Inventory management is entering a new era in 2026. Rapid technological advancements and shifting business needs are transforming how companies track and control stock. Gone are the days of relying solely on clunky spreadsheets and manual counts. Today’s inventory leaders are adopting smarter tools and strategies to stay efficient and competitive. This kind of bird’s-eye view of inventory is just one example of innovation in action.

This year, businesses must keep pace with emerging trends – from intelligent software to eco-friendly practices – that are reshaping inventory management. Below we explore the top five inventory management trends to watch in 2026. By understanding these trends, operations and inventory professionals can future-proof their processes, reduce costs, and satisfy ever-higher customer expectations.

1. AI-Powered Inventory Optimization and Forecasting

Artificial intelligence (AI) and machine learning are revolutionizing inventory management. In 2026, AI is moving from a buzzword to a daily operational tool. Companies are using AI-driven software to analyze vast amounts of data and make smarter decisions about stock levels, ordering, and distribution. Rather than relying on guesswork or simplistic spreadsheets, managers can leverage AI to accurately forecast demand, optimize stock, and even automate routine tasks.

Predictive demand forecasting is one of the most impactful applications. AI algorithms can study years of sales data, seasonality, market trends, and even external factors like weather or economic indicators to predict future product demand with remarkable accuracy. For example, an AI system might detect that demand for a certain product spikes every October, or that an upcoming marketing campaign will boost sales next month. Armed with these insights, businesses can adjust purchasing and production plans proactively. In fact, studies have shown that using AI-based demand forecasting can reduce inventory holding costs by double-digit percentages (as much as 10–20% in some cases) while simultaneously reducing stockouts. Better forecasts mean companies carry just the right amount of inventory – not so little that they miss sales, and not so much that capital is tied up in excess stock.

AI doesn’t stop at forecasting. Machine learning tools are improving real-time inventory optimization. They can automatically set or adjust reorder points and ideal stock levels for each item by learning from patterns. If sales accelerate or slow down, AI systems tweak inventory targets on the fly. This kind of continuous optimization was very difficult with legacy systems, but is becoming standard practice with modern AI-enabled inventory management software. Retail giants like Amazon have pioneered such techniques – their AI systems anticipate what customers will buy and ensure fulfillment centers are stocked accordingly, often pre-positioning items closer to areas of high demand before orders even come in.

Another growing use of AI in inventory management is anomaly detection and quality control. Intelligent vision systems and machine learning algorithms can inspect products moving through a warehouse, flagging defects or damages automatically. For instance, cameras equipped with AI might scan items for dents or packaging issues as they’re received, so that problems are caught early. AI can also monitor inventory data for irregularities – such as sudden unexplained stock drops that might indicate theft or errors – and alert managers instantly. This proactive monitoring helps reduce shrinkage and errors, keeping inventory records accurate.

Key benefits of AI in inventory management include:

- Sharper Forecasting: AI analyzes complex historical and real-time data to predict demand more precisely than humans, leading to smarter purchasing and production decisions.

- Automated Replenishment: Intelligent systems dynamically adjust reorder points and trigger purchase orders when inventory runs low, preventing stockouts without manual oversight.

- Optimized Stock Levels: By learning from sales patterns and lead times, AI helps maintain optimal stock – reducing overstock (and its carrying costs) while avoiding shortages.

- Real-Time Alerts: AI-driven monitoring flags anomalies (like sudden spikes in sales or inventory discrepancies) so managers can respond quickly to potential issues.

- Informed Decision-Making: Advanced analytics provide insights (e.g. which products are slow-moving, which locations need more stock) that guide strategic decisions on promotions, transfers, or discontinuing items.

Importantly, AI is becoming more accessible to businesses of all sizes. Many cloud-based inventory management systems now offer built-in AI features or integrations, so you don’t need a huge IT team to benefit. And the adoption is accelerating – industry surveys indicate that a large majority of companies plan to implement AI-powered inventory tools by 2026 if they haven’t already. As this technology matures, it’s evolving from a “nice-to-have” into a critical layer of inventory operations, working behind the scenes to cut through data noise and highlight what matters. In short, AI allows inventory professionals to be proactive instead of reactive. By anticipating trends and optimizing in real time, businesses can reduce waste, improve service levels (having the right product available at the right time), and ultimately boost their bottom line.

