Manufacturers often face dramatic seasonal inventory fluctuations – periods when demand for products surges or dips due to seasonal trends. For example, a factory producing snow blowers sees demand peak in winter and vanish by summer, while a grill equipment manufacturer experiences the opposite.

Managing these seasonal highs and lows is critical: if you don’t have enough stock during a peak season, you risk stockouts and lost sales, but if you overproduce, you could be stuck with excess inventory tying up cash in the off-season. Effective seasonal inventory management in manufacturing requires careful planning, flexibility, and the right tools to keep inventory levels balanced year-round.

Understanding Seasonal Inventory Fluctuations

Seasonal inventory fluctuations refer to predictable changes in demand and stock levels tied to the time of year. Unlike one-off spikes, seasonal changes happen on a regular cycle (often annually).

Common examples include holiday-driven demand (e.g. increased production of toys and electronics before Christmas), weather-related needs (like more HVAC parts in summer and heating components in winter), or industry cycles (such as agricultural equipment demand rising before planting season).

For manufacturers, these fluctuations mean you’ll have periods of peak production and inventory buildup followed by periods of slower sales or even excess stock.

These patterns are predictable to an extent – which is good news, because it allows you to plan ahead. However, predictable doesn’t always mean easy to manage. Seasonal swings can strain every part of your business, from production lines to warehouse space and cash flow. Understanding the specific seasonal trends for your products is the first step. Analyze historical sales data to identify when demand increases, by how much, and for which product lines. Often, a Pareto analysis or ABC classification of products can highlight which items are “A” items driving seasonal peaks versus “B” or “C” items with steadier demand. With a clear picture of your seasonal demand patterns, you can formulate strategies to handle them proactively.

Why Seasonal Fluctuations Are Challenging

Seasonal inventory swings present several challenges that manufacturers must overcome:

- Stockouts during peaks: Rapid demand spikes can lead to stockouts if inventory isn’t sufficient, resulting in missed sales and unhappy customers. Failing to deliver during the peak season not only loses immediate revenue but can also damage customer trust and send business to competitors.

- Overstock in off-season: After the rush, unsold inventory can pile up. Excess off-season inventory ties up capital and incurs storage costs. Products with seasonal appeal may become obsolete or lose value by the next year (think of dated fashion items or electronics). Overstock might require deep discounts, storage expansion, or write-offs, all hurting profitability.

- Strain on cash flow: Ramping up production for peak season often means purchasing raw materials in advance, increasing labor (overtime or temporary staff), and possibly investing in extra storage. These costs occur before the peak revenue comes in, which can strain cash flow. On the flip side, carrying costs for leftover inventory in the slow season also eat into budgets.

- Production capacity and scheduling: Seasonal peaks can overwhelm production capacity if not planned. Manufacturers may face overtime, rushed production runs, or the need to outsource/contract extra capacity at higher cost. Conversely, during slow periods, underutilized capacity and idle workers can hurt efficiency and morale. Balancing this is a major operational challenge.

- Supply chain and lead times: Your suppliers also need to be ready for your seasonal needs. If materials have long lead times, you must order well in advance of the peak. Any delay or shortfall upstream could cripple your ability to meet demand on time. Similarly, outbound logistics (trucking, shipping) must handle higher volumes during peak – not always easy if carrier capacity is tight during holidays or certain seasons.

- Warehouse space and organization: Storing the additional inventory for peak season requires space. Warehouses might become overcrowded during high season, making it harder to manage products efficiently. Inefficient use of space can lead to confusion, slower picking times, or even safety hazards. Then, during the off-season, that extra space (if leased or expanded) might sit underutilized, adding cost.

In summary, seasonal fluctuations put your inventory strategy and planning skills to the test. The goal is to find the sweet spot where you can meet high demand without overcommitting resources, and then scale back smoothly to avoid a glut. Below, we’ll outline a step-by-step guide on how to achieve this balance, including forecasting demand, adjusting production, optimizing inventory levels, and leveraging tools like CyberStockroom to stay agile and informed.

1. Forecast Seasonal Demand Early and Accurately

Effective management of seasonal inventory starts long before the peak season hits. Accurate forecasting is the cornerstone: you need a clear prediction of how much demand to expect and when it will occur. To do this, take a data-driven approach:

- Analyze Historical Data: Begin with sales and shipping data from previous years. Identify patterns: when did demand start ramping up? How high did it peak, and how quickly did it drop off afterward? Look at year-over-year trends to see if the peak is growing (for example, 10% higher each year) or if it shifts in timing. Don’t just rely on intuition – let the numbers guide you. If you’re a newer business without much history, look for industry reports or case studies of similar products to gather benchmarks.

- Consider External Factors: Numbers from the past are crucial, but context matters too. Account for factors like market trends, weather forecasts, and economic conditions. For instance, an unusually mild winter can diminish demand for snow-related equipment, whereas a booming housing market might increase demand for construction materials. Keep an eye on your industry news and even general economic indicators that might influence your customers’ behavior.

- Collaborate with Sales & Customers: If you supply other businesses (B2B), maintain open communication with your major customers or distributors about their seasonal projections. Retailers often have insights into consumer trends and upcoming promotions. Integrating their input (like advance orders or sales forecasts) can improve your own demand planning. Internally, coordinate with your sales and marketing teams – if marketing plans a big holiday promotion or if your sales team has large orders in the pipeline, these need to be factored into the forecast.

