Construction projects run on tight margins and even tighter schedules. Yet one of the most common challenges that derails both is material cost overruns – when you spend more on materials than budgeted. If you’re a construction project manager, inventory supervisor, or small contractor, you’ve likely felt the pain of an unexpected bill for extra lumber or rushed cement deliveries blowing your budget.

In fact, industry surveys have found that the majority of projects end up over budget, with materials often a major culprit. The good news is that it doesn’t have to be this way. By mastering the basics of construction project inventory budgeting and implementing smart inventory control, you can keep material costs in check and protect your project’s bottom line.

Construction materials – from steel beams and lumber to nails and cement – often account for a large portion of a project’s expenses. With prices for many building materials skyrocketing in recent years and supply chains prone to disruption, staying on budget requires proactive planning and vigilant management of these resources. Inventory budgeting is essentially the process of planning, allocating costs for all needed materials, and then managing those materials efficiently throughout the project so you don’t overspend.

Think of it as mapping out your project’s material needs and costs from day one, and then continuously tracking and adjusting to stay on course. In this how-to guide, we’ll walk through concrete steps and best practices for effective inventory budgeting in construction.

The High Cost of Material Overruns (and Why They Happen)

Before diving into solutions, it’s important to understand why material cost overruns are so common in construction. Knowing the root causes will help you target them head-on.

Here are some of the biggest factors that lead to overspending on materials:

- Inaccurate Estimates Upfront: A project’s fate is often sealed at the planning stage. If your initial material takeoffs and cost estimates are off, you’ll either run short (requiring expensive last-minute purchases) or over-order (wasting money on unused stock). Underestimating needs leads to budget-busting emergency orders, while overestimating means you paid for inventory that sits idle. Accurate estimating is the foundation of inventory budgeting, and any cracks in that foundation can cause costs to crumble later.

- Price Volatility and Inflation: Construction material prices can fluctuate dramatically. We all saw this during recent years when lumber, steel, and other materials spiked in price by double digits. If your project budget was set before a price surge, you could blow past it even if you use the exact quantities planned. Inflation and market volatility mean you have to budget for possible increases or lock in prices in advance. Without precautions, a sudden price jump on key materials can wreak havoc on your costs.

- Waste and Inefficient Use of Materials: On many jobsites, a significant percentage of materials end up as waste – off-cuts thrown away, concrete that hardens unused, excess tiles that get discarded, etc. It’s been estimated that around 10% or more of construction materials on a typical project go to waste due to over-ordering, damage, or misuse. That’s effectively money thrown in the dumpster. Poor handling and storage (letting materials get ruined) and lack of reusing leftover materials will drive your effective costs up and blow your budget with little to show for it.

- Theft, Loss, and Misplacement: Construction sites unfortunately are magnets for theft and losses. Valuable materials and equipment can “grow legs” if not secured – it’s estimated over $1 billion worth of construction materials and tools are stolen each year in the U.S. Even on smaller sites, missing bundles of copper wire or a few power tools here and there add up. Aside from outright theft, materials might simply get lost or buried on a chaotic site. Every time something needs to be re-purchased because the original went missing, your budget takes a hit.

- Scope Changes and Poor Communication: Construction projects are dynamic – plans change, designs get tweaked, or unexpected issues arise (like discovering you need extra rebar in a foundation). If there isn’t a clear process to handle change orders or if the project scope grows without re-budgeting for added materials, cost overruns are inevitable. Additionally, miscommunication between teams can cause budgeting nightmares: for example, the site crew might not tell the purchasing department that they already have ten pipes left from a previous phase, so more gets ordered unnecessarily. Siloed systems or lack of real-time info sharing means materials might be ordered twice or not at all, both of which burn money (either via double spending or work delays).

- Long Lead Times and Over-Buffering: To avoid running out of materials due to slow deliveries, contractors sometimes over-order “just in case.” While having a buffer stock can prevent schedule delays, excessive stockpiling ties up cash in inventory that may never be used. It’s a tricky balance – order too late and you risk delays (which can incur overtime costs), but order too much too early and you risk overshooting the budget and potentially wasting materials if plans change. Supply chain delays in recent years have only worsened this dilemma, leading some projects to hoard materials as insurance, at the expense of their budget.

As you can see, a lot of these issues boil down to one thing: lack of control and visibility. If you don’t have a firm grasp on what you need, what you have on hand, and what’s happening with your materials throughout the project, costs can spiral out of control. This is where inventory budgeting and management comes in as the hero to save your project.

What Is “Inventory Budgeting” for a Construction Project?