2. Warehouse Automation and Robotics

The warehouse of 2026 is smarter and more automated than ever. Automation and robotics technologies are stepping in to tackle labor-intensive tasks, speeding up processes and improving accuracy. Faced with ongoing labor shortages and pressure for faster fulfillment, companies are heavily investing in robots and automated systems to handle inventory movement, picking, and even packing. This trend isn’t about replacing humans entirely – it’s about robots and people working side by side, each doing what they do best, to achieve greater efficiency.

One prominent example is the rise of Autonomous Mobile Robots (AMRs) and Automated Guided Vehicles (AGVs) in warehouses. These robotic helpers can transport goods within facilities without direct human control. AGVs have been used for years, following fixed paths (like magnetic tracks on the floor) to move pallets and products. Newer AMRs take it a step further: they navigate dynamic environments using on-board sensors and maps, meaning they can adjust their route on the fly and work safely around human workers. For instance, an AMR might zip across a warehouse carrying a tote of picked items, smartly rerouting to avoid a congested aisle. By deploying fleets of AMRs, warehouses can dramatically cut the time workers spend walking back and forth. The robots handle the heavy hauling and shuttling, freeing human staff to focus on more complex duties like quality checking or exception handling.

Robotic picking systems are also becoming more common. Robotic arms equipped with advanced grippers and vision systems can identify products and pick individual items off shelves or bins. In automated fulfillment centers, you’ll find robots that can pick a variety of objects – from grabbing a single box of cereal off a shelf to plucking a specific electronic component from a bin – and place them into orders. These robots have improved a lot in recent years thanks to AI-driven image recognition and more dexterous end effectors (grippers). While humans are still often faster at handling very diverse or unstructured tasks, robots shine in repetitive picking of standardized items, working tirelessly 24/7 without losing accuracy. Some warehouses use a hybrid approach: human pickers in conjunction with cobots (collaborative robots) that assist by bringing shelves to workers (as seen in Amazon’s famous robotic system) or by handling parts of the picking process.

All kinds of material handling equipment are being automated. Conveyor systems and sorters now often come with smart sensors and AI to direct parcels efficiently. There are even autonomous forklifts in some modern warehouses that can load, unload, and stack pallets using lasers and cameras to navigate. Robotics-as-a-Service (RaaS) is a notable sub-trend making automation more accessible: instead of purchasing robots outright, companies subscribe to robotic solutions, paying a monthly fee while the provider handles maintenance and updates. This lowers the barrier to entry for mid-sized businesses to try robotics without huge capital expenditure.

Advantages of warehouse automation and robotics include:

- Faster Throughput: Robots move and pick items continuously and quickly, speeding up order fulfillment and reducing lead times to customers.

- Higher Accuracy: Automation minimizes human errors in picking and inventory counts – robots won’t grab the wrong item or skip a shelf by accident when programmed correctly.

- Labor Support: Automation alleviates the strain of repetitive, strenuous tasks on human workers. This helps address labor shortages and allows existing staff to focus on supervisory or value-added tasks.

- 24/7 Operations: Unlike humans, robots don’t need breaks or sleep. Automated systems can run overnight or during weekends, increasing productivity and making use of off-hours.

- Safety Improvements: Repetitive lifting or forklift work can be hazardous – robots can take on dangerous tasks (like handling heavy pallets or climbing high racks), reducing workplace injuries.

It’s telling that robotics is considered a “safe bet” for the future of supply chain operations. In industry surveys, a vast majority of supply chain executives plan to either start or expand use of robotics by 2026. Trust in robotics has remained high, even compared to trendier topics like blockchain or other hype technologies. This is because many of these automation tools have proven ROI – for example, automating a picking process might clearly reduce labor costs by X% and increase throughput by Y%, making the investment easy to justify. We’re likely to see even more sophisticated integration of AI with robotics too, such as robots that use AI vision to adapt to different products, or AI-driven software that orchestrates multiple types of robots in a warehouse seamlessly.

