As the calendar turns to 2026, businesses have a prime opportunity to refine their inventory strategy and set fresh goals for the year ahead. The past few years have taught companies valuable lessons about resilience, agility, and efficiency in supply chains. Now is the time to apply those lessons. A solid inventory strategy for 2026 can help your operations run smoother, cut costs, and keep customers happy even in a changing market. This comprehensive guide will walk you through how to plan your inventory strategy for the new year, with practical steps and forward-looking insights tailored for enterprise operations managers in the industrial manufacturing sector.

New Year, New Goals: Planning your inventory is not just about restocking products. It’s about aligning inventory management with your overall business objectives for 2026. Whether your goal is to avoid the stockouts of last year, reduce excess stock sitting in your warehouses, or implement new technology for better visibility, a clear strategy will get you there. Let’s dive into how you can evaluate where you stand today and chart a course for improvement in the year to come.

A Clear Picture of Your Inventory

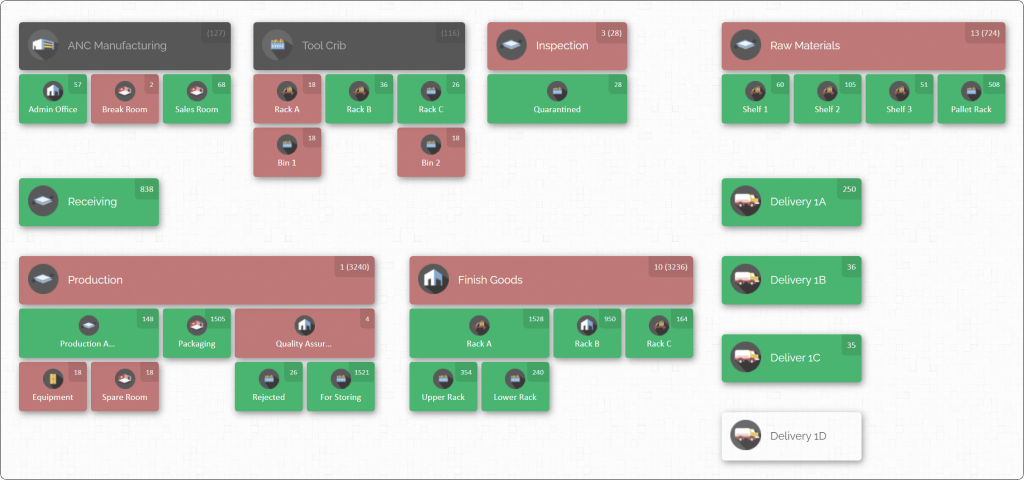

Before setting new goals, you need an accurate, big-picture view of your current inventory. After all, you can’t plan for the future if you don’t know where things stand today. Visualizing your entire inventory across all locations is a powerful first step in inventory planning. For example, the inventory map shown below (a CyberStockroom demo map) illustrates how a business can see all its stock and locations at a glance.

Why start with a map? Because a visual inventory map makes it easy to identify how products are spread out, where the bottlenecks might be, and which locations are under- or over-stocked. It turns complex inventory data into an intuitive picture. As you prepare for 2026, having this clarity will help you spot issues and opportunities quickly. For instance, you might notice one warehouse is overflowing with slow-moving items while another struggles with stockouts. With that insight, you can plan to rebalance stock or adjust purchasing. The key is to get everything out of spreadsheets and onto a clear visual, so you have a single source of truth about your inventory. With that foundation in place, you can move on to the next steps of strategy and planning.

Assess Your 2025 Inventory Performance

Every great plan starts with understanding the present. Begin your 2026 inventory strategy by taking a hard look at how your inventory performed in 2025. This “year in review” will highlight what worked well and what needs improvement. Here are some ways to assess your current inventory performance:

- Review Key Metrics: Dig into your inventory data from 2025. What was your average inventory turnover rate? How often did stockouts occur, and on which products? How much excess or obsolete stock did you end up carrying? Analyzing metrics like turnover, fill rate (the percentage of orders fulfilled without stockouts), and carrying cost will reveal strengths and weaknesses. For example, a low turnover on certain SKUs might indicate overstocking or weak demand, while frequent rush orders and stockouts might signal poor forecasting or not enough safety stock.

- Identify Fast and Slow Movers: Look at sales and usage data to see which products flew off the shelves and which gathered dust. Your fastest-moving items are critical – these are the products you can’t afford to run out of because they directly impact sales or production. Conversely, identify the slow-moving or dead stock that tied up capital and storage space. Perhaps certain raw materials or spare parts were rarely used, hinting that you could order them less frequently or find a way to liquidate excess. Knowing your top sellers and shelf-sitters from 2025 will inform how you stock them in 2026.

- Check for Seasonal Patterns: Did you notice predictable spikes or dips in inventory usage during the year? Many manufacturers and distributors have seasonal trends – for instance, a building materials supplier might see a surge in the spring and summer, while an HVAC parts provider might peak in winter. Review 2025 month by month. If you struggled with furnace parts last January or scrambled for extra components during a summer production ramp-up, note those patterns. They will likely repeat, and planning inventory around them (e.g. building up stock before the peak season) can prevent last-minute crises.

- Audit Physical Inventory and Accuracy: Take stock (literally) of your warehouse conditions. Do an end-of-year physical count or cycle counts on key items and compare with your records. Were there discrepancies between what your system said and what was actually on the shelf? Inventory accuracy issues can cause big problems – you might think you have stock that isn’t there (leading to missed shipments) or vice versa. Identify any problem areas: maybe certain locations or certain product lines had frequent count errors or losses due to damage or theft. Understanding where accuracy broke down in 2025 lets you target fixes (like improved barcode scanning procedures or security measures) for 2026.

- Gather Team Insights: Numbers tell a lot, but your frontline staff have invaluable knowledge too. Talk to your warehouse managers, purchasing team, and even production supervisors or sales reps. They can highlight pain points: “We were constantly short on Component X,” or “Product Y always seemed to be overstocked in the back.” They might reveal inefficiencies like a disorganized stock area that led to misplaced items, or supplier issues that caused delays. Make it a collaborative effort – an honest post-mortem of the past year’s inventory management can unearth lessons you might miss just looking at reports.