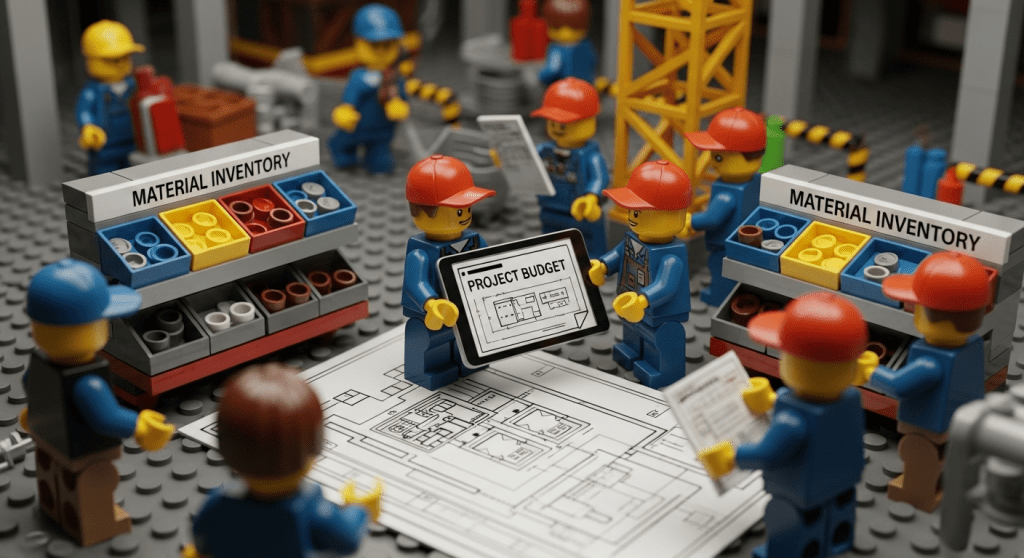

Inventory budgeting in construction is the process of planning and managing the costs of materials (and other inventory like equipment or consumables) throughout a project’s lifecycle. It starts before ground is ever broken, by carefully estimating the quantity and cost of every significant material your project will require. This initial budget becomes part of your project bid or plan. But it doesn’t stop there – once the project is underway, inventory budgeting means actively monitoring material usage and spending, adjusting orders and stock levels as needed, and making sure you’re getting the best value for every dollar spent on inventory.

In simpler terms, inventory budgeting is about allocating your financial resources for materials wisely and tracking them diligently so you don’t overspend. It combines good old-fashioned budgeting (deciding how much money is allotted for lumber, steel, concrete, etc., and when) with robust inventory management (knowing what you have in stock, what’s been used, and what still needs to be purchased). When done right, inventory budgeting ensures that you have the right materials in the right quantities at the right time – without breaking the bank.

Why does this matter so much? Because materials are often one of the largest cost components in construction. Depending on the project, materials can account for anywhere from roughly 30% to 50% (or more) of total costs. That means any savings (or overruns) on the materials side have a big impact on the overall budget. Effective inventory budgeting helps avoid the scenario of hitting 80% of your material budget when the project is only 50% complete – a clear red flag you’re headed for an overrun. It gives project managers early warning signs and tools to course-correct.

In short, inventory budgeting is both a plan and a continuous process: you plan the expected material costs at the outset, and then continuously manage and control those costs as the project progresses. It’s proactive cost control for your physical resources. Next, we’ll dive into how to actually do this in practice – from the planning stage through project completion – to prevent those dreaded cost overruns.

How to Prevent Material Cost Overruns: Best Practices and Strategies

Now let’s get into the actionable part: How can you actually keep your material costs under control? What steps can you take, from day one of planning to the final day of the project, to make sure you don’t overspend on inventory? Below are the key best practices for construction project inventory budgeting, laid out in a logical order. Think of this as your step-by-step guide to smarter material management:

1. Start with Detailed Material Takeoffs and Estimates

Every great inventory budget begins with a reliable estimate. This means performing a thorough material takeoff from your plans and specs – itemizing exactly what materials (and how much of each) the project requires. Use historical data and unit costs where possible to build your material budget. The more detailed and data-driven your estimate, the less likely you’ll be caught off guard later. Don’t just guesstimate “about 100 sheets of drywall”; calculate it out based on square footage, add proper waste factors (maybe 10% extra for cuts and breakage, if that’s standard), and check your numbers twice. Modern estimating software or even spreadsheets with built-in formulas can help automate accuracy here. It’s also wise to involve your field team or subcontractors in reviewing material estimates – the people who will actually use those materials might spot omissions or overly generous quantities that an office estimator missed.