In summary, warehouse automation and robotics are no longer experimental pilots; they are becoming standard practice. For inventory management, this means faster cycle times, more accurate counts, and an overall more resilient operation that can run around the clock. Operations leaders in 2026 should be evaluating which tasks in their warehouses can be automated or supported by robots – whether it’s moving materials, counting inventory, or picking orders – to stay ahead of the efficiency curve.

3. Enhanced Inventory Visibility with Mapping and Visualization

Knowing exactly what you have and where it is across your business is crucial. In 2026, companies are seeking greater inventory visibility through innovative mapping and visualization tools. Traditional inventory systems often present data in tables, spreadsheets, or basic lists. While functional, those formats can be hard to mentally translate into real-world understanding – especially if you manage inventory across multiple locations or in a large, complex warehouse. This is why a major trend is the adoption of visual inventory management, where software provides a bird’s-eye view of inventory in an intuitive, graphical way.

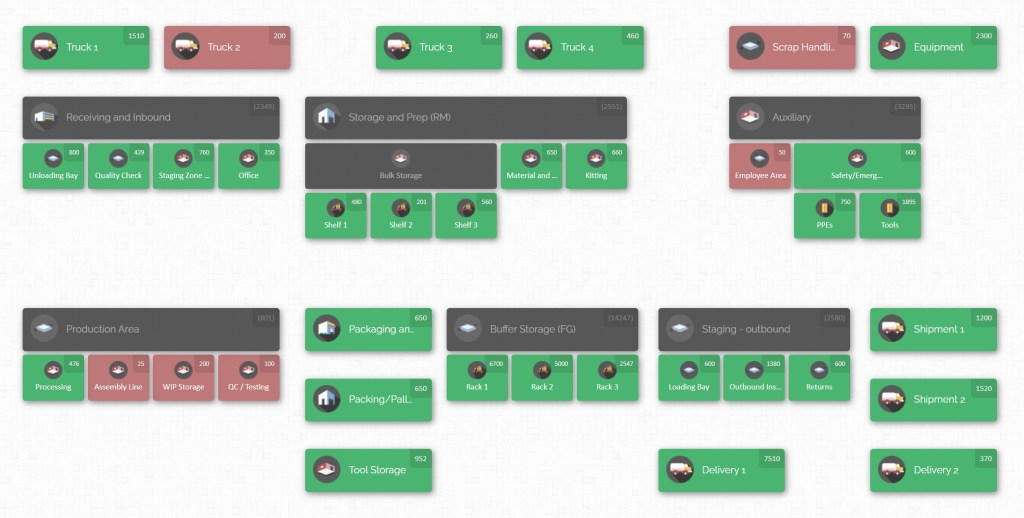

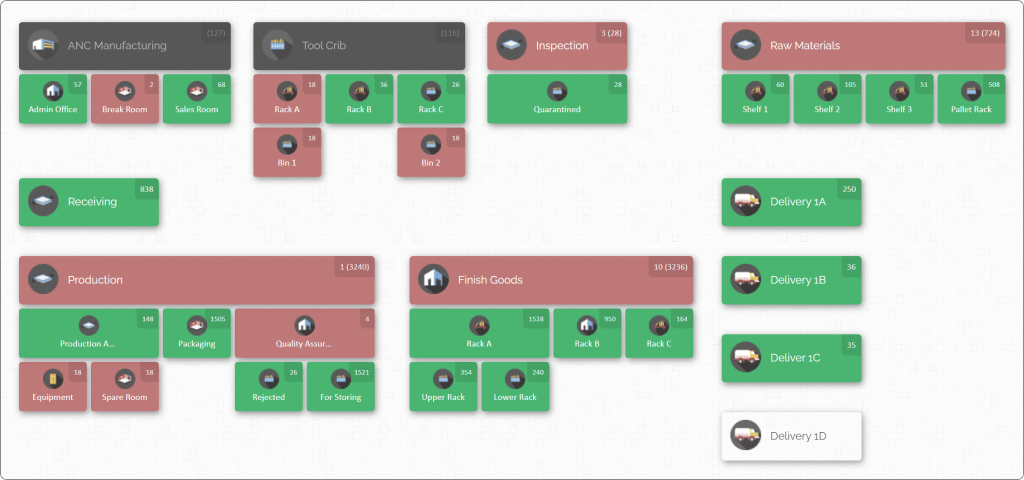

One cutting-edge approach to this is using inventory maps – essentially digital floor plans or geographic maps that display your inventory spread visually. Instead of reading through rows of SKUs and locations, managers and staff can look at a map interface to see stock levels and item locations represented visually. Imagine opening a dashboard and seeing an actual layout of your warehouse or stockroom, with icons or color coding showing where each product is stored and how much is there. Or, on a larger scale, imagine a world map or country map with markers indicating inventory across different warehouses, stores, or regions. This kind of visualization turns abstract data into an immediate snapshot that anyone can understand at a glance. It answers the vital question: “How many of what do we have, and where?” in the most straightforward way possible.

CyberStockroom: Visual Inventory Mapping

A great example of this trend is CyberStockroom, a cloud-based inventory management platform that emphasizes a map-driven approach. CyberStockroom allows businesses to create a customizable inventory map of their operations. Think of it like Google Maps for your inventory – every stockroom, warehouse section, shelf, or truck can be represented as a location on the map. Users drag-and-drop products into these locations on screen, mirroring reality. The result is a dynamic, zoomable map where you can click on any area and instantly see what inventory is there and in what quantity.

This visual method makes managing inventory much more intuitive. For instance, a warehouse manager can glance at the CyberStockroom map of their facility and immediately spot that Section B is running low on a certain item, while Section A has a surplus. If a customer calls asking if a product is available at a specific store or location, the manager can check the map and respond in seconds. Training new staff becomes easier too – instead of teaching them cryptic location codes, you can show them the visual layout on the software so they understand the space.

