Picture this: One of your primary production lines grinds to a halt because a critical machine component fails. Every passing minute of downtime means products aren’t being made, orders are delayed, and money is slipping away. You rush to the spare parts storeroom only to find the replacement part isn’t in stock. Now you’re scrambling—calling suppliers, expediting orders, or improvising a workaround—while your plant’s output remains at a standstill. For many manufacturing professionals, this nightmare scenario is all too familiar. It underscores a simple truth: effective MRO spare parts inventory management is key to minimizing downtime.

Manufacturing plants rely on thousands of components and supplies to keep equipment running. Maintenance, Repair, and Operations (MRO) spare parts include everything from large replacement motors and gearboxes to tiny sensors, gaskets, oils, and bolts. They may not be part of the final product you sell, but these parts are the lifeblood of your operations. When they’re properly managed, machines stay up and running, and downtime is kept to a minimum. When they’re mismanaged or neglected, even a minor missing part can bring production to a costly halt.

The High Cost of Downtime – and How Spare Parts Help

Downtime in manufacturing is more than just an inconvenience – it’s a direct hit to the bottom line. When production stops unexpectedly, the company is losing money every minute while overhead costs (labor, utilities, etc.) continue. Recent industry research has put this into perspective: unplanned manufacturing downtime can cost hundreds of thousands of dollars per hour on average, and in some sectors it’s even higher. In fact, one 2024 report found that the world’s largest manufacturers lose roughly 11% of their annual revenue due to unplanned outages. This includes not just lost production, but also emergency repair costs, expedited shipping for parts, and even penalties or reputation damage for late deliveries. In short, downtime is incredibly expensive.

So where do MRO spare parts come in? They are often the first line of defense against excessive downtime. For many equipment failures, the duration of downtime is directly tied to how quickly you can get the necessary replacement part. Consider two scenarios:

- Scenario A: A critical motor fails, but you have a spare on the shelf. Your maintenance team swaps it out immediately and the line is back up in a couple of hours. Downtime is minimized, and you meet your production targets for the day.

- Scenario B: The same motor fails, but you don’t have a spare. You must order one from the supplier, wait 24-48 hours (or longer) for delivery, and keep the line down that whole time. The downtime snowballs into delayed orders, idle workers, and a big financial loss.

In Scenario A, an effective spare parts inventory saved the day. Having the right part in stock can turn a potentially multi-day outage into a brief pause. This is why managing your MRO inventory is so critical. It ensures that when something breaks, you already have what you need to fix it. Well-managed spares can literally save you thousands or millions of dollars by preventing extended downtime.

Of course, there’s a balance to strike – keeping every possible part in stock “just in case” would eliminate some downtime, but it’s not financially practical. We’ll talk later about finding the right balance between avoiding stockouts and avoiding excessive inventory costs. The key takeaway here is that spare parts availability is a major factor in downtime reduction. A proactive MRO inventory strategy can dramatically improve your plant’s uptime, equipment reliability, and maintenance efficiency.

Common Challenges in MRO Spare Parts Inventory Management

Managing MRO spare parts in a manufacturing environment is no small task. Many organizations struggle with their MRO inventory for a variety of reasons. Before we dive into best practices, it’s useful to understand the common challenges you might face in spare parts management:

- Unpredictable Demand: Unlike production materials, spare parts usage can be highly irregular. A machine might run for years without a failure (no demand for its spare parts), then suddenly break down tomorrow. This intermittent and unpredictable demand makes forecasting difficult. You might have critical parts that sit unused for long periods, until the day they’re urgently needed.

- Huge Variety of Parts: Manufacturing plants can have thousands of different spare parts – from large assemblies down to tiny fasteners. Keeping track of all these SKUs (stock-keeping units), each with unique specs and suppliers, is complex. It’s easy for inventories to become disorganized or for teams to lose sight of what’s on hand.

- Stockouts vs. Overstock Dilemma: There’s constant pressure to avoid stockouts (which cause downtime) while also minimizing inventory costs. Maintenance teams often want to err on the side of holding more spares “just in case,” whereas procurement or finance might push to reduce stock to save money. This misalignment can lead to either critical shortages or excessive stock of items that tie up capital and storage space.

- Data and Tracking Issues: Surprisingly, a lot of companies still manage MRO inventory with manual methods. You might find spare parts tracked in spreadsheets, on whiteboards, or not tracked at all beyond purchasing records. This leads to inconsistent or outdated information – for example, a part might appear “in stock” on a spreadsheet when in reality it was used last week and not recorded. Lack of a centralized, real-time tracking system causes errors like duplicate orders, missing parts, or difficulty in locating items.

- Lack of Visibility: Even when parts are in inventory, finding them quickly is a challenge if the storage system isn’t organized. Some plants have multiple storerooms or tool cribs scattered around, with different people overseeing them. Without a clear view of what is where, maintenance techs may waste precious time searching or end up re-ordering parts that actually exist in a different closet across the facility. Limited visibility also means you might not realize a critical part is running low until it’s too late.

