Imagine this: You’re in the thick of a major construction project when – bam! – a critical delivery is delayed. Your crew is ready to work, but that shipment of steel beams or HVAC components that was supposed to arrive “just in time” is nowhere to be found. Work grinds to a halt as everyone scrambles to locate missing pieces or arrange an emergency replacement.

On the flip side, maybe you’ve been burned by such delays before. This time, you over-ordered materials “just in case” – only to find that half of it isn’t needed after a design change, now sitting idle and tying up your budget. Welcome to the construction inventory tug-of-war between Just-in-Time (JIT) and Just-in-Case (JIC) strategies. These two approaches sit at opposite ends of the spectrum: one minimizes inventory to keep things lean, the other stockpiles inventory as insurance against the unexpected. Both have their merits and pitfalls, especially in the unpredictable world of construction projects. In this comprehensive guide, we’ll explore JIT vs. JIC in a construction context, compare their pros and cons, and discuss how to strike the right balance for your projects.

Understanding JIT and JIC in Construction Inventory Management

Before diving into the nitty-gritty, let’s clarify what we mean by Just-in-Time versus Just-in-Case inventory, and why this debate matters for construction inventory management:

- Just-in-Time (JIT) – “Lean” inventory management. This strategy means scheduling material deliveries and orders to arrive exactly when needed – no sooner, no later. In a JIT system, you keep inventory levels as low as possible, replenishing only in response to current demand or immediate project requirements. It’s often called a “pull” system because site crews “pull” in materials in sync with the construction schedule. The goal is to eliminate excess stock: reducing storage needs, minimizing waste, and freeing up cash. JIT was famously pioneered by Toyota in manufacturing and has since influenced construction through lean construction principles. On a construction site, JIT might look like arranging for concrete trucks or steel joists to show up the morning they’ll be installed, rather than weeks in advance.

- Just-in-Case (JIC) – “Buffer stock” inventory management. This is essentially the opposite approach: stockpile what you might need, just in case something goes wrong or plans change. In a JIC system (a classic “push” system), project managers order extra materials and parts proactively based on forecasts or worst-case scenarios. The site or warehouse holds a healthy buffer of inventory at all times. The rationale is that by having more than enough on hand, you’re prepared for surprise demand spikes, supplier delays, or design changes. With JIC, if an unexpected need arises or a shipment is late, work can continue because you’ve got backup stock on site. It’s an insurance policy against downtime – bought at the cost of higher inventory and storage expenses.

In simpler terms: JIT is about efficiency – getting exactly what you need, exactly when you need it, to avoid the costs of overstocking. JIC is about insurance – having extra on hand so you never run out, even if that means some excess may never be used immediately. Every construction company lies somewhere between these two extremes, often by necessity. Let’s explore why neither approach is one-size-fits-all for construction projects.

The Appeal of Just-in-Time (Lean Inventory) in Construction

At first glance, Just-in-Time inventory sounds like a dream for any cost-conscious construction firm. Originating from lean manufacturing, JIT’s promise of minimal waste and maximum efficiency is very attractive in construction, where margins can be thin and schedules tight. Here are some key benefits of adopting a JIT approach on construction projects:

- Lower Storage Costs and Less Site Clutter: Construction sites and laydown yards have limited space. With JIT, materials arrive only when needed, so you don’t need vast on-site storage for months’ worth of supplies. This can save on warehouse rental or storage yard costs. Plus, a lean inventory means your site isn’t cluttered with piles of materials waiting around – making for a safer, more organized work area. Think of how much easier it is to maneuver equipment or set up work areas when you’re not navigating around mountains of unused bricks or piping.

- Improved Cash Flow and Cost Savings: By ordering only what you need right now, you avoid spending money upfront on excess materials that just sit on the balance sheet. This frees up cash for other project needs. Your budget isn’t tied up in unused inventory. Additionally, avoiding over-ordering reduces waste – you’re less likely to end up with surplus materials that can’t be returned. Eliminating those “just in case” extras can trim direct material costs and also cut down indirect costs like insurance (since you have fewer assets to insure) and handling.

- Reduced Waste and Material Degradation: In construction, many materials can get damaged or deteriorate if they sit around too long. For example, lumber can warp if left in the elements, certain chemicals or paints can expire, and delicate finishes can get nicked or dirty in storage. JIT minimizes the time materials spend waiting to be used. Less idle time for materials means less chance for damage, spoilage, or theft before they’re installed. This can improve overall quality and reduce the cost of replacing ruined stock.

- Efficiency and Focused Workflows: When a project adopts a JIT mindset, it forces better planning and coordination. Trade crews know when items are arriving and can plan installations accordingly. It encourages tighter scheduling and sequencing of work. Subcontractors and suppliers become part of a finely tuned schedule. This can create a more efficient workflow where labor and materials converge at the right place and time. When done well, JIT can prevent overproduction or early tasks that then wait – each part of the project gets done when it’s actually needed, which aligns with lean construction practices.

