In the past few years, manufacturers around the world have faced an unprecedented wave of supply chain disruptions. From global pandemics to port closures and raw material shortages, these challenges have exposed how vulnerable lean production systems can be. Supply chain resilience – the ability to anticipate, adapt to, and recover quickly from disruptions – has become a top priority in the manufacturing sector. One of the most critical components of resilience is how a company manages its inventory.

Manufacturing inventory isn’t just about raw materials on shelves – it’s the lifeblood of production that keeps everything running. By strengthening how inventory is planned, positioned, and managed, manufacturers can turn their supply chains into robust systems capable of withstanding shocks. Let’s delve into the key strategies that can bolster inventory resilience and keep your operations agile and prepared for anything.

Why Inventory Resilience Matters in Manufacturing

Modern manufacturing thrives on efficiency, often exemplified by just-in-time (JIT) inventory systems. JIT minimizes holding costs by delivering parts and materials right when they’re needed. However, as recent events have shown, an overly lean approach can become a single point of failure. When a critical supplier is suddenly unable to deliver – be it due to a natural disaster, a geopolitical issue, or a global crisis – a factory practicing JIT might have to halt production within days or even hours. This is where inventory resilience comes into play.

Inventory resilience means maintaining the right buffers, visibility, and flexibility to respond to surprises. The cost of not having resilient inventory strategies can be enormous. Industry studies have found that a single prolonged supply chain disruption can slash a manufacturer’s earnings by a significant margin, because idle assembly lines and unfulfilled orders directly hit the bottom line. On the other hand, companies that invest in resilience – for example, by holding strategic safety stock or quickly switching to backup suppliers – suffer far fewer interruptions.

For manufacturers, inventory is not merely an expense; it’s a strategic asset that can absorb shocks. Consider the examples of disruptions like the semiconductor chip shortage that crippled automotive production, or the blockage of the Suez Canal that delayed countless shipments. Manufacturers with contingency inventory or alternate stockpiles fared much better than those that had run extremely lean. Supply chain resilience in manufacturing is about balancing efficiency with preparation. By building slack in smart ways, manufacturers ensure continuity of production and protect customer relationships even when the supply chain gets turbulent.

Strategy 1: Diversify Your Supply and Inventory Sources

One foundational strategy for inventory resilience is diversifying where you get your materials and how you maintain inventory. Relying on a single supplier or a single source of inventory for critical components is risky – if that source fails, your production can grind to a halt. Manufacturers should qualify multiple suppliers for key raw materials and parts, ideally in different geographic regions. This multi-sourcing approach ensures that a disruption in one area (like a factory fire, political upheaval, or transportation strike) doesn’t completely cut off your supply.

In practice, diversification might mean developing relationships with backup vendors, or even dual sourcing essential items (splitting orders between two suppliers). It can also involve sourcing from different regions to hedge against regional risks. For example, if you currently source all critical electronic parts from one country, you might identify secondary suppliers in other countries or closer to home. The goal is to avoid “putting all your eggs in one basket” in case that basket breaks.

Diversifying inventory sources also extends to how inventory is stored and distributed in your own network. Instead of keeping all materials in one central warehouse, resilient manufacturers often spread inventory across multiple locations. By strategically positioning inventory in different plants or regional warehouses, you reduce the chance that a single event (like a warehouse flood or a local lockdown) will wipe out access to all stock. In essence, you’re building redundancy into the supply chain. Yes, diversification can introduce some complexity and possibly higher short-term costs, but it significantly reduces the risk of a total stoppage. In a world where disruptions are increasingly common, having multiple paths for supply and inventory flow is a prudent investment.

Key Takeaway: Audit your supply chain for single points of failure. Identify critical materials where you rely on one source and take steps to qualify alternatives. Split your inventory across different facilities or regions when possible. Diversification creates a safety net that makes your supply chain much more resilient when trouble strikes.

Strategy 2: Maintain Strategic Safety Stocks

Another pillar of inventory resilience is holding safety stock – extra inventory kept on hand to buffer against uncertainties. In the past, many manufacturers tried to minimize or even eliminate safety stocks to cut costs, but the equation has changed. Today, the question isn’t whether you can afford to hold safety stock; it’s whether you can afford not to. A well-calculated safety stock acts as a shock absorber for your production line. If a delivery is delayed or demand suddenly spikes, that buffer inventory ensures you can keep operations running until the situation stabilizes.