By thoroughly assessing 2025 in this way, you set a baseline. You’ll clearly see, for example, that Item A stocked out 5 times causing production delays, or Inventory holding costs rose 10% because of excess unsold stock. These insights are pure gold: they pinpoint what you must address in your 2026 strategy. Equally important, acknowledge what went well. Maybe switching to a new supplier cut lead times in half for a key component, or implementing monthly cycle counts improved accuracy to 98%. Celebrate those wins and plan to build on them. The goal of this assessment is to carry forward the successful practices and correct the missteps. With a solid understanding of where you stand, you can set clear and meaningful goals for improvement.

Set Clear Inventory Goals for 2026

Once you’ve reviewed last year’s performance, the next step is defining what you want to achieve in 2026. Clear goals give your inventory strategy direction and purpose. Rather than simply saying “we’ll manage inventory better,” set specific targets that address the issues you identified and align with your company’s broader objectives. Here are some examples of inventory goals you might consider:

- Improve Service Levels and Avoid Stockouts: If lost sales or downtime due to stockouts were a problem, make it a goal to boost your service level (the percentage of time you have the stock when customers or production need it). For instance, you might set a goal to maintain a 99% fill rate on all critical components or top-selling products. This could involve keeping higher safety stock for those items or improving your demand forecasting (we’ll cover that soon). The point is to ensure that in 2026, you rarely (if ever) have to tell a customer “Sorry, we’re out of that” or halt manufacturing because a part is missing.

- Reduce Excess Inventory and Carrying Costs: On the flip side of stockouts is the issue of overstock. Excess inventory ties up cash, consumes warehouse space, and sometimes ends up as obsolete waste. If your analysis showed a lot of slow movers, set a goal to trim that fat. You might aim to reduce overall inventory value by, say, 15% by mid-2026 without hurting availability. This can be achieved by implementing just-in-time practices for non-critical items, improving forecasting to order closer to actual demand, or running promotions to clear out old stock. A leaner inventory will lower your carrying costs (expenses for storage, insurance, and capital) and improve cash flow.

- Increase Inventory Turnover: Inventory turnover measures how many times you sell through or use your inventory in a period. A higher turnover generally means you’re keeping inventory levels efficient relative to sales. If currently your inventory turns are low (indicating product sits for too long), you could set a goal to increase the turnover rate in 2026. For example, if you turned inventory 4 times in 2025, aim for 5 or 6 times in 2026. Achieving this might involve better aligning purchase quantities with actual demand, phasing out unpopular SKUs, or speeding up the flow of materials from receiving to production to shipping. Higher turnover often correlates with less waste and fresher stock (important if your items have shelf life considerations).

- Implement a New Inventory System or Process by a Certain Date: Perhaps one takeaway from your 2025 assessment is that your current way of managing inventory isn’t cutting it – maybe you’re using manual spreadsheets or an outdated software that lacks features. An excellent goal could be to adopt a modern inventory management solution by Q2 2026 (more on technology later), or to roll out a new process like cycle counting or ABC analysis for prioritizing inventory control. Having a timeline for these implementations keeps your team accountable. For instance, “By March 2026, we will have a weekly cycle count program in place, covering A-class items (most valuable items) to maintain at least 95% accuracy.”

- Enhance Multi-Location Coordination: If you operate multiple warehouses, factories, or stock locations (common in industrial manufacturing with global operations), set goals around better coordination. This could mean establishing a centralized view of inventory (so all locations know what’s where), or reducing redundant stock across facilities. A goal could be: “Create a unified inventory database for all 5 warehouses by mid-year and optimize stock distribution so that no two locations are holding excess of the same SKU unnecessarily.” This ties in with visibility improvements, which we will discuss, but it’s important enough to be a goal on its own if siloed operations were an issue.

- Align Inventory with Production and Sales Plans: In manufacturing, inventory strategy is tightly connected to production schedules and sales forecasts. You might set a goal around integration of planning processes. For example, “In 2026, implement a Sales & Operations Planning (S&OP) process that ensures inventory levels (raw materials and finished goods) are aligned with the latest sales forecasts and production plans each month.” This goal acknowledges that inventory doesn’t exist in a vacuum – it should reflect what your sales team expects to sell and what your production team plans to build. Better alignment can reduce both shortages and overages.

When setting these goals, make them SMART: Specific, Measurable, Achievable, Relevant, Time-bound. Instead of a vague “we’ll cut costs,” specify “reduce inventory holding cost by $100k by Q4 2026.” Instead of “we’ll use new tech,” say “implement system X by June and train all staff by July.” Specific targets like these can be tracked throughout the year, so you know if you’re on pace or need to adjust.

Also, ensure the goals are realistic. For instance, eliminating stockouts entirely might be too aggressive if you had hundreds last year, but reducing them by 50% is attainable with effort. Engage various stakeholders in goal-setting – get input and buy-in from finance (who cares about cost targets), sales (who care about service levels), operations and warehouse teams (who will execute the changes), etc. This way, the inventory goals support broader business aims: maybe the company’s overall 2026 goal is to launch in new markets or increase revenue by 20%. Your inventory goals should facilitate that (ensuring stock availability for the sales growth, for example, while not ballooning costs).

By the end of this stage, you should have a clear list of 2026 inventory management objectives. Write them down, communicate them to your team, and keep them visible. These are the guiding stars for all the strategy steps to follow. Next, we’ll explore strategies and tactics to actually reach those goals.

Balance Efficiency with Resilience (Lean vs. Safety Stock)

One of the biggest strategic questions in inventory management is how to balance running “lean” versus having buffers for the unexpected. In other words, how can you minimize inventory costs while still protecting your business from supply chain shocks or demand spikes? In 2026, finding this balance will be more important than ever. The past few years have seen global supply disruptions, from trade instability to production delays, which taught many companies that just-in-time (JIT) inventory has risks. At the same time, holding too much “just-in-case” inventory can hurt the bottom line. So, how do you strike the right balance?

Just-in-Time (JIT) is the classic lean inventory strategy: you keep inventory levels as low as possible and replenish right when you need it, ideally “just in time” for production or sales. The benefit is efficiency – you’re not tying up money in unused stock, and you don’t need as much storage space. Many manufacturers have long favored JIT to streamline operations and reduce waste. However, JIT relies on everything working like clockwork: accurate forecasts, reliable suppliers, and smooth logistics. When something falters (a supplier delay, a sudden demand spike, a transport issue), JIT can leave you empty-handed at a critical moment. For example, a factory practicing strict JIT might shut down assembly lines if a single shipment of parts arrives late.