- Stronger Supplier Partnerships: JIT relies heavily on reliable suppliers and logistics. Construction companies that go this route often develop closer relationships with their vendors – frequent communication, long-term agreements, and shared scheduling. Over time, these partnerships can lead to benefits like priority service, better payment terms, or collaborative planning. Essentially, JIT can foster a team mentality between the contractor and suppliers, where both sides coordinate to keep the project moving smoothly.

When JIT works as intended, a construction project can hum along like a well-oiled machine. You get exactly the materials you need, exactly when you need them, with minimal idle inventory. This lean approach can be a competitive advantage – reducing overhead, enabling quicker project turnarounds, and even helping bid more aggressively thanks to lower projected costs. However, this coin has a flip side: JIT’s success in construction depends on things going right – and construction is an industry where things often don’t go as planned.

The Risks and Realities of JIT on the Jobsite

For all its efficiency, Just-in-Time inventory in construction comes with significant risks. Construction projects are not controlled factory environments – they’re affected by weather, transportation delays, design changes, and human unpredictability. Relying solely on JIT can sometimes feel like walking a tightrope without a safety net. Here are the major challenges and downsides of a strict JIT strategy in construction:

Vulnerability to Supply Chain Disruptions: JIT leaves very little room for error. If any link in the supply chain breaks, the project can come to a standstill. Common scenarios include suppliers running late, trucks getting delayed by traffic or weather, or a last-minute shortage of a critical material in the market. Unlike a manufacturing plant that might have alternate suppliers on speed dial, a construction site might be remote or dealing with specialty items not easily replaced on short notice. One storm that shuts down highways or one supplier’s production glitch can halt your work for days or weeks because you don’t have buffer stock. For example, imagine counting on just-in-time delivery of roof trusses, but a sudden snowstorm closes the mountain pass the delivery truck must travel – your framing crew might be twiddling their thumbs on site for days.

Can’t Meet Sudden Changes or Demand Spikes: Construction is notorious for last-minute changes. Perhaps the owner decides to add an extra feature, or you discover on site that you need additional pipe fittings or more lumber than planned. With JIT, you likely haven’t kept any extras around. Any unexpected increase in material needs can lead to immediate stockouts. That means rushing to source more (often at higher “last-minute” costs) or pausing work until new materials arrive. The same goes for demand spikes: if you suddenly need to accelerate the schedule and consume materials faster, a pure JIT system struggles to cope because it’s tuned to the original plan only.

Dependence on Accurate Forecasting and Scheduling: JIT demands a near-perfect prediction of what materials will be needed and when. In construction, forecasting material quantities and timing is as much art as science. If your takeoff or estimate was off, or if the project schedule shifts, a JIT approach can quickly fall apart. For instance, if an earlier task gets delayed (say, permitting issues push back the start date), your carefully timed deliveries might now arrive too early (causing storage issues) or too late for the revised timeline. In other words, JIT in construction requires agile, dynamic scheduling and constant communication to adjust orders on the fly – something that can be very challenging in practice.

Supplier Reliability and Coordination is Crucial: When you keep minimal inventory, you’re placing a lot of trust in suppliers and carriers. If they don’t uphold their end, you suffer. A supplier who was rock-solid last year might hit a rough patch or get overwhelmed with other orders. Even previously dependable delivery routes can be disrupted by new regulations, trucking shortages, or port delays. Construction firms using JIT often find themselves heavily involved in logistics management, tracking shipments in real time and coordinating deliveries closely. This adds management overhead. Essentially, you sometimes end up micromanaging suppliers to ensure JIT works – and not every company has the resources or clout to do that effectively.

No Room for Error on the Jobsite: With no buffer, any mistake on site can cause immediate stock problems. If a crew accidentally damages some materials during installation or a miscalculation leads to waste, you don’t have spare units sitting around. Even common occurrences like a few pieces of lumber getting warped or concrete batches being off-spec can cause a scramble if you were only stocking exactly the required amount. JIT assumes a smooth, perfectly efficient use of materials, but real construction has a bit of inherent waste and breakage. Without a cushion, small errors can create big holdups.

Potentially Higher Costs in Some Cases: While JIT often saves money by reducing inventory, it can sometimes increase costs in hidden ways. For example, purchasing in small, frequent batches might mean losing out on bulk discounts. If buying 1000 bricks at once is cheaper per unit than buying 100 at a time, a JIT purist approach could mean you pay more over the project’s duration. Also, if material prices are volatile (a common situation with commodities like lumber, steel, or cement), not buying ahead means you’re exposed to price increases. In recent years, we’ve seen how quickly construction material prices can spike – a JIT strategy could mean having to pay a premium because you didn’t purchase and stockpile when prices were lower.

