Imagine walking into your warehouse and seeing a live digital map of every shelf, bin, and workstation. Each item’s status is visible at a glance, with smart alerts highlighting low-stock alarms before they cause problems. This is no longer science fiction – it’s the emerging reality of modern inventory management. Today’s warehouses are evolving into dynamic, self-optimizing fulfillment centers. By harnessing artificial intelligence, advanced sensors, and robotics, businesses can dramatically improve efficiency and accuracy.

For context, growing e-commerce demand and supply chain volatility are pushing warehouses to become faster and smarter. Customers expect instant delivery, and companies operate with lean inventories. Labor shortages and global disruptions have shown the need for systems that can predict issues and adapt quickly. The combination of AI, networked sensors, and robotics directly addresses these pressures by enabling warehouses to be predictive, flexible, and efficient. Much of this vision is enabled by cloud computing. By storing inventory data and processing power online, even small warehouses can access advanced AI and mapping tools without heavy onsite IT infrastructure. These are the elements of the future of inventory management, reshaping warehouses right now.

AI-Powered Inventory Forecasting and Optimization

Artificial intelligence (AI) is central to this transformation. Future inventory systems will use AI and machine learning to predict demand, optimize stock levels, and automate decision-making.

Gone are the days of purely reactive ordering. Instead, AI analyzes vast datasets – including past sales trends, seasonality, lead times, and even external factors like market signals or weather forecasts – to anticipate exactly what products will be needed and when. For example, an AI model might notice that umbrella sales typically spike after five sunny days, and automatically increase orders for rain gear before the weekend storm.

In practice, AI delivers several tangible benefits:

- Dynamic Replenishment: As stock levels dip, the system automatically places new orders or moves items from one location to another. It adjusts reorder quantities and timing on the fly based on current demand and supplier lead times, rather than relying on rigid safety stock rules.

- Optimized Stock Mix: The system may suggest stocking more of fast-moving SKUs and less of slow-movers, or even changing storage assignments dynamically (known as dynamic slotting). For instance, if one part suddenly becomes hot-selling, the AI can recommend moving it closer to packing stations for quicker access.

- Real-Time Analytics: AI-driven dashboards and natural-language query tools let managers ask questions of the inventory system on the fly (e.g., “Which SKUs will stock out next week?”). These dashboards visualize current stock levels, forecast trends, and potential shortages, turning raw data into actionable insights.

- Enhanced Forecast Accuracy: AI models can incorporate unconventional data (like social media trends or local events) to catch demand shifts early. For example, detecting an online buzz about a product might trigger pre-stocking before sales even begin.

The results are dramatic. Companies using AI-driven inventory report faster order fulfillment and significantly lower carrying costs. Real-world pilots have shown some warehouses achieving 20–40% faster pick rates and sharply reducing excess inventory by leveraging AI. Less capital sits idle in slow-moving stock, while stockouts and rush orders become rare. Warehouse managers spend less time on routine calculations (like juggling reorder points) and more time on strategy. In effect, AI becomes a digital co-pilot – continuously fine-tuning inventory policies and operations based on real-time data.

AI also improves accuracy and foresight. The system can spot anomalies – such as unexpected stock drops or duplicate orders – and flag them immediately. Over time, machine learning reduces such errors by learning from past mistakes. For example, if the system sees that counts from one zone frequently mismatch, it can alert staff to double-check that area. By automating the thinking part of inventory control, AI frees humans to focus on exceptions and high-level planning, transforming inventory management into a proactive, self-improving process. Companies that embrace AI find themselves confidently meeting demand surges without massive safety stock, a key advantage in a fast-moving market.

Advanced Sensors and Tracking Technologies

The other key pillar of tomorrow’s warehouse is ubiquitous sensing. Instead of periodic audits, the warehouse will be blanketed with sensors that continuously feed information into the inventory system.