CyberStockroom’s map approach also improves inventory workflows like picking and restocking. For example, pickers can use the visual map to plan an optimal route through a warehouse, hitting all needed locations in order without backtracking – because they can literally see the item locations on a floor plan. Likewise, when restocking or putting away deliveries, the map can guide workers to the exact bin or shelf visually. This reduces errors (people are less likely to put something in the wrong spot if they have a visual reference) and saves time.

Because CyberStockroom is a cloud-based tool, this inventory map is accessible in real time from any device with an internet connection – in the office, on a tablet on the warehouse floor, or even on a manager’s smartphone while off-site. There’s no special app needed; users just log in through a web browser, and the map dashboard is there. Real-time access means if one team member moves stock from one location to another and updates it on the map, everyone else sees that change instantly. No more outdated spreadsheets or end-of-day syncing – the visual inventory is always current.

Key benefits of inventory mapping & visualization tools (like CyberStockroom) include:

- Instant Clarity: A visual map provides at-a-glance understanding of inventory distribution. Even someone unfamiliar with the data can quickly see where things are and how stock levels compare across locations.

- Faster Training and Onboarding: New employees or team members from other departments can grasp your inventory layout quickly through visual maps, reducing the learning curve in complex warehouses.

- Improved Picking Efficiency: Seeing item locations on a map helps plan picking routes and reduces time spent searching for products. It streamlines order fulfillment and reduces mistakes.

- Better Decision-Making: Managers can spot trends or issues visually – for example, noticing that one storage area is consistently running out of space or that certain high-value items are concentrated in one place (potentially a security concern). The visual context helps in planning space utilization and stock placement.

- Enhanced Communication: Sharing a visual snapshot with stakeholders (even outside the operations team) conveys information more clearly. For instance, you could show executives or partners a map of inventory levels across all distribution centers to discuss shifting stock for seasonal demand.

Beyond CyberStockroom, the general trend is that inventory software is becoming more user-friendly and visual. Dashboards now often include charts, graphs, and maps rather than just raw data.

Inventory mapping and visualization directly address a common pain point – the difficulty of tracking inventory across multiple locations and in complex environments. By adopting these tools, organizations can dramatically increase their inventory visibility, meaning fewer lost items, fewer surprises, and more control. In 2026, expect more businesses to say goodbye to confusing spreadsheets and embrace visual dashboards that make inventory data transparent and actionable at a glance.