Pure JIT in construction is a high-risk, high-reward strategy. It works brilliantly when all the stars align – your forecasts are spot-on, suppliers are flawless, and there are no surprises. But construction rarely enjoys such ideal conditions. A strictly lean approach can leave a project teetering on the brink of delays. As one project manager wryly put it, running a jobsite 100% just-in-time can feel like “playing supply chain roulette.”

Does that mean the opposite approach – Just-in-Case stockpiling – is the answer? Let’s examine the other side of the coin.

The Case for Just-in-Case (Buffer Stock) in Construction

If JIT is about keeping lean, Just-in-Case is about keeping safe. The JIC philosophy says: “Yes, inventory costs money, but running out costs even more.” In an industry as unpredictable as construction, there are plenty of reasons companies choose a just-in-case inventory strategy. Here are the key advantages of JIC for construction projects:

- Insurance Against Delays: The most obvious benefit – with extra materials on hand, you’re protected if something goes wrong. Supplier delay? No problem, you already have enough rebar on site to keep pouring concrete for a few more days. A sudden spike in material usage? You have spare drywall in the trailer ready to go. In essence, a buffer stock is like a safety net that ensures production never has to stop due to lack of materials. This is huge in construction, where schedule slippages can be incredibly costly. JIC practitioners can absorb shocks and keep the project moving despite supply hiccups. This “disaster-proofing” means less panic and firefighting when Murphy’s Law strikes.

- Flexibility for Changes and Scope Creep: Construction projects often evolve – design modifications, add-ons, or change orders are common. If you’ve got some extra materials stored ‘just in case’, those changes are easier to accommodate. For example, if an owner suddenly wants to extend a tiled area by a few hundred square feet, a JIC-oriented contractor might already have additional tiles from the same batch in stock – no waiting weeks for a new order (that might not match the dye lot). JIC inventory gives you wiggle room in the face of uncertain demand. Your project can adapt to changes without grinding to a halt. This can improve client satisfaction because you can respond quickly to new requests or scope changes.

- No Idle Crews (Materials Always Available): One of the worst things in construction is paying skilled workers who can’t work because materials are missing. By maintaining buffer inventory, you reduce the risk of work stoppages. Crews stay productive because whenever they reach for something, it’s likely there. There’s less downtime waiting around for deliveries or making emergency supply runs. In other words, JIC can help preserve labor productivity. It’s like keeping spare tools or backup equipment – you hope you don’t need the extras, but if you do, you’re glad to have them so your team isn’t standing idle.

- Bulk Purchasing and Cost Opportunities: JIC often involves buying larger quantities at once. This can sometimes translate to lower unit costs thanks to bulk discounts or wholesale pricing. It can also mean you purchase materials at an opportune time – for instance, buying lumber or drywall in the off-season when prices are lower, and storing it until it’s needed. Contractors experienced in JIC will keep an eye on commodity prices and availability, snapping up materials when they’re cheap or abundant. In a volatile market, this proactive purchasing can save money in the long run. (Of course, the flip side is you have to predict things right – which isn’t always guaranteed.)

- Less Pressure on Forecasting Accuracy: Because JIC assumes “better too much than too little,” it reduces the reliance on perfect forecasting. If your material estimates were a bit off, it’s usually okay – you bought extra anyway. If a project turns out to need 10% more of something, you likely have it covered. Essentially, carrying extra stock acts as a buffer for human error in planning and estimating. It provides peace of mind that even if the project scope grows or you miscalculated quantities, you won’t be immediately scrambling. For construction managers, this can remove some stress, knowing there’s a cushion.

- Competitive Edge in Availability: In times of general supply shortage, a JIC approach can actually give a contractor a competitive advantage. If certain materials become scarce industry-wide (think of sudden shortages of cement, or the global scramble for PPE and lumber we saw in recent years), those who stockpiled early can keep working while others are stalled. They might even take on additional projects or help out peers (at a cost). Having a reputation for never running out of materials can win client trust – clients want to know the builder they hired won’t delay their project due to lack of supplies.

For these reasons, many construction companies – especially those who have been “burned” by JIT failures in the past – feel more comfortable with a just-in-case mindset. It’s a conservative, risk-averse strategy: you plan for the worst so you can guarantee performance. In an industry where delays and overruns are common, being the contractor who always has what’s needed on hand can be a selling point.

However, JIC is not without its own costs and headaches. If it were perfect, everyone would just hoard inventory (and clearly that’s not the case). Let’s consider the downsides of a heavy stockpiling approach in construction.