Major sensor technologies include:

- RFID and Barcode Tracking: Most goods will carry RFID tags or barcodes. RFID readers installed at docks, aisle entrances, and packing stations automatically detect tagged pallets or cartons as they move. For example, an RFID reader at the shipping door can register all outgoing boxes in seconds without a single manual scan. Barcodes remain important too; future scanners will get faster and more ergonomic (think ring scanners or smart glasses that read codes hands-free). Together, these tools speed up receiving, picking, and inventory counts, and update the system in real time.

- Smart Shelving: Some futuristic warehouses use shelves or bins with built-in weight sensors or scales. These “smart shelves” can detect when items are added or removed and update counts automatically, without any scanning. For instance, placing a pallet on a sensor-equipped rack would instantly increase that location’s stock count, greatly reducing manual work.

- Beacon and Positioning Systems: In addition to RFID, newer technologies like Bluetooth beacons or Ultra-Wideband (UWB) tags can pinpoint assets with high precision indoors. These are used for tracking vehicles, tools, or expensive equipment so nothing is truly “lost” in the warehouse. A small beacon on a forklift or tool cart can report its location to the system, enabling instant lookup of where every key piece of equipment is.

- Environmental and Condition Sensors: Warehouses storing sensitive items (food, medicine, chemicals) will deploy sensors for conditions like temperature, humidity, or vibration. If a refrigeration unit spikes above safe limits, the system immediately flags which products are affected. In one scenario, wireless thermometers on each freezer rack could send alerts if an area warms up; the system could automatically set aside stock from that zone for inspection or faster use. Weight or pressure sensors can also detect when stock is removed or added to a shelf, further automating updates.

- Computer Vision and Drones: Cameras combined with AI vision software add yet another layer. Overhead cameras or robot-mounted cameras can scan barcodes or even visually count boxes on shelves. Drones are increasingly used for inventory checks: a drone can fly along racks at night and capture hundreds of barcode scans per minute. This automated cycle counting catches discrepancies much faster than human crews. Vision systems can also inspect damage or quality (e.g., spotting spilled products or a missing label).

- Predictive Alerts: By analyzing trends in sensor data, the system can alert managers before issues escalate. For example, if a shelf-weight sensor shows a gradual leak of fluid or a sudden drop (suggesting a spill or theft), AI can flag that location for immediate inspection before the loss grows.

All these sensors together create a live, instrumented warehouse. Data from every RFID reader, camera, and sensor streams into the central inventory platform (often cloud-based), updating stock levels continuously. Managers always know where every item is and what condition it’s in.

This transparency means the system can automatically trigger actions: a temperature alert might freeze stock movement or prompt a quick transfer, a low-level alert might auto-generate a purchase order, and so on. In short, smart sensors turn inventory into a transparent, always-monitored resource. Instead of wandering aisles hunting for missing boxes, workers get guided by data-driven prompts. The result is a warehouse that’s safer, with far fewer blind spots or surprises, and inventory becomes nearly self-reporting.

Robotics and Automation in Warehousing

Combine AI brains and sensor eyes with robotic hands and wheels, and you get a warehouse where physical tasks are mostly automated. Warehouse robotics – once a vision of the future – is now accelerating into reality. Robots of many types will work alongside human workers to handle materials:

- Autonomous Mobile Robots (AMRs): These self-driving carts and forklifts can navigate warehouse floors without fixed guides. AMRs can carry full shelves or loads of items to human pickers or to packing stations. For example, when an order is confirmed, an AMR might drive itself to the appropriate rack, pick the needed carton with a mounted mechanism, and deliver it to packing. Unlike older fixed-path vehicles, modern AMRs use LIDAR and cameras to map the facility and avoid obstacles in real time. Many warehouses already use fleets of AMRs to pull inventory from storage, dramatically cutting walking time. This means human workers no longer have to trek back and forth – the robots fetch the products and bring them to conveyor belts or workstations.