Safety stock should be strategic and data-driven. This means determining which materials or products are so critical that a stockout would be devastating to business – those are the ones that deserve a healthy safety buffer. It also means using data like supplier lead times, variability in demand, and historical disruption frequency to set the right safety stock levels. For example, if a particular component usually arrives in 2 weeks but has occasionally taken 4–6 weeks due to customs delays, you might hold an extra few weeks’ worth of that component in stock just in case.

It’s important to note that inventory resilience isn’t about hoarding mountains of stock indiscriminately. Just-in-case inventory (the practice of keeping additional inventory “just in case” of trouble) is making a comeback, but it must be implemented wisely. The goal is to protect against realistic risks while avoiding excessive overstock that ties up capital and storage space. Manufacturers should categorize inventory items by their importance and risk. Low-value or easily substitutable items might not need much safety stock at all, whereas long lead-time or single-sourced items likely do.

During the height of the COVID-19 pandemic, for instance, companies that had even a few extra weeks of key raw materials on hand were able to continue manufacturing while others waited for supply lines to recover. That buffer translated directly into resilience. By maintaining safety stocks for critical components – whether it’s specialized electronics, rare earth materials, or essential chemicals – you give your supply chain breathing room to handle the unexpected. It’s a relatively small cost to pay for a significant increase in peace of mind.

Strategy 3: Balance Just-in-Time with Just-in-Case

For decades, just-in-time (JIT) manufacturing was the gold standard for efficiency. Parts arrived at the production line exactly when needed, reducing inventory holding costs to a minimum. However, as noted earlier, JIT can leave a supply chain brittle. The opposite philosophy, just-in-case (JIC), involves keeping extra inventory on hand for emergencies. The most resilient strategy today lies in finding the right balance between JIT and JIC.

Think of it as a hybrid inventory approach. For many items – especially those that are readily available from multiple sources and have stable demand – JIT can still work well and save money. But for items that are prone to disruption or critically important to your product, a JIC approach may be smarter. In practice, manufacturers might continue lean, JIT-style inventory management for most common parts, but simultaneously maintain a cushion of JIC inventory for high-risk components.

For example, a manufacturer might receive frequent JIT deliveries for standard fasteners or packaging materials (which are easily sourced), but also keep a reserve stock of unique microchips or custom-molded parts that are harder to replace. If supply flows smoothly, those reserves might not be touched often. But if a disruption occurs – say a supplier’s factory goes offline temporarily – the just-in-case inventory is ready to fill the gap.

The shift from pure JIT to a more balanced model has already been happening in many industries. Companies have learned from events like natural disasters and trade disputes that sole reliance on JIT can be perilous. Balancing with JIC does come with increased carrying costs, so it must be justified by risk analysis. This is where tools like inventory optimization software can help, by calculating the cost-benefit of holding extra stock versus the potential cost of a stockout.

Ultimately, the message is: stay lean where you can, but build slack where you must. By combining the efficiency of JIT with the prudence of JIC, manufacturers can enjoy the best of both worlds – cost-effective operations that are also prepared for surprises. This balanced approach ensures that efficiency doesn’t come at the expense of reliability.

Strategy 4: Distribute and Decentralize Inventory

Imagine a scenario where all your finished goods and key inputs are stored in one massive distribution center. This might be efficient for day-to-day operations – until that one hub is hit by an unforeseen event (like a warehouse fire, an extreme weather event, or a local outbreak that shuts it down). Suddenly, your entire inventory becomes inaccessible. To avoid this kind of vulnerability, a smart strategy is to decentralize your inventory across multiple locations.

Decentralization means not keeping all inventory in one place. Manufacturers should evaluate their network of plants, warehouses, and distribution centers to ensure critical stock is spread out. For instance, instead of storing 100% of a crucial component in a single warehouse, you might store 50% in one region and 50% in another. If one site is compromised, the other can still supply your operations while you resolve the issue. Similarly, keeping some finished goods stock in different regions can allow you to continue fulfilling customer orders even if one region’s logistics are disrupted.

This strategy often goes hand-in-hand with regionalization of supply chains. Many companies are increasingly holding inventory closer to where it’s needed – for example, establishing regional hubs for North America, Europe, and Asia rather than one global hub. By doing so, they can respond faster to local demand surges and mitigate the impact of international transportation delays or cross-border issues. In manufacturing, this might mean having key spare parts and raw materials stored at each production site (or nearby) rather than only at headquarters.

