In the world of industrial construction, managing tools, heavy equipment, and materials across multiple sites can be a logistical nightmare. From hand-held power drills to massive excavators, items are constantly on the move. Without a good tracking system, tools get lost, misused, or misplaced, leading to wasted time and costly delays. The consequences go beyond just replacing missing wrenches or saws – lost tools can stall projects, inflate costs, and even create safety risks on the jobsite.

In fact, effective tool tracking in industrial construction is now recognized as a critical component of project management. Everyone from project managers and warehouse supervisors to foremen and field crews feels the pain when a needed tool isn’t where it should be. It’s not just an inconvenience – it directly impacts your bottom line and your team’s productivity.

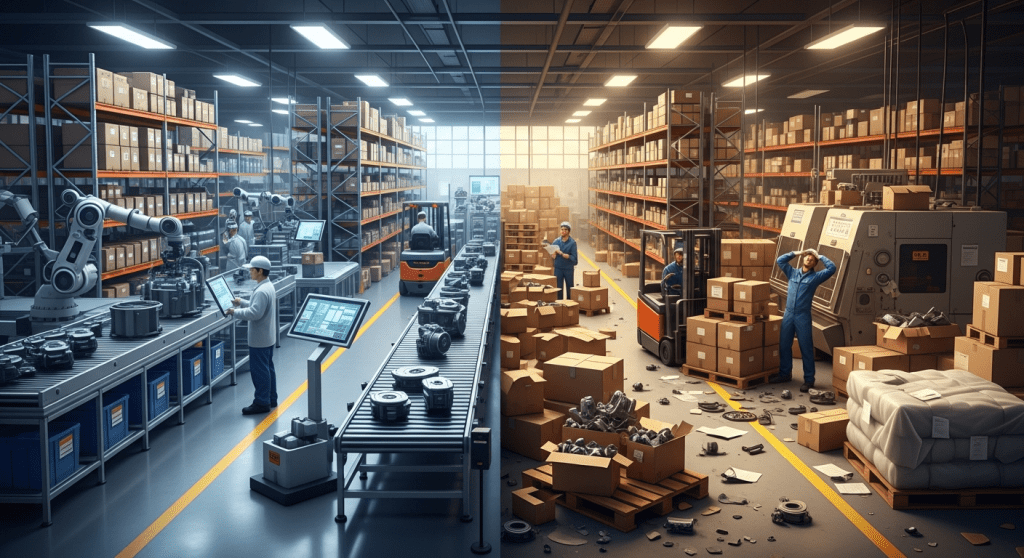

The Hidden Costs of Tool Waste in Construction

When tools and equipment go missing or sit unused due to poor tracking, the costs to your construction business are significant – and often hidden. Let’s break down the major ways that wasted tools hurt your projects:

- Lost Productivity: When a crew member can’t find a needed tool, they waste valuable time searching for it (or hunting down a replacement). It’s estimated that workers might lose over an hour per day looking for misplaced items. That’s time not spent doing productive work, which pushes deadlines further out. Multiply those lost minutes by an entire crew over weeks and months – the productivity loss is enormous.

- Increased Costs: Missing tools eventually have to be replaced. If a $300 drill disappears, you’ll probably buy a new one so work can continue. Do this a few times a month and you’re suddenly spending thousands in unplanned equipment costs. Over a year, these replacements can add tens of thousands of dollars to your expenses. And it’s not just tools – materials that “go missing” due to poor inventory control get reordered unnecessarily, further wasting money.

- Project Delays: A single lost tool can hold up an entire task. For example, if the only laser level on site can’t be found, the concrete pour might be postponed until a new level arrives or someone drives out to get one. These delays cascade into extended project timelines and potentially missed deadlines. In construction, time is money – delays mean higher labor costs, possible penalties, and unhappy clients.

- Decreased Profit Margins: All of the above – idle workers, buying extra tools, schedule overruns – cut directly into your profits. When you’re constantly repurchasing equipment you should already have, or paying overtime because the crew fell behind due to missing gear, your profit margins shrink. Over time, a culture of poor tool management can cost a construction firm hundreds of thousands of dollars, eroding the gains from even your best projects.

