Imagine running a factory where parts and materials arrive just as you need them, and finished products flow out the door without piling up in storage. This vision is the promise of lean manufacturing: eliminating waste, saving cost, and keeping operations agile. Inventory, in particular, is one of the biggest wastes lean manufacturing aims to reduce. After all, every extra unit sitting on a shelf ties up capital and risks becoming obsolete. The ideal is to have exactly what you need, exactly when you need it – no more, no less.

For many manufacturing operations managers, achieving this perfect balance is the ultimate goal. Lean manufacturing inventory optimization is all about aligning your inventory levels with your production and sales, so that you’re never caught with excess stock or with an empty bin that halts production. It’s a delicate dance of timing, forecasting, and coordination.

One of the most famous lean strategies is Just-in-Time (JIT) inventory management, pioneered by Toyota as part of the Toyota Production System. JIT strives to minimize inventory by scheduling inbound materials and production so closely that items arrive “just in time” for use. When done right, JIT virtually eliminates warehousing of raw materials and reduces finished goods stock to near zero. This results in lower carrying costs, less space needed, and quicker identification of problems in the supply chain.

However, as many companies discovered in recent years, just-in-time can sometimes turn into just-too-late. Global supply chain disruptions (like the COVID-19 pandemic and component shortages) taught manufacturers a hard lesson: running with no buffers at all can be risky. If a critical supplier fails to deliver on time, or demand spikes unexpectedly, a pure JIT system might leave you unable to fulfill orders. The lean ideal of zero inventory must be balanced with practical risk management.

In this comprehensive guide, we’ll explore how to optimize inventory in a lean manufacturing context – covering JIT and beyond. We’ll discuss proven techniques such as demand forecasting, safety stock calculation, and inventory segmentation that help you stay lean and resilient. You’ll also see how modern tools can provide the visibility needed to manage inventory dynamically across your operation. By the end, you’ll have a roadmap for implementing inventory optimization strategies that keep your production running smoothly with minimal waste.

Just-in-Time (JIT) Inventory Management

The cornerstone of lean inventory optimization is Just-in-Time (JIT) management. Under JIT, you aim to receive materials and produce goods only as needed, exactly when they’re needed. Instead of stockpiling weeks or months of supply, you have a continuous flow: parts arrive at your factory just before they go into production, and finished products ship out shortly after completion. When successful, JIT means minimal idle inventory. The payoff is huge: freed-up cash (since you’re not buying materials far in advance), reduced storage and handling costs, and less risk of inventory becoming damaged or obsolete on the shelf.

How to implement JIT: Transitioning to JIT requires careful coordination and a change in mindset from “just in case” to “right on time.” Here are key practices for making JIT work:

- Strong supplier relationships: Work closely with your suppliers so they know your production schedule and can deliver reliably on a tight timeline. Sharing forecasts and real-time production data helps suppliers synchronize their output to your needs.

- Smaller, frequent shipments: Instead of large bulk orders, arrange for smaller lot deliveries at more frequent intervals. This might mean ordering components daily or weekly rather than monthly. It can increase shipping activity, but drastically cuts average inventory on hand.

- Kanban signals: Many JIT systems use Kanban, a visual signaling method to trigger replenishment. For example, a kanban card in a bin of parts signals that once that bin is empty (or hits a low threshold), a new batch should be ordered or released. Electronic kanban systems or automated alerts can serve the same purpose in modern factories.

- Flexible production and quick changeovers: JIT works best when your production lines can adapt quickly. Techniques like SMED (Single-Minute Exchange of Dies) are used in lean manufacturing to reduce setup times, so smaller production runs are efficient. If you can switch products or models rapidly, you don’t need to produce huge batches “just in case,” which aligns with JIT philosophy.

- Quality at the source: With minimal inventory, there’s little room for defects. If a batch of parts arrives and half are faulty, a JIT operation could grind to a halt (since there aren’t extra on hand). Thus, building in quality controls and working with trusted, high-quality suppliers is critical. Essentially, “zero defects” becomes a goal to keep the just-in-time pipeline flowing smoothly.

- Employee training and culture: Your team needs to be on board with JIT processes. Employees on the line should know that if something is running low, it’s crucial to alert the system (or manually signal) immediately. A culture of responding quickly to needs and problems is necessary – there’s no cushion of extra inventory to hide issues or delays.

Benefits and risks: When JIT is firing on all cylinders, it truly streamlines operations. Companies see lower inventory carrying costs, higher inventory turnover rates, and often improved workflow efficiency. Problems become more immediately visible – if a supplier is late or a machine is slow, you notice it right away when you’re not buffered by weeks of stock. This rapid feedback can drive continuous improvement.