While decentralizing inventory can increase carrying costs and requires good coordination, the resilience payoff is significant. It reduces the risk of a single point of failure and often improves responsiveness. However, to make this work, visibility and coordination between locations are crucial (we’ll discuss technology to manage this soon). Inventory in multiple places must still be tracked and managed as one system so that overall stock levels are optimized and not unnecessarily duplicated.

In summary, distributing inventory across a network ensures that one disruption doesn’t paralyze your whole supply chain. It’s like having backup power generators for your factory – you hope you won’t need them, but if the main power goes out, you’ll be glad they’re there. Spread your inventory risk by not concentrating everything in one spot.

Strategy 5: Improve Demand Forecasting and Planning

Resilient inventory strategy isn’t just about having more stock; it’s also about having the right stock at the right time. That’s where robust demand forecasting and planning come into play. Better forecasting helps manufacturers anticipate changes in demand or potential supply issues early, so they can adjust inventory before a crisis hits.

Modern demand planning leverages a variety of data – historical sales, market trends, seasonality, and even real-time signals from customers or suppliers. By analyzing this data (increasingly with the help of advanced analytics and AI), companies can get a clearer picture of when they might need to ramp inventory up or down. For example, predictive models might alert a manufacturer that a certain component could be in short supply in six months due to rising global demand, giving them time to secure extra stock or find alternatives.

One strategy under this umbrella is scenario planning. Planners can ask “what if” questions and simulate how their inventory levels and production would hold up under various scenarios – such as a 20% surge in demand, or a two-month shutdown of a supplier. By running these simulations, they can identify weak links in the inventory plan and shore them up before those scenarios ever occur. This is akin to stress-testing your supply chain and adjusting your inventory policies based on the results.

Collaborative forecasting with key customers and suppliers also enhances resilience. If manufacturers share information with suppliers about upcoming needs (and conversely get early warnings from suppliers about possible delays), they can plan inventory more effectively. Similarly, being looped into customers’ sales trends can help adjust production and inventory proactively rather than reactively.

In practical terms, improving forecasting might involve implementing better software tools – from integrated business planning (IBP) systems to AI-driven forecasting platforms – or simply tightening the Sales and Operations Planning (S&OP) process to ensure all departments share information. It may also involve training teams to react quickly to forecast changes, treating forecasts as dynamic guides rather than static numbers.

The better a manufacturer can predict demand and detect potential disruptions, the less excess inventory they need to hold while still staying safe. Forecast accuracy directly reduces the uncertainty that necessitates large buffers, allowing you to be efficient yet resilient. In short, knowledge is power: the more accurately you can see the road ahead, the smoother you can drive your inventory strategy around any potholes.

