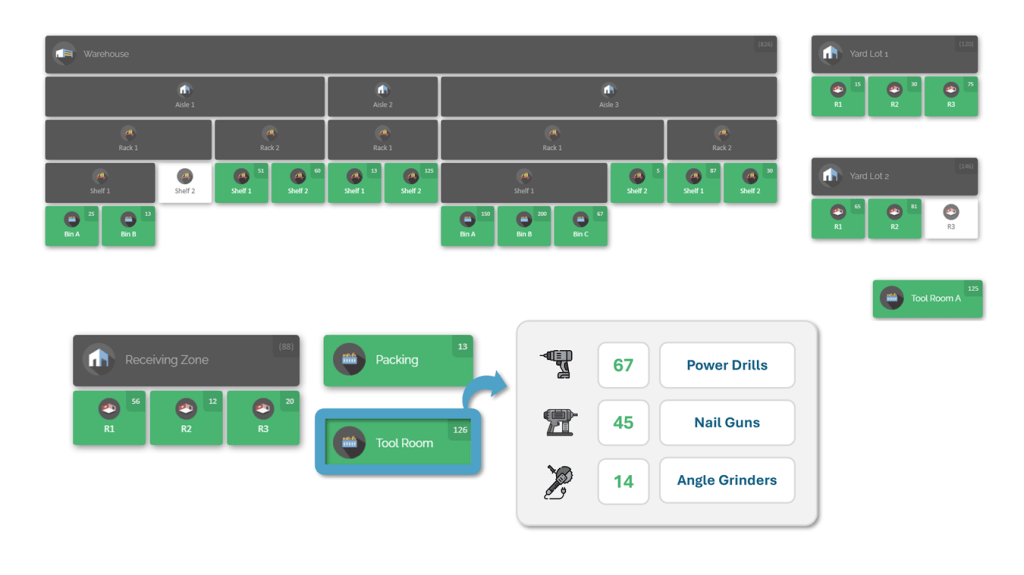

CyberStockroom is an inventory management system designed with a visual mapping interface – it allows you to create a digital map of your inventory across all locations (warehouses, job sites, storage trailers, even individual trucks or tool cribs). Instead of poring over lists, you get a bird’s-eye view of where everything is. For example, on your CyberStockroom inventory map, you could see that Site A’s trailer has 15 boxes of masonry nails, Site B has 8 boxes, and the central warehouse has 50 boxes, all at a glance.