- Robotic Picking and Sorting: At packing and shipping, high-speed robot arms and conveyor systems will handle boxes and packages. Advanced gripper arms can pick a wide variety of items (even odd shapes) and place them in bins or onto pallets. These systems dramatically cut errors: a robot programmed to place exactly the right item won’t accidentally slip the wrong part. Automated sorters will quickly divert items to different lanes or trucks based on barcode scans. By taking over repetitive lifting, bending, and heavy assembly tasks, robots boost speed and free human workers for higher-level tasks.

- Collaborative Robots (Cobots): Cobots are designed to work safely side by side with people. In a picking station, for example, a cobot might hand items to a human worker or vice versa. If a worker is assembling a large order, a cobot can present the needed piece in an ergonomic position. Because cobots have built-in sensors to avoid collisions, they enhance efficiency without the need for safety cages. This human-robot teaming lets warehouses benefit from automation while preserving flexibility. Humans still manage exceptions and quality checks, while cobots do the heavy lifting.

- Drones and Aerial Inspection: Flying drones will become inventory assistants, too. After hours, a drone can autonomously fly an inspection route along racks, scanning barcodes with its camera or using RFID receivers to verify stock levels. It can also scan for spilled material or obstacles on the floor. Drones help ensure accurate cycle counts and safety checks in tall or hard-to-reach areas.

- Automated Storage and Retrieval (AS/RS): These are highly automated storage towers or carousel systems. When an item is needed, a robotic shuttle or crane retrieves the pallet from deep storage. AS/RS systems greatly increase storage density by stacking items vertically in tightly packed racks. Integrated with conveyors and sorters, they form high-speed mini-warehouses for top-selling products, ensuring those SKUs are always ready to ship.

- Predictive Maintenance: Sensors on robots and equipment feed back health data constantly. The AI can analyze this and schedule maintenance only when needed (rather than on a strict timetable), maximizing uptime. For example, if a conveyor motor shows rising vibration over time, the system predicts it’s wearing out and arranges a brief replacement before it fails, avoiding unplanned downtime.

The growth of robotics in warehousing is explosive. Experts project millions of warehouse robots in operation globally in just a few years. The benefits are clear:

- Higher Throughput: Robots work much faster and longer than humans. They can keep up peak order volume 24/7, which is crucial for meeting same-day or next-day delivery demands.

- Improved Accuracy: Automated picking and scanning eliminate most human errors. Every robotic movement is tracked, so the system always knows exactly what was moved where.

- Safety and Ergonomics: Robots take on the dangerous tasks – moving heavy pallets, lifting above shoulder height, or working in extreme environments. This dramatically reduces injuries. For instance, offloading a lorry or unloading a full bin can now be done by a machine instead of risking worker strain.

- Space Optimization: Automated systems can pack inventory denser. AS/RS units, narrow-aisle robots, and high-bay shuttles can use vertical space far better than forklifts. This cuts facility costs since you can store more in the same footprint.

- Scalability: Robotics allow modular expansion. If an operation needs to double capacity for peak season, it can add more robots or extend shifts with minimal retraining – a flexibility hard to match with hiring and training human staff.

Some companies are even experimenting with lights-out warehouses: fully automated facilities that run overnight without any human staff. Advances in reliability and self-diagnosis are making such autonomous, round-the-clock operation possible for routine tasks. In effect, robots become the workhorses that never sleep, while humans monitor the system.

Importantly, robotics tie directly back into inventory tracking. Every time a robot moves goods, it updates the database instantly. For example, a robot placing 30 units of an item on a shelf immediately adds those 30 to inventory. This keeps the digital inventory in sync with reality.

Overall, robotics is transforming warehouses into high-speed, safe, and efficient environments. Combined with AI and sensors, it creates a system where managers orchestrate machines and data, rather than manually chasing orders.

Digital Twins and Visual Inventory Mapping

All this intelligence – from AI, sensors, and robots – demands clear visibility. Digital twins (real-time virtual models of the warehouse) and interactive inventory maps provide exactly that. A digital twin is a live replica of the entire facility, showing every rack, aisle, and bin.

Managers can visualize workflows in the twin and even simulate changes (like rearranging shelves or introducing a new packing line) before implementing them physically. This helps planners optimize layouts and processes risk-free.

