In construction, time is money – and materials are the lifeblood that keeps projects moving forward. Every construction project relies on having the right materials, tools, and equipment on site exactly when they’re needed. If you’ve ever been on a job site scrambling to find a missing tool or waiting on materials that should have arrived yesterday, you know how critical good inventory control is. When inventory is managed well, construction projects stay on schedule, and budgets remain in check, transforming potential bottlenecks into smooth workflows that boost the bottom line. But keeping projects on track isn’t just about materials – it’s also about timing. This is where project scheduling comes in, ensuring each phase of construction progresses in the right sequence and on deadline.

However, aligning inventory management with project scheduling is easier said than done. Construction companies often operate on razor-thin margins and tight timelines, so any slip-up with materials – whether it’s a shortage of rebar delaying a concrete pour or stacks of unused lumber piling up – can send a project off course. These issues aren’t minor inconveniences; they directly impact timelines, costs, productivity, and even safety on site. The good news is that with proper planning, modern tools, and best practices, contractors and project managers can tame the chaos.

The Dual Pillars of On-Time Construction: Inventory & Scheduling

Successful construction projects rest on two critical pillars: effective inventory management and precise project scheduling. Think of project scheduling as the roadmap for determining when each task and phase should occur, and inventory management as controlling the resources needed to execute those tasks. If either pillar is weak, the whole structure (i.e. the project) can start to wobble. Let’s break down each component and see how they interrelate.

Inventory Management in Construction – The Lifeblood of a Project

Inventory management in construction is more than just tracking a few materials. It’s the process of planning, ordering, receiving, storing, and tracking all the materials and equipment needed for a project. This ranges from everyday consumables (nails, screws, cables) to huge one-off items like structural steel beams or heavy machinery. In essence, it ensures the right supplies and tools are on site when required so that work can proceed on time and on budget.

Key aspects of construction inventory management include:

- Procurement Planning: Determining what materials are needed and when. This starts early, by analyzing the project’s plans and bill of materials to create a comprehensive list of required items. Long lead-time items (like custom-fabricated components or specialty equipment) are identified so they can be ordered well in advance.

- Scheduling Deliveries: Aligning material deliveries with project phases. Materials often need to arrive in a strict sequence – for example, foundation concrete before structural steel, framing materials before drywall. Good inventory management means timing deliveries so crews have what they need right as they need it, but not so early that stuff piles up and gets in the way. It’s a delicate balance: late deliveries can idle your crews, while excess materials delivered too soon clutter the site or risk damage.

- Storage and Handling: Once on site (or in a warehouse), materials must be stored safely and efficiently. Construction sites can be chaotic, with limited storage space and exposure to weather. Inventory management involves finding ways to organize materials (using laydown yards, containers, designated zones) and protect them from theft or damage – all while keeping them accessible for use.

- Tracking Usage and Stock Levels: Knowing what’s on hand at any given moment. This includes keeping accurate counts of materials and equipment, tracking where they are, and monitoring consumption rates. In construction, things are constantly moving between the main warehouse, trucks, and multiple job sites. Without a handle on this, it’s easy to lose track of items. (In fact, studies have found that construction workers spend around 10 minutes every day just looking for tools or equipment that aren’t where they should be – which adds up to an entire workweek of lost time per worker each year!)

- Replenishment and Lead Times: Reordering materials before they run out, factoring in supplier lead times. A smart inventory system sets reorder points for key items (e.g. if your stock of copper wiring falls below a threshold, trigger a new order). It also maintains a bit of buffer stock for critical materials that could hold up work if depleted. This avoids those nasty surprises where work stops because a $5 box of fasteners ran out.

- Cost Management: Materials are a huge chunk of any construction budget, so inventory control is directly tied to cost control. Overstocking ties up cash and can lead to waste if materials go unused, while understocking can result in pricey rush orders. Good inventory management finds the sweet spot, often by leveraging historical data from past projects to forecast needs more accurately. It also involves keeping an eye on material prices and supplier contracts to optimize costs.

When done right, inventory management ensures that materials and equipment are available when and where they are needed, in the quantities required – nothing more, nothing less. It’s about having “the right stuff at the right time”, which directly impacts the schedule and success of the project.

Project Scheduling – The Master Plan for Timing and Resources

On the other side of the coin is project scheduling. In construction, project scheduling is the practice of mapping out the entire project timeline, including all tasks, their sequence, duration, and the resources (labor, equipment, materials) required for each. A project schedule is typically represented in a Gantt chart or calendar that shows when each activity starts and finishes, and how tasks depend on one another.

Why is scheduling so important?

Because it’s essentially the game plan that keeps everyone coordinated. A solid schedule ensures that:

- Work happens in the correct order: You can’t install windows if the walls aren’t framed, and you shouldn’t pour the foundation after you’ve built the house! The schedule sequences activities logically (e.g., excavation → foundation → framing → roofing, etc.), often following critical path methods to identify which tasks must finish on time to avoid delaying the whole project.

- Deadlines are met: The schedule sets target dates for milestones (like “foundation complete by X date” or “project handover by Y date”). It allows project managers to monitor progress and catch delays early. If one activity slips, the schedule is updated, and everyone can see the ripple effects and adjust accordingly.

- Resources are allocated efficiently: Importantly, a good schedule accounts for when resources are needed. For instance, if the schedule shows that flooring installation starts in Week 12, the project manager knows to have flooring materials delivered by Week 11 latest. This is where scheduling ties closely with inventory management – the schedule informs the timing of procurement and delivery of materials.