When pricing out the materials, get quotes from suppliers for major items to use current pricing. If you expect price fluctuations (say, an industry forecast shows copper prices are trending up), you might build in a little cushion on those line items. Being realistic and comprehensive in your initial budgeting is crucial. This is your baseline. If you start on shaky ground with a flawed material estimate, everything else in the project will be playing catch-up. In contrast, a solid, detailed material budget sets you up to manage and monitor costs with confidence.

2. Build a Realistic Budget (and Include Contingency)

Once you have your detailed quantity takeoff and material costs, ensure that the budget you set is realistic. This means accounting for the unexpected. In construction, there are always surprises – a sudden design change, a spike in material prices, or a mistake that means you need to re-order some items.

Include a contingency fund for materials, typically around 5-10% of the total material budget, to handle these unplanned costs. It’s far better to allocate, say, an extra $50k in your material budget for “unknowns” and not use it all, than to pretend everything will be perfect and then be forced to blow the budget when something goes wrong.

A realistic budget also considers timing of purchases. If certain critical materials have a long lead time or volatile price, you might budget to purchase them earlier (locking the cost) rather than later when prices might be higher. For instance, if your project will need a large quantity of copper wire six months from now, and you see copper prices rising, your budget might plan for buying that stock now and storing it (provided storage cost is lower than the expected price increase). These tactical decisions are part of budgeting too. You’re essentially creating a budget strategy: not just how much to spend, but when and how to spend it for maximum efficiency.

Finally, get buy-in on the budget. Communicate the material budget to your team – project managers, site supervisors, procurement officers – so everyone knows the targets. If everyone knows, for example, that “we have $X allocated for lumber on this job,” they are more likely to be judicious in how they use and order lumber. In short, set a clear budget with a buffer, and treat it as a hard guideline. This upfront clarity will guide decisions throughout the project.

3. Optimize Your Procurement Strategy

How and when you purchase materials can significantly affect whether you stay on budget. A smart procurement strategy helps you avoid paying premium prices or incurring unnecessary costs. Here are a few tactics:

Shop Around and Lock in Prices: Don’t just go with the first quote – get competitive bids from suppliers for big-ticket materials. Once you find a good price, consider locking it in with a purchase order or contract. Some suppliers offer price guarantees or bulk pricing agreements that can protect you against market swings. For example, you might secure a deal for all the structural steel at a fixed price per ton for the next 6 months, which shields you if steel prices jump during the project.

Bulk Order Common Materials (Strategically): If you have several upcoming projects or phases that use the same materials, buying in bulk can get you volume discounts and reduce per-unit cost. However, balance this against the carrying cost of inventory. Bulk-buy items that you are confident will get used (or that have a long shelf life), and that you have space to store safely. Avoid bulk ordering items that could potentially change (due to design changes) or degrade in storage. Some construction firms even partner with other contractors to collectively place bulk orders for better pricing – essentially leveraging group buying power.

Schedule Purchases Just-In-Time (When Feasible): For materials that you don’t want sitting around (either due to theft/damage risk or cash flow concerns), try to time the deliveries closer to when they’ll be needed. This “just-in-time” approach prevents money being tied up in a plywood stack that won’t be used for months. But be cautious: you need good scheduling and reliable suppliers for this to work, or else a late delivery could delay your project (which has its own costs).

Negotiate Payment Terms: A small but helpful detail – negotiate with suppliers for favorable payment terms or discounts. Net-60 or net-90 terms, for instance, can improve your cash flow, keeping your budget healthier month-to-month. Early payment discounts (like 2% off if paid in 10 days) can also save a bit if you have the cash available. These savings might not show directly in the “materials” line, but they do affect your overall project cost and can offset overruns elsewhere.

Collaborate with Suppliers and Subs: Treat procurement as a team effort. Talk to your subcontractors about material choices – maybe an alternate material could do the job at lower cost. This is often called value engineering: finding different products or methods that achieve the same result for less money. Also, maintain good relationships with your suppliers. Suppliers who value your business might give you heads-up on upcoming price increases or help you find scarce items, which can be priceless for budgeting.

By optimizing procurement, you’re aiming to get the best price and terms for the materials you need, and to schedule those purchases in a way that supports the budget. This reduces the chance of paying through the nose due to poor planning or market surprises. It’s all about being proactive rather than reactive when it comes to buying materials.

4. Implement Real-Time Inventory Tracking on Site

All the planning in the world can be undone if once materials start arriving, you don’t keep track of them. To prevent cost overruns, you need a firm grip on your inventory in real time during the project. This means knowing at any given moment what materials you have in stock, where they are located, and how that compares to what was budgeted or expected to be used. If that sounds difficult to do manually – it is! This is where leveraging technology and systems becomes crucial.