4. Cloud-Based Systems and Real-Time Connectivity

The days of on-premise inventory software and isolated data are dwindling. Cloud-based inventory management systems have become the go-to solution for companies of all sizes, and this trend will only strengthen in 2026. Cloud inventory platforms (often delivered as Software-as-a-Service) offer accessibility, scalability, and integration capabilities that traditional systems struggle to match. In parallel, businesses are striving for real-time connectivity – linking their inventory data across sales channels, warehouses, and supply chain partners to get instant updates and a single source of truth. Together, cloud technology and real-time data flow are enabling a more agile and responsive approach to inventory management.

Why the strong push toward cloud? For one, a cloud-based system means your inventory database is centralized and accessible anytime, anywhere. Teams in different locations can log into the same system through the internet and see up-to-the-minute inventory information. This is crucial as operations spread across multiple warehouses, stores, or even countries. A sales rep should be able to check stock availability while on the road or working from home; a warehouse manager should update counts and have those reflected immediately for colleagues at HQ. Cloud systems make this possible without cumbersome VPNs or remote desktop setups that older systems required. Additionally, cloud services tend to offer high uptime, data backups, and security measures handled by the provider, relieving companies of a lot of IT burden.

Another big advantage is scalability and flexibility. In a cloud inventory system, adding a new location, user, or even integrating a new sales channel (like opening an e-commerce store) is often just a configuration change rather than a major IT project. The system’s capacity grows with you – no need to install new servers or worry about running out of database space. If your business experiences seasonal spikes, cloud infrastructure can handle the load and then scale back, so you only pay for what you use. This flexibility is particularly helpful for inventory management because sales volumes can fluctuate and supply chains can be unpredictable. The year 2026 is still likely to see surprises in global supply and demand (as the past few years taught us), so having a nimble cloud system allows companies to adapt quickly without missing a beat.

Real-time inventory tracking is often married with cloud systems. When we say real-time, we mean that transactions (sales, shipments, receipts, movements) update inventory counts immediately as they happen. Achieving real-time accuracy might involve technologies like barcode scanning at the moment of picking or receiving, RFID tags that automatically register movement of goods, and software that syncs data instantaneously through the cloud. The benefit is obvious: anyone looking at the system sees the current stock status, not yesterday’s numbers. This enables better decisions. For example, if an online order comes in, the system can allocate stock knowing exactly what’s available that second, preventing scenarios of selling an item that just went out of stock an hour ago. Or if a warehouse worker finds some damage and adjusts the inventory down, sales channels can immediately reflect that loss and avoid overselling. Real-time data is the backbone of things like omnichannel retail – where a customer might order online for pickup in store. The store’s inventory needs to be synced with the online system live; a cloud platform makes that integration much easier.

Speaking of omnichannel and integration: cloud inventory tools often come with or support integration to many other systems (accounting, ERP, e-commerce platforms, shipping carriers, etc.). While not every inventory system integrates with everything out-of-the-box, the cloud architecture means at least it has APIs or import/export capabilities to connect data. This is increasingly important because companies want their inventory management to not exist in a silo. For instance, connecting inventory software with point-of-sale systems ensures that when a sale happens at a retail register, the inventory is updated immediately company-wide. Linking inventory with procurement or manufacturing software means production planners see raw material stocks in real time. In 2026, we’re seeing more businesses strive for end-to-end visibility – unifying data from supply, inventory, and demand so that all departments are on the same page. Cloud platforms facilitate this unity by serving as central hubs that other applications can plug into without everyone needing to be on the exact same software.

Benefits of cloud-based and real-time inventory management include:

- Universal Access: Team members can log in from anywhere (office, warehouse floor, home, or on the go) and collaborate on inventory management with the same up-to-date information. This was particularly valuable during recent periods of remote work and will continue to be a staple of flexible operations.

- Lower IT Overhead: No more maintaining local servers or installing software on every device. The provider handles maintenance, updates, and security. Users always have the latest version and features without manual upgrades.

- Faster Deployment and Scaling: Implementing a cloud inventory system can be done in weeks or even days, not months. As your business grows or changes, it’s easy to add new locations or modules. This agility means your inventory system never holds back expansion or pivots.

- Real-Time Accuracy: With live updating, the data in the system reflects reality moment by moment. This reduces double-selling and backorders, improves customer satisfaction (since availability shown online or quoted by sales is accurate), and helps avoid production delays due to missing materials.