- Use Forecasting Tools and Techniques: Modern demand planning software can greatly enhance accuracy. Statistical forecasting models (taking into account seasonality indices) or more advanced tools using AI can help process historical data alongside external variables. If possible, use software that allows you to create multiple scenarios (best-case, worst-case demand) so you can gauge a range. Many inventory management systems support basic forecasting or data export to analytics tools. Even a well-structured spreadsheet model can work if you incorporate seasonal uplift factors. The key is to base predictions on evidence and to update them as new information comes in.

Early planning is crucial. Begin your forecasting process well ahead of the seasonal peak – often several months in advance. This lead time gives you breathing room to arrange everything from raw materials to staffing (which we’ll cover later). Additionally, revisit and refine your forecast frequently. As you get closer to the season, you’ll have more up-to-date info (e.g. early sales indicators, customer feedback, or updated economic data). A forecast shouldn’t be static; treat it as a living plan that evolves. By nailing this step, you create the foundation for all other actions – knowing what will be needed and when sets the stage for successful seasonal inventory management.

2. Align Production and Procurement with the Peaks

Once you have a solid demand forecast, the next step is to align your production schedule and procurement of materials with that forecast. Essentially, you’re gearing up your supply-side to be ready for the coming wave (and to ease off when it recedes):

- Advance Procurement of Materials: Review the lead times for all critical raw materials and components. For items that have lengthy lead times or come from single-source suppliers, place orders well ahead of the peak. It might even be wise to hold anticipation inventory (extra stock of raw materials) if you know those inputs could become scarce or slower to arrive during your busy season. Yes, this ties up capital earlier, but it ensures your production won’t grind to a halt due to missing parts. Negotiate with suppliers for seasonal terms – some may offer volume discounts or deferred payment options if you’re making large seasonal purchases. Also, consider diversifying suppliers or securing backup vendors for crucial materials (as a risk mitigation if your main supplier faces issues at the wrong time).

- Scale Production Strategically: Look at your manufacturing capacity and determine if it can meet peak demand with current resources. If not, plan how to scale up. There are a few approaches:

- Increase Output Gradually: In many cases, you won’t wait for the absolute peak to produce everything. Instead, start ramping up production in the weeks or months prior to the peak season. By producing a surplus of goods ahead of time (often called seasonal stockpiling), you build inventory buffers that can be drawn down during the rush. This avoids overloading the factory at the last minute. Be mindful of how early you build inventory – too early and you incur storage costs longer than necessary; too late and you might not have enough. Find a balance based on how long products can be stored and cash flow considerations.

- Overtime and Extra Shifts: For some manufacturers, meeting peak season means adding evening or weekend shifts, or authorizing overtime for workers to boost throughput. Calculate the cost of overtime versus other options like temporary labor or outsourcing (including the impact on worker fatigue and quality). Overtime can be a flexible way to surge capacity in the short term, but ensure it’s sustainable over the peak period duration – you don’t want burnout or quality slips if overtime runs for months.

- Temporary or Contract Manufacturing: If your facility cannot handle the peak even with overtime, you might arrange for a contract manufacturer or a partner facility to produce some of the volume. This can be more expensive per unit, but it may be worthwhile to capture peak sales without investing in permanent new capacity. The key is to vet any third-party production for quality and timing, since a delay or defect from a partner reflects on you.

- Alternate Product Scheduling: If you produce multiple product lines, consider adjusting your production calendar. During the peak season for one line, you could reduce or pause production of non-seasonal products to free up capacity for the hot items. For example, if you make both lawn mowers and snow blowers, you might heavily produce lawn mowers in spring/summer, then switch over and stockpile snow blowers in the months leading to winter, and vice versa. This staggers production in line with seasonal demand for each product, utilizing capacity efficiently year-round.

- Increase Output Gradually: In many cases, you won’t wait for the absolute peak to produce everything. Instead, start ramping up production in the weeks or months prior to the peak season. By producing a surplus of goods ahead of time (often called seasonal stockpiling), you build inventory buffers that can be drawn down during the rush. This avoids overloading the factory at the last minute. Be mindful of how early you build inventory – too early and you incur storage costs longer than necessary; too late and you might not have enough. Find a balance based on how long products can be stored and cash flow considerations.

- Flexible Production Systems: It helps if your manufacturing setup is agile. Quick changeovers, cross-trained workers (more on workforce later), and modular equipment that can scale output up or down quickly will give you an edge. Investing in some flexibility – even if it means slightly higher costs in machinery or training – can pay off when you can respond faster to demand shifts. For instance, if you suddenly get a mid-season surge above forecast, an agile production line could add an extra run with minimal downtime.

- Coordinate with Suppliers Closely: Just as you’re scaling your own production, ensure your suppliers (for both raw materials and services like packaging) are looped into your plans. Share your forecast or at least give them a heads-up about larger orders and critical timing. Collaborating with suppliers might mean scheduling deliveries in batches to build up inventory gradually, rather than one massive shipment that could overwhelm receiving. Strong supplier relationships can also lead to preferential treatment – like priority in allocation if there are wider shortages during a season. In some cases, consider vendor-managed inventory (VMI) arrangements for components, where the supplier maintains a certain level of stock at your site ready for use. This can shift some inventory burden upstream, though it requires trust and good partnerships.