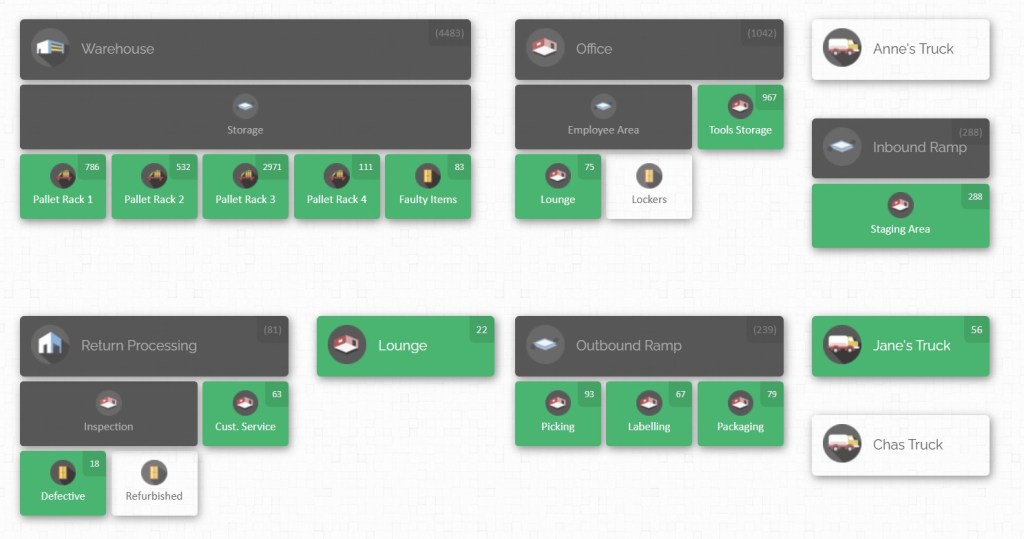

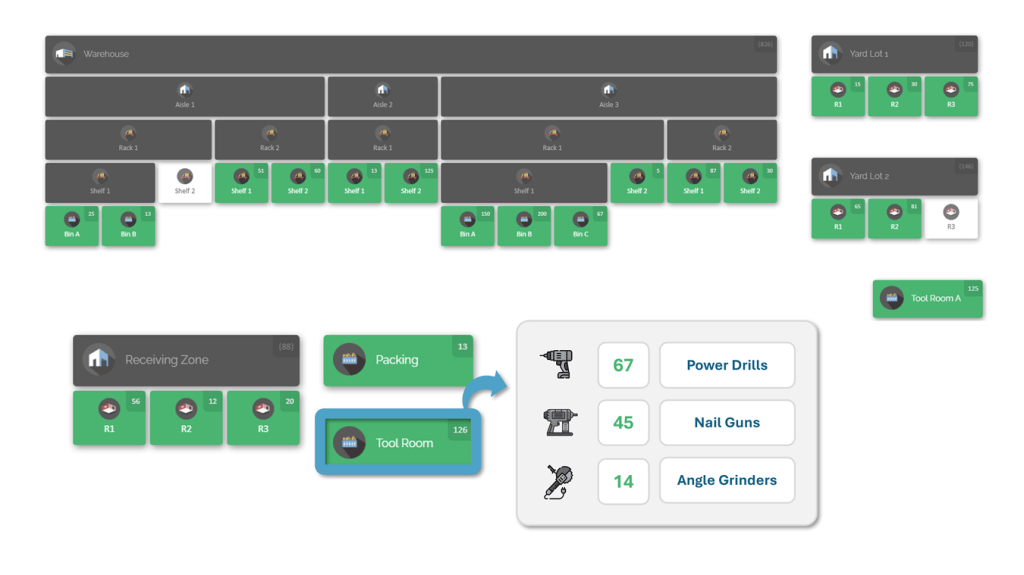

Simpler 2D inventory mapping tools achieve similar insight. These let you draw your warehouse layout on-screen and tie your products to each bin or shelf. Stock levels then display on this map view. For example, the map we saw above highlights which areas are low on inventory. Clicking on any location on the map immediately lists the SKUs stored there and their quantities. Conversely, searching for a specific part highlights all the map locations holding that part. This visual interface turns abstract data into an intuitive dashboard. A manager can instantly answer questions like “Which bin holds part #1234?” or “Where is our oldest batch of bolts?” without digging through tables. It also speeds up routine tasks: performing a cycle count becomes a quick review of each map zone, and moving inventory is as simple as dragging an item’s icon from one map box to another.