The Downsides of Just-in-Case (Overstocking and Hoarding)

Just-in-Case might keep you safe from shortages, but it brings along a different set of problems. Hoarding inventory “just in case” can easily slip into inefficiency and waste if not managed carefully. Here are the main challenges and disadvantages of a JIC strategy in construction:

- High Carrying Costs and Storage Issues: The most immediate drawback of keeping extra inventory is the cost of storage and handling. All that material needs to sit somewhere – whether it’s a warehouse, a rented storage yard, or on the jobsite itself. Storage isn’t free. You might be paying monthly fees for warehouse space, or if on-site, you might need to invest in shipping containers, sheds, or additional security. There’s also the labor of moving, organizing, and managing that inventory. Industry analyses often estimate inventory carrying costs to be around 20–30% of the inventory’s value per year when you factor in storage, capital, insurance, and obsolescence. For construction, even short-term projects can see costs add up when you’re juggling tons of materials across multiple sites. In short, excess inventory ties up capital and demands resources to look after it.

- Risk of Waste, Damage, and Obsolescence: When you stockpile materials, you accept that some of it may never get used (or not used for its intended project). If demand never reaches the “worst case” you planned for, you end up with leftover materials. Best case, you return them to the supplier (often with restocking fees). Worst case, they sit until they become obsolete or deteriorate. In construction, spec changes can quickly make surplus materials useless – e.g., an engineering change means that expensive custom-size beams you bought in advance are now the wrong size. Also, items can get lost, damaged, or stolen the longer they lie around unused. We’ve all seen forgotten pallets of materials at the back of a laydown yard that eventually get written off. Overstocking increases the chance of waste. It’s painful to realize that the pricey fixtures you stockpiled are now out of spec or that a portion of your cement expired because the project got delayed beyond its shelf life.

- Cash Flow Drain and Opportunity Cost: Every dollar sitting in a pile of bricks or a stack of copper wire in your warehouse is a dollar not available for other uses. JIC ties up working capital. For smaller contractors especially, this can strain finances – money spent on excess materials can’t be used to invest in new equipment, hire needed staff, or pursue new projects. The opportunity cost of overstocking can be significant. If the project gets canceled or delayed, that money might be tied up indefinitely. Additionally, if prices drop after you bought (which can happen in cyclic markets), you’ve effectively spent more than necessary. Unlike JIT which stays very liquid, JIC can make a company “inventory rich but cash poor,” which is a risky position if other costs or surprises come up.

- Logistical Complexity: More inventory means more complexity in management. You have to track a larger volume of items, across potentially multiple storage locations. Ensuring that the right materials still make it to the right site when needed can get confusing if you have stashes of supplies in various places. Without good inventory control, you might fall into scenarios like ordering material that you actually already have (but forgot about in the far corner of the yard). Organization and inventory tracking become critical – and not every firm has modern systems for this (many still rely on spreadsheets or manual counts). JIC essentially shifts some burden from suppliers (in a JIT system) back onto your internal team to manage inventory. That’s manageable, but it requires discipline and possibly software/tools to do well.

- Site Management and Safety Issues: On active jobsites, excess materials can be a double-edged sword. Yes, it’s great to have spares, but those piles of materials can become hazards or impediments. Large stockpiles can clutter the site, making navigation difficult for workers and machinery. Clutter can lead to accidents (tripping over materials, blocked emergency access, etc.). Materials left lying around can also attract theft or vandalism, especially valuable items like copper pipes or power tools. So with JIC, you often need to implement stronger site security and loss prevention measures – more costs and management effort. A neat, minimal site is generally safer and more efficient; an overstocked site requires careful layout planning to avoid turning into a maze of pallets and tarp-covered heaps.

- Potential for Overestimation and Wasteful Practices: Human nature can sometimes take “just in case” too far. Project teams might overestimate needs by a wide margin, just to be safe, and end up ordering far more than realistically required. This “better to have too much” mentality, if unchecked, can lead to significant waste and complacency in planning. There’s less incentive to optimize usage or cut waste because, well, we’ve got plenty more if we screw up. In the long run, this can erode profitability. Also, if multiple projects or contractors hoard materials at the same time (especially during scare supply periods), it can exacerbate market shortages and drive prices up for everyone – a broader economic downside of JIC on an industry-wide level.

As we can see, all-in on JIC can backfire by driving up costs and inefficiencies, even if it reduces immediate risk of stockouts. A warehouse full of unused materials is essentially money gathering dust. Construction companies have gone under not from lack of work, but from poor inventory management causing cost overruns and cash crunches (imagine buying a ton of material on credit and then the project gets delayed – you’re stuck with debt and stuff you can’t use yet).

Clearly, both JIT and JIC have serious pros and cons for construction. This leads to an important realization: it’s not about choosing one or the other universally – it’s about finding the right mix.