By aligning production and procurement to anticipated demand, you create a smoother ramp-up to peak season. The aim is to produce enough inventory to cover the surge without either underproducing (and missing sales) or grossly overproducing (and ending up with heaps of leftover goods). It’s a delicate balancing act – essentially doing the Goldilocks routine: not too little, not too much, just right. With careful planning, you can fulfill customer orders on time during the frenzy, without drowning in surplus when things quiet down.

3. Optimize Inventory Levels and Stocking Strategies

Managing seasonal inventory isn’t just about making more products – it’s about managing how much inventory to carry at different points in time.

This is where you fine-tune your inventory strategy using techniques like safety stock, reorder points, and stocking methods tailored for seasonality. Key tactics include:

- Implement Safety Stock for Peaks: Safety stock (buffer inventory) is extra inventory held to guard against uncertainties in demand or supply. For seasonal peaks, it’s wise to calculate a safety stock level that can cover an unexpected demand spike above your forecast or a supply delay. Use a standard safety stock formula (based on variability in demand and lead time) to compute this. Many companies will scale up safety stock in the peak season because the cost of a stockout (lost sale in peak) far outweighs the cost of holding a bit of extra inventory. For example, if your maximum expected sales in December are 20% higher than average, you might set aside roughly that much in extra units as a buffer. The key is to adjust it based on risk tolerance – if your forecast is very confident you might keep minimal buffer, but if there’s uncertainty (new product, volatile trend) you carry more. CyberStockroom and similar tools can assist by highlighting minimum stock thresholds (with a feature like thresholding that flags when inventory falls below preset levels) – this ensures you get alerts to replenish before you hit zero.

- Just-In-Time vs. Seasonal Stockpiling: Consider whether a Just-in-Time (JIT) approach is feasible during your season. JIT means you aim to receive or produce inventory only as it’s needed, minimizing holding costs. In low-demand periods, JIT can reduce excess stock. However, during a peak, pure JIT might be risky – if any link in the chain fails, you could stock out quickly. Many manufacturers use a hybrid approach: lean inventory most of the year, but build up inventory “just in case” before a known peak. This is sometimes called anticipation or seasonal stockpiling – essentially the opposite of JIT, where you intentionally overstock in preparation for high demand. For example, a beverage manufacturer might produce and warehouse a large volume of drinks in late spring anticipating summer sales. The approach you choose depends on how predictable your surge is and how costly stockouts are versus holding costs. If warehouse space and cash allow, erring on the side of slightly more inventory is usually better for seasonal items – you don’t get a second chance at a Christmas or a summer season.

- Use ABC Analysis to Prioritize Stock: Not all products contribute equally to your seasonal sales. Use an ABC classification (or a variant) to identify which items (A-items) are the heavy hitters for the season. These are the ones you absolutely cannot afford to run out of during peak. Plan to keep higher coverage (days of supply) for A-items. Meanwhile, C-items (low-volume or low-value) might not need much extra stock – you could even let those run lean to prioritize space and cash for the A’s and B’s. Prioritizing inventory investment in your top seasonal performers ensures the most bang for your buck and avoids wasting resources on slow-movers.

- Set Clear Reorder Points and Lead Times: Well before the season, update your reorder point calculations to reflect the higher consumption rates during the peak. For instance, if you normally reorder a widget when stock hits 100 units because you use 10 a week, but in peak you use 50 a week, your reorder trigger should be adjusted upward accordingly (plus safety). Ensure your inventory management system is configured with seasonal reorder points or that your team knows to override the usual settings during this period. This also ties back to supplier coordination – make sure suppliers can meet shorter interval reorders if you plan to replenish mid-season. In some cases, you may do one big buy of certain seasonal items and that’s it (especially if lead times are long or suppliers also go on holiday shutdowns, etc.), meaning your inventory has to last through the entire season. In other cases, a two-wave restock might be planned if your season is long (e.g., one order for early season, another halfway through).

- Avoiding Excess: While preparing for high demand, keep an eye on mitigating overstock. One technique is to establish a maximum stock level for each item – basically a cap based on what you realistically expect to sell and a little extra. If production or purchasing plans would create inventory beyond that cap, reconsider. This prevents extreme leftovers. Another approach is to plan some mid-season reviews: for example, after the first two weeks of the peak season, assess actual sales vs forecast. If sales are slower than expected, you might curtail production for the remaining weeks or cancel a last batch of supply orders to avoid piling up inventory. Build these checkpoints into your plan so you can be agile and adjust course before it’s too late.

Optimizing inventory levels is a balancing act between service level (not running out) and cost efficiency (not tying up too much capital). During seasonal peaks, the pendulum tends to swing a bit more toward service level – it’s often worth the extra inventory cost to capture all possible sales in the peak window. During the off-season, the focus shifts to efficiency – minimizing holding costs and clearing out excess. By using smart inventory strategies like safety stock and careful planning of how much to stock and when, you can thread this needle effectively. The result is having enough of the right products at the right time, and few enough left over afterward that your warehouse (and balance sheet) aren’t overloaded.