Leveraging Technology: How CyberStockroom Supports Inventory Resilience

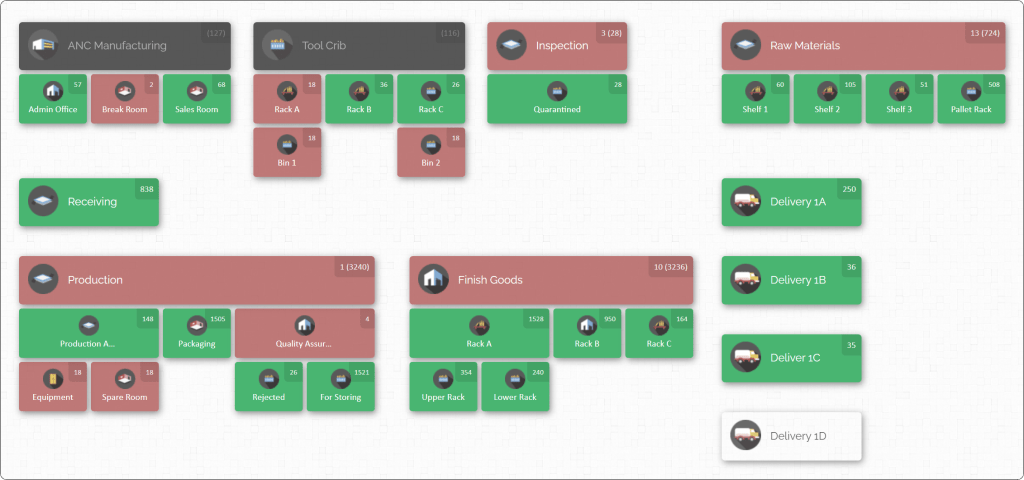

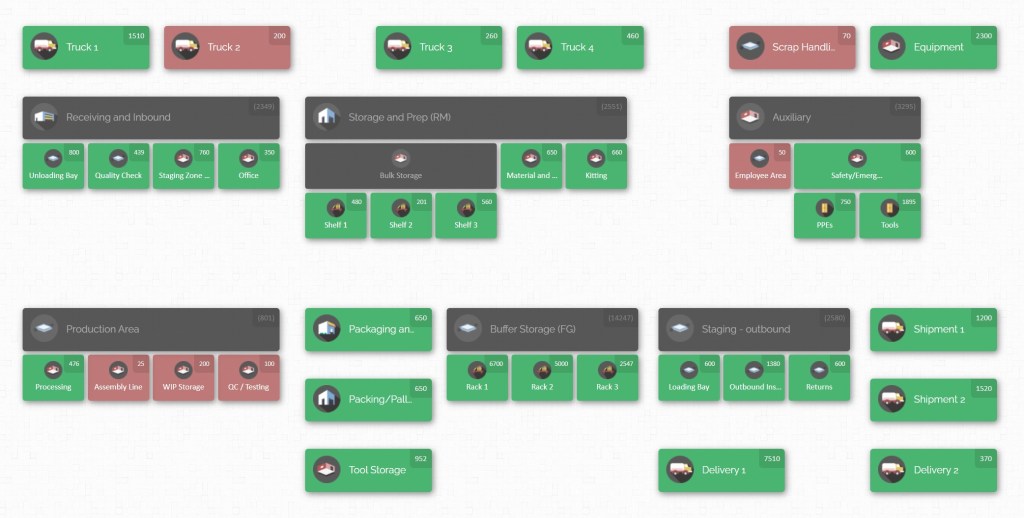

Technology plays a pivotal role in executing the inventory strategies we’ve discussed, and one standout example is CyberStockroom. CyberStockroom is a cloud-based inventory management platform that introduces a unique feature highly relevant to resilience: a visual inventory map.

Instead of just viewing stock as numbers in a spreadsheet, CyberStockroom lets manufacturers literally map out their inventory across all locations – from warehouses and production floors to storage rooms and trucks. This approach offers several advantages for building a resilient supply chain:

- End-to-End Visibility: With a quick glance at the CyberStockroom inventory map, you can see exactly where every product or material is located and how much is available there. For a manufacturer with multiple plants or storage sites, this is invaluable. If one location faces a disruption, the team can instantly identify other locations that have the needed stock. This kind of visibility turns the theory of “decentralized inventory” into a practical reality – you always know your options when it comes to reallocating inventory on the fly.

- Real-Time Updates: CyberStockroom’s cloud-based design means inventory data updates in real time as stock moves. Whether a pallet of components is transferred from Warehouse A to Warehouse B, or finished goods are shipped out to a distributor, the changes are immediately reflected on the map. During a fast-developing disruption, real-time information is crucial. It enables quick decisions, such as halting shipments, expediting replenishments, or redistributing materials, with confidence that you’re acting on current data. And because it’s cloud software, any authorized team member can access it from anywhere – whether they’re on the factory floor with a tablet or working remotely from home.

- Ease of Inventory Transfers and Adjustments: Resilience often requires agility, like moving inventory to where it’s needed most. CyberStockroom’s interface allows users to drag and drop items between locations on the map, effectively streamlining the process of transferring stock. Let’s say a sudden surge in demand hits one region, or a specific plant runs into a shortage due to a delayed delivery – with a tool like this, the inventory manager can swiftly reassign stock from another location by updating the system, and the team can act on that plan immediately. It simplifies what could otherwise be a chaotic process of emergency reallocation.

- Accurate Tracking and Reduced Errors: In crisis scenarios, the last thing you want is to find out that your system’s inventory records were wrong. CyberStockroom supports barcoding and quick scanning of items, making it easy to perform cycle counts and keep inventory records accurate. It also logs every transaction (every check-in, check-out, transfer, and adjustment), providing a full history of inventory movements. This level of accuracy and traceability means that when you rely on the system during a disruption, you won’t be flying blind. You can trust the data, and after the dust settles, you can audit what happened and identify lessons (for instance, how consumption spiked or which items became bottlenecks).