Beyond these immediate impacts, there are other ripple effects of poor tool control. Workers get frustrated (which affects morale and retention) and may start to care less about caring for tools if they feel things just disappear anyway. There’s also the risk of safety issues – for instance, if a required safety tool or piece of protective equipment isn’t available when needed, workers might improvise or skip steps, potentially leading to accidents. Clearly, the waste and mismanagement of tools isn’t just a small annoyance; it’s a serious business problem.

Impact of Tool Loss in Dollars

To put things in perspective, consider these estimates of what missing tools and equipment can cost:

| Tools/Equipment Category | Estimated Annual Loss |

| Hand Tools (hammers, wrenches, etc.) | $10,000+ per year (per company) |

| Power Tools (drills, saws, grinders) | $25,000+ per year (per company) |

| Heavy Equipment Theft (large machinery) | ~$300 million annually (industry-wide!) |

Even a mid-sized construction company can lose tens of thousands of dollars worth of smaller tools each year. And across the industry, heavy equipment theft alone accounts for hundreds of millions in losses annually.* In fact, construction equipment theft is such a problem that fewer than 1 in 4 stolen machines are ever recovered.** All these losses — whether a $30 hammer or a $300,000 backhoe — ultimately come out of someone’s pocket.*

Why Tools Go Missing: Common Causes

It’s easy to blame workers for “losing” tools, but in reality the jobsite environment itself often sets the stage for tools and supplies to disappear. Understanding why it happens is the first step to solving the problem. Here are some common causes of tool loss and waste in construction:

- Decentralized Job Sites: Construction crews often work across multiple sites at once. Tools and equipment tend to migrate between locations as needs arise. Without a centralized system, a drill that was brought from the warehouse to Site A might later get sent to Site B – and then no one at Site A knows where it went. In a flurry of activity, tools get scattered across locations, and tracking them becomes a nightmare.

- Lack of Visibility and Tracking: Many construction companies still rely on manual methods (or nothing at all) to track tools. A worker grabs a saw from the tool crib and maybe scribbles something on a clipboard – or just verbally tells a supervisor. There’s no real-time visibility into who has what. No digital record means it’s easy for items to “walk away” without accountability. If you don’t know where an item is at any given moment, it’s effectively lost until someone stumbles across it.

- Theft (Internal and External): Unfortunately, construction sites are prime targets for theft. Expensive equipment can literally drive off if not secured, and smaller tools are easy to slip into a pocket or vehicle. Theft can be external (unrelated thieves sneaking onto the site, especially after hours) or internal (a dissatisfied worker thinking they won’t be caught taking a tool home). When there’s chaotic inventory management, theft is harder to detect – a missing tool might not be noticed for days or weeks, giving thieves a big head start. This also ties back to visibility: if nobody’s watching, the foxes will raid the henhouse.

- Misplacement & Misuse: On busy sites, tools often get set down in random places. A crew member might leave a drill on the scaffolding or toss a wrench in a pickup truck bed “just for now” and forget about it. By day’s end, that tool is nowhere to be found. Misuse can also sideline tools – using a tool for the wrong task can damage it, effectively taking it out of circulation and requiring a replacement.

- Overstocking & Hoarding: Sometimes the opposite problem occurs – because teams can’t find what they need, they assume it doesn’t exist and order new tools or supplies. This leads to duplicate items and overstock. In other cases, individual jobsite trailers might hoard certain tools (“just in case we need it”) so others end up buying additional units. Overstocking ties up cash in unnecessary inventory and can lead to waste (e.g. materials that expire or degrade in storage).

- Poor Record-Keeping: Even when companies try to keep records, if the process isn’t easy, it often gets skipped. Paper sign-out sheets get lost or aren’t filled in. Spreadsheets get outdated quickly if not updated daily. A tool might have been returned, but if no one logs it, someone else might think it’s still missing and go buy a new one. In short, lack of real-time record keeping means your inventory data is always playing catch-up with reality.