Start by establishing a system for tracking every material delivery and usage as it happens. When materials arrive on site or at the warehouse, record them immediately – whether that’s in an inventory management software, a spreadsheet, or a logbook (digital methods are far preferred for speed and accuracy). Each time materials are taken from the stock and used in the project, that should also be logged. The goal is to always have an up-to-date count. For example, if you purchased 1,000 bricks and by mid-project 750 have been used, you should know that 250 remain – not still be assuming you have 400 because of a data entry delay or oversight.

Barcoding or QR code scanning can make this process much more efficient. By tagging materials or batches and scanning them when they move (received, moved to site, installed in work, etc.), you build a real-time ledger without the tedium of manual entry.

Many construction companies now equip their warehouse staff or site foremen with mobile barcode scanners or smartphone apps to scan material usage on the fly. Real-time tracking helps catch discrepancies early: if a delivery was short, you’ll spot it that day (and can call the supplier to send the missing items); if materials are being used faster than anticipated, you’ll notice before you completely run out. Essentially, you get early warning signs of any budget issues. For instance, if by the second week of a phase you’ve used 80% of the wiring conduit that was supposed to last the whole phase, you might be headed for an overrun – and you can investigate why (perhaps workers are wasting pieces or a miscalculation in the estimate) and rectify it.

Additionally, real-time tracking prevents duplicate orders. It’s not uncommon on a chaotic job for someone to order a pallet of something because they think stock is low, not realizing more was sitting in a different storage area. With a live inventory system, everyone can check what’s on hand before reordering. This avoids the classic budget killer of “oh, we actually had those parts already, now we have double and wasted money.” In summary, make real-time inventory visibility a priority – it’s like having a live dashboard for your project’s material budget, so you can steer it in the right direction throughout the job.

5. Conduct Regular Inventory Audits and Reconciliation

Even with a real-time tracking system, it’s important to periodically audit your inventory. Things can still slip through the cracks – maybe a pallet was misplaced and never scanned, or a data entry mistake claimed you had 50 pieces when there are 45. By doing regular physical counts and reconciling them with your records, you ensure that the numbers on paper (or screen) match reality. This practice can catch issues early and prevent costly surprises.

For high-value items or critical materials, consider doing weekly or bi-weekly mini-audits. This could be as simple as walking the yard or storage and counting how many steel beams or how many bags of cement are actually there, and cross-checking with the log. If you spot a discrepancy (e.g., you should have 20 pressure valves but only find 18), you can investigate right away – maybe they were used and not logged, or moved to a different site, or worst case, stolen. The sooner you find out, the sooner you can take corrective action (order replacements if needed, improve the process, etc.). Waiting until the end of the project to realize you “lost” thousands of dollars in materials is too late for the budget.

Cycle counting is another useful approach: instead of a massive inventory count at one time, you spread it out by counting certain items or areas on a rotating basis. For example, each week you audit a different category of materials. Over a month or two, you’ve audited everything with minimal disruption to work. This continuous monitoring keeps your data accurate.

Accurate inventory data also ties into accurate cost tracking. If your finance or accounting team knows exactly what’s in inventory vs. what’s been installed, they can properly account for costs in progress. Many contractors integrate inventory counts with job costing – ensuring that materials are billed to the project when used, and any excess is noted. Regular audits feed into this, making sure the cost reports reflect reality. In short, trust but verify your inventory records regularly. It’s an investment of time that can save a lot of money by preventing unnoticed losses and overruns.

6. Safeguard Materials from Theft and Loss

As noted earlier, theft and loss can silently eat away at your materials and your budget. Preventing these requires a combination of security measures and inventory controls:

- Secure Your Site and Storage: Make sure your construction site isn’t an easy target. Use fencing, security cameras, and proper lighting after hours. Store valuable materials and tools in locked containers (like a shipping container or locked tool crib) overnight. For high-value items, consider on-site security personnel or at least routine patrols. Even signage warning of surveillance or property marking can deter opportunistic thieves. Remember that every dollar spent on security could save five in theft losses and project delays.

- Implement Check-In/Check-Out Systems: For tools and equipment (and even materials), have a clear process for assigning responsibility. If a worker needs a concrete mixer or a laser level, have them sign it out (or log it out via a scanner) and return it at end of day. Knowing who has or last had an item creates accountability – people are far less likely to “misplace” or walk off with something if they know it’s tracked. Many inventory management systems allow you to assign items to employees or teams, so you always know, for example, that John checked out the drill or Crew A has the surveying equipment this week.

- Use Asset Tracking Tech for High-Value Items: You can go a step further for expensive movable assets (generators, skid steers, etc.) by using GPS trackers or Bluetooth tags. These devices can alert you if equipment leaves the site or help you locate it. While this might not be used for bulk materials, it’s great for costly tools and machinery. Recovering a $50,000 piece of equipment via a GPS tracker obviously saves a huge potential budget hit.