- Obsolete and Excess Stock: Over years of operation, it’s common for storerooms to accumulate obsolete parts (for decommissioned equipment) or excess quantities of slow-moving items. Without periodic review, these items gather dust and take up space (and money). They also make it harder to find the parts that are actually needed, cluttering the inventory.

- Emergency Ordering Costs: When a needed spare isn’t on hand, you often incur rush costs – expedited shipping fees, paying premium prices to get a part overnight, or cannibalizing parts from another machine. These emergency measures are expensive and disrupt the normal workflow. Frequent emergencies usually indicate weaknesses in the inventory management process.

- Departmental Silos: MRO inventory touches multiple groups – maintenance, operations, procurement, finance, even IT. If these groups don’t communicate well, it leads to siloed decision-making. For example, maintenance might decide to stock a certain part, but procurement wasn’t looped in to manage the supplier relationship, or vice versa. Siloes can also result in inconsistent priorities (as mentioned, maintenance vs. purchasing tension over stock levels). Without collaboration, an optimal spare parts strategy is hard to achieve.

These challenges can make MRO spare parts management feel overwhelming. The good news is that each challenge has a solution or best practice to counter it. In the next section, we’ll break down a step-by-step approach and strategies to overcome these issues and build a robust MRO inventory management system that keeps downtime to a minimum.

How to Optimize MRO Spare Parts Inventory Management (Step by Step)

Effective MRO spare parts management isn’t just about stocking more parts – it’s about smart planning, organization, and using the right tools. Below, we outline a series of steps and best practices to help you get your MRO inventory under control and aligned with your downtime reduction goals. Think of this as a roadmap to building a resilient spare parts program for your manufacturing operations.

1. Catalog Your Inventory and Clean Up Data

Start with the basics: know exactly what you have and what you need. This begins by creating a comprehensive catalog of all MRO spare parts in your facility. If you already have a list, take time to clean up the data. If not, conduct an inventory audit. Key actions in this step include:

- Inventory Audit: Go through storerooms, maintenance trucks, tool cribs – any place where spare parts reside – and record every item. Note the part name, description, part number, supplier or manufacturer, and the quantity on hand. This might be tedious, but it’s a foundational step. Often, teams discover duplicates or surprises (“I didn’t know we had three of those in the back shelf!”) during this process.

- Data Cleansing: Standardize the naming and information for each part. Ensure that each item has a unique identifier or SKU in your system. Clear out or mark obsolete parts (for equipment you no longer use) so they’re not mistaken as active inventory. Resolve any duplicate entries (e.g., the same bearing listed under two slightly different names). Consistent data is critical for avoiding confusion later.

- Categorize Parts: Organize the catalog in a logical way that makes sense for your operations. For example, categorize by equipment type (all spare parts for the CNC Machine #5 in one group), by part function (all pumps, all electrical components, etc.), or by department. Many companies use a combination of categories and subcategories. The goal is to make it easy to filter and find what you need in a database. You might also tag parts with attributes like critical spares, consumables, fasteners, etc. This categorization will help later in setting priorities and stock levels.

- Record Key Attributes: For each part, record details that will help in decision-making. This can include the lead time to get a new one from the supplier, the cost, the vendor contact, and which machines or processes the part is used in. For example, note if a specific type of belt fits multiple motors around the plant or just one machine model. This information will be invaluable when deciding how many to keep and where.

By the end of this step, you should have a single source of truth for all your spare parts – ideally in a digital format. Whether that’s an Excel sheet or (better yet) an inventory management software database, it’s important that everyone uses the same master list moving forward. This catalog forms the backbone of your MRO inventory management program.

2. Identify Critical Spares and Set Priorities

Not all spare parts are equally important. The next step is to identify your critical spares – the parts that are absolutely vital to keep on hand because their absence would cause significant downtime or safety issues. Focusing on critical items ensures you allocate resources to the areas with the biggest impact on uptime. Here’s how to approach it:

- Determine Criticality: Review each piece of equipment in your plant and ask, “What spare parts does this machine need to keep it running, and what happens if this part fails?” If failure of a part would stop production entirely (with no workaround) or pose a safety hazard, that part is critical. Also consider the lead time: a part might be deemed critical if it takes a long time to procure, even if it doesn’t fail often. For example, a unique circuit board that rarely fails but would take 8 weeks to replace should be treated as critical.

- ABC (or XYZ) Classification: Many organizations use an ABC classification for inventory, which often factors in usage value (annual consumption value). For MRO, you might tweak this to factor in criticality and usage frequency. “A” parts could be high-value or critical spares that you must always have, “B” parts are important but with moderate usage/impact, and “C” parts are low-cost, low-impact items. There’s also an approach to classify by usage variability (sometimes called XYZ) especially for spares with intermittent demand. The exact method is less important than the outcome: a ranked list of parts by importance.