- Multiple crews and trades coordinate: Construction involves many different trades (concrete, steel, plumbing, electrical, etc.), often working one after the other or sometimes in parallel. The schedule ensures these teams aren’t stepping on each other’s toes and that prerequisites are completed. For example, the electricians know when the walls will be open for wiring, and the drywall crew knows when they can start closing them up.

- Contingencies are planned: Good schedules include some buffer or contingency for weather delays, unforeseen site conditions, or other surprises. When something unexpected happens (a week of rain, a permit delay), the schedule can be adjusted – but that might also mean adjusting inventory plans (e.g., delaying a material delivery or finding short-term storage if something arrived early).

In short, project scheduling is the time-management counterpart to inventory management’s resource focus. It provides the when to the inventory’s what. And only when both are in sync can a construction project truly stay on track.

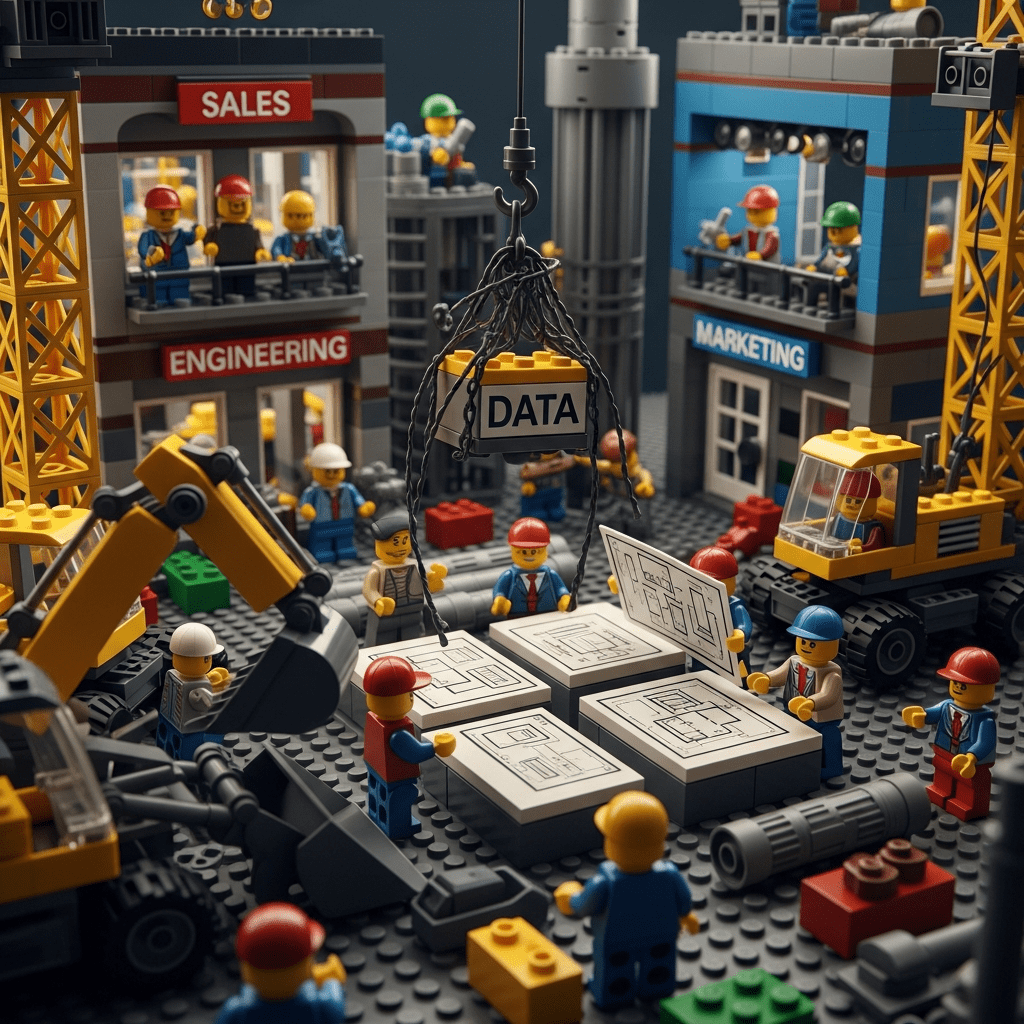

Where Inventory and Scheduling Intersect

Consider a simple scenario: pouring a concrete foundation. The project schedule says the foundation pour is set for July 15th. Working backwards, the project manager knows forms must be set by the 14th, excavation done by the 10th, etc. From an inventory standpoint, several things need to happen in lockstep:

- Rebar (reinforcing steel) must be on site and installed before the pour.

- The concrete plant delivery must be booked for that date and time.

- Formwork panels and related hardware need to be available for the crew to set up beforehand.

- The right equipment (mixers, vibrators, etc.) should be scheduled and on site.

If any one of those inventory pieces is missing or late – say the rebar delivery is delayed or wasn’t ordered far enough in advance – the entire schedule can slip. The crew might be left idle waiting, and you might even miss your concrete pour slot (which, in busy seasons, could push the pour by days). This cascade illustrates how inventory issues become schedule issues.

Conversely, if the schedule changes (maybe the excavation hit unexpected rock and took an extra week), it affects inventory: you might need to delay deliveries of materials to avoid having them sit around, or find temporary storage if they’re already in transit. The project schedule and the procurement schedule have to talk to each other constantly.