- Better Insights and Analytics: Cloud systems often include or integrate with analytics tools that crunch large datasets quickly. You can generate reports or dashboards to spot trends (fast vs slow-moving items, regional stock differences, etc.) across all your operations without manual data consolidation. Having accurate, centralized data makes analysis far more trustworthy and useful.

In 2026, adopting a cloud inventory management system is practically a must for modern businesses. Those still clinging to legacy offline systems will find themselves at a disadvantage – working with lagging information, struggling to coordinate across departments, and spending too much on IT upkeep. Meanwhile, those on the cloud will be positioned to implement advanced capabilities (like the AI and automation we discussed earlier) much more easily, since most new tech integrates best with cloud platforms. The bottom line: moving to the cloud and embracing real-time connectivity lays the foundation for all other inventory innovations. It’s like upgrading the roads before deploying faster cars. With a solid, connected system in place, companies can respond faster to market changes, serve customers better, and run leaner operations.

5. Sustainable and Resilient Inventory Practices

Sustainability isn’t just a buzzword – it’s an increasing priority in inventory and supply chain management. As we head into 2026, green and resilient inventory practices are a notable trend driven by consumer expectations, cost considerations, and sometimes even regulatory requirements. Companies are recognizing that efficient inventory management and sustainability often go hand-in-hand: reducing waste, avoiding excess stock, and improving supply chain transparency can save money while also benefiting the environment and society. At the same time, the past few years of global disruptions have taught businesses the importance of building resilience – that is, having inventory strategies that can withstand shocks like supplier outages or transportation delays. In this trend, we see inventory management evolving to be not just lean and profitable, but also responsible and robust.

On the sustainability side, one key practice is minimizing waste through better inventory control. Excess inventory that sits unsold until it expires or becomes obsolete is essentially pure waste – it ties up capital and often ends up in landfills or as scrap. By using the advanced forecasting methods we discussed (like AI) and just-in-time replenishment where feasible, companies can avoid overstocking and thereby reduce the likelihood of waste. This is particularly important for perishable goods or fashion items that have a short lifecycle. Smarter planning leads to only procuring what you need when you need it, which naturally cuts down on discarded or unused products. It’s both eco-friendly and cost-effective.

Another aspect is adopting eco-friendly inventory handling. This includes everything from the packaging materials used to store and ship inventory, to the energy efficiency of warehouses, to the routing of shipments. Many businesses are switching to recyclable or biodegradable packaging for their products and spare parts in inventory. Others are redesigning packaging to be right-sized (reducing excess padding and space) which not only lowers material use but also optimizes shipping loads – meaning more units per truck and fewer trips, thus cutting fuel usage and emissions. Efficient warehouse management can also contribute: for example, using LED lighting and solar panels in facilities, or smart HVAC systems that adjust cooling based on occupancy, all contribute to a greener operation in the inventory holding stage.

Reverse logistics is a big piece of sustainable inventory practice. This refers to the process of handling returned goods, recyclables, or any product moving backward in the supply chain. Companies are now focusing on how to efficiently reintegrate returns into inventory or dispose of them responsibly. A robust returns management system can allow returned items in good condition to be inspected and put back into stock quickly (reselling them instead of scrapping them). If products are defective or cannot be resold, businesses look for recycling opportunities or donations to avoid landfill. This not only reduces environmental impact but also recaptures value from returns – turning what was once seen only as a cost center into a potential source of recovered inventory or materials. With the continued growth of e-commerce (which typically has higher return rates than in-store retail), having a smart reverse logistics process is both a sustainability move and a necessity for inventory accuracy.

Resilience goes hand in hand with sustainability in many respects. A resilient inventory strategy means you can keep serving customers even when disruptions occur, and that often involves sustainable practices. For example, diversifying suppliers and keeping strategic safety stock of critical items can buffer against one supplier’s factory getting hit by a natural disaster. While holding extra safety stock may seem at odds with lean principles, it’s a matter of balance – ensuring you aren’t so lean that you’re brittle. The push for resilience in 2026 has led companies to invest in better data on their supply chains (knowing where each component comes from and potential risks) and sometimes to nearshore or localize certain inventory to shorten supply lines. These decisions can reduce transportation emissions (local sourcing is often greener) and also reduce risk of long-distance disruptions.