All these factors contribute to an environment where tools and equipment are perpetually at risk of being wasted. The good news? These problems are entirely solvable. With a combination of better processes and modern technology, construction companies can dramatically reduce tool loss, prevent theft, and keep projects running smoothly.

Tools Most Commonly Wasted on Construction Sites

Another way to grasp the scope of the problem is to look at what tends to go missing or get underutilized. In industrial construction and contracting, certain categories of assets are notoriously prone to being wasted:

- Hand Tools: Simple tools like hammers, screwdrivers, wrenches, pliers, and tape measures are small and frequently used – a recipe for being easily misplaced. Because they’re inexpensive individually, people may not be diligent about tracking them, but the costs add up when you lose dozens of hand tools over time. (How many times have you repurchased the same size wrench because it walked off?)

- Power Tools: Drills, impact drivers, circular saws, grinders, nail guns – these portable power tools are high-value targets for both loss and theft. They often move between crews and sites, and without a checkout system a tool might be borrowed by one team and never returned. Power tools are also hot items on the theft market because they’re easily resold. Losing a $500 hammer drill or sawzall here and there puts a serious dent in the budget.

- Heavy Equipment: You might think it’s hard to “lose” a forklift or bulldozer, but heavy machinery can effectively vanish if you’re not tracking where it’s supposed to be. More commonly, heavy equipment is at risk of theft or unauthorized use. Construction machinery like backhoes, loaders, and generators are valuable – organized thieves target them, especially if sites lack proper security and tracking. Also, if your company has multiple projects, one site might “claim” a piece of equipment longer than they need it, while another site sits idle waiting for it. Without visibility, coordinating the use of expensive machinery is difficult, leading to underutilization or rental of equipment you actually already have.

- Small Equipment & Consumables: This bucket includes things like laser levels, survey equipment, personal protective equipment (PPE) like harnesses and hardhats, as well as fasteners, screws, welding rods, adhesives, and other consumable supplies. These items often don’t get the same tracking attention as major tools, yet they are essential and frequently lost or wasted. Consumables in particular tend to get over-ordered “just in case” because nobody is sure what’s in the inventory. Poor tracking of consumables can result in hefty waste – boxes of screws left to rust, or tubes of epoxy expiring on a shelf. And if critical small equipment (say a laser distance meter) goes missing, it can cause as much delay as a lost power drill.

All of these tools and supplies are essential for day-to-day operations, but they’re also vulnerable to disappearing in the chaos of a busy jobsite. They represent a significant chunk of the wasted spending in construction. Simply put, every lost tool is money down the drain and time you can’t get back.

So, how do we address this? The answer lies in smarter inventory practices and using the right technology to bring order to the chaos. Let’s explore how modern solutions are helping construction firms stop wasting tools and keep their operations on track.

Smart Inventory Solutions: Addressing the Problem

It’s clear that traditional approaches to managing tools – or lack thereof – aren’t keeping up with the demands of modern construction projects. The good news is that technology and better processes can solve the problem. In recent years, a range of inventory management solutions tailored to construction and industrial environments have emerged. These systems provide real-time visibility, accountability, and control that simply weren’t possible with pen-and-paper or spreadsheets. By adopting some smart strategies and tools, you can drastically reduce tool loss and improve efficiency.

Effective Strategies to Manage Tools and Supplies

Modern inventory management isn’t just about software – it’s about combining technology with good practices. Here are some highly effective strategies and systems that construction companies are using to keep track of tools, equipment, and supplies:

Real-Time Tracking

Use digital tags and scanners to always know where your stuff is. Many firms now assign barcodes, QR codes, or even RFID tags to every tool and piece of equipment. Scanning an item (with a handheld scanner or a smartphone) whenever it’s checked out, moved, or returned updates its location instantly.

Benefit: You’ll know exactly where each tool is, who has it, and when it was last used. If a tool goes missing, you can quickly pinpoint the last person or place that had it. This level of traceability both deters casual theft and eliminates time wasted searching multiple sites – the system can tell you “Joe from Crew B still has the laser level, and it’s at Site 3.”

Tool Assignment & Accountability

Assign tools to people or teams to create clear responsibility. Instead of a free-for-all where anyone can grab any tool, some companies implement a check-out system where specific crew members are assigned certain tools or a kit of tools for the day/project. They become responsible for those items until checked back in.