- Customizable and Scalable: Every manufacturing business is different. CyberStockroom’s map can be customized to mirror your actual operations – you can define your own locations, whether that’s buildings, rooms, or specific production lines. This tailored approach means resilience planning can also be specific. You might highlight certain areas on the map for high-priority inventory (like a “critical spares” stockroom) so they’re always in view. And as your business grows or changes (new warehouse, new product lines, etc.), the system scales with you, allowing unlimited locations and items. This flexibility is important because building resilience is not a one-time project; it evolves with your supply chain.

In the context of the strategies we’ve covered, CyberStockroom essentially serves as a powerful enabler. It brings to life the concepts of visibility, decentralization, and agility. By seeing your inventory as a dynamic map, your team can more easily identify where to build buffers, how to reroute supplies when needed, and where potential weak spots in inventory might be. For example, if one facility consistently runs lower on a critical part, you’ll see it visually and can proactively adjust your strategy (maybe by increasing safety stock there or redistributing inventory).

Moreover, because it’s cloud-based, CyberStockroom fits well into a modern, collaborative supply chain environment. Suppliers or partners can potentially be granted access to specific views if you choose, supporting better collaboration (as discussed in the next section). And while some inventory systems focus on just counting stock, CyberStockroom focuses on where the stock is – a question that is at the heart of responding effectively to disruptions.

In summary, leveraging an inventory management tool like CyberStockroom can greatly strengthen a manufacturer’s supply chain resilience. It provides the real-time visibility and control needed to execute many of the resilience strategies in this guide. Technology cannot prevent disruptions from happening, but it can ensure that when they do happen, you have the information and capabilities at your fingertips to respond intelligently.

Strategy 7: Collaborate with Suppliers and Partners

Resilience is a team sport. No manufacturer operates in isolation – you depend on suppliers for components and raw materials, and often on third-party logistics providers or distributors to get products to customers. Collaborating closely with these partners can greatly enhance your inventory resilience. Supplier collaboration, in particular, is critical: if your suppliers understand your needs and potential vulnerabilities, they can help by providing early warnings and flexibility when issues arise.

One approach is to engage in Vendor-Managed Inventory (VMI) or consignment stock arrangements for critical items. In a VMI setup, your supplier monitors your inventory levels (sometimes even via direct system access) and takes responsibility for replenishing stock when it gets low. This means the supplier is actively involved in preventing stockouts on your behalf. It’s in their interest too, because a stoppage at your plant could mean lost business for them. Such arrangements can lead to more proactive restocking and often give you priority when supplies are tight.

Another collaborative strategy is to develop joint risk mitigation plans with suppliers. For example, you can discuss contingency plans: if Supplier A has a problem, perhaps Supplier B (even if normally a smaller backup) is ready to step in with increased volume. Or perhaps your supplier can store an emergency stash of your key raw material at their site, reserved for you in case of an urgent need. This is a form of upstream safety stock that the supplier holds – effectively increasing resilience without you having to hold all the inventory yourself.

Communication is the foundation of collaboration. Manufacturers should ensure they have open lines of communication with all critical suppliers. This might involve regular business reviews where you discuss not just immediate orders but also share forecasts, growth plans, and any red flags on the horizon. If a supplier knows you’re planning to ramp up production next quarter, they can prepare their own inventory and capacity. Conversely, if they are facing a potential raw material shortage, you’d want to know as soon as possible so you can adjust your plans. Sharing information in a timely manner can turn potential disruptions into manageable events.

Beyond suppliers, collaboration with logistics partners is also important. If you use third-party carriers or warehouse providers, having them aware of your resilience priorities (like which shipments are most critical, or where to divert goods if a route is closed) can save precious time during a disruption. Some manufacturers even involve key customers in collaborative planning. If you and your major customers share inventory data (e.g. sell-through rates or on-hand stock at their locations), you can both respond faster to changes in demand or supply hiccups.

Finally, technology can facilitate collaboration. Shared dashboards, electronic data interchange (EDI), or cloud-based supply chain portals allow you and your partners to view certain data and status updates together. This transparency builds trust and ensures everyone is on the same page when quick action is needed.