- Safety and Regulatory Critical Items: Don’t forget parts that might not stop production but are legally or safely critical. For example, spare filters for an environmental control system, or emergency equipment spares. These should also be high priority to avoid compliance issues or unsafe conditions.

- Set Service Level Targets: For your most critical spare parts, decide on a target service level – essentially, the desired probability that the part will be available when needed. Critical “A” parts might warrant a 99% availability target (almost never stockout), whereas “B” parts might have 95%, etc. This will guide how much safety stock to hold, which we’ll cover next.

By identifying critical spares and priority levels, you create a focused approach. Rather than treating 10,000 spare SKUs with equal attention, you know exactly which 100 items (for example) deserve the most careful monitoring and generous stocking. This prioritization helps in budgeting too – you’ll justify spending more to stock a $5,000 spare motor that can cripple production, while being more frugal with non-essential items. The result is a smarter allocation of inventory dollars to maximize uptime.

3. Establish Optimal Stock Levels (Min-Max and Safety Stock)

Once you know which parts are most important, the next question is how many of each to keep on hand. Keeping too few risks stockouts and downtime, while keeping too many ties up capital and storage space. The goal is to define an optimal reorder point and safety stock level for your key MRO items. Here’s a step-by-step method:

- Analyze Usage History: If you have historical data on how often a part is used (or how often the associated equipment fails), use it. Look at the past year or two: how many of each spare did you actually consume? Keep in mind MRO demand can be sporadic, but any patterns help. If a certain pump tends to fail twice a year on average, that’s a clue. If another part hasn’t been used in five years, that’s another clue (maybe it’s candidate for reduction or careful evaluation if truly needed).

- Consider Lead Time: Lead time is critical in setting stock levels. Ask: How long will we be waiting if we order this part from the supplier today? If the lead time is long, you’ll need more on the shelf to cover that wait. For example, if a critical bearing has a 1-week lead time and you typically use about 2 per month (perhaps due to failures or PM replacements), you’d want at least 2 (one week’s worth) as safety stock, plus more if you want extra cushion.

- Minimum and Maximum Levels: Set a minimum stock level (reorder point) for each important part. This is the level at which you need to trigger a reorder to replenish. The minimum is often equal to the safety stock (the reserve you don’t want to dip below) plus expected usage during the lead time. For instance, if you never want fewer than 1 of a certain part on hand (safety stock = 1) and you’ll use about 2 during the lead time, your reorder point might be 3. Also consider setting a maximum level especially for expensive parts – this prevents over-ordering. If you know you’ll never reasonably need more than 5 of something before you can get more, max = 5 helps signals you to stop ordering until you consume some.

- Use a Formula or Tool if Available: Some companies use formulas like basic safety stock calculations (which involve service factor, lead time, demand variability) or more advanced inventory optimization software to set these levels. If you have a materials management or CMMS system, it might suggest reorder points based on your parameters. Even a simple formula can help: Safety Stock = (Max daily usage * Max lead time) – (Avg daily usage * Avg lead time), for example, to cover variability. Don’t be intimidated by formulas – even an educated guess adjusted over time is better than nothing for establishing initial levels.

- Review and Adjust Regularly: Stock levels shouldn’t be “set and forget.” Revisit them periodically (say, quarterly or biannually). If production ramps up and you’re using a part more frequently, you may need to raise its min. If a product line is phased out, you might lower or eliminate stock of certain spares. Continuous improvement means tweaking these levels as you gather more data on what works.

By establishing clear reorder points and safety stock for your MRO spares, you create an early warning system. Instead of reacting when a bin is empty (and the part is needed now), you’ll get signals when inventory dips to a threshold, prompting you to reorder before you hit a crisis. This step greatly reduces the chance of stockouts that lead to downtime, while also preventing overzealous stocking. It strikes that golden balance between “just-in-time” and “just-in-case” inventory. You’re essentially saying: “For each important part, this is how low we can comfortably go, and when we reach that point, we’ll replenish.” It’s a fundamental practice for keeping your spare parts inventory lean but reliable.

4. Organize and Secure Your Storeroom (Inventory Visibility)

Having the right parts on the books is one thing – being able to find them quickly is another. Many downtime minutes (or hours) have been lost simply due to searching for a part that was somewhere on a shelf. A well-organized MRO storeroom (or warehouse, or cabinet) is vital for both efficiency and accuracy. The goal is to create a place for everything and ensure everything is in its place, with clear visibility into where items are kept. Key tips for storeroom organization and visibility:

- Logical Layout: Arrange parts in a logical order. This could be by category, size, or frequency of use. For example, keep all bearings in one section, all electrical spares in another, etc. Within a category, you might sort by part number or size. Another approach is to organize by equipment – parts for Machine A on one shelf. Choose a method that your team finds intuitive. Label shelves and bins clearly with both the part name and number.