Benefit: This creates accountability – it’s always clear who is answerable if something goes missing or gets damaged. Workers tend to take better care of tools when their name is attached to it. And at shift’s end, you have a natural inventory check as each person returns their assigned kit.

Mobile Inventory Management: Put the power of inventory tracking in the palm of your hand. Relying on someone in the office to update a database doesn’t work on a fluid jobsite. Modern tool tracking systems often include mobile access or apps that let workers in the field participate in inventory management. For example, a worker can use a smartphone or tablet to scan a QR code on a tool as they take it, effectively “checking it out” in real time.

Benefit: This reduces the need for paper logs and ensures that inventory data is updated from the field instantly. It also empowers the field crew – they can quickly look up if a needed tool is available on site or if it’s sitting back at the warehouse, without a bunch of phone calls.

Centralized, Cloud-Based Platform

Use a single source of truth for inventory across all locations. Cloud-based inventory management platforms allow you to track tools and supplies across multiple projects and warehouses in one unified system. Managers and team members can log in from anywhere (office computer, jobsite laptop, or on their phone) to see what’s in stock and where.

Benefit: You get instant visibility into the entire company’s inventory. If Site A is short on extension cords, a quick check might show that Site B has plenty – you can reallocate instead of buying more. A centralized system prevents the “left hand doesn’t know what the right hand is doing” scenario and cuts down on redundant purchases.

Easy Tool Transfers & Location Updates

Simplify the process of moving equipment between sites. In construction, tools and equipment often need to be shuffled around as project needs change. Modern inventory software can make transfers as simple as a few clicks – for instance, drag-and-drop a tool’s icon from one jobsite location on a digital map to another. This immediately updates its recorded location. Some systems even allow you to log a transfer by scanning a tool and then scanning the new location’s barcode or selecting from a list.

Benefit: Up-to-date records of where everything is, with minimal effort. There’s no confusion like “Did that generator ever make it to the south site, or is it still at the main yard?” – you’ll have it recorded. Smooth transfer logging also means you can coordinate sharing of equipment between sites instead of each site overstocking “just in case.”

Routine Audits and Cycle Counts

Trust, but verify – regularly. Even with great systems, it’s wise to schedule periodic inventory audits. This might mean a quick weekly check of high-value items and a more thorough monthly or quarterly count of everything. Modern systems can generate an audit checklist and then you can scan each item to verify it’s present.

Benefit: Regular audits catch discrepancies early – if something’s missing, you’ll know before it’s been gone for months. Auditing also highlights any data entry mistakes or tools that might have broken and weren’t reported. In short, routine reconciliation keeps the system honest and accurate, and it reinforces to the team that inventory control is a priority (which further encourages them to be diligent).

By implementing these strategies – ideally using a software platform that supports them – construction companies can dramatically reduce tool waste. In fact, firms that have embraced digital tool tracking often report immediate improvements: missing tool incidents drop, crews spend less time hunting down gear, and purchasing managers notice they’re ordering fewer “replacement” tools. It all comes down to better visibility and accountability.

One such tool tracking and inventory management platform, designed with these very issues in mind, is CyberStockroom. Let’s take a closer look at how it works and how it can help solve the tool tracking challenge in industrial construction.