Just-in-Case (JIC), on the other hand, means keeping extra inventory on hand “just in case” something goes wrong. It’s a more cautious approach: you maintain higher stock levels (safety stock) as a buffer against uncertainty. The obvious benefit is resilience – if demand suddenly jumps or a supplier can’t deliver on time, you have backup inventory to keep things running. In the post-2020 world, many companies that suffered stockouts have embraced a bit more JIC to avoid repeats of those costly disruptions. The downside, of course, is higher holding costs and potential waste (if that extra inventory never gets used or becomes obsolete).

The 2026 Reality: A Hybrid Approach. In today’s environment, the smartest strategy is often neither extreme but a hybrid. Many businesses are realizing that one size doesn’t fit all when it comes to inventory policy. You might apply JIT principles to certain items and JIC to others, based on specific factors:

- Critical vs. Non-critical Items: For commodities or easily sourced parts with stable demand, you might stick closer to JIT to keep lean. But for critical components that have long lead times or single-source suppliers, maintaining a safety stock is wise. For example, if you have a custom-engineered part that only one supplier makes, you’ll want a few weeks’ extra supply in the warehouse because if that supplier has issues, you’re stuck.

- Demand Predictability: If an item’s demand is highly predictable and steady, JIT can work well. If demand is very volatile or seasonal, a buffer stock might be necessary to cover the swings. Analyze the coefficient of variation of demand for each SKU; high variability items require more cushion.

- Supplier Reliability and Lead Times: If your suppliers are local and have a track record of on-time deliveries in 2 days, you can lean on them with less on-hand stock. But if your items come from overseas or an area prone to disruptions (port delays, customs, political issues), you might carry extra inventory stateside. Many companies are reevaluating their global supply chain footprint; some are increasing nearshoring or reshoring (bringing sourcing closer to home) precisely to reduce lead times and the need for huge safety stocks. In fact, as of late 2025, a significant number of manufacturers have started reshoring initiatives to gain more control – indicating a trend toward balancing efficiency with security of supply.

- Cost of Stockouts vs. Cost of Holding: Perform a risk-cost analysis. What costs you more: having too much or having too little? For example, if a stockout would shut down a production line that costs $10,000 per hour in downtime, that’s a very high cost, worth keeping extra inventory. Conversely, if holding an extra pallet of a cheap part costs you only minor storage fees, maybe it’s aan cceptable insurance. On the other hand, if an item is expensive and ties up $100k of capital sitting on the shelf, maybe you’d rather risk a stockout or find a faster way to expedite it only if needed. Weigh these factors for different categories of products.

In 2026, supply chain resilience remains a top priority for many companies. Surveys of manufacturing executives show that concerns about supply disruptions, trade policy changes, and logistics challenges are still front-of-mind. Many firms are carrying more safety stock than they did a few years ago as a hedge against this uncertainty. However, this doesn’t mean abandoning lean principles altogether – it means being strategic about where to build in buffers.

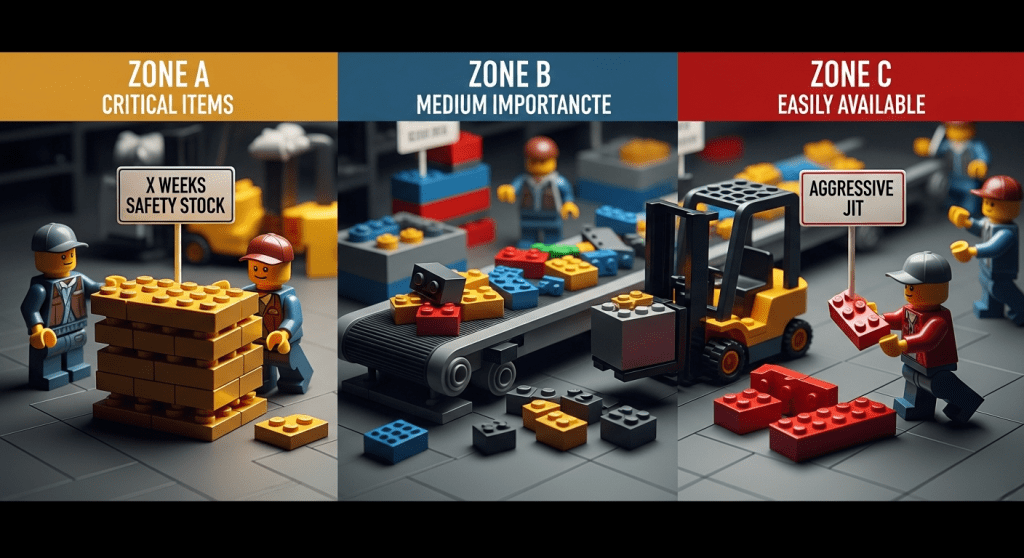

Create a Segmented Inventory Strategy: You might formally segment your inventory into categories with different strategies. For example:

- Category A: Critical, high-value, or long lead time items – maintain X weeks of safety stock.

- Category B: Medium importance items – moderate stock, maybe JIT with a small buffer.

- Category C: Easily available or low risk items – aggressive JIT, reorder as needed with minimal extra.

This approach is sometimes called ABC analysis or multi-echelon planning where each item has an appropriate policy. Modern inventory optimization tools can even calculate optimal safety stock levels for each item, considering service level targets and variability.

Don’t Forget Quality and Obsolescence: Another aspect of resilience is ensuring the extra inventory you keep doesn’t go bad or become obsolete. If you’re stocking more “just in case,” implement practices to rotate stock (FIFO/LIFO as applicable, check expiration dates if they exist, etc.) and keep inventory data updated so that you can identify if something hasn’t moved in a long time. Part of your 2026 strategy might be establishing a quarterly review of slow-moving inventory to decide if it should be repurposed, sold off, or if future orders should be halted for that item.

In summary, for 2026, aim to be as lean as you can, but as buffered as you need. The “new goal” here is agility: you want an inventory strategy that can flex when something changes. If supply chain complexity throws you a curveball (and it likely will at some point in the year), having a bit of breathing room in your inventory or a plan B source for materials can save the day. The key is to consciously decide these policies now, rather than reacting in panic later. By balancing efficiency with resilience, you can satisfy customer demand reliably without breaking the bank on carrying costs.

Leverage Data and Forecasting for Proactive Planning

Forecasting demand accurately is the backbone of a successful inventory strategy. After all, your inventory exists to meet demand – whether that demand is external (customer orders) or internal (production requirements). If you can anticipate what will be needed, when, and in what quantity, you can plan inventory to match, reducing both shortages and surpluses. Going into 2026, it’s time to sharpen your forecasting tools and use data more intelligently for proactive inventory planning instead of reactive fire-fighting.