A key concept that successful contractors use is the procurement (or material) schedule – essentially a sub-schedule that outlines when each material will be ordered, shipped, delivered, and used. This is aligned with the main project timeline. For example, long-lead items like custom windows or a steel beam might be ordered 3-4 months before needed on site, with the procurement schedule tracking that process to ensure timely delivery. A procurement schedule helps avoid last-minute scrambles and ensures that procurement activities don’t lag behind construction activities.

In modern, complex projects, inventory management and scheduling are often integrated through software. Some advanced project management systems connect inventory data with the project plan, so that as tasks progress, the system can automatically update stock levels or flag upcoming material needs. Even if you’re a smaller firm not using a fancy integrated system, the principle stands: to keep a project on track, you must coordinate the flow of materials with the flow of work.

So, the take-home point is: Project scheduling and inventory management are two sides of the same coin. Scheduling sets the pace; inventory provides the fuel. If the schedule is the “when” and “who,” inventory is the “what” and “where.” Only by managing both together can you avoid the common pitfalls that lead to delays, cost overruns, and chaos on the job site.

Next, let’s look at those pitfalls – the typical challenges that tend to throw projects off schedule – and how to address them.

Common Inventory Management Challenges that Derail Schedules

Construction inventory management is notoriously challenging. Unlike a factory that churns out the same widgets every day, construction projects are one-of-a-kind endeavors with a constant churn of different materials, changing site conditions, and multiple moving locations. Below are some of the biggest inventory-related challenges that construction teams face, especially when it comes to keeping projects on schedule. Recognizing these problems is the first step to solving them.

1. Inaccurate Inventory Data

One pervasive issue is simply not knowing what you actually have on hand (and where it is). It’s all too common to find that the numbers in the spreadsheet or procurement report don’t match reality on site. Perhaps your records say there are 50 light fixtures in the warehouse, but only 30 are actually on the shelf. Or a tool was checked out to a crew but never logged back in. These discrepancies arise from human error in record-keeping, lack of real-time updates, or reliance on outdated manual tracking methods (pens, paper, and Excel files prone to typos).

Why it derails projects: When inventory counts are wrong, you get unpleasant surprises. You might schedule work thinking you have enough material, only to discover a shortfall at the worst time (e.g. the electrician is ready to go, but you’re actually missing half the conduit needed). This leads to work stoppages and urgent reorders. Conversely, bad data can cause over-ordering – you buy items you already have in some corner, wasting money and cluttering the site. Both scenarios can throw off the project timeline. For example, if your system mistakenly showed plenty of copper wire in stock and you didn’t order in time, your electrical work could be delayed waiting for an emergency delivery.

Solution approaches: Conduct regular inventory counts and reconciliations (don’t wait for year-end; do cycle counts on a rotating basis). Use a real-time tracking system (more on that later) – barcodes or RFID tags on materials can make updates instantaneous when something is moved or used. And importantly, train your team to diligently record every withdrawal or movement of inventory. Having one centralized, cloud-based inventory log that everyone updates ensures that all stakeholders (warehouse managers, site supervisors, project managers) are seeing the same information at all times.

The payoff of accurate data is huge: you can trust your inventory records when making decisions, avoiding nasty last-minute surprises that wreak havoc on the schedule.

2. Unpredictable Demand and Scope Changes

Construction projects rarely go exactly as originally planned. Demand for materials can be a moving target. Maybe the project scope changes mid-stream (the client adds a new feature or design changes require different materials), or perhaps weather delays and resequencing of tasks means materials are used at different rates. Forecasting how much of each material you’ll need, and when, is tricky when things keep shifting.

Why it derails projects: Poor forecasting usually leads to either running short or overstocking. Understocking a critical item – say you underestimated the number of cinder blocks needed and run out halfway through a wall – causes work to halt until you get more. That idle time can push the whole schedule out (imagine multiple crews twiddling their thumbs because one material is missing). On the other hand, overstocking by overestimating demand means you’ve spent extra money and filled up space with stuff that might not be used. Those surplus materials can clutter the site (impeding progress) and may tie up funds unnecessarily. If plans change and those materials are no longer needed, that’s wasted budget and effort handling them. In short, unpredictable demand makes it hard to perfectly time inventory to the schedule.

Solution approaches: Embrace data and flexibility. Use historical data from past projects to inform your estimates – if similar projects consistently used 5% more concrete or 10% less piping than planned, adjust your new project forecasts accordingly. Maintain open communication with the project team so you hear about scope changes or potential design modifications early, and can adjust orders. Some contractors adopt a hybrid strategy between Just-in-Time and Just-in-Case inventory. That is, keep a small buffer stock of critical items (your “just-in-case” safety net) while trying to schedule regular deliveries just in time for use. Another tip: identify items that are at risk of change (like something that could be value-engineered out) and hold off on bulk ordering those until necessary, even if it means a separate order later. Agile project management techniques – breaking work into smaller chunks and reviewing needs frequently – can also help adjust inventory plans on the fly. The goal is to stay responsive so that when the project schedule shifts, your inventory plan can shift with it, minimizing downtime.

3. Supplier Delays and Long Lead Times

Even with perfect planning on your end, sometimes the supply chain throws a curveball. Key materials might have long manufacturing lead times or come from distant suppliers. And vendors can run into their own issues – stock shortages, shipping delays, factory errors, you name it. In recent years, construction has felt the pain of global supply chain disruptions (for example, sudden spikes in lumber or steel prices and availability). If a supplier doesn’t deliver on time, your carefully crafted schedule can crumble.