4. Optimize Warehouse Space and Distribution

Seasonal inventory fluctuations can literally change the face of your warehouse. Going into peak season, you might be bringing in far more stock than usual, which requires savvy warehouse management and distribution planning to handle smoothly. This aspect is about ensuring you have space, organization, and logistic capacity for the ebb and flow:

- Evaluate and Expand Storage Space: Before the peak hits, do a frank assessment of your warehouse capacity. Will your existing shelving and floor space hold the extra inventory comfortably? If you foresee a space crunch, consider solutions in advance. Options include renting temporary warehouse space (or on-site storage containers) for the duration of the peak, using overflow warehouses, or partnering with a 3PL (third-party logistics provider) that can store and even help fulfill orders for the surplus stock. It’s far easier to line these up ahead of time than to scramble when pallets are sitting in aisles with nowhere to go. If renting extra space, factor that into cost calculations for the season. Some manufacturers even negotiate seasonal warehouse leases that only span the months needed.

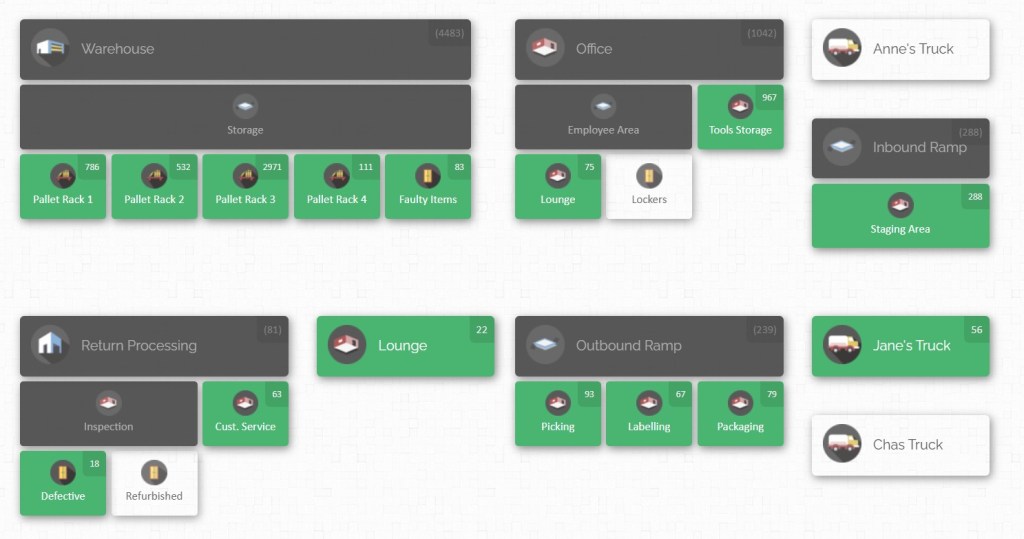

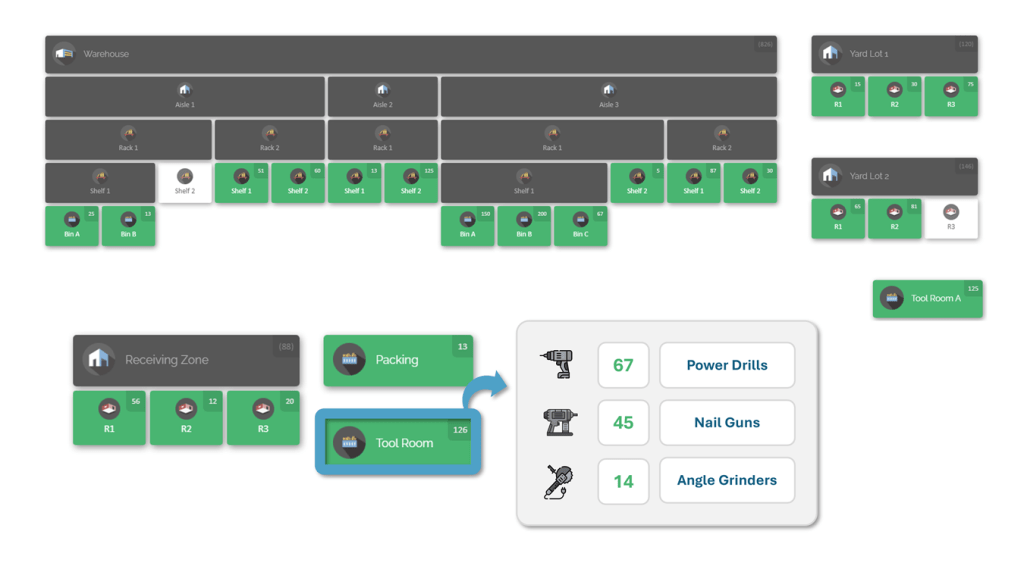

- Optimize Warehouse Layout for the Season: As inventory levels swell, having an organized layout is paramount. Consider reorganizing the warehouse to make high-demand items easily accessible. For example, dedicate a prominent, convenient area of the warehouse for the seasonal top-sellers (even if it means moving some normally steady items to a back corner temporarily). Ensure there are clear, labeled locations for the incoming extra stock – slotting plans can help assign space for each product. If you implemented an inventory map, update the map with any new sublocations or changes so your team has a clear picture of where everything will be. A visual inventory map can be extremely useful here: it allows you to see at a glance where each SKU is located and how full each area is. This reduces confusion when the warehouse fills up and helps avoid misplaced inventory.