Use Historical Data (But Adjust for the Future): Start with your sales and usage data from previous years as a baseline for 2026 predictions. Look at monthly or weekly demand for each product. However, don’t assume 2026 will be a carbon copy of 2025 – adjust for known changes. For example, if you know certain contracts are ending or new ones are beginning, factor that in. If your company is launching a new product line in Q2 2026, project how that might cannibalize or increase demand for related items. Essentially, create a forecast that’s grounded in data but tweaked by business intelligence (market trends, sales team input, marketing promotions planned, etc.).

Incorporate Seasonality and Cycles: We touched on this in the assessment section – make sure your forecasts reflect seasonal peaks and troughs. If you identified that Q1 is slow but Q3 is booming, your inventory plan should ramp down and up accordingly, rather than keeping a flat level year-round. Advanced forecasting might even consider week-of-year patterns (e.g., a spike every Black Friday week for certain products). The goal is to stock in anticipation of these known cycles so you’re prepared ahead of time. Mark your calendar now for major events that impact inventory – whether it’s industry trade shows, seasonal weather impacts (hurricane season affecting supply routes, etc.), or end-of-year holiday demand for those in B2C channels.

Leverage Technology and Analytics: Manual forecasting via spreadsheets can only go so far, especially for a complex operation. Consider using forecasting software or advanced analytics that can handle multiple variables. Modern inventory management systems often have forecasting modules that use statistical models (like exponential smoothing, ARIMA, or more advanced machine learning) to predict demand. These can automatically detect trends and seasonal patterns in your data that might not be obvious. For example, a system might learn that every time your company’s product A’s demand goes up, product B goes down (substitution effect), or find correlations with external data like economic indicators or even weather (if relevant).

In 2026, AI-driven forecasting is more accessible than ever. AI and machine learning can churn through historical sales, current market trends, and even external factors to forecast needs with increasing accuracy. Imagine a model that considers not just your past sales, but also trends in your industry, Google search trends for products like yours, or macroeconomic data. These tools can flag when demand might shift and help you plan inventory levels accordingly. If adopting AI tools is feasible, it could be a game-changer for staying ahead of demand fluctuations. Even if you don’t use dedicated AI software, you can apply the principles: incorporate more data points and continuously update forecasts as new information comes in.

Forecast Both Demand and Supply: Many focus only on the demand side, but supply forecasting is important too. If you know a supplier has a plant maintenance shutdown every July, forecast that into your plan (order extra in June). If raw material prices or availability are trending, account for that. Also track supplier lead times data: if one vendor’s lead times have been lengthening, you might forecast that trend to continue and adjust reorder points or find alternatives. 2026 might bring its own supply-side challenges (for example, if certain commodities are projected to be in short supply). Keep an eye on industry news and incorporate those insights.

Scenario Planning: A smart way to handle uncertainty is to do scenario planning. Create best-case, worst-case, and likely-case scenarios for your demand forecasts. For instance, “If our new product is a hit, demand could be 50% higher than baseline; if the market slows, it could be 20% lower.” Then outline inventory strategies for those scenarios. While you can’t stock for every scenario (especially the extremes), you can at least have contingency plans. If by mid-2026 you see the “high demand” scenario playing out, you’ll know you planned to expedite orders or activate secondary suppliers. If it’s the low scenario, you might slow down purchasing to avoid glut. Scenario planning is like having a playbook for different futures, which makes you more agile in response to real conditions.

Tie Forecasting into S&OP: Consider integrating your forecasting into a formal Sales and Operations Planning (S&OP) process. This usually means on a monthly (or quarterly) basis, teams from sales, operations, finance, etc., come together to reconcile the forecast with actuals and make adjustments. In an S&OP meeting, for example, the sales team might say “We’re seeing increased interest in Product X in Europe, we expect 20% more orders next quarter,” and the operations/inventory team can respond “Alright, we will secure more stock of X’s components and ensure production can scale up.” The finance team might weigh in on the cost implications. By collaborating, you ensure the inventory plan is always up to date with the latest intel from each department. Establishing a rhythm of these meetings in 2026 ensures that your inventory strategy remains a living plan, not something you set on January 1 and forget.

Measure Forecast Accuracy: As you implement better forecasting, track how you’re doing. A good KPI is forecast accuracy or error (like Mean Absolute Percentage Error, MAPE). If you set a goal to improve forecast accuracy, monitor it monthly. When you miss, find out why – was there a sudden unpredicted event, or did your model consistently overestimate demand for a group of products? Learning from misses will improve future projections. Perhaps you’ll find certain product lines are inherently hard to forecast and need a different approach (like more safety stock or on-demand manufacturing) versus others that are very predictable.

In summary, data-driven forecasting lets you shift from reacting to demand to anticipating it. By leveraging historical data, advanced tools, and cross-functional planning, you can get much closer to the mark in matching inventory to actual needs. This means fewer emergency stock replenishments, less last-minute expediting (which can be costly), and less surplus gathering dust. For 2026, make it a goal to trust your data and let it guide your inventory levels. When combined with the flexibility we discussed earlier, you’ll create a system that is both efficient and responsive to whatever the year throws at you.

Improve Inventory Visibility and Accuracy Across Locations

If your business operates multiple warehouses, factories, stockrooms, or even service vans with parts, one of the greatest challenges is knowing exactly what you have and where it is at any given time. Inventory visibility means having a clear line of sight into your stock across all locations in real time. Accuracy goes hand in hand with visibility – the data you see should reflect the physical reality. In 2026, enhancing both visibility and accuracy will be critical for efficient operations, especially as supply chains and distribution networks grow more complex.

Centralize Your Inventory Data: A common pain point in large organizations is fragmented inventory systems. Perhaps each warehouse has its own spreadsheet or system, or different product lines are managed separately. This siloed approach leads to confusion and inefficiency. For instance, Warehouse A might be overstocked on a part that Warehouse B urgently needs, but without visibility, they’d both place separate orders and miss the chance to rebalance internally. Solve this by centralizing inventory tracking. Ideally, use a single inventory management software or platform for all locations so that when someone pulls up the inventory status, they see one unified view of stock levels everywhere. If a customer asks, “Do you have Product X available?” your team should be able to quickly see total inventory and where it’s located. In 2026, aim to eliminate blind spots – no more guessing or making phone calls from one site to another to find stock.