Why it derails projects: Many construction tasks are sequential and interdependent, so a delay in one material can hold up a whole chain of activities. If the custom windows are late, you can’t finish closing in the building, which might delay interior work, which then delays finishing trades, and so on. Additionally, if materials arrive late, you might have crews and equipment standing by with nothing to do – a direct hit to productivity and cost. Alternatively, to avoid delays, you might pay extra for faster shipping or last-minute purchasing from a different source ata higher cost. All these disrupt the planned schedule and budget.

Solution approaches: Contingency planning is key. Identify which items are critical path (i.e. their delay would delay the project) and have backup options. This could mean pre-qualifying alternate suppliers, or at least knowing emergency procurement options. For long-lead items, order them as early as possible and get updates from the supplier regularly – if a delay is looming, you want to know ASAP to rework the schedule. Some contractors build a bit of buffer into the schedule for procurement of risk-prone items. Also consider flexible contracts with suppliers if possible (to adapt to changes without huge penalties). Another tactic: stagger deliveries for large quantities instead of one big batch, so if one shipment is delayed, it doesn’t halt everything (assuming initial batches are enough to start work). Lastly, maintain good relationships and communication with vendors – being a valued partner might put you at the top of their priority list when supply is tight.

4. Theft, Loss, and Mishandling

Construction sites are notorious for things “walking away.” With numerous workers, subcontractors, and sometimes minimal security, theft and loss of materials or tools is an ever-present problem. Equipment might get left in an unlocked area and stolen overnight, or smaller tools simply vanish. In other cases, items are misplaced – left at the wrong location, or buried under debris, only to be “found” after you’ve already bought replacements. Additionally, mishandling or poor storage (exposed to rain, dropped from a height) can render materials unusable, effectively causing a shortage when you thought you had enough.

Why it derails projects: If critical materials or equipment go missing, you’re in the same boat as if you under-ordered – facing potential delays while replacements are procured. Theft can be especially damaging if the item is specialized or expensive (imagine your only generator being stolen; now you can’t power your tools in a remote site until you get another). Even smaller losses add up; for example, missing power tools mean workers spend time searching or sharing tools, slowing down work. Beyond schedule impact, theft and loss hit the budget and can cause project managers to pad orders “just in case,” which again ties up resources inefficiently.

Solution approaches: Secure your inventory. This means physical security (fences, locks, cameras, security personnel after hours) as well as procedural controls. Use locked storage containers for valuable items and implement check-in/check-out systems for tools so there’s accountability (who had it last?). Many companies mark or tag their equipment – even using GPS trackers on high-value items like loaders or generators – so if something goes missing, it might be traceable. Good site organization also helps: if everything has a designated place and is returned there, it’s easier to notice if something’s amiss. Training crews to take inventory of their tools at day’s end can catch losses quickly. Also, consider insurance for theft on big ticket items, which doesn’t prevent delays but can mitigate financial loss. On the tech side, an inventory system that logs usage can flag unusual patterns (e.g., a sudden drop in stock that might indicate theft). The bottom line is a proactive approach to prevent theft and loss will save you from the scramble of replacing vital items mid-project.

5. Poor Communication

Construction involves numerous stakeholders – project managers, site superintendents, warehouse managers, procurement officers, subcontractors, etc. If these parties aren’t in sync regarding inventory needs and status, things fall through the cracks. Perhaps the site crew assumes the warehouse ordered more concrete, while the purchasing team thought the site was going to request it – result: nobody orders it and you run out. Or a delivery arrives on site, but the site team wasn’t expecting it that day, so it sits unprotected or even gets turned away. Lack of communication and using disconnected systems (like one team on spreadsheets, another on a different software) can create costly mix-ups.

Why it derails projects: Miscommunication can lead to double-ordering or, worse, no ordering of something crucial. It can also mean materials are delivered to the wrong place or at the wrong time. For instance, if the procurement office isn’t updated that the schedule shifted, they might not postpone a shipment, causing it to arrive before the site is ready (and perhaps no one to receive it or nowhere to store it). Alternatively, if a schedule acceleration isn’t communicated, the site may expect materials that haven’t actually been expedited. These disconnects often result in delays, rework, or idle time while issues get sorted out.

Solution approaches: Establish clear, cross-functional communication channels and responsibilities. Some best practices include: having a single point of contact for inventory at each site (so everyone knows who to call about material status), holding regular coordination meetings or calls between the project management team and procurement/warehouse teams to review upcoming needs, and using standardized forms or requests for materials. If possible, use a unified inventory management system accessible to all stakeholders – when materials are received, used, or transferred, it’s logged in one place that everyone can view in real time. This way, a site supervisor can check the system to see if an item was ordered or if it’s available at another site, without a dozen phone calls. Encourage a culture where field staff promptly report any potential shortfalls or changes in usage, and office staff inform field teams of order statuses. When everyone’s on the same page, it prevents those “I thought you were handling it!” moments that can derail a project.

6. Storage Constraints and Material Handling on Site

Construction sites, especially in urban or confined areas, often have very limited space to store materials. This means if items arrive too early, they might clutter the site, block work areas, or need to be moved multiple times (wasting labor and risking damage). Conversely, a strategy of “deliver just in time to use” can backfire if there’s any hiccup and materials arrive late – since there’s no buffer, work grinds to a halt. Striking the right balance is tough. Additionally, once materials are on site, if they’re not stored and organized properly, workers can waste time searching for them (which ties back to the lost time issue).