- Improve Storage Efficiency: Peak season might be the time to use every inch of vertical and horizontal space wisely. Consider employing dynamic storage solutions: if you have pallet racking, make sure it’s safe to load to higher levels if needed; use stackable bins or shelving for small items to compress space. For items that move quickly, floor stacking in larger quantities might make sense (to speed access and because they’ll cycle out fast). Also, clearly segregate seasonal inventory that will move soon versus excess or off-season items you might still have around – you don’t want slow-moving inventory clogging prime locations needed for current high runners. Some companies set up a dedicated “seasonal zone” in the warehouse that gets re-purposed each season for the items in focus.

- Efficient Material Handling: With more inventory and possibly new storage arrangements, ensure your material handling processes can cope. This might mean having extra forklifts or pallet jacks available, or reorganizing pick paths so that pickers can grab all high-volume items in one efficient route. If your peak season orders are larger or more frequent, consider temporary layout changes like creating a staging area for outbound shipments to handle the higher throughput. The goal is to avoid bottlenecks: it’s great if production made the inventory, but if your warehouse can’t retrieve and ship it efficiently, customers will still be left waiting.

- Distribution and Logistics Planning: Inventory isn’t just sitting in the warehouse; it’s destined to move out. Coordinate with carriers or your internal logistics team about the expected outbound surge. Book carrier capacity early for the peak shipping days – during holiday seasons, trucks and freight space can become limited. If you have multiple distribution centers or stock at multiple locations, plan how to allocate inventory among them. Often, it’s wise to position products closer to the demand source. For instance, if you know East Coast sales spike earlier or heavier than West Coast, adjust inventory distribution accordingly to reduce transit time and prevent regional stockouts.

- Maintain Inventory Accuracy: Amid the chaos of peak season, inventory accuracy is at risk – and yet more critical than ever. Implement tighter cycle counts or stock audits on fast-moving items. Even doing quick daily counts on top SKUs can catch discrepancies early (before they result in an unexpected shortage). Encourage your team to double-down on scanning barcodes for every movement if you use a barcoding system. CyberStockroom’s system can log every check-in, check-out, or transfer, providing a history trail – this kind of audit trail helps pinpoint issues and maintain trust in the numbers even as volumes explode. An accurate picture prevents the scenario of thinking you have 50 units when there are none (a nasty surprise when fulfilling orders).

By optimizing your warehouse and distribution for seasonal swings, you ensure that all the inventory you’ve built up is accessible and deliverable efficiently when orders flood in. Think of it as decluttering and organizing your “store room” before the big rush – everything in its place, paths cleared, and processes amped up. This not only speeds up fulfillment during peak season (keeping customers happy with on-time deliveries) but also reduces the stress on your warehouse staff, who will be grateful for a well-organized environment when working at maximum pace.

5. Ensure Operational Flexibility with Workforce and Processes

Your inventory strategy can’t succeed without the people and processes to execute it. Seasonal surges demand operational flexibility – meaning you have the right workforce in place and streamlined processes to handle the fluctuation. Let’s break this down:

- Scale Your Workforce: During peak season, consider augmenting your team. This could mean hiring seasonal temporary workers to assist in production, packing, or warehouse duties. Many manufacturers bring on temp staff or part-timers for the busy months. If you go this route, plan recruitment well in advance – other companies are also searching for seasonal labor at the same time, so you want to secure reliable workers early. Additionally, coordinate with any temp agencies to ensure workers receive necessary training before they’re thrown into the rush. Don’t forget about your existing staff: offering opportunities for overtime or bonuses during peak season can motivate your core team to go the extra mile. However, be mindful of burnout – ensure labor laws on hours are followed and give people reasonable rest to maintain safety and quality.

- Cross-Train Employees: One of the best ways to build flexibility is cross-training your employees. By training your staff in multiple roles (for example, training assembly line workers to also operate packing machines, or training office staff to assist with inventory counts), you create a workforce that can shift as needed. In a crunch, you can redirect cross-trained employees to the areas of highest need. During off-peak times, invest time in this cross-training. It pays off when peak arrives and you suddenly need “all hands on deck” in a certain department. Employees also often appreciate learning new skills, and it breaks monotony. For seasonal swings, maybe your shipping department is overwhelmed in December – having folks from, say, Quality Control who can step in to pack boxes or load trucks will help get orders out the door faster.

- Streamline Processes: Evaluate your operational workflows for any inefficiencies that could become exacerbated under stress. For instance, if your inventory receiving process is cumbersome, during peak it could create a huge backup when lots of materials arrive. Look for ways to simplify and speed up processes: maybe pre-label locations for incoming seasonal stock for quick put-away, or pre-kit certain components to speed up assembly when orders pour in. Use lean principles to eliminate unnecessary steps – even saving a couple of minutes on a task can translate to hours saved when volume is 5x higher than normal. Document clear standard operating procedures (SOPs) for the seasonal period so even new temp workers can follow along and maintain consistency.