- Set Up Inventory Alerts: Leverage any alert features in your inventory system. For instance, get notified if stock levels drop unexpectedly or go below a threshold when they shouldn’t. If you were supposed to have 100 copper pipes and suddenly the system shows 80, an alert can prompt you to investigate today, not a month from now. It could reveal theft or miscounts early. Some systems let you flag certain items as “high watch” so that any movement is reported.

- Foster a Culture of Accountability: Beyond systems and tech, instill in your team the importance of caring for materials. Make it clear that everyone is responsible for helping prevent losses. Encourage crew members to report if they see something suspicious or if they accidentally damage materials (it’s better they tell you and you reorder with slight delay than hide it and cause bigger issues later). Consider small incentives – for example, if a crew goes three months with no missing tools or minimal waste, acknowledge it. When the team takes ownership of the equipment and materials, they’re more likely to be careful and honest, which in turn protects your budget.

By reducing theft and loss, you not only save the direct cost of replacing those items, but you also avoid indirect costs like work stoppages (waiting on a new delivery) and higher insurance premiums. It’s a critical part of inventory budgeting that sometimes gets overlooked – you budget for X units of material, but if you keep having to buy replacements for stolen/damaged ones, you bust the budget. So, lock it down and log it out is the mantra.

7. Minimize Waste and Rework of Materials

Waste is the enemy of budgeting. Every piece of material that gets tossed in a dumpster or torn out due to a mistake is essentially money wasted. While some waste is inevitable, a lot can be prevented with good practices:

- Improve Storage and Handling: Many materials get ruined simply because they weren’t stored properly. Keep materials in conditions that suit them – for instance, store cement bags in a dry area off the ground, keep lumber covered from rain, protect glass and delicate finishes from breakage, etc. Organize your storage so items aren’t at risk of being crushed or lost. Training workers on proper handling (e.g., how to carry drywall to not break corners) also goes a long way.

- Use First-In-First-Out (FIFO): Especially for materials with a shelf life or that can degrade, always use older stock first. If you got a delivery of paint last month and another this month, use last month’s batch first. Mark dates on perishable materials and organize your yard/warehouse accordingly (oldest in front). FIFO prevents situations where something expires or becomes unusable while newer stock gets used up – a common cause of hidden waste.

- Right-Size Your Orders: Refining your estimating and ordering process can cut down on surplus. If you consistently find you’re over-ordering certain materials, adjust your calculations. It might be better to order in smaller batches more frequently than one bulk drop that leaves you with excess. This ties back to estimation: analyze past projects to see where you ordered, say, 20% too much tile or pipe, and improve your takeoff method next time. Aiming for just a small cushion rather than mountains of “just in case” materials will reduce leftovers.

- Plan for Leftovers: Despite best efforts, there will be leftover materials – half a pallet of bricks, a few gallons of paint, etc. Don’t let them become waste. Set up a system to return, reuse, or sell surplus materials. Some suppliers allow returns of unused materials (even if for partial store credit). If not, store the excess properly and note it in an “excess inventory” list that project managers can check before buying for the next job. You might find that the extra steel from Project A can be repurposed in Project B. Some companies establish a central yard for surplus materials that any project can draw from. Another option is donating or recycling materials that can’t be used – it won’t help your current budget, but it can yield tax benefits or goodwill and avoids disposal costs.

- Avoid Rework Through Quality Control: Rework – tearing out and re-doing work – is a massive source of wasted materials (not to mention labor costs). Ensuring quality control and correct installation the first time will prevent scenarios like “we had to throw out those installed tiles because the substrate was wrong” or “we poured that wall and then had to demo and repour it.” This comes down to good project management and supervision, but it’s worth mentioning: doing it right the first time saves your material budget from double-spending.

- Track and Analyze Waste: Make waste visible. If you can, quantify waste materials (like count the off-cuts or the unused pieces) and discuss it in project meetings. When people see that “we threw away $5,000 worth of drywall on this job,” it tends to get their attention and can drive process changes. Some firms use waste tracking reports as part of project close-out to improve future estimates and methods. The goal is to learn and not repeat the same wasteful practices.

Reducing waste is essentially increasing your effective budget. If you planned $100k for materials but end up wasting 10%, that’s $10k lost. If you can cut waste in half, that’s $5k saved – which could be the difference between a project coming in under budget or over. Moreover, a lean approach to materials often means a cleaner, safer site and a more organized project, which has its own benefits.