- Simulation and Optimization: Advanced digital twins even allow full 3D simulation. Managers can test different warehouse configurations or workflows on the digital model to find the fastest arrangement before physically moving any equipment.

- Interactive Transfers: With mapping tools, moving stock on the map updates quantities automatically, eliminating manual data entry. If you drag 20 units from Shelf A to Shelf B on the screen, the system logs that move instantly.

- Data-Enriched Views: Modern mapping systems (like CyberStockroom) allow attaching images, notes, and custom fields to locations. For instance, a photograph of a packed pallet can be linked to its map location for quick identification.

These visual systems amplify the power of AI and sensors. For example, if a sensor alerts that Shelf A is unexpectedly empty, the inventory map immediately highlights Shelf A in red. Managers can then investigate or instruct robots to restock from nearby locations. Essentially, the map or twin makes the data tangible, so humans can interact with the automated system in a natural way.

CyberStockroom: Visual Inventory Mapping in Action

CyberStockroom is a concrete example of the map-centric approach. It’s a cloud-based inventory management platform built around visual mapping. In CyberStockroom, users create a digital layout of their facility – defining zones, aisles, shelves, and bins – and then assign each product to its physical location on the map. The software becomes an interactive dashboard: warehouse teams see color-coded boxes representing each location, and the stock levels appear inside them.

CyberStockroom’s key features include:

- Map-Driven UI: Easily draw and save the warehouse layout. Each location is an interactive block on the map.

- Drag-and-Drop: Move stock between locations on the map with a simple drag-and-drop gesture; the system updates quantities automatically.

- Barcode Integration: Use handheld scanners to check items in and out for fast data entry, keeping counts accurate with minimal typing.

- Batch Import: Handle large inventories via CSV/Excel upload, populating the map from existing lists quickly.

- Full Audit Trail: Every change (transfers, adjustments, counts) is timestamped and traceable to the user who made it.

- Cloud-Based Access: Run the software on any device with a browser; all users see updates in real time without manual syncing.

Each location on the map is color-coded to indicate status. Clicking on a location box drills down to details: which SKUs are there, how many units, batch or serial numbers, and even which supplier or owner. Opening on particular product in the system highlights all the map locations that hold it and shows the quantities. This makes it effortless to locate items and understand stock levels anywhere on the property.

CyberStockroom supports barcode scanning and spreadsheet imports to populate and update inventory. It runs in any modern web browser (no separate mobile app is needed, though phones and tablets can access it via their browsers).

Integration and Connectivity

All of these technologies – AI modules, sensor networks, robotic equipment, and mapping software – must work together in a connected ecosystem.

Modern inventory solutions offer open APIs and cloud services so they can sync with other business systems. For example, many platforms now directly connect to e-commerce sites (Shopify, Amazon) and accounting packages (QuickBooks, SAP).

This means when a customer order is placed online, the warehouse system immediately reserves and picks the item in real time without manual intervention. Similarly, receiving goods on an ERP or purchasing system can automatically create the inventory entries in the warehouse software.

In practice, seamless data flow eliminates manual handoffs. Purchase orders, sales updates, and shipping events move between systems in real time. For instance, if an AI-driven forecast suggests inventory will run out, it can trigger a purchase order in the ERP, then the warehouse system receives those items and updates stock without anyone retyping data. Some cutting-edge solutions even tap directly into customer demand signals: e-commerce traffic surges or social media trends can feed into the system, allowing stock levels to adjust before traditional order channels even recognize the spike.