- Quality and Maintenance: Don’t let quality control slip in the rush. Defects or mistakes can multiply under pressure and end up causing returns or rework (which is the last thing you need in peak season). Ensure your quality checks are well-integrated but not overly time-consuming. Also, consider scheduling critical equipment maintenance before the peak hits. The last thing you want is a machine breakdown in the middle of your busiest month. Do preventive maintenance in the slower period leading up, and have contingency plans or spare parts handy for equipment that’s prone to issues.

- Flexible Policies and Scheduling: It might help to introduce flexible work schedules during peak – for example, splitting shifts differently or adding a swing shift to extend operating hours. Some manufacturers even adopt a **“all hands” policy where salaried staff from offices help out on the shop floor or in the warehouse during a short peak (packing boxes, answering customer calls, etc.). This fosters a team spirit and fills gaps, albeit it’s more common in smaller companies. Ensure you communicate any policy changes (like mandatory overtime or weekend work) well in advance to your team so they can plan their lives accordingly and remain positive about it.

A well-prepared and flexible operation means that when the forecasted demand becomes reality, your people and processes can absorb the impact without chaos. Think of it as making your operation elastic: it can stretch to handle the big push, then contract back to normal gracefully. This human element is just as critical as the inventory numbers – without a capable team, even the best inventory plan can fall apart. Investing in your workforce and workflows will translate to smoother execution of all the inventory strategies we’ve discussed.

6. Leverage Technology and Tools (How CyberStockroom Can Help)

In the midst of planning and adjustments, one powerful enabler for managing seasonal inventory is the use of technology. The right inventory management software or system can provide real-time visibility, data insights, and efficiency boosts that are game-changers during seasonal fluctuations.

One such tool is CyberStockroom, a cloud-based inventory management platform with a unique visual approach. Let’s discuss how leveraging a system like CyberStockroom can streamline seasonal inventory management:

- Real-Time Inventory Visibility: During a busy season, knowing exactly what you have and where it is can make the difference between timely decisions or costly mistakes. CyberStockroom provides a live inventory map – essentially a virtual representation of all your stock across multiple locations. At a glance, you can see if Warehouse A is running low on a critical component while Warehouse B has excess, or if a particular production cell is piled with finished goods ready to ship. This level of visibility is especially useful for seasonal management: as inventory moves quickly, the map updates so you’re never relying on outdated info. For example, if sales in the Midwest region suddenly spike, you can quickly spot on the map if that region’s distribution center needs replenishment from elsewhere. Instead of combing through spreadsheets, a quick look at the visual dashboard tells you where attention is needed.

- Easy Inventory Transfers and Adjustments: In seasonal peaks, agility is key. CyberStockroom’s interface allows users to drag and drop inventory between locations on the map to record transfers. Suppose mid-season you realize one store or region has more stock than it will sell, and another is selling out. You can reallocate inventory in the system easily, and physically ship it where it’s needed. The software keeps a complete history of these transfers, which adds accountability (you’ll know exactly who moved what, when – great for auditing and learning for next year’s plan). This feature helps prevent localized stockouts and reduces the need to panic-order new stock when the overall system might have enough, just in the wrong place.

- Threshold Alerts and Reordering: We talked about safety stock and reorder points – CyberStockroom can assist by letting you set threshold levels for your products. As inventory drops below a set threshold, it can flag those items (even visually, such as turning portions of the map red when a location’s stock is under the minimum). This proactive alert system is ideal in a fast-paced season when you might otherwise overlook a depleting SKU until it’s almost gone. With the alert, your team can reorder or produce more in time to avoid a stockout.

- Barcoding and Fast Check-In/Out: During high volume periods, speed and accuracy in inventory handling are crucial. CyberStockroom supports barcoding, allowing your team to scan items for quick check-in (adding to inventory) or check-out (removing for usage or shipping). This reduces errors in data entry and ensures that as inventory is consumed for production or sent out the door, the system immediately reflects it. You’ll appreciate this in the thick of the season when hundreds of parts might be moving in and out daily – instead of manual logging (which might be prone to lag or mistakes under pressure), scanning keeps everything up-to-date. Having a reliable digital record means no guessing games about current stock.

- Cloud-Based Access Anywhere: Because CyberStockroom is cloud-based, it’s accessible from any device with a web browser. You can use tablets or laptops on the shop floor or in the warehouse to update and view inventory status in real time. This is useful if, say, you’re walking the warehouse and want to compare what you see on the shelf with what’s recorded on the map – you can do that on the spot. Multiple team members can access the system simultaneously, which is great when different departments (purchasing, production, warehouse, management) need insights during decision-making. Everyone sees the same real-time data, improving coordination during the seasonal rush.

- Analytics and Reporting: After or during the season, CyberStockroom lets you pull reports on inventory movements, which products were checked out the most, how inventory levels fluctuated, etc. These analytics can highlight patterns like “Product X nearly stocked out on three occasions” or “We transferred 30% of inventory from West Coast to East Coast mid-season.” Such insights are gold for post-season analysis (which we’ll cover next) and planning improvements. It’s hard to get these insights from a paper-based system or simple spreadsheets, but an inventory system captures it effortlessly as a byproduct of daily operations.