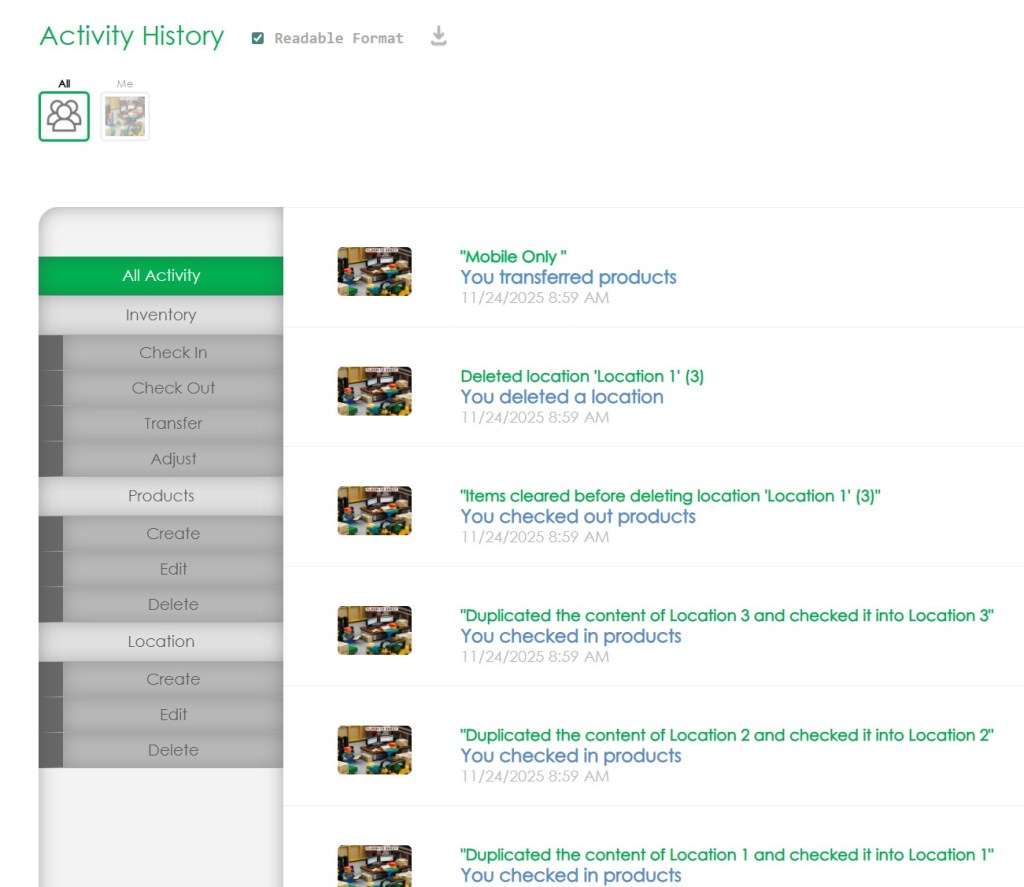

How does this help manage consumables? First, it provides real-time visibility. Every time an item is used or moved, it can be logged in the system (via a quick update or barcode scan), and the inventory counts update immediately on the map. This means you’re never in the dark about stock levels – if a crew at the remote site takes the last spool of copper wire, you’ll see that reflected and can act instantly to replenish. No more guesswork or driving out to a site just to check what’s left in the storage bin. CyberStockroom also makes multi-site coordination far easier. If one job site is running low on a consumable, you can check the map and quickly identify if another site or your main shop has surplus that can be transferred. The software supports drag-and-drop transfers on the map, so you can virtually “move” inventory from one location to another, and everyone sees that update. This level of coordination helps prevent over-ordering and emergency runs – you use what you have efficiently by redistributing items to where they’re needed most.

Another benefit of an inventory system like CyberStockroom is improved accountability and tracking. The system can keep an audit trail of each transaction: who moved or used an item, from which location, and when. For instance, if a batch of expensive epoxy is taken out from the warehouse and sent to Site C, the map and logs will show that transaction. If later there’s a question about where those materials went, you have a clear record. This logging feature deters internal shrinkage as well – crew members know that the inventory isn’t a free-for-all; it’s actively monitored. CyberStockroom’s map interface is very intuitive, which means field teams and warehouse staff can learn it quickly without frustration. The visual aspect (seeing icons or images for each location and item) makes it almost like managing a virtual job site, which resonates well with teams who may not be fond of scrolling through spreadsheets.

Moreover, CyberStockroom supports barcoding, so you can tag your consumable item boxes or bins with barcodes/QR codes. With a simple scan (using a scanner or even a device’s camera), items can be checked in or out, and the system updates the count. This reduces manual data entry and errors. Being a cloud-based system, CyberStockroom allows you to access the inventory info from anywhere – whether you’re at the head office, in the field with a tablet, or on your phone at home planning the next day. The real-time synchronization means everyone – project managers, site supervisors, procurement – stays on the same page about stock status.

In essence, using a dedicated inventory management tool like CyberStockroom brings a level of organization and insight that manual methods can’t match. It directly addresses many of the earlier challenges: it handles high volumes of items easily, tracks frequent usage in real time, consolidates multi-site data in one dashboard, and keeps a log for accountability. By leveraging such technology, construction companies can save significant time (no more constant physical checks), reduce waste (since they know exactly when to reorder and can avoid overstocking), and avoid those dreaded work stoppages due to missing parts. While CyberStockroom is one great option – especially with its unique visual map approach – the broader point is that investing in an inventory management system is a best practice that pays off. The upfront effort to set up your inventory in the system will be rewarded with ongoing clarity and control over your consumables. Little parts no longer fall through the cracks when you have big technology watching them!

6. Monitor Usage Rates and Set Reorder Points

An effective consumables management strategy isn’t just about knowing current stock levels – it’s also about knowing when to replenish and ensuring you never run completely out. This is where the concept of reorder points and ongoing monitoring comes in. For each type of consumable, determine a minimum quantity (threshold). The ideal reorder point will depend on the item’s usage rate and the lead time to get a new supply. For example, if you use about 200 dust masks a week on average and it takes your supplier one week to deliver more, you might set a reorder point at, say, 300 masks. That way, when inventory falls to 300, you place an order, and the new stock arrives before you dip below a week’s supply. This prevents a stockout scenario.

Regularly monitor how fast consumables are being used so you can adjust these thresholds if needed. If a project ramps up and you start going through materials faster than before, you’ll want to increase your par levels accordingly. Modern inventory systems often have features like low-stock alerts. If you’re managing manually, you might keep a log sheet updated daily or weekly and review it to see trends. The key is not to wait until the last box is opened to think about reordering; by then you’re on the brink of a shortage.

Another best practice related to monitoring is to implement a perpetual inventory system for consumables. This means continuously updating the inventory records as items are used or received, rather than doing it only periodically. A perpetual system (enabled by software or diligent manual logging) allows you to always have an accurate view of stock on hand. It goes hand-in-hand with setting reorder points because the data you’re relying on is current. If using software, much of this monitoring can be automated. If you’re relying on manual methods, it might involve one person doing a quick daily count of key fast-moving consumables to ensure the tally is up to date.

Additionally, consider factors like safety stock for critical consumables. Safety stock is an extra quantity kept to mitigate uncertainties in demand or supply. For example, you might normally reorder electrical tape at 10 rolls left, but you also keep an additional 5 rolls as safety stock in case a delivery is delayed or you unexpectedly need more for an urgent task. This way, even if your usage spikes or a shipment is late, that safety buffer prevents a zero-stock situation.