Real-Time Updates: Visibility is most powerful when it’s real-time. Static reports that are even a day old can be problematic – you could commit to a customer based on yesterday’s inventory, not realizing a bunch of it was allocated or shipped today. Ensure that every inventory movement (receipts, shipments, transfers, usage in production, etc.) is recorded as it happens. Modern cloud-based inventory systems are very good at this, allowing multiple users across different facilities to update stock transactions instantly. Real-time syncing means if a pallet is consumed in Factory 1, the inventory count in Headquarters’ system updates immediately. This prevents the classic scenario of two people in different locations unknowingly allocating the same stock to two orders. In a world where speed matters, real-time data helps you respond faster — for example, rerouting an incoming shipment to the facility that just had a surge in demand.

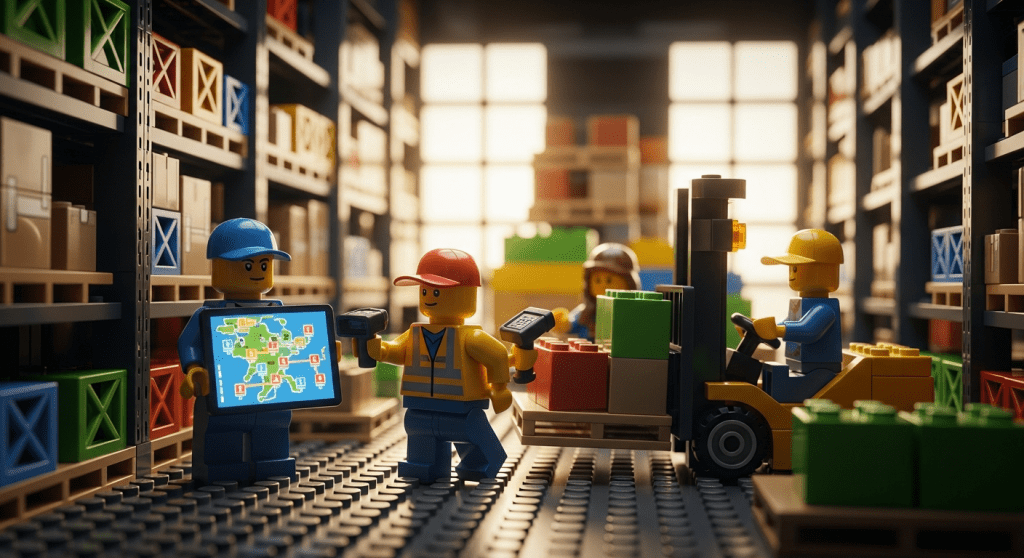

Track Inventory by Location and Sub-location: It’s not enough to know you have 1,000 units of something; you need to know where it resides. Implement a clear location-tracking system down to sub-locations. That could mean bin locations or shelf codes in a warehouse, or department zones in a factory store room. By keeping track of inventory at a granular location level, your team can actually find and use the items that the system says are in stock. In 2026, if you haven’t already, consider a location labeling and barcode system if your warehouses lack one. It’s far easier to maintain accuracy when every item is tagged and every shelf has a code, so that transactions can be scanned to specific locations.

Use Barcoding or RFID for Accuracy: Human error in data entry is a big cause of inventory inaccuracies. Writing down counts on paper, manually typing them into spreadsheets, or relying on memory inevitably leads to mistakes. A simple yet extremely effective solution is barcoding. Each SKU (and even each location) gets a barcode label, and staff use scanners (which can be traditional handheld scanners or even mobile devices with scanning apps) to scan items whenever they are moved, sold, or received. Scanning reduces errors and speeds up processes like receiving, picking, and cycle counting. If you haven’t implemented barcoding, 2026 is a great time to do it – the technology is affordable and often integrates directly with inventory software. For even more advanced needs, RFID tags can automatically track movement of items without needing line-of-sight scans, but they are more costly and complex; many companies find barcodes sufficient. The key point: automate data capture as much as possible to keep inventory records accurate.

Conduct Regular Cycle Counts: Instead of relying only on an annual full inventory count (which is time-consuming and often disruptive), incorporate cycle counting into your operations. Cycle counting means counting a subset of inventory on a regular, rolling schedule. For example, you might count a few items every day such that over a quarter or year, you’ve counted everything multiple times. Focus more frequent counts on your high-value or fast-moving items (count those monthly, perhaps) and less frequent on the low-value slow movers. By cycle counting regularly, you catch discrepancies early. If item A was supposed to have 100 units but you only count 95, you can investigate promptly – maybe there was a mis-recorded shipment or a theft issue. Fixing that record prevents ongoing errors from compounding. Make cycle counts a routine in 2026 – assign team members specific count tasks, perhaps incentivize accuracy improvements, and track cycle count results as a KPI. Over time, you want to see fewer and smaller discrepancies, meaning your system’s numbers and reality are lining up.

Implement Inventory Audits and Accountability: Encourage a culture of accuracy by assigning clear ownership of inventory data. For instance, each warehouse manager could be accountable for keeping their location’s inventory accuracy above, say, 98%. When everyone knows that accuracy is a priority (and measured), they’re more likely to follow procedures carefully (like scanning every transaction, double-checking counts, etc.). Some companies even gamify it – showing accuracy metrics on a dashboard or having friendly competitions between sites on who maintains the best accuracy. It might sound trivial, but these efforts keep everyone engaged in the common goal of trustworthy inventory data.

Multi-Location Coordination and Transfers: With better visibility, you can also strategically redistribute inventory across locations. If you notice in real time that one distribution center has a six-month supply of a part while another location is about to run out, you can initiate a transfer rather than ordering new stock. In 2026’s strategy, build in plans to do periodic rebalancing transfers. This not only prevents shortages but also optimizes overall inventory levels (using up excess where it’s needed). It’s an area where many companies save money—why buy more of something if the total company inventory is sufficient but just in the wrong place? Use your visibility to intelligently reposition stock. Of course, factor in transfer costs and times; it’s most effective for moderate or high-value items that justify the effort.

By improving visibility and accuracy, you are essentially creating a strong foundation for all other inventory initiatives. It’s much easier to plan and optimize when you trust the data you’re seeing. Plus, enhanced visibility makes customer service better – sales and service teams can promise orders to clients with confidence knowing the information is accurate. And management gains peace of mind being able to see, on a dashboard, exactly how the inventory stands company-wide, which is valuable for financial planning and risk management.