Why it derails projects: Space issues can slow down work – e.g., if a truckload of drywall is sitting in the area where you needed to set up scaffolding, you either waste time moving it or delay the work. Or if materials are haphazardly piled, retrieving them takes extra time and can be a safety hazard. Multiple handling of materials (moving them around the site repeatedly) is not only inefficient time-wise, but increases the chance of damage or loss. In worst cases, if a site literally can’t find room for something delivered early, they might refuse a delivery, leading to schedule slips waiting for re-delivery. On the flip side, minimal on-site inventory means any delivery delay immediately causes downtime since there’s no slack.

Solution approaches: Optimize storage and delivery timing. Use off-site warehouses or laydown yards when possible to hold materials and feed them to the site in manageable quantities. Within the site, implement some of the storage best practices: designate specific zones for different materials (e.g., lumber in one area, plumbing supplies in another) and store items near where they’ll be used (like pallets of tiles on the floor they’ll be installed, rather than all at the ground level). Use vertical space (racks, shelves) or containers to maximize space and protect materials. Make one person (or crew) responsible for keeping the storage area organized and tracking inventory on site. As for scheduling deliveries, coordinate with suppliers to deliver in smaller batches if large deliveries would overwhelm the site. Many projects create a Just-in-Time delivery schedule: for instance, instead of receiving all 100 doors at once, get 20 at a time the week before each group of installations. This requires careful planning and good supplier coordination, but it can keep the site lean. The goal is to minimize material sitting idle on site while also ensuring it’s there before it’s needed – a balancing act that, when achieved, greatly boosts efficiency.

Best Practices for Aligning Inventory Management with Project Schedules

To keep a construction project running like a well-oiled machine, you need to be proactive about how you manage inventory in relation to your schedule. The following best practices represent a compilation of proven strategies – from planning techniques to technology tools – that construction companies use to ensure materials and timelines stay in sync. By implementing these, you can significantly reduce delays, avoid cost overruns, and improve overall efficiency on your projects.

1. Integrate Procurement Planning into the Project Schedule

Don’t treat purchasing and scheduling as separate silos. At the project planning stage, develop a detailed procurement schedule alongside your construction schedule. Identify all key materials and long-lead items, and assign order-by and delivery dates to each. This should factor in supplier lead times, transit durations, and time for inspections upon arrival. By scheduling material orders and deliveries as project tasks or milestones, you create accountability and visibility. For example, if structural steel erection is in March, the procurement schedule might show “Order steel by January 5th” and “Steel delivery by March 1st” as linked items. Project management software or even a simple shared spreadsheet can help track these dates. Integrating procurement into your main timeline means that when the project timeline shifts, you’ll also adjust order and delivery dates in tandem, preventing mismatches.

2. Forecast and Build Buffers Using Data

Leverage historical data and industry benchmarks to forecast material needs more accurately, and consider buffer stock for critical items. If past projects show you often use a bit more of certain materials than estimated (say 5% extra drywall or concrete), factor that into your orders (or at least be aware and monitor usage closely). For items that could halt work if missing (like fasteners, safety gear, or common lumber sizes), it’s wise to keep a small safety stock on hand. This acts as a cushion for minor overruns or delays in resupply. The key is balance: buffers should be strategic – enough to cover uncertainties, but not so much that you bloat inventory across the board. Also, identify potential forks in the road: for instance, if a design decision is pending that could affect material choice (e.g., type of flooring), avoid committing to huge orders until finalized. In sum, plan with the best info available, add contingency for the unknowns (both time and quantity), and continuously refine your forecasts as the project progresses.

3. Centralize Inventory Information with Cloud Tools

Many of the challenges of miscommunication and inaccurate data can be solved by moving away from isolated spreadsheets and onto a central, cloud-based inventory management system. Modern inventory software tailored to construction can track materials across multiple locations in real time. By having one source of truth that everyone can access – whether they’re in the office or on the job site – you eliminate confusion over which numbers are correct. Look for systems that allow updates from the field (e.g. via mobile device or tablet) so that when a delivery is received or materials are used, the stock levels update immediately for all to see. A centralized system can also integrate with other functions like project management or accounting, tying material usage to specific jobs or cost codes. Even if you’re a small company, there are affordable inventory apps that vastly outperform manual methods in accuracy and convenience. The bottom line: when all teams reference the same live data, decisions and coordination become much easier and mistakes become fewer.

4. Standardize Inventory Processes and Train Your Team

Consistency is king. Establish standard operating procedures for how inventory is managed across all your sites and projects. This includes how items are labeled, how/when to do counts, how to request new stock, and how to handle transfers between locations. For example, implement uniform naming and coding for items (so “½” plywood” isn’t called “Half Ply” by one person and “0.5in sheet” by another – which could confuse counts). Create a simple process for field personnel to requisition materials or report low stock – perhaps a standard form or a mobile app workflow. Ensure that every material delivery comes with proper documentation and that someone is responsible for immediately checking it against the order and updating the inventory records. Likewise, define how tools are checked out and checked in, and what info needs logging (who took it, expected return date, etc.). Once these practices are defined, train your team and explain why it matters. When everyone follows the same playbook, there’s far less chance of items slipping through cracks or data getting bungled. It also makes it easier to onboard new employees, since they have a clear guide. Standardization might sound a bit tedious, but it pays off in enabling smoother, more predictable operations across the company.