How CyberStockroom Solves Tool Waste in Construction

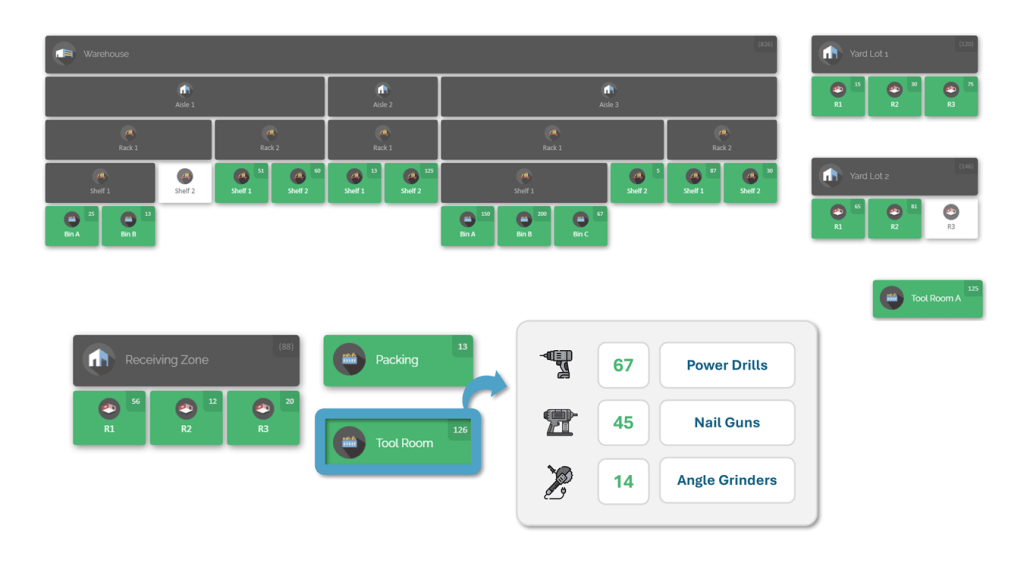

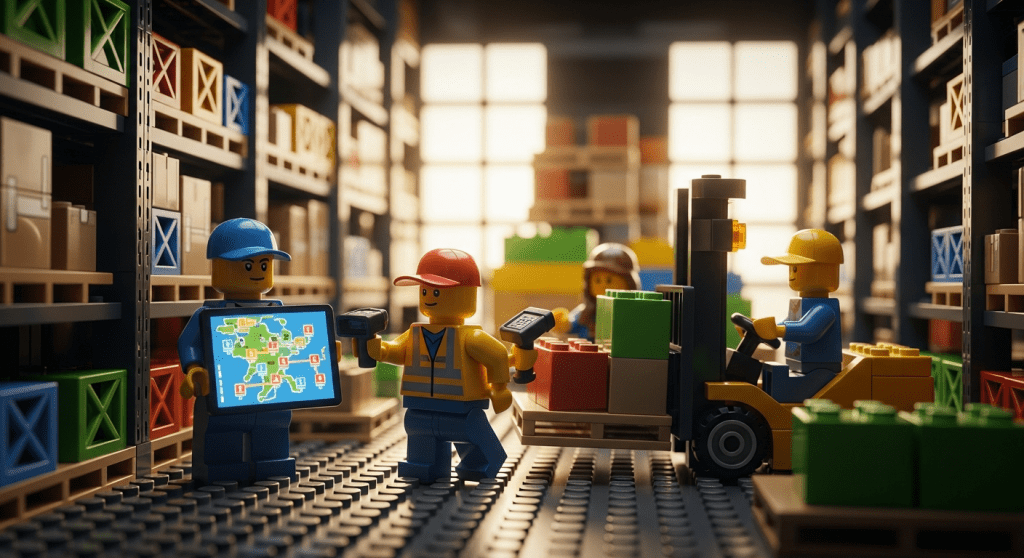

Modern problems require modern solutions. CyberStockroom is an inventory management software platform that tackles tool and equipment tracking challenges head-on, particularly for industries like construction that operate across multiple locations. It provides a cloud-based, real-time inventory system with a unique twist: a visual map interface. Instead of dealing with boring spreadsheets or text-based lists, CyberStockroom lets you see your warehouses, job sites, and storage rooms on a digital map and quickly view what items are in each location.

In practice, using CyberStockroom on a construction project means you’ll always know what you have, where it is, and who is responsible for it. The system is accessible from any device with an internet connection, so whether you’re a project manager at HQ or a foreman out in the field, you can log in and get the latest info.

Crucially, CyberStockroom isn’t just about tracking small tools – you can manage everything from your smallest drill bit to your largest bulldozer in one system. Heavy equipment, tools, spare parts, consumables – they all can be tagged and placed on the inventory map. This gives construction companies a comprehensive view of their assets. For example, you could zoom into your map and see that Site A has two compressors and a generator, Site B has one compressor (currently checked out to John Doe), and the main warehouse has four more generators in storage. If someone at Site B suddenly needs an extra generator, you can immediately decide to send one over from the warehouse, and you’ll know exactly where it is and who to assign that task to.