Before we talk about blending the strategies, here’s a quick side-by-side comparison of key traits of JIT vs JIC in construction:

Just-in-Time vs Just-in-Case: Quick Comparison

| Aspect | Just-in-Time (JIT) | Just-in-Case (JIC) |

|---|---|---|

| Approach | Reactive “pull” – order as needed in real time based on current demand. | Proactive “push” – purchase based on forecasts and worst-case needs in advance. |

| Inventory Levels | Minimal – only keep what’s immediately needed on site. | Ample – maintain a buffer stock (safety stock) of key materials. |

| Goal/Focus | Efficiency and cost reduction by avoiding excess. Lean operations. | Preparedness and resilience by avoiding running out. Continuity of work. |

| Benefits | Low storage costs, less waste, better cash flow, no clutter. | Avoid project delays, handle demand spikes or changes easily, bulk pricing. |

| Risks | High risk of delays if supply chain falters, reliant on accurate timing and forecasts. | High carrying costs, potential waste/obsolescence, ties up capital, requires space. |

| Best For | Stable, predictable usage items; reliable suppliers; fast lead times. | Unpredictable usage items; long lead-time or critical materials; unreliable supply lines. |

| Key Requirement | Precise planning & scheduling; strong supplier coordination; agile project management. | Sufficient storage & security; good tracking system to manage stock; financial capacity for upfront purchases. |

Striking a Balance: Hybrid Inventory Strategies for Construction

In practice, the smartest construction inventory strategy isn’t all-or-nothing with JIT or JIC, but rather a hybrid approach. The idea is to balance lean efficiency with buffer-stock security. This balanced strategy is sometimes playfully called “lean buffering” – having just enough inventory cushion to protect the project, but not so much that it becomes overkill. Here’s how construction teams can achieve this balance:

1. Categorize Materials by Criticality and Risk

Not all construction items should be treated the same. Go through your project’s bill of materials and classify items into groups such as:

- JIT-Friendly Materials – These are materials that are easy to source on short notice, readily available from multiple suppliers, or inexpensive to procure as needed. They often include standard, off-the-shelf items or bulk commodities with stable supply. For example, common fasteners, standard dimension lumber, or generic hardware might fall here if local suppliers are abundant. You can feel comfortable using JIT for these because the risk of shortage is low and the impact of any delay is minor.

- Buffer Candidates – These are important items with moderate lead times or some supply uncertainty. Perhaps you can get them within a week or two, but any delay would start impacting the schedule. Here, you might keep a small safety stock. For instance, certain electrical components or plumbing fixtures that are somewhat standard but could delay multiple crews if unavailable might warrant a buffer of a few extra days’ or weeks’ supply. Maybe you maintain a two-week cushion for these – enough to handle minor hiccups, but not an excessive hoard.

- Critical Stockpile Essentials – These are the make-or-break materials: items with long lead times, limited suppliers, or absolutely critical to the project’s critical path. Think custom-fabricated steel connectors, specialized glass panels, unique finish materials, or crucial equipment parts. Any delay on these can freeze construction progress. For such items, a larger reserve or an upfront stockpile is justified. You might order extra units or have backups on hand in case one is delayed or a piece is damaged. This way, work can continue even if the primary supply is disrupted.

By classifying materials this way, you’re essentially deciding where to be lean and where to be cautious. Many construction experts use an 80/20 type rule: 80% of your materials (by variety) might be fine on JIT, but 20% (often the most critical or tricky ones) deserve JIC treatment. The result is a much more resilient plan that doesn’t break the bank with storage of everything, but also doesn’t leave you exposed on the most important needs.

2. Maintain a Strategic Buffer – Not an Overstock

For the items you decide to buffer or stockpile, determine how much is truly needed as a safety net. This could be based on lead time (e.g., “if the lead time is 4 weeks, we’ll hold 4 weeks of use in reserve”) or based on past variability (e.g., “we usually order 100, but usage can vary ±10, so we’ll keep an extra 10%”). The key is to avoid the extremes: not zero extra, but also not hoarding a year’s supply for a 3-month project.

A concept borrowed from manufacturing is to store enough to cover the “longest reasonable delay” you might face. For example, if historically the worst supplier delay you’ve had for a given item is 2 weeks, you might keep 2 weeks of that item on hand at all times. This way, you’re prepared for a realistic worst-case, not an Armageddon scenario. The aim of a strategic buffer is to cushion against normal variability and hiccups, not every imaginable disaster.

3. Use Data and Forecasts to Continuously Adjust

A balanced strategy isn’t “set it and forget it.” It requires monitoring and adjusting as a project progresses. Regularly review your inventory levels and usage rates. Are certain materials being used faster than expected? Increase their buffer a bit. Are others not moving at all? Perhaps you can slow down further orders (to avoid piling up more). Modern inventory tracking (even simple weekly stock reviews or using software) can help spot trends. Over time, you might refine how much buffer is truly needed.

Forecasting tools or even simple spreadsheets can be used to project when you’ll run out given current usage, so you can plan reorders with just enough lead time.