5. Conduct Regular Cycle Counts and Audits

Waiting until year-end to do a full inventory count is a recipe for surprises. Instead, adopt a cycle counting program – where you count subsets of inventory on a rotating basis (say weekly or biweekly), so that over a few months you’ve audited all key items. Focus more frequent counts on high-value or fast-moving items (maybe count the copper pipes and contractor packs of nails monthly) and less frequent on rarely used stuff. Regular audits will catch discrepancies early, allowing you to reconcile records before they become major issues. It’s much better to discover you’re 5 bags of cement short a week before the pour than on the morning of the pour. Additionally, do a quick inventory check before major phases start – e.g. in the week before the roofing crew mobilizes, verify that all roofing materials are indeed on hand and in the expected quantities. These proactive checks act as fail-safes against schedule slips. And if the thought of frequent counts sounds labor-intensive, remember that technology like barcode scanning can speed this up dramatically, making counts a quick task rather than an all-day slog.

6. Improve Communication Between Field and Office

Make it a priority to break down communication barriers between the jobsite and the office. This could mean daily or weekly check-ins specifically about inventory status and upcoming needs. For instance, a weekly inventory meeting might include the project manager, site supervisor, and procurement manager to review what’s running low, what’s coming up next in the schedule, and any issues or changes. Encourage site crews to report any material shortages or overages promptly, rather than hoping they’ll resolve themselves. Implementing something like a shared chat group or channel for each project can be handy – e.g., the site foreman can snap a photo of a nearly empty materials rack and send it as a heads-up to procurement. Also, when deliveries are en route, ensure the site knows exactly when to expect them and has prepared space. Many firms use delivery logs or tickets that the site must sign off, which then gets back to the office to close the loop. Essentially, strive for a culture of “no surprises.” Everyone should feel it’s better to over-communicate about a potential problem or change than to assume someone else knows. By tightening communication, you’ll prevent a lot of small problems (like “I thought those pipes were arriving today!” – “No, we scheduled them for next week!”) from ever occurring.

7. Optimize On-Site Storage and Material Layout

Efficiency on site isn’t only about what and when – it’s also where. Take the time to plan your site logistics for material storage and flow. A well-organized site can save hours of labor and keep the schedule on track. Some best practices include: using laydown yards or staging areas where deliveries are first received and sorted; clearly marking zones for different trades or phases (e.g., an area for mechanical ductwork vs. an area for finish materials); and storing items as close as feasible to where they’ll be installed. If your project is a multi-story building, consider setting up mini-storage areas on each floor for the materials needed there, replenished as needed. Also, ensure that pathways are kept clear and safety is maintained – a cluttered site not only slows work but risks accidents. Appoint a team member or a rotating responsibility to act as the “material coordinator” on site, who keeps an eye on the inventory organization daily. They can ensure, for instance, that pallets are stacked safely, or that the next day’s needed materials are positioned in the work zone. When materials are easy to find and access, crews spend more time building and less time fetching or moving things around – which directly translates to staying on schedule.

8. Use Technology for Real-Time Tracking and Alerts

Leverage the power of technology to get ahead of inventory issues. Modern inventory management systems often include features like low-stock alerts – you set minimum levels for important items, and the system pings you when you dip below them, giving you lead time to reorder. Some systems can forecast usage based on your construction schedule (for example, if you log that you’ll need 500 bricks for a certain task next week, the system can warn if you don’t currently have that in stock). Barcode and QR scanning can make updating inventory a breeze – scanning materials as they arrive on site or as they are used means your digital inventory is always up to date, without manual entry errors. For equipment, consider asset tracking solutions – there are tagging systems that let you check where a piece of equipment was last scanned or even GPS-tagged tools to monitor their location. Additionally, digital solutions can help with documentation – attaching photos of deliveries, packing lists, or even keeping a log of who checked out which tool and when. The construction industry has been historically slow to digitalize, but that is rapidly changing; today there are many user-friendly apps and cloud platforms (including specialized ones for construction inventory) that don’t require a steep learning curve. By having real-time data and automated reminders, you essentially create an early warning system that keeps small hiccups from turning into schedule crises.

By implementing these best practices, you build a robust framework that keeps your project’s supply of materials flowing smoothly in tandem with the project timeline. Of course, even with perfect practices, the unexpected can still happen – but you’ll be in a much better position to adapt and respond if you’ve laid the groundwork above.