In summary, by actively monitoring consumption and establishing clear reorder points for each item, you can shift from reactive to proactive inventory management. This practice ensures that you always have the right amount of consumables: enough to avoid halts in work, but not so much that excess stock piles up unused. It’s a balance that saves both time and money.

7. Coordinate Inventory Across Multiple Sites

For construction firms operating on multiple projects or sites at once, central coordination of consumable inventory is crucial. Without it, each site tends to function like an island – one site might run short on a supply while another has plenty sitting in a conex box. A best practice is to treat all your consumables as part of a company-wide inventory pool (even if physically spread out), rather than isolated silos. This means keeping a centralized record (or system) that shows the stock levels at each location in one view.

Regular communication between sites and a central inventory manager is key. If Site X reports they have more epoxy or rebar caps than they will need this month, and Site Y is running low, arrange an internal transfer before buying new stock for Y. Shuffling consumables between job sites can be far faster and cheaper than always ordering fresh supplies, and it prevents waste of surplus materials at project end.

Having a central warehouse or storage yard that feeds the sites can simplify coordination.

For example, you might stock most consumables at headquarters and have a routine where each site puts in a “pull request” weekly to top up what they used. This way, purchasing is centralized (getting bulk discounts and consistency in quality) and sites get what they need regularly. However, even with decentralized site purchasing, coordination helps avoid pitfalls like two different sites unknowingly ordering the same item that could have been shared.

Modern inventory tools once again make this easier – as mentioned, a system like CyberStockroom visually integrates all locations. But even with spreadsheets, you can set up a shared doc that lists inventory by site, updated daily or weekly by someone at each site. Project managers can then review that and identify opportunities to balance stock. Another aspect of multi-site coordination is standardization: try to use the same brands and types of consumables across projects when possible. This makes sharing feasible. If one crew insists on a specific type of anchor that no other site uses, then those become less transferable. Standardizing on common consumable products (where it doesn’t negatively impact quality or spec) means any item is interchangeable among sites. It also simplifies buying and tracking.

Lastly, when a project wraps up, have a process to recover and reallocate leftover consumables. Many times, at the end of a job, there will be unused materials like half a box of brackets or extra conduit hangers. Instead of tossing or forgetting them on a shelf, those should be collected and returned to central inventory so they can be used on the next job. A coordinated system will account for these returns and ensure they’re visible for future use. In essence, treating the company’s various sites as one connected network of inventory ensures that the right items are in the right place at the right time, without unnecessary purchasing or waste. It’s all about visibility and communication across the organization.

8. Conduct Regular Inventory Audits and Improvements

No matter how good your day-to-day tracking system is, it’s important to verify that the reality matches the records. Regular inventory audits – where you physically count the consumables on hand and compare to the logged quantities – will catch any discrepancies and help you adjust processes accordingly. For high-turnover or critical consumables, you might do mini-audits (cycle counts) weekly or bi-weekly. For everything else, a monthly or quarterly audit might suffice, with a full inventory count at least annually. During an audit, note any significant differences. Are boxes of certain screws consistently missing? Is there always more of something on the shelf than on the books (indicating perhaps it wasn’t logged when delivered)? This is how you identify shrinkage, loss, or data entry errors. Maybe you’ll discover that a particular site has an issue with things getting lost, prompting more training or security there.

Beyond just counts, use audits as an opportunity to assess inventory health: check expiration dates on chemicals or adhesives (and dispose of any that are expired), inspect the condition of stored items (are they rusting or damaged due to poor storage?), and ensure everything is still organized properly. If you find, for example, several boxes of fasteners that were hidden in a corner and never used (while you kept ordering more because you thought you were out), that’s a lesson to improve organization and visibility. After each audit, update your records to reset the baseline and investigate the root causes of any variances. It might turn out you need a tighter checkout process for certain items or better labeling.

Auditing isn’t only about finding problems – it’s also about continuous improvement. Use the insights to refine your inventory management practices. Perhaps you realize you can reduce the par level of an item because audits show you always have far more on hand than used. Or you might find you need to increase order frequency for another item that’s always nearly empty by audit time. Also, gather feedback from the field during these checks: ask the crew if they’ve had issues getting any consumables or if there were times they ran out but didn’t report it. Sometimes the people using the materials have good suggestions to improve the system (“it would help if we had a sign-out sheet right at the storage cabinet” or “we should keep a small kit of common screws on each floor instead of only in the main container”).

In summary, regular audits are your safety net to ensure your consumables management is truly working. They correct the record, keep everyone honest, and provide valuable data to tweak and optimize your process. By periodically stepping back and reviewing the inventory, you can maintain accuracy and adapt to changing project needs or identify issues before they become costly. Combined with the other best practices, audits help close the loop in an effective inventory control cycle: Plan – Execute – Monitor – Adjust. This continuous loop will keep your construction consumables running like a well-oiled machine.

Leave a comment