8. Coordinate Inventory Across Teams and Locations

In construction, materials often move through a supply chain of their own: from vendor to central warehouse, to jobsite A, maybe back to warehouse, then to jobsite B, and so on. Plus, multiple teams (purchasing, site management, warehouse crew) are involved. Good inventory budgeting requires strong communication and coordination among all these players to avoid costly mix-ups.

Break down silos between departments. The purchasing team should have visibility into what the site already has in stock; the site supervisor should know what’s been ordered and arriving when. Using a centralized inventory management system or at least regular coordination meetings can help ensure everyone is on the same page. For example, if the warehouse ships 10 generators to Site X, make sure Site X knows it’s coming (so they don’t rent generators locally out of panic, incurring extra cost). Conversely, if Site X decides they won’t need those generators after all, the warehouse should know to redirect or hold that inventory for another project rather than just letting it sit (tying up budget).

If your company operates multiple projects or storage yards, treat the entire network of locations as one big inventory pool from a management perspective. This way you can transfer surplus materials from one job to another as needed rather than buying new. Let’s say Project Y is wrapping up and has extra rebar, and Project Z is just starting and will need rebar – if you have good coordination, you can shift the material and save Project Z’s budget the cost of new rebar (only incurring maybe transport cost). Without coordination, Project Z might obliviously place a new order while perfectly good rebar gathers dust at Project Y’s site.

Modern software tools make this multi-location visibility much easier by literally showing you what’s at each place. But even with simpler means, establishing a process like a weekly inventory coordination call can yield savings. During such check-ins, teams can discuss: “We have extra drywall sheets here, anyone need them? or X item is running low at Site B, but Site A has spare – let’s shift it.” These actions prevent unnecessary purchases and maximize the usage of what’s already been bought (stretching your budget further).

Finally, ensure change orders and scope changes are communicated across teams. A change in design might eliminate the need for a material – if the memo doesn’t reach procurement in time, they might still buy it (wasting money). Or a change might add a new material – if the field doesn’t tell purchasing early, they might have to rush ship something at high cost. Setting protocols that any change in plans triggers a review of inventory and budget impact can save a lot of grief. In summary, no part of your inventory budget should exist in isolation – tie together the knowledge and resources of all teams to run a tight ship.

9. Monitor Budget vs. Actual and Adjust in Real Time

Inventory budgeting isn’t a “set it and forget it” task. Throughout the project, project managers and accountants should continuously compare the budgeted costs vs. actual costs for materials. This means looking at how much of the budget has been spent and how that aligns with progress. If you’ve completed 50% of the project but already used 75% of the material budget, that’s a glaring warning sign. Identifying such trends early allows you to take corrective action: perhaps find cost savings in other areas, negotiate better prices for remaining materials, or, if absolutely necessary, inform the client early and work on a change order or scope adjustment to mitigate the damage.

One practical way to do this is maintaining a living project budget document that is updated weekly (or even daily) with actual material expenditures and remaining committed costs. Pair this with your inventory tracking – for instance, if your inventory system shows you’ve used X units of a material, multiply by unit cost to see dollars consumed versus budget for that material line. Some project management software will do this automatically, but even a manual spreadsheet can work if diligently kept.

If you spot a potential overrun developing, dig into the why immediately. Is it because the crew is using more material than estimated? (Maybe the estimate was wrong or waste is higher – address it operationally.) Is it because material prices went up? (Maybe you can find an alternate supplier or substitute material, or tap into contingency funds.) Is it because the project scope increased? (Then you need to adjust the budget formally with the client if possible.) The key is not to be surprised at the end. Early detection gives you options; late detection leaves you with consequences.

On the flip side, monitoring can also highlight if you’re under budget on some items, which could free resources to cover others. For example, maybe you budgeted $20k for landscaping materials but due to a design simplification you only spent $15k; that $5k could offset a shortage in the concrete budget due to a price hike. These decisions can be made if you have timely data.

Adjusting in real time might involve reforecasting your budget mid-project. It’s not a failure to reforecast; in fact, it’s wise to reallocate and rebalance the budget as conditions change, as long as you keep the overall budget in check. Think of it like navigating a ship – small course corrections along the way will keep you aimed at the destination (on budget), whereas if you never check the compass, you could drift far off course and not realize until you’re way off target.

How Technology (and CyberStockroom) Can Help You Stay on Budget

By now it’s clear that organization, visibility, and data are your allies in inventory budgeting. Trying to achieve all the above practices with pen-and-paper or disparate spreadsheets can be challenging, especially on larger projects or if you manage multiple jobs at once. This is where leveraging modern inventory management software becomes a game-changer. The right tool will essentially support and automate many of the best practices we covered: from real-time tracking and multi-site visibility to alerts and reporting.