In essence, no manufacturer should try to handle resilience alone. By treating suppliers and other partners as extensions of your operation – and working together on inventory management and contingency planning – you create a more integrated and robust supply chain. When disruption strikes, this networked approach means you have allies working with you to solve the problem, rather than isolated links all struggling separately.

Strategy 8: Continuously Improve and Adapt

Building supply chain resilience through inventory is not a one-time project – it’s an ongoing process. The final strategy is to establish a cycle of continuous improvement and risk assessment around inventory management. This means regularly reviewing what’s working, what isn’t, and how changing circumstances might introduce new vulnerabilities.

One best practice is to conduct periodic inventory risk audits. Every so often (say, annually or after any major industry event), gather your supply chain and operations team and map out potential risks in your current inventory setup. Have any of your suppliers become riskier (financial troubles, geopolitical issues in their region)? Are there new single points of failure creeping in (maybe you’ve started relying heavily on a new material from one source)? Are there changes in demand patterns that could cause certain stockouts or overstock situations? By systematically going through these questions, you can update your resilience strategies accordingly.

Another aspect of continuous improvement is learning from any disruption that does occur. If your company went through, for example, a sudden shortage of a key part, treat it as a case study. Perform a post-mortem analysis: How much inventory did you have? How long did it carry you? What actions did you take and were they effective? What could you do differently next time? This reflective process often yields ideas like, “We should keep more of Part X in stock,” or “Next time, let’s immediately inform our customers about delays and adjust delivery promises.” These are actionable tweaks that strengthen your resilience for the future.

Resilience also benefits from keeping abreast of external trends. The global supply chain environment can change quickly – tariffs can appear, new regulations on critical materials can be enacted, or technologies can shift demand. A resilient organization is one that scans the horizon. For instance, if there’s news of a raw material shortage in your industry, you might proactively secure additional inventory or alternative materials before it becomes a crisis. If a new forecasting technology promises better accuracy, you consider adopting it to improve your planning.

Empowering a cross-functional team to oversee supply chain risk and resilience can formalize this continuous improvement. Such a team can be responsible for updating the risk register, running simulation drills (e.g. “What if our top supplier suddenly faces an eight-week shutdown?”), and ensuring that lessons from past incidents are implemented. They can also drive training programs for staff – having knowledgeable employees who understand these strategies is itself a form of resilience. People on the ground who know how to react quickly and follow a plan can make a huge difference in the outcome of a disruption.

In summary, think of inventory resilience as a living program, not a one-off checklist. By continually adapting and improving, manufacturers can stay one step ahead of the next challenge. The investment in time and resources to do this pays off when you encounter the next major supply chain test – and handle it with far more confidence and capability than competitors who haven’t prepared.

Conclusion

Resilient supply chains don’t happen by accident; they are built through deliberate strategies and smart planning. For manufacturers, inventory is at the heart of this resilience. By diversifying suppliers, holding strategic safety stocks, balancing lean practices with backup plans, spreading out inventory, and leveraging cutting-edge tools and collaboration, you create a buffer between your operations and the chaos of the outside world.

The strategies outlined in this guide form a comprehensive approach to inventory resilience in manufacturing. Implementing them will require effort and sometimes a shift in mindset – from “run as lean and cheap as possible” to “invest in resilience as a competitive advantage.” But that investment can pay dividends the next time there’s a port shutdown, a natural disaster, or any shock that reverberates through your industry. Companies that have adopted resilient inventory practices have consistently found that they can respond faster, recover sooner, and even capture market opportunities while others are scrambling.

In the journey to ensure supply chain resilience, remember that visibility and agility are your best friends. Use technology (like the inventory mapping from CyberStockroom, among others) to gain clear visibility so you’re never caught off guard by what you do or don’t have on hand. Foster agility by practicing how you would redistribute or substitute inventory under different scenarios. And build strong relationships with those around you – suppliers, partners, and even customers – so that you’re not alone in facing challenges.

Ultimately, ensuring inventory resilience is about being prepared without being paranoid. It’s a balanced approach: you hope for the best, but you plan for the worst. Manufacturers who get this balance right will find that they not only survive disruptions, but can often turn resilience into a competitive edge – delivering reliably to their customers when others cannot. In today’s unpredictable world, that reliability is the hallmark of an industry leader. By following these inventory strategies and continuously refining them, you’ll put your manufacturing business on solid footing to weather any storm that comes its way.

Leave a comment