- Location Records: In your inventory system or spreadsheet, record the exact location of each part. For instance: “Aisle 3, Bin B-2” or “Tool Crib Cabinet 1, Drawer 4.” The important part is that anyone can lookup an item and instantly know where to go get it. No guessing or hunting.

- Housekeeping and 5S: Apply basic 5S principles (Sort, Set in order, Shine, Standardize, Sustain) to your storeroom. Remove clutter and junk, keep the area clean, and regularly audit that items are in their correct spots. If a part gets used, make sure the empty spot is obvious (don’t leave an empty box on the shelf – remove it or mark it so it gets refilled). Shadow boards or outlines can help for hanging tools or common items so you notice if something’s missing.

- Accessibility: Place the most frequently used or critical items in the easiest-to-access locations. Heavy or bulky spares should be on lower shelves for safety. Items needed for emergency repairs should not be buried behind rarely used stuff. You want maintenance techs to grab and go with minimal friction when time is of the essence.

- Security for Critical Parts: Unfortunately, shrinkage (theft or misplacement) can happen, even with spare parts. Consider keeping very expensive or mission-critical spares in a secure, maybe locked area, with controlled access. This not only prevents unauthorized use or pilfering, but also creates an extra check-out step to ensure usage is recorded. Some plants issue critical spares through a tool crib attendant or require sign-out so that it’s always tracked.

- Use Barcoding or QR Codes: Implementing a simple barcoding system can greatly streamline storeroom management. Each part or bin gets a barcode/QR label; when a part is taken or restocked, a quick scan updates the inventory counts. Barcode scanning reduces human error in data entry and speeds up the transaction. Modern inventory software often supports Bluetooth barcode scanners or even smartphone scanning. This ties into cloud systems like CyberStockroom which support barcoding for quick updates as items move between locations.

- Regular Cycle Counts: To ensure the physical stock matches your records, perform cycle counts routinely. Instead of a full inventory once a year, cycle counting means checking a subset of items every week or month. For example, each week count 10 random parts and reconcile any discrepancies. This continuous auditing keeps data accurate and catches issues (like missing stock or data errors) early. It’s much easier to fix an inventory record when you find it off by one or two, than to discover 100 items missing at a critical moment.

Organizing for visibility isn’t a one-time project – it’s an ongoing discipline. However, the payoff is huge: when everything is orderly and locations are tracked, a maintenance technician can respond to a breakdown and immediately find the needed part. There’s no frustration or delay searching shelves or calling around to ask “do we have this in stock?” It’s all about speed and confidence. A well-run storeroom ensures that your carefully planned inventory is actually usable when crisis strikes, shaving precious minutes (or hours) off your downtime.

5. Align Inventory with Maintenance and Production Plans

Inventory management for spare parts doesn’t happen in a vacuum – it needs to sync up with what’s happening in maintenance and production. One of the best ways to avoid surprises is to plan your spare parts needs around your maintenance schedules and production cycles. This proactive alignment keeps everyone on the same page and prevents the “I needed it yesterday” scenario. Here’s how to connect the dots:

- Scheduled Preventive Maintenance (PM): Coordinate with your maintenance planners or facility manager to understand the PM calendar. If certain machines undergo regular maintenance every month or quarter, identify which parts are typically replaced during those PMs (filters, seals, etc.). Make sure those parts are in stock before the scheduled date. For example, if you have a big annual overhaul planned for the extrusion line, build a checklist of all parts and consumables required and stock them well in advance. This ensures planned downtime stays on schedule and doesn’t extend because of missing parts.

- Predictive Maintenance Insights: If your plant uses condition monitoring or predictive maintenance (such as vibration analysis, thermal imaging, oil analysis, etc.), integrate those insights into inventory planning. For instance, if a motor’s vibration trend suggests a bearing may fail in the next two months, proactive maintenance can be scheduled and the replacement bearing can be procured ahead of time. This leverages data to prevent unplanned downtime. (Even without fancy IoT sensors, maintenance staff often have intuition about parts nearing end-of-life – listen to those hunches and be ready.)

- Production Peaks and Seasonality: Align with production management about any seasonal cycles or peak periods. If you know that Q4 every year has double the output, anticipate that machines will be working harder and might require more frequent part replacements. Plan to have extra spares on hand during these high-stress periods. Conversely, if there’s a yearly shutdown or slow season, that might be a good time to do inventory review and replenishment, or to schedule major maintenance that uses spares.