Key Features of CyberStockroom for Construction Teams

CyberStockroom is packed with features tailored to make tool tracking and inventory control easy. Here are some of the standout features that are especially useful on construction sites, and how each one helps you stop wasting tools and supplies:

- Real-Time Tracking: Every item in CyberStockroom can be tagged with a barcode (or QR code) that links to its record on the platform. Scanning a tool as it moves or is used updates its status immediately. Pair this with the system’s visual inventory map, and you get instant visibility into each item’s location and usage history. You’ll never be in the dark about where a tool is at any moment.

- Mobile Access: CyberStockroom is cloud-based and mobile-friendly, which means your crew can use smartphones or tablets on site to interact with the inventory. There’s no complicated handheld terminal needed – any device with a web browser can access the system. Field workers can check out tools, perform a quick barcode scan with their phone camera, and update inventory in real time without returning to the office. This on-the-go access is a game-changer for accuracy and convenience.

- Drag-and-Drop Transfers: The platform’s interface lets you move items between locations with a simple drag-and-drop on the map or a couple of clicks in a list. Say a batch of scaffolding components is moved from the warehouse to Lot 4 of Site C – just drag that item icon from the warehouse on the map over to Site C (and even into the Lot 4 sub-location on the map). The system instantly updates the item’s location. This intuitive method makes it easy to record transfers as they happen, so your digital inventory always matches reality.

- Cloud-Based Dashboard: Because it’s a cloud system, managers can view the inventory from any device, anywhere. Whether you’re at head office, in a hotel on a business trip, or at a jobsite trailer, you can log into CyberStockroom and see the latest status. There’s no need to wait for nightly spreadsheet updates or phone calls from the field – it’s all live. This full visibility across all job sites helps in decision-making (like reallocating resources or identifying shortages) in real time.

- Tool Assignment & User Accountability: CyberStockroom allows you to assign tools to specific employees or teams within the system. You can, for instance, note that a particular generator is checked out under “John Smith – Electricians Crew”. The platform will log who has what and when it’s due back. This feature builds accountability by clearly recording who is responsible for each item. Next time someone asks “Where did that laser level go?”, you can check the history and see who had it last.

- Custom Fields & Attachments: Construction equipment often comes with manuals, maintenance schedules, inspection certificates, and other documentation. CyberStockroom lets you add custom data fields to each item’s record, and you can also attach files like PDF manuals, calibration certificates, or photos of the item. This means all information about a tool is in one place – you can check out a ladder and see its last inspection date and safety certificate right from the app. Keeping maintenance records with the inventory helps ensure tools are used properly and serviced on time, reducing accidents and prolonging tool life.

- Inventory History & Audit Logs: Every activity in CyberStockroom is recorded in a history log. You can easily pull up an item’s timeline – when it was moved, who checked it out, when it came back, etc. These inventory history logs are like a fingerprint for each tool’s journey. If something goes missing, you can trace its last known movements and users. The logs also aid in auditing: you can run reports to see patterns (like a particular crew that frequently loses tools, or tools that haven’t been used in 6 months). Having this data allows managers to identify problem areas and address them with training or process changes.

All of these features work together to dramatically improve tool visibility and control on construction projects. CyberStockroom basically provides a live digital twin of your physical inventory. Instead of reacting to missing tools after the fact, you proactively manage and monitor everything.

Benefits for Construction Sites

Using a system like CyberStockroom and the strategies we described brings tangible benefits to any construction operation. Here are some key benefits you can expect when you implement robust tool tracking and inventory management:

- Improved Visibility: No more guesswork or blind searches – you gain complete visibility into your inventory. At any moment, you can pull up the system and see exactly what tools and equipment you have, and where they are. This bird’s-eye view is especially valuable if you oversee multiple crews or locations. It also means fewer surprises, like discovering at the last minute that a needed tool isn’t on site.