Technology is also aiding sustainable and transparent inventory management. Blockchain, for instance, is being explored to improve traceability of products from source to store. In industries like food and pharmaceuticals, blockchain ledgers can record each handoff of a product through the supply chain. This provides an immutable record that the product was sourced ethically and handled properly, and if there’s a recall or safety issue, companies can pinpoint where the affected lots are in the supply chain quickly. Major retailers have already used blockchain for tracing produce and meats to improve food safety and reduce waste from broad recalls. Knowing exactly “farm to shelf” journey means if a problem is found at one farm, you can recall only the produce from that source instead of dumping all your inventory of that product. While blockchain is still emerging in inventory use, it underscores the trend of supply chain transparency which is closely tied to sustainability – consumers and partners want proof of ethical sourcing, and companies want precise visibility to minimize unnecessary loss.

Key elements of sustainable & resilient inventory management include:

- Optimizing Stock Levels: Avoiding overproduction and overstock is eco-friendly and cost-saving. It reduces waste of materials, energy, and storage space, while also preventing large disposal of unsold goods.

- Eco-Conscious Operations: Using sustainable packaging and reducing the carbon footprint of inventory storage and transport (through energy-efficient warehouses and optimized delivery routes) contributes to corporate sustainability goals.

- Reverse Logistics & Recycling: Implementing strong processes for returns, refurbishment, or recycling of products. This might mean reselling returned items, recycling materials from damaged goods, or partnering with recycling firms. It keeps inventory circulating in a circular economy rather than ending up as waste.

- Diversified and Ethical Sourcing: Sourcing from multiple suppliers (ideally ones that also adhere to sustainable practices) so that no single point of failure can halt your inventory flow. This also includes ensuring suppliers meet certain environmental and social standards, which reduces risk of scandals or supply shocks.

- Data-Driven Risk Management: Using inventory analytics to simulate “what-if” scenarios (what if supplier X fails, what if demand surges 200% next month?) and having contingency plans. Keeping some safety stock of critical items, or using regional warehouses to hedge against localized disruptions, are strategies that add resilience.

Customers today do care about the story behind the products they purchase. They ask questions like: Was this sourced responsibly? Is the company minimizing waste? If you can incorporate positive answers to those questions into your inventory practices, it not only helps the planet but also appeals to market demand. Additionally, many regions are introducing stricter regulations (for example, around carbon reporting or recycling) that will impact inventory and logistics – companies that adapt early will avoid penalties and perhaps gain incentives. In sum, sustainability and resilience are about future-proofing inventory management. They ensure that you can serve your customers and communities not just efficiently, but also responsibly, no matter what challenges arise. For inventory professionals, embracing this trend means looking beyond immediate costs and stock levels, and considering the larger footprint and durability of their inventory strategy in a changing world.

Conclusion:

Inventory management in 2026 is defined by innovation and adaptation. From intelligent AI algorithms and warehouse robots, to visual maps and cloud connectivity, the tools at our disposal are more powerful than ever. By leveraging these technologies and trends, companies can achieve unprecedented efficiency, accuracy, and agility in their inventory operations. At the same time, a forward-thinking inventory strategy also incorporates sustainability and resilience, ensuring the business can thrive responsibly amid uncertainties.

For inventory and operations professionals, the message is clear: staying informed about these trends is no longer optional – it’s essential. Those who embrace the likes of AI-driven forecasting, automation, visual inventory mapping (with solutions such as CyberStockroom’s platform), real-time cloud systems, and sustainable practices will set themselves apart as industry leaders. They’ll be better equipped to delight customers with perfect stock availability and speedy delivery, all while reducing costs and waste. On the other hand, businesses that resist change may find it increasingly hard to keep up with competitors who have optimized every facet of their inventory management.

As you plan for 2026 and beyond, consider how each of these top trends might fit into your own operations. Even small steps – like automating a single process or piloting an AI prediction tool – can yield significant improvements. Inventory management has always been about balancing supply and demand, but now we have a myriad of advanced tools to tip that balance in our favor. The companies that effectively combine human expertise with these new technologies and methods will achieve the best results. By watching these trends and taking action, you can ensure your inventory management is not just keeping up with the times, but leading the pack into the future.

Leave a comment