For example, imagine an online retailer whose AI notices a viral surge in demand for a product. The system can automatically reallocate stock from low-priority locations to fulfill those high-demand orders, all while updating the inventory map. Or if a critical supplier shipment is delayed, the platform can reroute existing stock from other facilities, reschedule outbound shipments, or send alerts to managers. The key is real-time coordination: every subsystem (sales, purchasing, warehouse equipment) becomes part of one information network.

Implementing this connectivity requires solid infrastructure. Warehouses of the future will rely on robust wireless networks (Wi-Fi 6, 5G, or private wireless) to handle constant device chatter. Edge computing – processing data near the sensors and robots – will help keep system responses instant (for example, a robot avoiding an obstacle should not wait for cloud commands). At the same time, central cloud servers run the heavy analytics and data storage.

With so many connected devices, cybersecurity is critical. Warehouses will need strong encryption, secure authentication, and network segmentation to protect inventory data. In practice, this means treating the warehouse like any other IT environment – using firewalls, VPNs, and continuous monitoring. The goal is to make the warehouse network reliable and safe, so that managers trust the data flow and systems keep running without interruption.

Integration is an ongoing journey. Major WMS and ERP vendors are building more AI and robotics hooks into their platforms, signaling that the industry is moving in this direction universally. In practical terms, each new scanner, robot, or supplier link should be added to the network incrementally, continuously making the warehouse smarter. Ultimately, full integration means the entire supply chain — from supplier orders to customer deliveries — becomes transparent and tightly coordinated.

Use Cases and Benefits

These technological trends translate into concrete benefits for warehouse operations. Consider these examples:

Faster, More Accurate Order Fulfillment

Automation and AI mean orders get processed and shipped more quickly. For instance, an e-commerce center using AMRs and robotic pickers can fulfill same-day orders that used to take hours, with near-zero picking mistakes.

Near-Perfect Inventory Accuracy

Continuous scanning and automated counts keep the system synchronized with reality. Shrinkage and misplaced goods become rare because discrepancies are caught immediately. Stock levels in the database match the floor, so managers know exactly what is available.

Better Capital Efficiency

AI-driven demand planning and just-in-time restocking reduce excess safety stock. Warehouses hold only what’s needed, minimizing storage costs. This frees up cash and space. At the same time, critical items are never left out of stock, avoiding lost sales.

Enhanced Visibility

Real-time dashboards and visual maps give managers a holistic view. They can spot low inventory at a glance or see bottlenecks in workflows. This transparency enables quicker response to trends, surges, or problems.

Improved Safety

Robots and sensors improve ergonomics and reduce accidents. Heavy lifting, hazardous zones, and repetitive motions can be handled by machines. Automated safety systems (like slowing robots around humans) further protect workers, creating a safer environment.

Scalability and Flexibility

These technologies scale with demand. During peak season, you can deploy extra robot shifts, activate additional counting drones, or give the AI more input data, all without a proportional increase in labor. In slow periods, systems can idle down to save costs. Manual methods rarely offer this level of agility.

Resilience

Real-time data and predictive insights let the warehouse adapt rapidly to disruptions (such as supplier delays or sudden order surges). For example, the system might automatically reroute inbound shipments to alternate docks or switch to backup suppliers. This agility helps maintain service levels even under stress.

Sustainability

Intelligent systems often lead to greener operations. Optimized routes and energy-managed lighting reduce fuel and power usage. Precise inventory planning cuts waste (fewer expired or obsolete items). As companies focus on ESG goals, these efficiencies also reduce costs.

Omni-Channel Optimization

Modern platforms can allocate stock across multiple channels (stores, online stores, and distribution) in real time. For example, AI might reroute high-demand items from a store’s inventory to fulfill online orders during a flash sale, ensuring high-priority orders get filled first.