In short, make 2026 the year you eliminate the phrase “I’m not sure if we have that in stock.” With the right systems and habits in place, you and your team will always know what you have, where it is, and that the numbers are right. That clarity is powerful: it reduces stress, prevents mistakes, and opens the door for advanced optimization in the rest of your inventory strategy.

Embrace Modern Inventory Management Tools and Technology

Technology is a major catalyst for improvement in inventory management. If you’re still using manual processes or outdated software, upgrading to modern tools in 2026 can dramatically enhance everything we’ve discussed so far – from visibility and accuracy to forecasting and efficiency. Embracing the right inventory management software and technologies will give you an edge, turning your inventory strategy into a well-oiled, automated machine (with you in control of the dashboard). Let’s explore what kinds of tools and tech can make a real difference, and how they tie into your new year goals.

Cloud-Based Inventory Software: More and more companies are moving to cloud-based inventory management systems, and for good reason. Cloud systems allow your data to be accessible anywhere, anytime, by anyone on your team (with permissions). There’s no need for complex local installations or worrying about syncing data between multiple sites – the cloud ensures everyone is looking at the same real-time information. In 2026, if you’re not on a modern cloud platform, it’s worth evaluating options. Cloud inventory software typically includes modules for tracking stock levels, receiving and shipping transactions, purchase orders, sales orders, and even integrations to accounting or ERP systems. By having all these functions in one system, you reduce errors that come from juggling multiple tools. Plus, cloud systems tend to update automatically with new features and security patches, so you stay current without extra effort.

Data Analytics and Reporting Tools: Modern systems come with dashboards and reporting features that can crunch your inventory data into meaningful insights. For example, you can quickly generate reports on aging stock (items not moved in X days), or inventory valuation by category, or supplier delivery performance. In 2026, make use of these analytics. Set up a dashboard that tracks your key KPIs (like service level, turnover, accuracy, etc.) so at a glance you know how you’re performing against your goals. Some tools even incorporate AI to highlight anomalies – “Hey, the system noticed that widget A’s sales this month are 40% higher than usual – perhaps we should adjust forecasts or stock.” This kind of intelligence helps you stay proactive.

Mobile Access and Scanning: Equip your team with the ability to manage inventory on the go. In 2026, nobody should have to scribble something on paper in the warehouse and then go to a desktop computer later to enter it. Whether through a mobile-friendly web interface or dedicated devices, empower your workers to perform tasks like receiving goods, picking orders, or doing stock counts right where they are. This not only saves time but also increases accuracy (fewer transcriptions and delays). For example, a store room clerk could scan a part’s barcode with a smartphone as they hand it to a production worker, instantly reducing the inventory count in the system. That level of immediacy keeps data fresh.

Integrations with Other Systems: Inventory management doesn’t operate in isolation. Consider how your inventory system can integrate with your purchasing, accounting, or sales systems. Integration means when a sales order is placed, inventory is automatically allocated; or when a supplier invoice is received, it matches to the inventory receipt. While earlier we cautioned not to over-promise integration capabilities, many inventory tools do allow at least basic integration or data import/export that can streamline processes. For manufacturing, integration with an MRP (Material Requirements Planning) or ERP system can tie production schedules directly to inventory availability. Even integrating with an e-commerce platform (if you sell online) will ensure online orders pull from available stock. The more your systems talk to each other, the less manual work and cross-checking for your team. When evaluating tools for 2026, look for ones that can fit into your existing software ecosystem or at least give you accessible data you can share across platforms.

CyberStockroom: A Visual Approach to Inventory Management

In the spirit of leveraging modern tools, CyberStockroom is an example of an inventory management solution that brings some unique and powerful features to the table. It’s particularly relevant if you’re dealing with multi-location inventory and want a more intuitive way to manage it. CyberStockroom takes a visual mapping approach to inventory, which aligns perfectly with the idea of having a clear picture of your stock (remember that demo map we referenced earlier?).

What is CyberStockroom? It’s a cloud-based inventory management software that lets you create a virtual map of your business – think of it like a bird’s-eye schematic of all your inventory locations. You can map out each warehouse, stockroom, job site, or even vehicle (for service fleets carrying parts) as distinct areas on the map. Within each, you can have sub-locations (aisles, shelves, sections, etc.). This visual layout isn’t just for show; it becomes your main dashboard for managing inventory. Instead of scrolling through spreadsheets, you can click on a location on the map and instantly see what’s inside and in what quantity.

Visual Inventory Mapping: This feature shines when you have inventory spread over several places. For a manufacturing enterprise, imagine having one map where you can see raw materials at Factory A, finished goods at Warehouse B, and spare parts on Service Truck C. CyberStockroom’s interface lets you easily zoom into each and see the details. This is immensely helpful for planning: if you’re allocating stock for a new project, you might visually spot that Factory A has plenty of extra component X that you can send to Factory B, which is running low. The map essentially acts as a live snapshot of your supply chain’s inventory aspect.

Drag-and-Drop Transfers: One particularly user-friendly feature of CyberStockroom is the ability to drag and drop inventory items between locations on the map. Say you want to transfer 50 units of Part #123 from Warehouse East to Warehouse West – you can literally drag the item icon from one to the other on the screen, and it will initiate a transfer transaction in the system. This kind of simplicity is great for operations managers who want to execute quick decisions without fussing through multiple menus. It also reflects how inventory moves in the real world; the software’s design makes it intuitive, reducing the learning curve for your team.

Real-Time Updates and Team Collaboration: Because it’s cloud-based, everyone from the floor workers to the HQ analysts can use CyberStockroom simultaneously. If someone scans in a new shipment of goods at the receiving dock, those quantities update on the map in real time for all to see. Likewise, if an item is checked out or used in production, the quantity decreases immediately. This supports collaboration – sales teams could check the map to answer customer availability questions, purchasing can see current stock before ordering more, and management can watch inventory levels live during, say, a big fulfillment push at year-end. You eliminate a lot of internal emails and calls by empowering people to self-serve the info from the system.