In essence, technology acts as a force multiplier for all the strategies you implement. CyberStockroom, in particular, is aligned with giving businesses a clear picture of their inventory – literally – which is incredibly helpful when managing seasonal complexity. It won’t replace sound planning and execution, but it will make those things easier to do and reduce the likelihood of human error or blind spots. By leveraging such inventory management tools, manufacturers can respond faster to real conditions during the season, maintain better control over their stock, and ultimately serve their customers better when it counts the most.

7. Plan for End-of-Season Inventory and Transitions

As the peak season winds down, a new challenge emerges: What do we do with remaining inventory? A hallmark of savvy seasonal inventory management is having a game plan for the tail end of the season and the period immediately after. The goals here are to smoothly transition out of the peak, minimize leftover stock, and reset for the next cycle. Here’s how:

- Scale Down Production Gradually: Just as you ramped up before the peak, avoid slamming on the brakes abruptly (unless demand truly free-falls overnight). Monitor sales as the season tapers off and start dialing back production or procurement in a controlled way. Ideally, you want to time things so that production of seasonal items stops right as demand fades, to prevent overshooting. For example, if you produce holiday-themed goods, you might stop production a few weeks before the holiday and switch factory lines back to non-seasonal products or maintenance work. Any unfinished work-in-progress that’s seasonal should be completed and shipped out or shelved for next year if possible, not left hanging.

- Mark-Downs and Promotions: Despite our best efforts, there’s often some excess finished goods inventory at season’s end. Plan ahead for clearance strategies. Many manufacturers coordinate with their sales channels to run end-of-season promotions or discounts to help move the remaining stock. This could be post-Christmas sales for winter items, or end-of-summer blowouts. The idea is to convert inventory to cash rather than store it indefinitely. It’s better to sell at a smaller margin than not at all (especially if products have carrying costs or risk obsolescence). If you sell direct, you can run your own clearance sales; if you sell through retailers, perhaps offer them incentives or buy-back options to push those last units out.

- Re-purpose or Hold for Next Season: Not all seasonal inventory loses value. Some goods are carryover items that can be stored and sold in the next season. For instance, a classic design winter coat that doesn’t sell out this winter can be kept in storage and added to next winter’s inventory (assuming you have the space and the item isn’t going out of style). If you choose to carry inventory over, be mindful of storage conditions, potential degradation (for perishables or tech that might become outdated), and the cost of holding it for months. Sometimes it’s perfectly fine to warehouse durable items until next year, effectively giving you a head start next season. CyberStockroom’s mapping can help here by earmarking a “holding” sub-location for off-season stock that you plan to revisit later, ensuring it’s not forgotten.

- Liquidate or Recycle Unmovable Stock: For truly seasonal or dated items (for example, merchandise with year-specific branding, or perishable goods near expiration), you need exit strategies. Options include:

- Liquidation outlets: There are buyers and outlet stores specializing in taking excess inventory at a discount. Establish those relationships so you can offload leftover stock quickly if needed. You won’t get full price, but you’ll free up space and recover some cost.

- Donations: Consider donating excess inventory to charities or community organizations. This can be a win-win: people in need get useful products, and you may benefit from a tax write-off (plus good PR in the community). Make sure to document donations properly for accounting purposes. This works best for items like clothing, tools, or non-perishable goods that can benefit others.

- Recycling/Scrap: In worst-case scenarios (e.g., product that cannot be sold or donated due to regulations or lack of market), arrange for proper recycling or disposal. Try to salvage parts or materials if possible. For example, unsold electronics might have components that can be reused or recycled for a minor credit.

- Liquidation outlets: There are buyers and outlet stores specializing in taking excess inventory at a discount. Establish those relationships so you can offload leftover stock quickly if needed. You won’t get full price, but you’ll free up space and recover some cost.

- Warehouse Reset: After the season, take the time to reorganize the warehouse back to normal. Remove any temporary racks or reorganize seasonal zones back to off-season configuration. Perform a thorough inventory count once the dust settles – this will reconcile any discrepancies that occurred during the rush and give you an accurate starting point for the steady period. It’s also a good moment to inspect for any damage that occurred in the frenzy (e.g., pallet damages, misplaced goods) and tidy up. Essentially, you want to reset the stage so that your operations don’t carry chaos into the next cycle.

Planning for the end-of-season is as important as planning for the start. It ensures that you’re not caught off guard with a warehouse full of unsold stuff or a production line idle with excess raw materials. By thinking ahead about how to ramp down and what to do with leftovers, you can minimize financial impact and even extract some extra value (through sales or donations) from inventory that would otherwise collect dust. Plus, a smooth transition keeps your team from being overwhelmed or demoralized by post-season cleanup – instead, everyone knows the plan and can execute it to wrap up the season neatly.

8. Conduct Post-Season Analysis and Continuous Improvement

After you’ve navigated a seasonal peak, one of the most valuable things you can do is learn from the experience. Each season provides data and insights that can make the next one even more successful. This final step is about analyzing performance, capturing lessons, and continuously improving your seasonal inventory management strategy.