- Fewer Losses and Thefts: When every tool is being tracked and logged, it becomes much harder for items to just disappear. The accountability features (like assignments and history logs) act as a deterrent against theft or carelessness. Crew members know that if something goes missing, it will be noticed quickly and its last known handler is recorded. Companies that introduce these systems often see a sharp drop in lost tools – saving money on replacements and reducing the “missing tool” headache.

- Time Savings and Less Frustration: With better tracking, workers spend far less time searching for equipment. A quick scan or lookup can tell them if the item is on site or who last used it. Instead of 30-60 minutes of downtime looking for a tool, they can get back to work almost immediately. Over weeks and months, reclaiming those hours has a huge effect on productivity. Plus, your team stays happier when they’re not constantly playing hide-and-seek with tools.

- Higher Project Efficiency: Effective inventory management helps avoid delays and keeps projects on schedule. For example, materials and consumables can be monitored to prevent stockouts – you won’t unexpectedly run out of screws or welding rods because the system will show current quantities and can even flag low stock. Moreover, having a clear view of all equipment allows you to optimize usage: you might notice that one site has an idle skid-steer loader that another site urgently needs, and you can reassign it promptly. The result is better utilization of assets, less waste, and more streamlined operations overall.

- Cost Savings and Better Budget Control: Fewer lost tools and efficient sharing of resources directly translate to cost savings. Your budget for tool replacement and emergency rentals will shrink. Over time, a good tracking system can pay for itself just in the value of tools not lost and duplicate purchases not made. Additionally, by analyzing inventory data, you can make smarter purchasing decisions – knowing exactly how many of each item you truly need, and avoiding overbuying. It’s all about doing more with what you already have.

How to Implement CyberStockroom on Your Construction Sites

Knowing the benefits is one thing – rolling out a new system is another. Fortunately, implementing CyberStockroom (or a similar inventory solution) in your construction business is straightforward. It doesn’t require a huge IT project or expensive hardware. Here’s a step-by-step roadmap to get your tool tracking solution up and running:

- Assess Your Needs: Start by taking stock of what you have and what you need to track. Make a list of all categories of tools, equipment, and supplies in your operations. How many job sites and storage locations do you operate? This step is essentially scoping out the size of your inventory and the complexity of your environment. Determine the pain points – e.g., are power tools your biggest loss area, or is it heavy equipment logistics, or materials? This assessment will guide how you set up your system and where to focus first.

- Tag and Catalog Your Tools: Next, you’ll want to label each item and enter it into the CyberStockroom system. Decide on a tagging method – barcodes and QR code labels are most common (they’re easy to generate and scan with phones or scanners). For very rugged or valuable items, some companies use RFID tags, but barcodes/QR are usually sufficient. Go through your inventory and attach a label to each tool, piece of equipment, toolbox, and even bins of consumables. Then, use CyberStockroom to create an entry for each item (you can do this quickly by scanning the new barcode and filling in the item details like name, category, value, etc.). This cataloging might take a bit of effort upfront if you have a lot of inventory, but it’s a critical foundation. Once everything is tagged and in the system, you have a baseline to work from.

- Set Up Locations and the Inventory Map: In CyberStockroom, you will configure your locations and sub-locations to mirror your real-world setup. For example, you might set up “Main Warehouse” as one location, “Jobsite Alpha” as another, “Jobsite Beta” as another, etc. Under “Jobsite Alpha” you could have sub-locations like “Site Office Trailer,” “Storage Container 1,” “Storage Container 2,” etc. The idea is to create a digital map that resembles how your physical locations are organized. This is where CyberStockroom’s visual mapping really shines – you can actually create a map layout with drag-and-drop zones for each site. Spend a little time customizing this; it will make life much easier for your team when they can literally see where things are supposed to be.