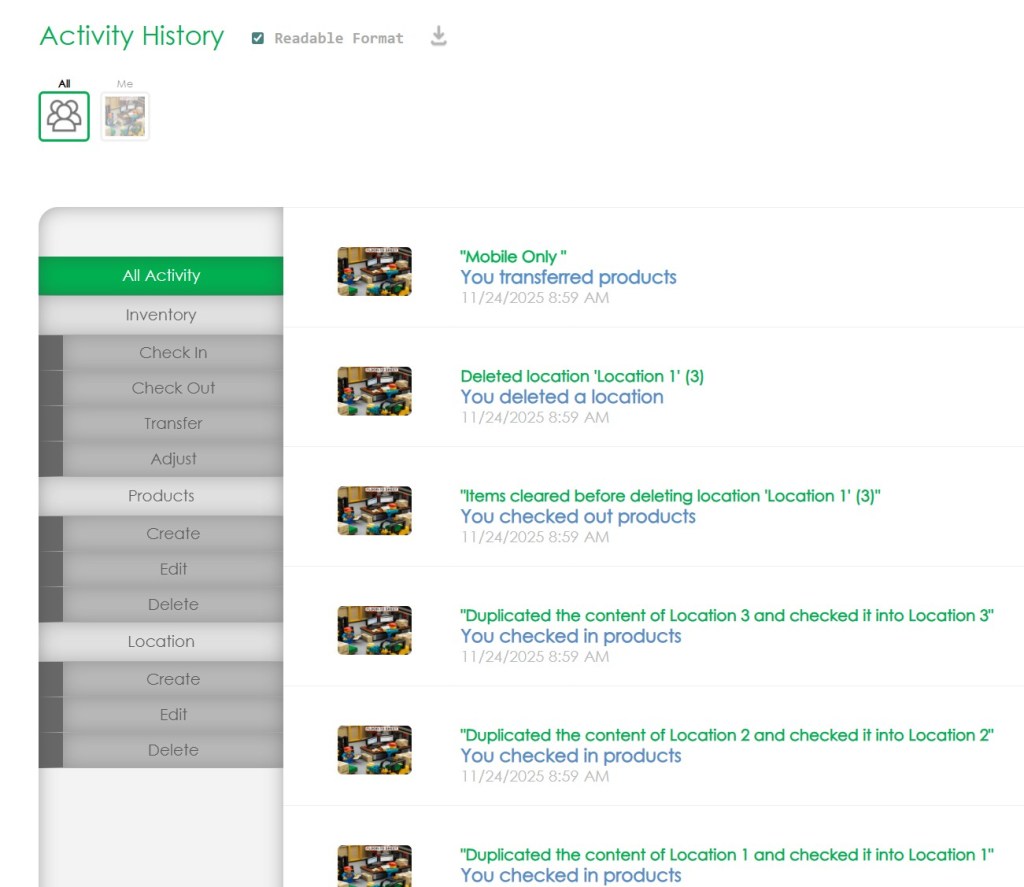

Audit Trails and Accountability: CyberStockroom also provides a detailed activity history. Every move, add, remove, or edit of inventory is recorded with a timestamp and user. This is fantastic for traceability – if something goes missing or numbers don’t match, you can audit the log to see what happened. In industries with compliance needs or where theft/loss is a concern, this feature gives managers oversight and peace of mind. It aligns well with our emphasis on accuracy and accountability; the tool helps enforce those by making every action visible and reviewable.

Customization and Flexibility: The software allows custom fields and tagging of products, so you can adapt it to various types of inventory (finished goods, raw materials, components, tools, etc.) with relevant attributes (like serial numbers, lot numbers, expiration dates if needed). This flexibility is important for manufacturing operations that might have diverse inventory items – from bulk raw materials to individually tracked expensive equipment. CyberStockroom doesn’t force a one-size-fits-all approach; you configure the map and data to mirror your actual business.

How CyberStockroom Supports 2026 Goals: If we tie this back to the broader inventory strategy:

- It improves visibility by literally visualizing all inventory. No more guessing what’s where – just glance at the map.

- It aids in multi-location coordination by making transfers easy and showing surplus/shortage at different sites.

- It helps maintain accuracy with scanning and real-time updates, plus the audit trail for accountability.

- It can speed up training and adoption because new team members often find a visual interface more intuitive than complex tables and forms. That means you can get everyone on board and using the system correctly faster (addressing the training aspect).

- Being cloud-based, it ticks the box for modernizing your tech and enabling data-driven decisions through its reports and dashboards.

For example, let’s say one of your 2026 goals is to reduce excess stock by redistributing it rather than buying new. CyberStockroom’s map might reveal at a glance that your European warehouse has a lot of spare Product XYZ, while your U.S. warehouse is low. You can drag-drop to create a transfer, and ship some over, delaying or reducing a reorder. Goal achieved – thanks to the visibility and simplicity the tool provided.

Another scenario: you want to implement regular cycle counts. With CyberStockroom, you could divide the map into sections and assign a person to count one section per week, updating the map counts as they go. The system can make it easy to print out barcodes for each section or item, and as counts are adjusted, managers see the changes live and can approve them. Over a cycle, you’ve covered the whole inventory, all within the system.

In short, CyberStockroom acts as a force multiplier for your inventory strategy. It embodies the principle of “work smarter, not harder.” The software handles the heavy lifting of tracking and visualizing, so you and your team can focus on making strategic decisions (like how much to stock and where) rather than spending time fighting with clunky spreadsheets or reconciling data from disparate sources. If adopting a new inventory management solution is on your agenda for 2026, a platform like CyberStockroom is worth considering, especially if visual mapping and ease-of-use are high priorities for you.

Train Your Team and Refine Your Processes

Even the best strategies and fanciest software will fall short if the people using them aren’t on board and well-prepared. Inventory management is as much about people and processes as it is about systems and numbers. As you implement new goals, policies, or tools in 2026, invest time in training your team and refining standard operating procedures. This ensures that all the improvements you’re aiming for actually take root in daily operations and have a lasting impact.

Provide Comprehensive Training: Whenever new processes or systems are introduced, schedule formal training sessions for all relevant staff. Don’t assume people will just figure it out. Walk them through the new tool step by step, ideally with hands-on exercises. For instance, if you roll out barcode scanning, have a training day where everyone practices scanning items in and out, doing a mock cycle count, etc., in a test environment. The goal is to make everyone comfortable and to highlight why this new method is beneficial (e.g., “Scanning these barcodes will save you time and reduce mistakes compared to writing things down”). When people understand the value and know how to do it, they’re more likely to embrace the change.

Document Standard Operating Procedures (SOPs): Update or create SOPs for all key inventory processes. This might include how to receive shipments, how to issue parts to production, how to conduct a cycle count, how to handle returns, etc. With new tools in place, your SOP might change (for example, “all movements must be recorded in the system immediately via scan”). Write these procedures in clear, step-by-step format and make them easily accessible (perhaps as a small handbook or a digital wiki that employees can refer to). When everyone follows the same playbook, consistency and accuracy improve. In 2026, aim to eliminate tribal knowledge and replace it with standardized processes – this also helps when new employees come in or when people switch roles, as they can quickly get up to speed by reading the SOP.