- New Equipment and Changes: Keep the inventory team in the loop whenever new equipment is installed or old equipment is retired. New machines mean new types of spare parts to stock (often vendors provide a recommended spare parts list – use it as a starting point). Retired machines mean some parts can be phased out of active inventory (though consider keeping some for a while if similar machines are still running). Any changes in the production process that could affect part wear rates (like running a machine faster or using a different raw material) should also trigger a review of spare parts needs.

- Collaborative Planning Meetings: It’s a great practice to have regular meetings or check-ins between the maintenance department and the inventory/procurement team. These can be monthly reliability meetings where upcoming maintenance work is discussed alongside spare parts status. In these forums, maintenance can voice concerns like “we’ve been burning through a lot of these belts lately” which signals inventory to stock more, or procurement can say “this supplier has a 12-week delay right now” which signals maintenance to adjust plans. The idea is to break down walls so that spare parts supply and maintenance demand are planned together, not in isolation.

By aligning inventory planning with maintenance and production, you essentially prevent a lot of emergencies before they happen. When maintenance is scheduled, parts are ready; when production is ramping up, inventory is prepared. This synchronization means fewer last-minute scrambles and a smoother operation overall. It turns spare parts management from reactive fire-fighting into a proactive, strategic partner in keeping the plant running efficiently.

6. Improve Cross-Department Collaboration

As mentioned earlier in the challenges, one major obstacle to effective MRO inventory management can be organizational silos. The solution is to actively foster collaboration between departments that have a stake in spare parts. When maintenance, operations, procurement, and even finance work in concert, you’ll find a much better balance between availability and cost. Here are some tips to enhance collaboration:

- Unified MRO Policy: Develop a clear MRO spare parts management policy or SOP that is agreed upon by all relevant departments. This policy might outline how critical spares are defined, who can make decisions on inventory levels, how reorder requests are handled, etc. By having this documented and endorsed by department heads (maintenance manager, plant manager, purchasing manager, etc.), everyone is on the same page. It sends a message that “MRO inventory is a strategic priority, not just a cost.”

- Joint Decision Making: For key decisions like stocking an expensive new spare or choosing a supplier for parts, involve both maintenance and procurement teams (and finance if budgets are significant). Maintenance provides insight on why a part is needed and how urgently; procurement provides insight on cost, supplier reliability, and alternatives. Together they can decide the best approach – maybe negotiating a consignment stock with the supplier (so you only pay when you use the part), or finding a cheaper equivalent part that still meets specs. When these decisions are made jointly, there’s less second-guessing and finger pointing later.

- Shared Metrics and Goals: Align on common metrics that matter to both sides. For example, downtime hours could be a shared KPI for maintenance (obviously) and for the inventory team, because parts availability impacts it. Likewise, inventory turn rate or value could be a shared metric, where maintenance understands they can’t just hoard everything – they have a goal to keep inventory efficient too. If both departments are measured on a mix of uptime and inventory cost metrics, they will naturally work more closely to balance those goals.

- Communication Channels: Establish easy channels for communication. Something as simple as a group chat or Slack channel between maintenance techs and the storeroom team can improve day-to-day coordination (“Hey, I just used the last of Part X, please reorder”). For higher level coordination, a weekly meeting or a dashboard that both teams review can help spot trends (like usage spikes or stockouts) and address them together.

- Training and Awareness: Educate each other. Train maintenance staff on how the inventory system works and why it’s important to follow procedures (like signing out parts, updating records). Train procurement/inventory staff on the basics of how critical equipment works and why certain spares are vital. This mutual understanding builds respect. For instance, a buyer who knows that a certain $1 O-ring can shut down a whole line will take stocking it more seriously. Conversely, a technician who understands the cost implications of overnight shipping or holding excess stock might be more conscientious in planning ahead.

When departments collaborate on MRO spare parts management, you create a culture where “we’re all in this together” to keep the plant running optimally. Instead of adversarial “maintenance vs. procurement” dynamics, the teams operate with a shared vision: maximize uptime cost-effectively. Over time, this can lead to innovative solutions like vendor-managed inventories, shared budgets for reliability projects, or cross-training staff to cover each other’s blind spots. The plant as a whole becomes more resilient and efficient when everyone pulls in the same direction.

7. Leverage Technology and Inventory Management Tools

In the digital age, relying on paper logs or scattered spreadsheets for MRO inventory just doesn’t cut it. Modern technology tools can greatly simplify and enhance spare parts management. They help you maintain accuracy, gain insights from data, and respond faster when issues arise. Here’s how leveraging the right tools can boost your MRO inventory management:

- Centralized Inventory Software: If you haven’t already, strongly consider implementing a computerized inventory management system for your spare parts. This could be a module within your existing ERP, a feature of a CMMS (Computerized Maintenance Management System), or a dedicated MRO inventory software. The key is that it provides a single, shared database where all parts info, stock levels, and transactions are recorded in real time. No more wondering which spreadsheet is up to date – the system becomes the source of truth.