Also keep an eye on external factors: if a supplier warns of an upcoming shortage or price hike, you might pre-order extra as a one-time JIC measure. If a certain material’s critical phase on the project is nearing completion, you might let its buffer run down rather than reordering more. This dynamic adjustment ensures you’re lean when you can be, and buffered when you need to be, at the right times.

4. Develop Strong Supplier Relationships (and Backups)

Whether leaning JIT or JIC, supplier relationships are your lifeline. For a balanced approach, communicate closely with suppliers about what items are critical to you and where you might need priority. Consider setting up agreements or understandings: for example, a supplier could hold a certain amount of stock in reserve for you (effectively an off-site JIC stock that you don’t have to store). It’s also wise to qualify backup suppliers for critical items – even if you prefer Supplier A for main deliveries (JIT), having Supplier B who can bail you out with a rush order (your JIC backup plan) is valuable. Some contractors even adopt a dual-supplier strategy: one provides the regular JIT supply, another is contracted to provide emergency shipments if needed. This can cost a little more (maintaining two relationships), but drastically cuts risk.

In construction, collaborations like these can make your inventory approach far more resilient. It’s much easier to be lean when you know you have a friend to call who can pull you out of the fire in a pinch.

5. Leverage Technology and Tools

Managing a hybrid strategy manually can get complicated – this is where inventory management software and other digital tools become game-changers. A good system can track inventory levels across multiple locations in real time, alert you when you’re running low (so you can reorder before it’s too late), and help analyze usage patterns to set optimal reorder points. Some companies use barcoding or RFID tracking on materials to monitor consumption automatically. Others implement a Kanban system (borrowed from lean manufacturing) where a visual signal or automated trigger is set off when supplies drop to a certain level, prompting a reorder just in time before reaching zero. Technologies like these effectively enable JIT for normal operations, while ensuring JIC buffers are maintained as a fallback.

Real-time tracking is especially useful in construction where materials often move between a central warehouse, laydown yards, and jobsite storage. Knowing exactly how much of each item is at each location helps you decide if you truly need more or if you can redistribute existing stock. It also prevents accidental over-ordering because you have clear visibility.

6. Plan for the Worst (Within Reason)

A balanced strategy also includes contingency planning. Identify the nightmare scenarios that could hit your project – a supplier going bankrupt, a sudden import tariff on a material, a natural disaster delaying shipments, etc. For the high-impact, moderate-probability risks, consider specific mitigation: maybe that means ordering a critical component earlier than usual (not exactly JIT) to make sure it’s on hand, or having a rental agreement ready for a backup piece of equipment, or negotiating a consignment stock that you only pay for if used. Essentially, where the consequences are dire, lean a bit more JIC; where things are more routine, lean JIT.

The beauty of a hybrid approach is flexibility. You are not dogmatically tied to one philosophy. You can be lean in areas that allow it and cushioned where it’s necessary. Construction projects often have phases – you might start with more JIC during foundational stages (when any delay is very costly), then move to more JIT during finishing stages when procurement is simpler and you want to avoid leftover specialty finishes. Or vice versa, depending on project specifics. The key is to be intentional and strategic in how you manage inventory, rather than letting it just “happen” to you.

To illustrate the power of balancing strategies, consider a quick example: A modular building factory found that standard materials like drywall and screws could be delivered weekly without issues (JIT), but custom-fabricated steel frames had 8-week lead times and occasional supplier delays. So they kept a small on-site buffer of those steel frames (maybe 2-3 weeks’ worth). In one instance, when their supplier’s shipment was delayed by a storm, this buffer allowed them to continue production without interruption – by the time they used up the buffer, the supplier’s delivery had arrived. They avoided a costly shutdown, yet they weren’t overstocking everything, only the risky item. Overall, they reported saving on storage costs (by not stockpiling everything), while also preventing downtime – the best of both worlds.

How CyberStockroom Can Help You Balance JIT and JIC

Managing a hybrid inventory strategy across multiple job sites and warehouses might sound complex – but that’s exactly where modern tools like CyberStockroom come into play.