Assign Roles and Responsibilities: Clarify who is responsible for what in the new strategy. For example, if you’re starting a cycle count program, decide who will coordinate it (maybe an inventory control specialist or warehouse supervisor). If you’re implementing a new software, who is the admin or point person for it? If you have multiple sites, perhaps designate an “inventory champion” at each site to monitor accuracy and be the liaison for issues or improvements. By giving individuals ownership – “Alice is responsible for maintaining the item master data; Bob oversees safety stock levels; Carol will train any new hires on inventory procedures” – you ensure accountability. It also makes it clear to employees who they can turn to with questions on a given aspect.

Foster a Culture of Continuous Improvement: Encourage your team to provide feedback and suggestions on the inventory processes. They are the ones on the ground and will often spot inefficiencies or have ideas to improve. Maybe a stockroom worker notices that certain items would be faster to pick if they were stored nearer to the packing station – let them voice that and act on it. Consider holding brief periodic meetings (perhaps monthly) just to discuss inventory process improvements. Make it safe for people to admit mistakes and learn from them. For example, if an inventory discrepancy occurred, discuss it openly: “We found we were short 10 units because receiving didn’t get recorded properly during a rush – how can we prevent that? Maybe we need a backup person to enter data during peak times.” When the team feels involved in shaping the process, they take more pride and care in their work, which boosts overall performance.

Cross-Train Staff: Flexibility is a huge asset. Cross-training team members on multiple tasks ensures that if someone is out or if a sudden surge of work happens in one area, others can pitch in. Train warehouse pickers to handle receiving, train receivers to do cycle counts, train an office person to do a physical pick if needed, etc. This breaks down silos and also gives everyone a better understanding of the whole inventory lifecycle. It’s easier to maintain accuracy and efficiency when each person knows how their role connects to the next. In 2026, perhaps set a goal that each team member learns one new inventory-related skill beyond their core job. Not only does this prepare you for the unexpected, but it also tends to increase employee satisfaction as they gain new skills and break monotony.

Monitor Adoption of New Tools: If you introduced new software or technology, keep an eye on whether it’s being used correctly. For instance, if you notice some staff still scribbling notes on paper and updating later (old habits die hard), gently remind and re-train them on using the scanners or the system directly. Sometimes additional training or simply addressing a concern (“I didn’t trust that the data saved, so I wrote it down too”) can help. Track usage metrics if the system provides them (like how many transactions are done via scanning versus manual entry, etc.). Celebrate successes as people adapt – when your team hits a milestone like “100 days with 100% transactions recorded properly,” acknowledge it.

Emphasize the Why: When asking people to change processes or put in extra effort for accuracy, explaining the “why” is crucial. For example, let them know, “By keeping inventory accurate, we avoid production stoppages and we meet customer orders on time – which secures our jobs and makes the company profitable.” Or “Using this new system might feel awkward at first, but it will save you time and avoid us having to do huge inventory recounts later under pressure.” When people see the big picture, they are more motivated. Tie it back to real outcomes: maybe share a story of how a well-executed inventory process prevented a major issue (“Thanks to our cycle count catching an error, we reordered in time and avoided a line shutdown – great job team!”).

Keep Processes Agile: While standardization is important, avoid letting your processes become too rigid or outdated. Be open to tweaking them as you learn what works best. Perhaps your initial plan of cycle counting 5 items per day is too much overhead and you realize weekly counts of 25 items in one go is better – change the SOP accordingly. Or maybe staff feedback indicates that the new software’s workflow could be adjusted (like using a different field or screen to save time) – incorporate those improvements. Agility in processes means you don’t stick with something that’s not yielding results just for the sake of policy. Continuously align the process with the goals: is this practice helping us reach our inventory goals or not? If not, change it.

In essence, your team is the engine that drives the inventory strategy. You can fuel it with great data and polish it with good tools, but without a well-trained and engaged crew, it won’t go far. By prioritizing training and clear processes in 2026, you ensure that the strategic plans translate into daily actions on the warehouse floor and in the stockroom. This human element is what turns plans on paper into real-world success. And when everyone is rowing in the same direction, you’ll find you can hit those ambitious inventory goals and then set even higher ones in the future.

Conclusion: Start 2026 with a Strategic Inventory Advantage

The new year brings new challenges and opportunities, but with a well-crafted inventory strategy, you can turn 2026 into a year of smoother operations, lower costs, and higher customer satisfaction. We’ve covered a lot of ground: from reviewing last year’s performance and setting clear goals, to balancing lean efficiency with resilient buffers, to harnessing data and modern tools like CyberStockroom, and finally empowering your team and continuously improving. It might sound like a lot of work, and it does require effort – but the payoff is a supply chain that runs with fewer surprises and a business that’s ready to seize opportunities rather than react to crises.

By preparing your inventory strategy for 2026, you’re essentially doing preventative maintenance on one of the most critical parts of your business engine. You’re ensuring that when sales surge, you’re ready to deliver; when supply hiccups happen, you have a backup plan; when management looks to cut costs, you’ve already identified waste to eliminate; and when using new technology can give you an edge, you’ve integrated it thoughtfully.

Remember that inventory management isn’t a one-time project but an ongoing discipline. Make it part of your company’s culture to value good inventory practices. When everyone from the C-suite to the stock clerk understands why inventory strategy matters (it affects cash flow, customer trust, and competitive advantage), you create an environment where these best practices will stick and continue to evolve.

So as the calendar flips and you hang up that new 2026 planner on the wall, take a moment to envision the end of the year: a well-organized warehouse (or network of warehouses) with the right stock in the right place, a happy operations team hitting their performance targets, a finance department pleased with optimized working capital, and customers getting what they need on time. That vision is attainable with the steps we’ve outlined.

New Year, New Goals, New Gains: Don’t let your inventory be an afterthought. Make it a strategic focus, and it will reward you with efficiency and growth. Start by implementing the first steps – conduct that 2025 audit, get your key people in a room to set 2026 targets, evaluate the tools you’re using – and build momentum from there. By this time next year, you’ll be able to look back and say that 2026 was the year your inventory management turned from a headache into a well-orchestrated operation.

Leave a comment