- Real-Time Tracking: Modern systems, especially cloud-based ones, offer real-time tracking. This means when a part is used or moved, the system is updated instantly, and anyone can see the new status. Real-time data is crucial for avoiding mistakes like two people grabbing the “last” part unaware of each other. It also enables accurate alerts (for reorder points, etc.) since the data isn’t lagging behind reality.

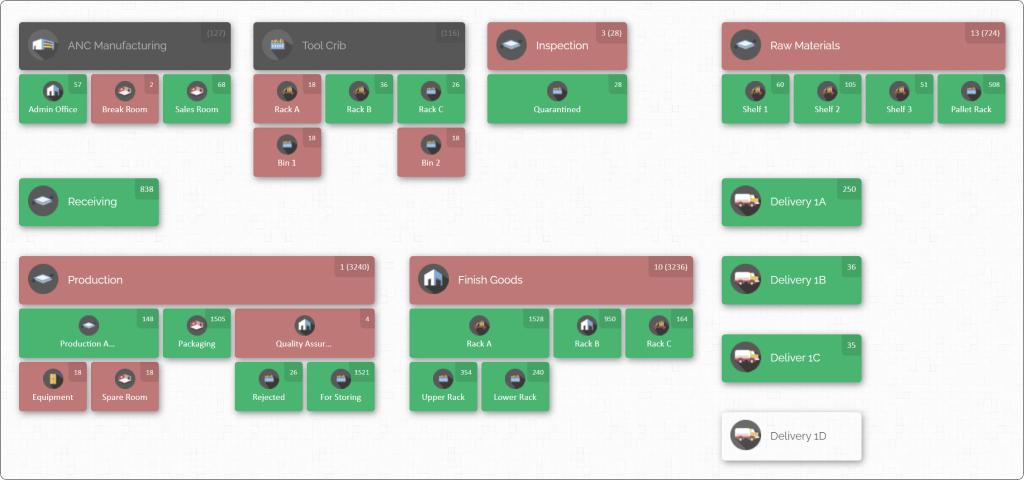

- Visual Inventory Mapping: As we discussed, a visual map interface adds an intuitive layer on top of raw data. Instead of parsing through lists, you click on a location and see what’s there, or search an item and see everywhere it’s stored. This is particularly useful if you have a large facility or multiple storage areas. It’s a quick answer to “where is it?” that saves time and reduces misplacement. The visual aspect is also great for training new staff or giving higher management a clear picture of the inventory layout.

- Cloud-Based Access: Cloud-based inventory systems mean your team can access the info from anywhere – on a shop floor tablet, on a manager’s smartphone, or from a home office after hours. There’s no need to “go check the computer in the storeroom” – if someone needs to verify a spare part at 11 PM during a maintenance emergency, they can log in remotely and see what’s available. Cloud access also ensures that even if one server or computer is down, your inventory data isn’t lost – it’s safely hosted and backed up, usually with high uptime reliability.

- Analytics and Reporting: Take advantage of the reporting capabilities of your system. Good inventory tools will let you generate reports on usage patterns, stockouts, excess stock, and so on. These analytics can uncover trends: e.g., “We had 5 stockouts of Part Y in the last quarter” (indicating maybe we should raise its min level) or “We haven’t used Part Z in 3 years” (maybe we can phase it out). Some advanced systems even use predictive analytics to suggest optimal stock levels or predict which parts you might need soon based on historical data and maintenance schedules. While you can manage without fancy AI, even basic usage reports are gold mines for continuous improvement.

- User-Friendly Interface: The technology will only be used properly if it’s user-friendly. Choose tools that are easy for your team to learn and use on a daily basis.The simpler it is, the more consistently your team will keep the system updated, and that accuracy is what ultimately prevents downtime.

In summary, investing in the right technology is investing in uptime. It might require some budget and training upfront, but the returns come in the form of fewer production interruptions, less time spent chasing parts, and more informed decisions about inventory.

Boosting MRO Inventory Management with CyberStockroom

Technology in general can improve spare parts management, but let’s talk specifically about CyberStockroom and how it can play a transformative role in your MRO inventory strategy. CyberStockroom is a cloud-based inventory management platform that features a unique visual inventory map system. For manufacturing plants dealing with MRO spares, it offers several benefits that directly address the challenges we’ve discussed:

Visual Map for Instant Clarity

CyberStockroom’s trademark feature is its Inventory Map – essentially a digital floor plan of your business where you can place and track inventory items. In the context of a manufacturing plant, you could create a map that includes your main warehouse, maintenance storerooms, production lines, equipment locations, and even service vehicles if you have field maintenance crews. Each spare part in the system is not just a number in a database; it’s visually pinned to a location on the map. This means when a machine goes down and you need a part, you can literally see where that part is stored. The time saved in locating items can be significant, especially in larger facilities. It’s the difference between scrolling through rows in a spreadsheet versus looking at a map and saying “There it is.”