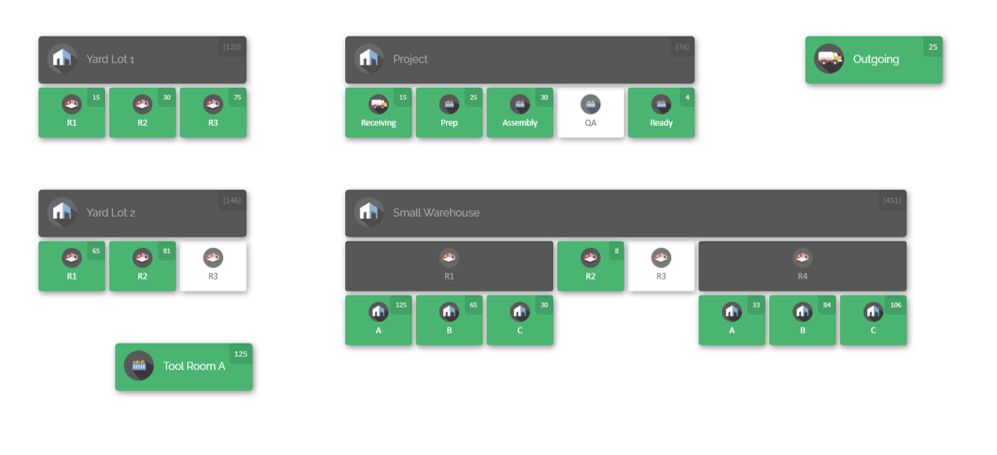

CyberStockroom is a visual, map-based inventory management system designed with scenarios like construction projects in mind, where materials and equipment are constantly on the move. Here’s how a tool like CyberStockroom can support and enhance your JIT/JIC balancing act:

- Interactive Inventory Map (Bird’s-Eye View): At the heart of CyberStockroom is an interactive map that represents your warehouses, laydown yards, and construction sites. Instead of sifting through spreadsheets or paperwork, you get a visual overview of where all your materials and tools are located in real time. For example, you can look at the map and instantly see that you have 50 cement bags at Warehouse A, 20 at Jobsite B, and another 30 in a laydown yard. This bird’s-eye view makes it much easier to decide when to use existing stock (if one site has excess, you can transfer it) versus when to order new stock. It supports a JIT approach by helping you find and deploy what you already have on hand first – reducing unnecessary new orders – while also highlighting if your buffer stock in any location is running low.

- Real-Time Multi-Location Visibility: Construction inventory often spans several locations. CyberStockroom’s cloud-based platform gives you real-time visibility across all your sites simultaneously. This means if you transfer 100 bricks from the main warehouse to Site C, everyone (warehouse manager, Site C supervisor, project manager at HQ) sees that update instantly on the map. Such visibility is crucial for avoiding the common JIC pitfall of over-ordering “just in case” because one hand of the organization doesn’t know what the other hand has. With all teams sharing one live system, you can confidently lean on JIT where appropriate – you’re not ordering blind, you know exactly what’s available and where. Conversely, you can also keep tabs on your strategic buffers: the system will show current quantities and even allow you to set threshold alerts (e.g. flag if stock of rebar falls below the two-day reserve level you want). This multi-location tracking essentially acts as the nervous system for a hybrid inventory strategy.

- Easy Updating with Barcode Scanning: One reason some construction firms struggle with JIT is that their inventory data isn’t up to date (leading to nasty surprises like thinking something is in stock when it’s not). CyberStockroom helps solve this by making it easy for your team to update inventory movements. It supports simple barcode scanning and quick data entry whenever items are received, moved, or used. For example, when a pallet of copper pipes arrives on site, a staff member can scan a code and instantly log it into the system at that site. Later, if some pipes are transferred to another site or used up, a quick scan updates their new location or reduces the count. This real-time accuracy means your JIT calculations (like how much to order for next week) and JIC monitoring (like ensuring your safety stock is intact) are based on reliable data, not yesterday’s guess. And since CyberStockroom is designed to be user-friendly (even for non-technical crew), your field teams can actually keep it updated without a ton of training or hassle.

- Drag-and-Drop and Visual Organization: CyberStockroom’s interface lets you manage inventory with intuitive drag-and-drop actions on the map. Say you have a container on your site map representing the “East Lot storage” and you want to move equipment or materials into it – you can literally drag items on the map to that container location. This visual and physical approach to inventory management makes it easier to plan and execute where to keep buffer stock on a site. You can virtually lay out your laydown yard: designate zones for different materials and see capacity. Organizing this way helps prevent the chaos that sometimes comes with JIC hoarding. You’ll see if one area is overloaded or if items are not where they should be. A clean, updated visual map cuts down the time workers spend searching for stuff (recall that statistic about hours lost each week looking for misplaced items – a map solves a lot of that). Essentially, CyberStockroom brings order and clarity, which is vital whether you’re trying to be lean or maintain buffers – because knowing what you have and where it is underpins any strategy.

- Cloud-Based Access Anywhere: CyberStockroom is cloud-based and works on common devices, so whether you’re a project manager at the main office, a superintendent in the field, or a warehouse coordinator, everyone can access the same system simultaneously. This fosters collaboration. You can literally have a morning meeting where the team looks at the live inventory map together to decide that day’s plan: “Okay, we’re running low on gravel at Site A – let’s send a truck from Site B’s excess pile. The map shows Site B has plenty. Meanwhile, make sure to reorder conduit by Friday since our buffer is almost at its minimum there.” This shared situational awareness is incredibly valuable. It helps break down the silos between procurement, warehouse, and field teams – a common cause of inventory issues. With better communication and info, you naturally become more efficient (JIT) while staying prepared (JIC).