In short, inventory becomes a competitive advantage rather than a headache. Warehouses can ship orders faster and more reliably while carrying less excess stock. Human workers can focus on customer service and exception handling, rather than chasing paper. The combination of AI, sensors, and robotics turns the warehouse into a highly efficient machine whose throughput and accuracy far exceed traditional approaches.

Challenges and Considerations

Of course, moving to this high-tech warehouse has its challenges. Key considerations include:

- Upfront Investment: New technology costs money. Automating machinery, sensors, and software can be expensive. It makes sense to start with a clear ROI plan: implement in phases (for example, automating one zone first) and measure the gains before expanding. Over time the cost is offset by labor savings and efficiency improvements.

- Phased Implementation: Roll out changes gradually. Test each technology (e.g., a new robotic system or software module) in a controlled way, learn from it, and then scale. This reduces risk and helps fine-tune processes.

- Data Quality: AI and sensors only work well with good data. Companies must have accurate SKU definitions, locations, and counts as a baseline. Training staff to always scan and update the system is crucial; even the best algorithms fail if the underlying data is wrong.

- Integration Complexity: Connecting new tools to existing ERP or WMS systems can be complex. Each integration requires planning and sometimes custom coding. Choosing platforms with known connectors and open APIs can ease this process.

- Workforce Training and Change Management: New tech means new workflows. Employees need training and time to adjust. Clearly communicating the benefits (like safer jobs and less drudgery) and involving workers in the transition helps gain buy-in.

- Security and Reliability: A networked warehouse must be protected. This includes cybersecurity measures (encryption, access control) and operational safeguards (backup power, manual fallback plans). Downtime or breaches can halt operations, so robust defenses and contingency plans are important.

- Vendor and Technology Selection: With many new products on the market, it’s important to choose solutions that fit the business size and industry. Not every warehouse needs a giant sorting robot; sometimes low-cost sensors and off-the-shelf AI apps can deliver great benefits. Do pilot tests to find the right mix of solutions.

- Regulatory and Safety Compliance: Automation must still comply with safety standards (e.g., robots with people) and industry regulations (especially for food or pharma tracking). Ensure any new tech has the needed certifications or features.

Despite these challenges, most companies find the investment worthwhile. The key is careful planning, starting small, and iterating. Each implemented feature – from RFID tagging to a pilot robot – builds the foundation for the next step. Over time, the warehouse transforms into a highly efficient, data-driven center with far better control over inventory.

Preparing for Tomorrow’s Warehouse

The future of inventory management is here, and it is powered by technology. Warehouses will become high-tech command centers, where AI-driven forecasts, sensor networks, and fleets of robots work together seamlessly. Inventory will no longer be a static list – it will be a dynamic, visible asset managed in real time on virtual maps and digital twins. Managers will oversee operations from dashboards, making strategic decisions instead of chasing orders or firefighting stock issues.

For today’s warehouse leaders, the time to act is now. Begin by improving data and visibility: implement barcode or RFID tracking and consider a cloud inventory tool to centralize information. Pilot an AI forecasting add-on or introduce a single robot or drone in one area to prove value. Then scale up gradually. Each step taken now lays the groundwork for greater agility and success in the fast-paced years ahead.

This shift has tangible benefits: reduced labor and error rates, faster fulfillment, and higher customer satisfaction. Importantly, these advances are practical and data-driven – they can be implemented step by step. By gradually adopting these tools and iterating, any warehouse can begin reaping rewards and positioning itself for the next leap in efficiency. The journey may seem challenging, but many vendors now offer consulting and managed services to help. Starting small – by cleaning up data, tagging inventory, or automating one process – can lead to big gains.

Warehouses are in a race to adopt these innovations; those who wait risk falling behind competitors who leverage AI and automation for efficiency and accuracy. For warehouse managers ready to adapt, this future offers an exciting challenge: technology handles the routine, and people focus on innovation. The time to start is now – stay ahead of the curve. Embracing this transformation today will empower warehouses to become even more responsive, accurate, and efficient tomorrow. Every step forward is a step toward a smarter, more resilient supply chain.

Leave a comment