Cloud-Based, Real-Time Updates

CyberStockroom is fully cloud-based, which brings the advantages we noted: accessibility from any device and real-time updates. Maintenance technicians can update inventory counts on the fly as they use parts – for example, using a tablet to deduct a part from the inventory as they take it. Immediately, everyone else sees that update (the map might show one less item at that location, for instance). There’s no waiting to “sync” or risk of multiple versions of truth. If you have multiple plants or remote team members, the cloud system keeps all spare parts data unified and up-to-date across the board.

Drag-and-Drop Transfers

One very intuitive feature of CyberStockroom is the ability to drag and drop items between locations on the map to record inventory transfers. Suppose you move a batch of spare filters from the central warehouse to a line-side cabinet near production. Instead of manually adjusting numbers in two places, you simply transfer using drag and drop. The system will decrement the quantity in the source location and increment it in the destination automatically. This makes inventory redistribution easy and error-free, encouraging your staff to actually record movements (which is often a pain point in inventory management).

Custom Fields and Barcoding

Manufacturing operations often have specific data they want to track for spare parts (like equipment ID, manufacturer, criticality rating, etc.). CyberStockroom allows custom fields, so you can tailor the data to your needs. It also supports barcoding, meaning you can use barcode scanners to scan parts in and out, instantly pulling up the item in the system via its code. This ties nicely with the visual map – scan a part’s barcode and CyberStockroom can highlight where it is on the map, or confirm if it’s checked out.

Inventory Visibility and Accountability

The platform maintains a history of inventory transactions – who moved what, when, and where. This is great for accountability. If a part goes missing or was used without recording, you have a log of activity to investigate. Moreover, supervisors can see usage patterns by person or department, which can inform training or process improvements. It essentially provides a clear audit trail, reducing the chances of things “falling through the cracks.”

Easy Onboarding and Use

For all its capabilities, CyberStockroom is designed to be user-friendly. The visual aspect makes it less intimidating for folks who might not be inventory experts. A maintenance tech can quickly learn to navigate the map, click on a location, and enter the quantity of parts they took. The learning curve is relatively gentle, which means better adoption by the team. And if your plant is currently using nothing more than a whiteboard or an Excel sheet, transitioning to CyberStockroom can be done gradually – you can import existing inventory lists via spreadsheet to get started, and then refine your map over time.

In essence, CyberStockroom acts like a real-time map-based control center for your spare parts. It addresses visibility challenges head-on by showing you exactly where parts are, and it simplifies record-keeping so that your inventory data stays accurate with minimal effort.

By using such a tool, manufacturing companies can reduce the time spent searching for spares, prevent stockouts through timely alerts, and make better strategic decisions (like redistributing inventory between locations or identifying surplus/shortage trends). The result is a more agile and responsive maintenance operation. When a breakdown happens, your team knows instantly what spares are available and where – enabling faster fixes and less downtime. And beyond the emergencies, day-to-day management of spares becomes more efficient, so you’re always prepared before a crisis hits.

Continuous Improvement: Refining Your MRO Inventory Strategy

Implementing the steps and tools above will set you well on your way to optimal MRO spare parts management. However, it’s important to treat this as an ongoing process rather than a one-time project. Manufacturing operations and needs evolve, and your MRO inventory strategy should evolve with them. Here are some ways to ensure continuous improvement:

- Track Key Metrics: Establish a set of KPIs to monitor the effectiveness of your MRO inventory management. Examples include:

- Stockout Frequency: How often do you find yourself completely out of a part when it’s needed? This should trend downward as you improve.

- Fill Rate: The percentage of maintenance requests or work orders where all required parts were available from stock. Aim to increase this toward your target (e.g., 98% for critical requests).

- Inventory Turnover: How quickly are you using your inventory (annual usage value / average inventory value)? A very low turnover might indicate excess stock, while too high could mean risk of shortages. Find a healthy middle ground and try to improve capital efficiency without hurting availability.

- Value of Obsolete Stock: Periodically measure how much money is tied in parts that haven’t been used in, say, 2+ years. Your goal might be to reduce this by identifying and removing truly obsolete items (through resale, return to vendor, or safe disposal) and preventing over-ordering.

- Downtime Hours Due to Parts Unavailability: This is the ultimate metric that ties inventory management to your downtime goal. If you can log incidents where lack of a spare part extended downtime, track those hours. As your processes mature, this number should shrink close to zero.

- Stockout Frequency: How often do you find yourself completely out of a part when it’s needed? This should trend downward as you improve.

- Regular Reviews and Audits: Schedule regular reviews of your inventory and processes. For example, quarterly reviews to:

- Re-evaluate safety stock levels based on recent data (did demand for any parts spike or drop? adjust accordingly).

- Audit a section of inventory for accuracy and organization.