- Audit Trails and Accountability: With every movement logged (who moved what, when, from where to where), CyberStockroom creates a history for each item. This is great for addressing one of the hidden issues of JIC: theft and loss. If something goes missing, you can trace its last known location and who last handled it. This discourages pilferage and increases accountability among the crew. When people know that inventory is being tracked meticulously, they tend to respect the processes more. So, if you are holding valuable buffer stock on site, you have less fear that it will “mysteriously disappear.” And for JIT, if a delivery comes in and is logged, everyone knows it arrived – reducing miscommunication. The audit trail can also be useful for end-of-project wrap-up, to easily see what surplus you have (maybe you can return or reuse on the next job, rather than it getting forgotten).

CyberStockroom acts as the “central brain” for your inventory, allowing you to execute a balanced strategy with confidence. By knowing exactly what you have, where it is, and how it’s changing in real time, you gain the agility to be lean and the insight to maintain safety stocks smartly. Instead of reacting blindly to stockouts or over-ordering out of fear, you make data-driven decisions. The result? Construction projects that run on time, on budget, and with a lot less stress over missing materials or overstuffed warehouses.

Finding Your Optimal Inventory Strategy

In the grand debate of Just-in-Time vs. Just-in-Case, the real winner for construction projects is often neither extreme, but a thoughtful combination of both. As we’ve explored, construction inventory management is a balancing act – avoiding the costly consequences of running out of materials, while also curbing the waste and expense of overstocking. The stakes are high: manage it well and your project flows smoothly with minimal waste; manage it poorly and you face delays, budget overruns, and logistical nightmares.

Key takeaways to remember:

- JIT and JIC each have a role. JIT shines in efficiency and cost-savings, perfect for items that are predictable or easily obtained. JIC provides a safety net and peace of mind, critical for items that are irreplaceable or prone to supply hiccups. Don’t view them as adversaries, but as tools in your toolkit.

- Assess your project’s needs and risks. Every project might require a different mix. A straightforward build with reliable local suppliers might lean heavily on JIT. A complex, one-of-a-kind project with imported materials might need more JIC. Take the time in project planning to identify which materials/processes could bottleneck your job and plan inventory for those accordingly.

- Communicate and collaborate. Inventory strategy doesn’t exist in a vacuum. It intersects with your scheduling, budgeting, procurement, and supplier management. Bring your purchasing people, site managers, and even key suppliers into the conversation. A well-aligned team will ensure that if you’re trying a lean approach, everyone is on board to make it work – and if you’re buffering some stock, everyone knows why it’s important.

- Iterate and improve. Think of your inventory strategy as a living aspect of project management. Gather lessons from each project: Did we run out of anything unexpectedly? Did we end up with a lot of surplus? Use those lessons to refine your approach next time. Over multiple projects, you’ll get better at dialing in that “sweet spot” of inventory levels. What’s more, your suppliers will learn your style too – a contractor known for planning well and communicating needs is more likely to get priority service, which further helps JIT performance.

- Use modern solutions to stay on top of inventory. The days of managing construction inventory with clipboards and memory are fading. Whether it’s a comprehensive tool like CyberStockroom’s inventory map or another system, technology can greatly enhance visibility and control. It’s much easier to be proactive (a must for JIT) and organized (a must for JIC) when you have real-time data and maybe even AI-driven forecasts at your fingertips. These tools often pay for themselves by preventing just one or two major inventory mistakes (like an expensive express shipment or a project delay).

For construction professionals, mastering this balance between JIT and JIC can become a competitive advantage. You’ll be able to deliver projects with lower costs and fewer delays, which is something clients and stakeholders notice. In an era of tight timelines and even tighter margins, optimizing inventory management is no longer optional – it’s an integral part of successful project execution.

In the end, the goal is straightforward: Have the right materials in the right place at the right time, and in the right quantity. Achieving that consistently may require a bit of JIT, a dash of JIC, and a lot of smart planning – but it’s absolutely within reach for any construction team willing to put thought into their inventory processes. With a balanced strategy and maybe a high-tech map in hand, you can keep your projects well-supplied without breaking the bank on excess. That means fewer frantic phone calls about late deliveries, fewer yards packed like overstuffed storage units, and more days where the crew can just get to work with everything they need.

Finding the balance between just-in-time and just-in-case ultimately means greater resilience and efficiency – so you can build with confidence, knowing you’re prepared for whatever challenges come your way, but also running a lean, competitive operation. And when you strike that balance just right, it can feel as satisfying as finishing a project on schedule and under budget – because often, that’s exactly what a good inventory strategy helps you do. Here’s to building smarter with better inventory management!

Leave a comment