- Review Key Performance Metrics: Gather data on how you performed relative to your plan. Important metrics to examine include:

- Forecast Accuracy: How close were your demand forecasts to actual sales? Identify any major deviations – for instance, if you forecasted a 30% increase and got 50%, or vice versa. Pinpoint which products had the biggest forecast errors and investigate why (Was there an unexpected market trend? Did a competitor do something? Or was the data off?).

- Stockouts and Overstock Instances: Did you run out of any products at any point? If so, what did it cost you (in terms of lost sales or emergency costs to expedite more)? Conversely, what’s the quantity and value of leftover inventory? Calculate your sell-through rate for the season (what percentage of the inventory you prepared was actually sold). If sell-through is low for certain items, that indicates overestimation of demand or need for better end-of-season tactics.

- Customer Service Levels: Look at on-time delivery rates during the peak, order fulfillment times, and any customer feedback. If there were delays or errors, trace them back to root causes (e.g., was the warehouse picking process overwhelmed, or did a supplier delay cause late production?). Positive metrics like high on-time shipping percentages are wins to replicate; negatives highlight process breakdowns to fix.

- Cost Analysis: Examine how the seasonal strategy affected costs. This includes additional labor costs (overtime, temp staff), storage costs for extra inventory, any premium shipping or production costs incurred, and compare them to budget or to the revenue generated. You might find, for example, that a certain product’s peak season profit was eroded by excessive air freight expenses due to last-minute stock replenishment – a sign that better planning could save money next time.

- Forecast Accuracy: How close were your demand forecasts to actual sales? Identify any major deviations – for instance, if you forecasted a 30% increase and got 50%, or vice versa. Pinpoint which products had the biggest forecast errors and investigate why (Was there an unexpected market trend? Did a competitor do something? Or was the data off?).

- Debrief with the Team: Numbers are important, but so is qualitative feedback. Conduct a post-mortem meeting with key team members from different departments – production, warehouse, sales, procurement, finance, etc. Discuss what went well and what challenges arose. Often, front-line employees will have valuable insights (“We lost time constantly searching for Item X because it wasn’t where we expected,” or “Our supplier changed their delivery schedule and we weren’t informed early”). Encourage honesty and make it a blame-free discussion focused on improvement. Document the suggestions and pain points raised.

- Identify Improvement Opportunities: Based on the data and team input, list concrete areas to improve. Maybe you realize you need to invest in better forecasting software, or perhaps adding another loading dock would prevent trucking bottlenecks in peak shipping days. It could be simpler, like adjusting the layout of a particular section of the warehouse, or training an extra person on inventory management so there’s more coverage. Prioritize these improvements by impact and feasibility. Some can be done immediately (e.g., updating the inventory map labeling in CyberStockroom to avoid confusion next time), while others might be longer-term projects (like acquiring a new machine to increase production capacity).

- Update Standard Operating Procedures (SOPs): If you encountered any procedural hiccups or devised ad-hoc solutions during the season, formalize the learnings into your SOPs for next time. Maybe you found a better way to coordinate supplier deliveries – write that into your procurement timeline. If communication channels were an issue, set up a clearer communication plan (who contacts who, and when, for critical updates). Essentially, refine your seasonal playbook so you’re not starting from scratch each year.

- Leverage Technology Insights: Use tools like CyberStockroom to generate reports for analysis. If transfers were frequently done from one region to another mid-season, perhaps inventory allocation at the start was off – you can plan to distribute differently next time. Data doesn’t lie, and having it recorded in an inventory system makes analysis much easier than relying on memory. Chart out inventory level curves over time for key items to visualize how well your supply matched the demand curve.

- Iterate on Forecasting Models: Feed the latest season’s data back into your forecasting model. Each year of data can improve the model’s accuracy by adjusting trend and seasonal indices. If there were anomalies (like an unusual one-time event), note them so they can be considered (or excluded) in future plans. The goal is to refine your predictions continually, making each cycle’s plan more precise.

Continuous improvement is what turns seasonal inventory management from a stressful scramble into a well-oiled routine. By investing time after the season to learn and adapt, you build a competitive advantage – you’ll handle future fluctuations more smoothly and profitably. Manufacturing is a learning process; every production run, every sales season teaches something. Capture that value. And remember, even if a season went very well, there’s always room to innovate or prepare for even larger swings (businesses grow, markets change). Being proactive in this way means that when the next seasonal peak comes knocking, you’ll greet it with confidence and a stronger game plan than ever.

Conclusion

Seasonal demand fluctuations in manufacturing are a fact of life for many industries – but with the right strategies, they don’t have to be a nightmare. By forecasting early, calibrating production and inventory levels, optimizing your warehouse and resources, and leveraging modern tools like CyberStockroom’s visual inventory management, you can navigate the peaks and valleys of seasonal inventory with much greater ease. It’s all about balance and preparation: meet the high-demand periods head-on without overextending, and recover from them without excess baggage.

Manufacturers who master seasonal inventory management often turn what could be a challenge into an opportunity – peak seasons become highly profitable periods that fuel the business, and slow seasons become times to regroup, improve efficiency, and innovate. By following the how-to steps outlined in this guide and continuously refining your approach, you’ll build a resilient operation that thrives all year round. Here’s to smooth inventory sailing through every season!

Leave a comment