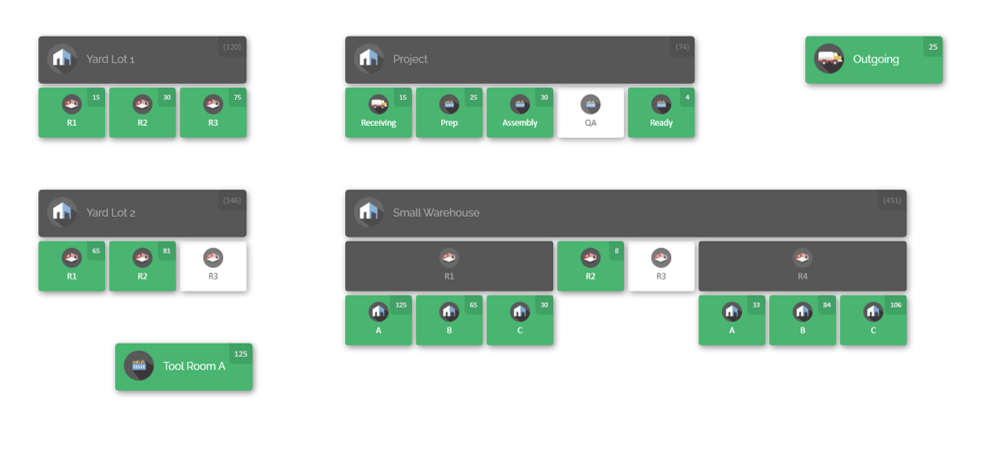

One such tool purpose-built for inventory management is CyberStockroom. CyberStockroom is a cloud-based inventory management platform that has gained popularity with construction companies (as well as other industries) for its intuitive, visual approach. Here’s how a solution like CyberStockroom can directly help prevent material cost overruns in construction projects:

Visual Inventory Map

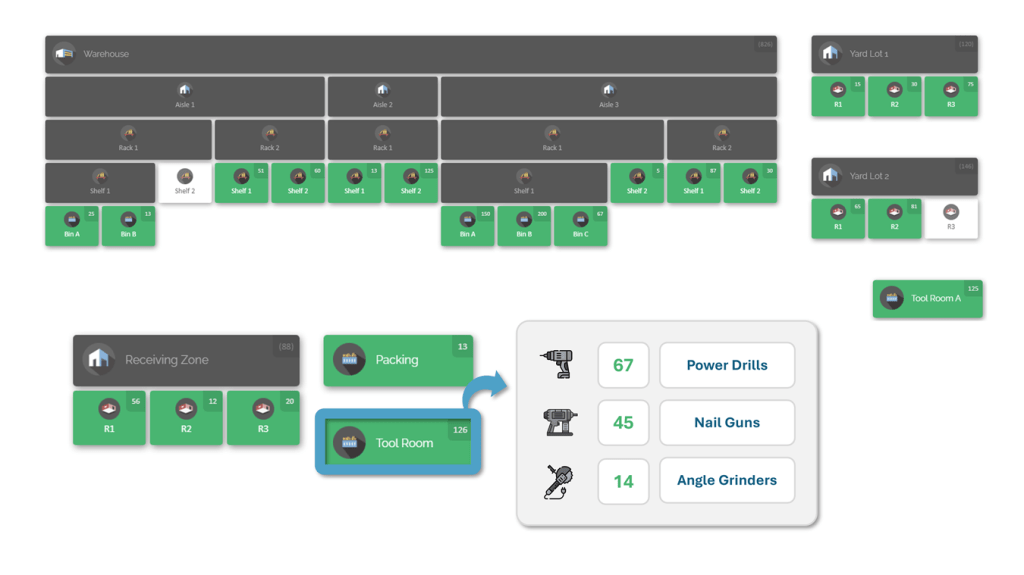

CyberStockroom’s signature feature is its map-based interface. You create a digital map of all your locations – e.g. your main warehouse, Yard A, Jobsite B, Truck #5, etc. – and you can see at a glance what inventory is at each location. For a construction manager, this is incredibly useful to avoid duplicate orders and wasted trips. Instead of calling around or guessing, you’d open the map and instantly know, for example, that Site B still has 20 spare lighting fixtures left, so you don’t need to buy new ones for Site C; you can transfer them. This kind of visibility across locations ensures materials are utilized efficiently, reducing over-purchasing and idle stock. It essentially tackles the coordination challenge (#8 above) by putting all sites on the same page.