How CyberStockroom Helps Keep Construction Inventory on Track

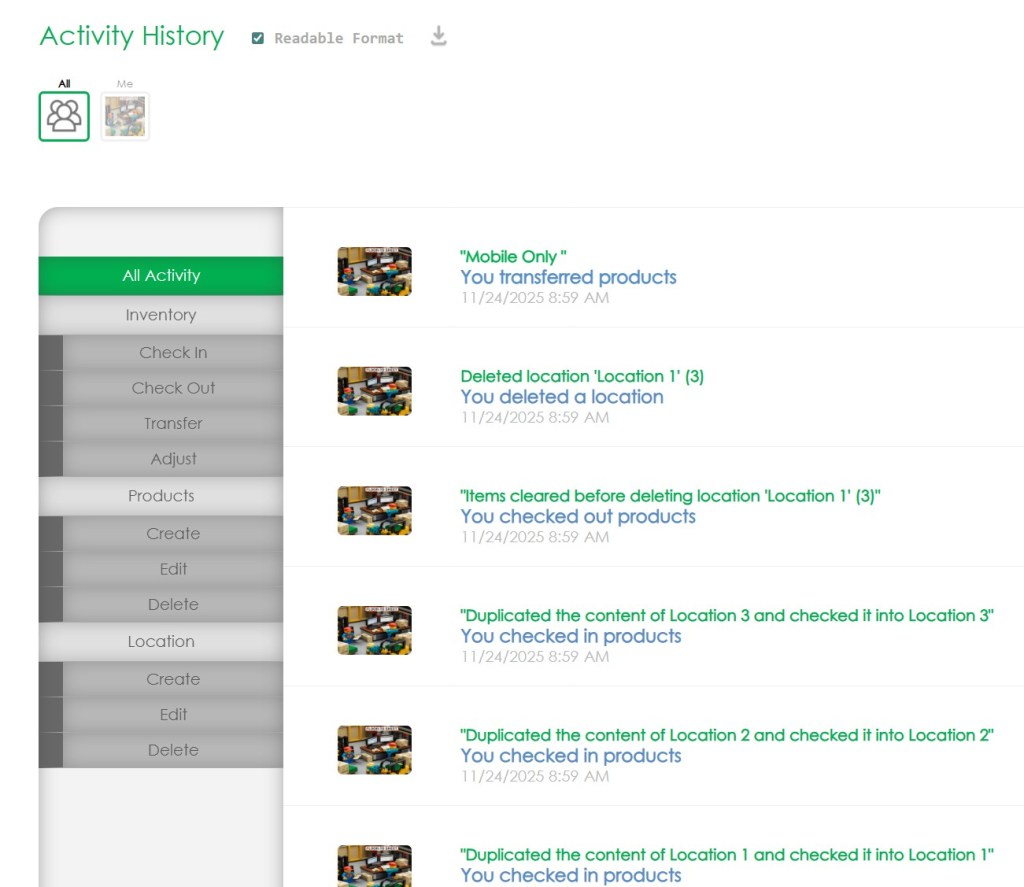

In today’s tech-driven world, having the right software tool can significantly enhance your inventory management and coordination with project schedules. One such tool built with construction and field operations in mind is CyberStockroom. CyberStockroom is a cloud-based inventory management platform that takes a unique visual mapping approach to track your materials, tools, and equipment across all locations in real time. Let’s explore how a solution like CyberStockroom can directly address many of the challenges we discussed and help your team maintain control over inventory throughout a project.

Visual Inventory Mapping for Clarity and Communication

Unlike traditional inventory systems that show you just lists or spreadsheets of items, CyberStockroom lets you create an interactive map of your operations – whether it’s a map of your construction site, warehouse, laydown yard, or all of the above. For construction, this means you can virtually map out all key areas: the main warehouse, each job site, specific zones on a site, and even vehicles or storage trailers. On this map, every item is represented in its location, giving you a bird’s-eye view of where everything is.

This visual layout is incredibly intuitive – crews and managers can just glance at the map and instantly understand inventory distribution. This greatly improves communication: field teams and office staff are literally looking at the same picture, which minimizes confusion about where something is or whose responsibility it is. If a project manager wonders, “Do we have more 2-inch pipe couplings, and where are they right now?”, they can see on the map that, say, 50 are in the central warehouse and 20 are at Jobsite B. No need for 5 phone calls – the info is at everyone’s fingertips.

Real-Time, Multi-Location Tracking

CyberStockroom is cloud-based and updates in real time. This means whether you’re at the head office, in a regional warehouse, or out on a job site with your phone or tablet, you’re all seeing the latest data. When someone moves inventory – for example, transfers a pallet of cement from the warehouse to a jobsite, or a crew member checks out a laser level from the tool crib – that movement can be recorded instantly (via a quick drag-and-drop on the map or scanning a barcode). Instantly, everyone knows the new location and quantity. This tackles the problem of inaccurate data and delays in updates: there’s no “lag” where one hand doesn’t know what the other is doing. All locations are connected – you can manage inventory across multiple active projects at once, which is great for contractors juggling several jobs. It ensures that if one site is short on something, you can quickly see if another site has extras, facilitating resource sharing to avoid emergency orders.

Easy Organization and Faster Retrieval

The map-based approach encourages better organization. Because you define and label every zone or container on the map, it forces a certain discipline in the real world too: you’ll label shelves, bins, and yard sections accordingly. CyberStockroom’s interface allows you to drill down into each location – e.g., clicking on the “North Laydown Yard” might show sub-locations like “Steel Beams Stack” or “Formwork Pile” with the counts of items there. This level of detail means no more wandering the site wondering where something is stored – you can find it virtually and then go straight to the physical spot. And if something isn’t where it should be, that becomes apparent quickly, helping to prevent loss. One of CyberStockroom’s aims is to reduce search time drastically. As we noted earlier, workers lose hours looking for misplaced tools – an issue this system can mitigate by making inventory locations transparent to everyone.

Inventory by Project, Team, or Phase

Construction inventory isn’t just about where things are, but often who or what they’re assigned to. CyberStockroom allows you to track inventory by project, team, or even individual. For example, you could map out your company’s crews or departments – say “Electrical Crew Truck” or “Crew A – Tools Container” – and assign items to those on the map. This is hugely beneficial for accountability and scheduling: if each crew has certain tools allocated, you’ll know who has what and when it’s available. It helps avoid scheduling conflicts like two teams needing the same equipment on the same day – the map can show that the concrete crew has the generator today, so the paving crew needs to plan around that. Essentially, CyberStockroom’s flexibility in mapping means you can align it with how you schedule work (by location, by team, by phase). During planning, you might allocate certain materials to a future phase; on the map, you could place those materials in a “holding” location for that phase or tag them for that purpose, so they’re reserved and visible as such.