- Train Your Crew: Any new system is only as good as its adoption. Gather your team – especially those who handle tools daily (foremen, warehouse manager, tool crib attendants, etc.) – and introduce them to CyberStockroom. Show them how to use the mobile interface or scanners to check tools in and out. Demonstrate the inventory map and how they can find items or update a tool’s status. Emphasize that this system is there to make everyone’s job easier (less time looking for stuff, more accountability so no one gets unfairly blamed for losses). Training doesn’t have to be lengthy – CyberStockroom’s interface is designed to be user-friendly – but do make sure everyone gets hands-on practice. For example, run a small drill: have each person log into the system, check out a sample tool to themselves, move it to a new location on the map, then check it back in. This builds confidence that “okay, I know how to do this.”

- Start Using the System (Go Live): With everything tagged and people trained, it’s time to go live. From a certain date, make CyberStockroom the official source of truth for tool tracking. Instruct the crew that whenever they take or return a tool, it must be recorded in the system – no exceptions. In the first few weeks, you might need to remind folks and supervise the process a bit, just until it becomes habit. It helps to have a champion or two (say, the warehouse manager or a tech-savvy foreman) who really buys in and can assist others on site. Begin using the system’s features actively: for example, before purchasing new materials, check the inventory levels on CyberStockroom; or when planning the next project, use the map to decide how to allocate equipment. As you use it daily, it will quickly integrate into your workflows.

- Monitor, Audit, and Refine: Once the system is in place, continuously monitor the results. CyberStockroom will provide reports and logs – review them. Are tools still going missing, or has that stopped? Which items are most frequently checked out, and do you have enough of them? You can set up periodic audits where a supervisor uses the system to scan all items in a particular location and reconcile with what the database says. This will catch any slips (for example, if someone forgot to log a transfer, the audit will flag an item as “physically here but digitally marked elsewhere”). Use these insights to refine your processes: maybe you discover that crew members aren’t scanning tools at the end of the day – a quick refresher training or a tweak in process (like a sign at the tool crib saying “Did you check it in?”) can fix that. Perhaps you’ll find you have surplus of certain tools that you can sell off or avoid buying more of. Over the first few months, the data will guide you to optimize inventory levels and policies. Essentially, treat the system as a living part of operations – maintain it, and it will reward you with smooth, predictable tool management.

By following these steps, you’ll establish a robust inventory control system with CyberStockroom at its core. The transition from chaos to clarity can happen in a matter of weeks. Soon enough, your team will wonder how they ever managed without being able to just type in or scan a tool and immediately find its location. The key is to make the system an integral part of daily routines on the jobsite and in the warehouse. Once it’s ingrained, tool tracking becomes almost second nature – and the days of constant tool loss will be firmly behind you.

Final Thoughts

Tool waste and missing equipment don’t have to be “just a cost of doing business” in construction. With the right approach and tools , you can bring order to the chaos of jobsite inventory. Modern inventory tracking technology combined with good practices creates transparency and accountability that were unimaginable in the old days of clipboards and sporadic spreadsheets. The result is fewer lost tools, fewer project delays, and a more efficient operation overall.

Imagine running your projects knowing that from the smallest drill bit to the largest excavator, everything is accounted for. No more emergency runs to the supply store because you “thought you had one, but can’t find it.” No more crews standing around idle because a critical tool vanished. By investing time in proper tool tracking and using solutions like CyberStockroom, you’re investing in smoother projects and healthier profit margins. It’s about working smarter, not harder – making the tools and equipment you already paid for work for you at full capacity.

At the end of the day, effective tool tracking in industrial construction is about peace of mind. It’s knowing that you have control over your assets instead of them controlling your schedule and budget. The construction industry has enough uncertainties (weather, client changes, unforeseen site conditions…); by eliminating the uncertainty around your inventory, you remove one major variable from the equation.

So, stop wasting tools and start managing them proactively. Your team will thank you, your projects will run better, and your balance sheet will reflect the difference.

Ready to Take Control of Your Tools?

If you’re tired of the chaos and cost of lost tools, now is the time to act. Empower your team with CyberStockroom’s inventory mapping solution and start seeing the difference it makes on your job sites. From day one, you’ll gain visibility and peace of mind knowing that every hammer, drill, and heavy machine is accounted for. Don’t let tool loss eat into your profits and productivity any longer – take control of your inventory today and keep your construction projects running like the well-oiled machines they’re meant to be!

Leave a comment