Real-Time Updates with Easy Tracking

CyberStockroom is designed to update inventory counts in real time as items move. It supports barcoding/QR code scanning – team members on the ground can check items in or out, or transfer them on the system with a quick scan or a drag-and-drop on the map. This feeds into the real-time inventory tracking practice (#4). The benefit is accuracy: if 500 bricks were delivered this morning and 200 were used by afternoon, the system can show 300 remaining by evening. Everyone with access to the system can trust the data is current. This prevents those scenarios of ordering something you already have, or running out because someone forgot to update a spreadsheet. It also creates an audit trail – you can see exactly when and by whom an item was moved or used, which boosts accountability.

Loss & Theft Prevention Features

CyberStockroom has features geared toward preventing loss. You can assign items to specific people or teams in the system. For example, you could mark that “John Doe checked out a laser level on Oct 10” and it will show that until John returns it. The map might even display that item as being “with John” rather than in a location. This level of tracking ties into practice (#6) of check-in/check-out accountability. Additionally, because it keeps a log of inventory changes, if something goes missing you can pinpoint when it was last seen and who had it. CyberStockroom also allows setting custom alerts – for instance, if the quantity of a high-value item drops unexpectedly, you’d get notified (similar to what we discussed about theft alerts). Simply put, the system acts as a watchdog on your inventory, helping catch and deter shrinkage that would hurt your budget.

Multi-Project Coordination

If you’re running multiple projects, CyberStockroom lets you manage all within one account by setting up various locations and sub-locations. It essentially centralizes your inventory data. A warehouse manager can see what every jobsite has, and site supervisors can see what’s at the warehouse or even in each other’s site (if you set it up that way). This directly helps you reallocate surplus materials from one project to another (#8) since you can identify where the excess is. The software can record transfers between sites too, so the financials can be adjusted accordingly (you’ll know Project A gave 10 beams to Project B, which might be an internal adjustment but at least you won’t order another 10 beams for B). Even “mobile inventory” like the tools kept in a foreman’s pickup truck can be accounted for by treating the vehicle as a location on the map. This holistic view ensures nothing “falls off the radar”, which is crucial for full-budget control.

Ease of Use in the Field

All these features are only helpful if your team actually uses the system. CyberStockroom is designed to be user-friendly and visual (with that map and drag-and-drop interface). Field crews who might not be keen on complex software often find a map-based system more intuitive – it’s more like using a simple app than filling out a spreadsheet. It’s also cloud-based, which means anyone can access it from a web browser on their laptop or tablet in the field, as well as back in the office. This addresses the adoption challenge: when it’s easy, your staff will actually log those inventory movements, and you’ll have good data to work with. In short, CyberStockroom focuses on making inventory management simple and even a bit interactive, which helps embed these best practices into daily routines without it feeling like a chore.

While CyberStockroom is one example (and the one we know well), the broader point is: leveraging technology amplifies your ability to budget effectively. It enforces discipline (because the system keeps everyone honest and organized), provides real-time insight (so you can act fast), and reduces manual errors. For construction companies, especially small to mid-sized ones, using an inventory management tool can level the playing field by giving you capabilities that only large firms with dedicated teams used to have. When it comes to preventing cost overruns, this is a huge advantage. Instead of reacting to problems at the end, you’re actively managing costs throughout.

Conclusion: Keep Your Project on Track with Proactive Inventory Budgeting

Material cost overruns don’t have to be “just a cost of doing business” in construction. With careful inventory budgeting and the strategies outlined above, you can significantly tilt the odds in favor of coming in at or even under budget for your project’s materials. It boils down to being proactive: planning thoroughly, monitoring relentlessly, and adjusting quickly. By knowing your needs, protecting your resources, and using data to guide decisions, you transform inventory management from a potential chaos into a controlled process.

For construction project managers and inventory supervisors in particular, these practices mean fewer surprises and emergencies. Instead of firefighting – rushing to buy extra materials or explaining to the boss why the lumber bill was 20% over – you can spend time driving the project forward, confident that the inventory side is under control. Clients and stakeholders will appreciate the professionalism of a project that stays on budget, and your company’s profit margins will reflect the reduction in waste and overruns.

One final thought: building a culture of good inventory management is just as important as the technical steps. Encourage your team to see materials as money: every 2×4 and every gallon of fuel is part of the project’s cash. When crews take ownership of that idea, they’re more likely to avoid wasting materials, report issues, and embrace systems that help. Pair that culture with the right tools and processes – like clear protocols and helpful software – and you have a winning combination.

In the high-stakes world of construction, controlling costs is key to success. By treating inventory budgeting as a priority from day one, you can prevent material cost overruns before they happen. That means more successful projects, healthier profit margins, and less stress all around. Consider it the equivalent of surveying the land before you build: if you map out and manage your materials wisely, you’re laying a solid foundation for your project’s financial success. Here’s to your next construction project staying on track, on time, and on budget – with no nasty cost surprises waiting at the end!

Leave a comment