Barcoding and Rapid Updates

To make the process of recording inventory changes quick and error-free, CyberStockroom supports barcoding. You can generate barcode labels for items or pallets; then, using a scanner or even a smartphone camera, you can scan items as they move in or out. This automatically updates quantities in the system without manual data entry. For a construction context, imagine pallets of materials coming in – the receiving clerk scans the delivery, it’s instantly logged as “on site” in the system. Later, as those materials are consumed, a site worker could scan the last bag used and mark the stock as low, triggering an alert for restock. Barcoding reduces the chance of forgetting to update something or typing the wrong number. CyberStockroom also lets you import data from files and integrates with certain systems, making it easier to get started without tedious setup.

Loss and Theft Prevention Features

We discussed theft and loss as a big issue. CyberStockroom can help here as well. By keeping a clear record of where each item is and who moved it when, it creates accountability. If a tool assigned to “Jobsite X – Tool Crib” suddenly isn’t there, you can see from the logs who last checked it or moved it. This kind of audit trail can deter casual theft and encourage employees to be responsible.

Some systems, CyberStockroom included, allow you to set permissions and user roles – for instance, requiring a supervisor’s approval to mark certain high-value items as transferred. Also, because the system updates in real time, if something is missing, you’ll catch it sooner rather than at the next quarterly audit. That 24/7 visibility (even from your phone at home) means no more guessing or nasty Monday morning surprises – you can check over the weekend if everything’s secure or if an unexpected movement happened Friday evening.

In summary, CyberStockroom acts as a force multiplier for your inventory management efforts. It encapsulates many best practices – such as centralization of data, real-time updates, clear assignment of items to locations/teams, and ease of audits – within one tool. By using a platform like this, a general contractor or inventory manager at a small construction firm gains capabilities that previously only big companies with custom systems had. It’s worth noting that while technology like CyberStockroom can greatly assist, it works best in tandem with the processes and culture we discussed earlier. In other words, you still set the strategy (when to order, how to organize), but the software makes executing that strategy far more efficient and foolproof. For any construction team struggling with inventory chaos and its ripple effects on schedules, adopting a modern inventory management system can be a game-changer in keeping projects on track.

Conclusion: Building Success with Coordinated Inventory and Scheduling

In the fast-paced world of construction, keeping projects on track requires a harmonious dance between planning and execution, between having a solid schedule and making sure the resources to meet that schedule are at hand. We’ve seen that inventory management and project scheduling are deeply interconnected – like two gears that must mesh smoothly. If one gear slips, the whole machine can grind to a halt. By now, it should be clear that investing time and effort into improving your inventory practices isn’t a “nice to have” – it’s a must for any contractor or project manager who wants to deliver projects on time and within budget.

Let’s recap some key takeaways:

- The right materials, in the right place, at the right time – that mantra is at the core of construction success. Effective inventory management ensures that what you need is available when you need it, thus directly supporting your project schedule. It prevents those dreaded downtime moments when workers stand idle, and it cuts down on costly last-minute runs or shipping fees.

- Common pitfalls are avoidable. Issues like missing stock, supplier delays, or lost tools are not just “bad luck” – they often result from lack of planning or oversight. By recognizing challenges (from data inaccuracies to theft) and addressing them proactively with best practices, you can significantly reduce surprises and disruptions.

- Plan, plan, plan – but stay flexible. Up-front planning via integrated procurement schedules and forecasting pays huge dividends. However, construction is dynamic, so the ability to adjust (with contingency plans and real-time info) is equally important. A well-coordinated team that communicates changes early will navigate the unexpected far more gracefully.

- Technology is your ally. Modern construction management is as much about smart use of tools as it is about bricks and mortar. Adopting a system like CyberStockroom for inventory visibility, or any reliable inventory management software, can elevate your control to new heights. These tools don’t replace good management – they amplify it. They handle the heavy lifting of tracking and updating, freeing your team to focus on decision-making and problem-solving.

- Small companies can benefit just as much as large ones. If you’re a small construction firm or a general contractor running a few projects a year, you might feel that sophisticated inventory management is something only big players worry about. But even on a modest scale, the principles apply: a delay on a small project can be just as damaging proportionally, and a bit of organization can save you thousands and lots of stress. The strategies we discussed – like cycle counts, standardization, or using a visual map – can be scaled to any size. In fact, smaller teams can implement changes faster and with more agility.

- People and culture matter. Lastly, remember that systems and processes work only if people follow them. Fostering a culture where field crews understand the “why” behind inventory protocols, and where office staff appreciate on-site challenges, creates mutual respect and diligence. When everyone is invested in the common goal of smooth inventory flow and hitting schedule milestones, it becomes part of the company’s DNA. Success stories in construction often boil down to teams that are proactive, communicative, and accountable.

By keeping a firm grip on inventory management and seamlessly weaving it into your project scheduling, you’re essentially building a safety net for your project. You’re insulating it from many of the common risks that cause delays and budget blowouts. Sure, not everything is under your control – there will always be external factors like weather or market volatility – but by controlling the controllables (materials, equipment, information flow), you put your project in the best possible position to adapt and thrive despite those challenges.

Ultimately, great inventory management and scheduling is about delivering on promises: the promise to your clients that their project will be done on time, the promise to your team that their work won’t be held up by avoidable issues, and the promise to your business that projects will be profitable and efficient. By applying the guidance from this explainer and utilizing tools like CyberStockroom to boost your capabilities, you can keep your construction projects on track and set your company up for repeat success.

Remember, a well-built project starts with a well-built plan – and that plan must include not just what to build and when, but also how to get the materials there in time to make it happen. With that holistic approach, you’ll be constructing not only buildings, but a reputation for reliability and excellence in execution. Here’s to building smarter, faster, and right on schedule!

Leave a comment