- Review the “critical spares” list – has anything new become critical or something old become less critical due to changes in operations?

- Examine if any new failure modes were experienced in equipment that should inform stocking a part that wasn’t considered before.

- Re-evaluate safety stock levels based on recent data (did demand for any parts spike or drop? adjust accordingly).

- Feedback from Maintenance Team: Your maintenance technicians are on the front lines and will have valuable feedback. Maybe they notice a certain part is troublesome to replace and often breaks other small components (so you should stock those components too), or maybe the new arrangement of the storeroom has some impractical aspects that could be improved. Create an environment where the maintenance team can easily provide feedback on spares management, and act on that feedback.

- Stay Updated with Suppliers: Maintain good relationships and communication with your spare parts suppliers. If lead times or prices change, update your inventory plans. Also, suppliers might inform you of parts becoming obsolete or superseded by new models – you wouldn’t want to find out only when you try to order an urgent part that it’s no longer made. Proactive communication can help you phase in new replacement parts or purchase last-time buys for critical but end-of-life components.

- Training and Knowledge Retention: Keep training new staff on your MRO inventory procedures and tools. As workforce changes happen (new hires, retirements), you want to retain the knowledge and culture of good spare parts management. Document processes clearly for how to receive new stock, how to issue parts during emergencies, how to update the inventory system, etc. Make sure this is part of onboarding for both maintenance and store personnel.

- Benchmark and Learn: It can be useful to benchmark your practices and performance against similar facilities or industry standards. Industry associations, maintenance conferences, or publications often share benchmarks for MRO metrics or case studies of improvements. Maybe another plant achieved a 20% reduction in inventory value while improving uptime – learning how they did it (perhaps through better forecasting or vendor partnerships) could spark ideas for your operation. Always be on the lookout for best practices and new technologies (like advanced analytics or RFID tracking, for instance) that could further enhance your program.

Continuous improvement ensures that your MRO spare parts inventory management stays dynamic and effective. The manufacturing landscape changes with new equipment, technologies, and economic conditions, so flexibility is key. By monitoring progress and staying proactive, you’ll not only maintain the gains you’ve achieved but also find new opportunities to refine your approach. Over time, what used to be a fire-fighting area of the business transforms into a well-oiled (pun intended) machine that quietly and efficiently supports the core of your manufacturing operations.

Conclusion: Turning Spare Parts Management into Uptime Advantage

Minimizing downtime in manufacturing plants is a multifaceted challenge, but MRO spare parts inventory management stands out as one of the most actionable and impactful levers you can pull. By ensuring that the right parts are available at the right time (and in the right place), you empower your maintenance teams to respond quickly and effectively to any mechanical issues, turning potential hours-long outages into swift recoveries.

Let’s recap the journey to optimizing MRO spare parts management:

- Understand the Stakes: Downtime is costly, and spare parts are your insurance policy against prolonged downtime. Recognize the critical role these unsung heroes play in keeping production continuous.

- Get Organized and Informed: Build a solid foundation with a clean, comprehensive inventory of parts. Know what you have, what you need, and where everything is. Shine a light on your inventory data so there are no dark corners or surprises.

- Prioritize What Matters: Identify your most critical spares and invest your attention (and budget) there. Not every bolt and bearing is mission-critical – focus on the ones that are, and manage the rest with proportional effort.

- Plan, Don’t Just React: Use maintenance schedules, historical data, and cross-department input to anticipate needs. Setting reorder points, aligning with preventive maintenance, and collaborating across teams all turn spare parts management into a proactive practice rather than a reactive scramble.

- Leverage Modern Tools: Embrace technology like cloud-based inventory systems and visual mapping (for example, CyberStockroom) to gain real-time visibility and control. The right tools not only prevent errors and delays, they make the whole process more transparent and easier for your team to follow consistently.

- Keep Improving: Treat this as an ongoing cycle. Measure your performance, listen to feedback, and refine your strategies. Small improvements – a tweak in stock level here, a faster process there – add up to significant gains over time.

By following the strategies in this guide, you’ll build an MRO spare parts inventory management program that serves as a strategic asset to your manufacturing operation. Instead of spare parts being an afterthought or a source of frustration, they become a well-managed resource that gives you a competitive edge. You’ll reduce unplanned downtime, optimize inventory costs, and have a more smoothly running plant where everyone from the storeroom clerk to the maintenance manager is in sync.

In the end, effective MRO spare parts management is about ensuring reliability. It’s about knowing that when something goes wrong – and in manufacturing, something eventually will – your team has the right part on hand to set it right with minimal interruption. It’s peace of mind for you as a manufacturing professional, and it’s tangible performance and financial benefit for your business. So take control of those spare parts, map them, track them, plan for them, and watch as your downtime headaches diminish. Your production lines, your balance sheet, and your sanity will all thank you for it.

Leave a comment