However, JIT’s weakness is its dependency on perfect conditions. Any disruption can cascade. A classic example is the 1997 Aisin fire in Japan: a fire at a key Toyota parts supplier’s plant halted Toyota’s production within hours because, under JIT, there were almost no excess parts in the pipeline. Similarly, many manufacturers experienced JIT vulnerabilities during recent global supply chain upheavals – factories had to slow down or stop because the next delivery of critical components was stuck in transit or delayed.

The lesson is that JIT, while powerful, isn’t one-size-fits-all or foolproof. It works best in a stable, predictable environment with dependable partners. In practice, most firms find they need to blend JIT with some safety measures. Next, we’ll look at how the industry has evolved beyond JIT to create a more resilient approach without giving up the efficiency gains.

Beyond JIT: Balancing Efficiency with Resilience

Lean purists might dream of zero inventory, but reality has nudged many companies toward a compromise between ‘just-in-time’ and ‘just-in-case’. After the supply chain shocks of recent years, manufacturers increasingly recognize the need for a buffer. In fact, surveys have found that a majority of companies have adjusted their strategies, shifting away from pure JIT and incorporating more safety stock or backup supplies. The idea of “just-in-case” inventory is making a comeback – holding a bit of extra inventory for critical parts or materials so that you can weather unexpected disruptions.

Importantly, this doesn’t mean abandoning lean principles. It’s about being strategic with your buffers. Rather than overstocking everything (which would be a return to old inefficient habits), forward-thinking operations managers are identifying key risk areas and protecting them. The result is often a hybrid approach: you continue running lean and JIT for most items, but for a select few components that are high-risk (long lead times, single source, or historically unpredictable demand), you keep a cushion.

For example, a factory might operate JIT for common screws, bolts, and other easily obtained supplies – there’s no need to hoard those because suppliers can deliver them quickly. But for a specialized electronic chip that comes from overseas and has volatile availability, the manufacturer might store an extra month or two of supply “just in case” shipments get delayed. Similarly, some companies set up dual sourcing for crucial materials: if Supplier A runs into trouble, Supplier B can step in. That way, they’re not solely reliant on one supply line.

Here are some tactics to build resilience without bloating your inventory:

- Safety stock for critical items: Calculate and keep a safety stock level for items that would truly shut down your operation if they ran out. We’ll delve more into how to calculate optimal safety stock in the next section, but the key is to target this buffer where it’s most needed.

- Prioritize based on risk and impact: Perform a risk assessment of your inventory. Which parts have the longest replenishment lead times? Which materials come from a single vendor or a distant region prone to delays? Which components have no easy substitutes? These are candidates for a just-in-case cushion. By contrast, items that are readily available or have low impact on production can stay strictly JIT.

- Strengthen supplier relationships and contracts: Work with suppliers on flexibility. For instance, you might negotiate agreements where a supplier holds some inventory on their end (vendor-managed inventory) or can expedite emergency orders for you. This way the “extra” inventory isn’t sitting in your warehouse, but you know it’s accessible if needed.

- Invest in visibility: Having end-to-end visibility of your supply chain can help anticipate problems before they hit. If you can see that a shipment is delayed at a port or a supplier is facing a shortage, you can react (perhaps by tapping into your safety stock or switching to an alternate source) before your factory has to stop. Modern inventory management systems, and approaches like the inventory mapping we showed above, play a big role in this visibility.

The goal of these resilience tactics is to balance efficiency with preparedness. Lean manufacturing isn’t about recklessness; it’s about trimming fat while staying strong. By carefully choosing where to hold extra inventory (and how much), you ensure that one hiccup doesn’t shut down your line. In other words, you’re optimizing inventory not just for cost and speed, but also for reliability.

Next, let’s talk about the planning side of this equation: demand forecasting and how it feeds into a successful lean inventory strategy.

Demand Forecasting: Planning for Lean Inventory

If JIT is the tactical execution of “only what’s needed, when it’s needed,” then demand forecasting is the strategic brain telling you what will be needed and when. In a lean environment, accurate forecasting is absolutely critical. The better you can predict customer demand, the more confidently you can trim down inventory without risking stockouts. Forecasting essentially guides your whole supply chain: it informs how much raw material to order, how to schedule production, and how much finished goods to keep on hand (if any).

Why forecasting matters for lean: Imagine cutting your inventory to the bone, only to discover a week later that orders are double what you expected – you’d be in trouble. Conversely, overestimating demand means you’ll overproduce or over-order, leaving excess inventory sitting around (the very waste lean aims to eliminate). Thus, demand forecasting and inventory optimization go hand in hand. Lean manufacturing inventory systems typically rely on a pull-based approach (produce to actual demand or real consumption), but you still need a forward-looking view to prepare for what’s coming down the pipeline.

Techniques for better forecasts: Even if you’re not a data scientist, you can adopt several practices to improve forecast accuracy:

- Analyze historical data: Start with past sales or usage data for your products and components. Look for patterns – seasonal fluctuations, trends upward or downward, and any recurring spikes (e.g., every end-of-quarter there’s a rush order). Simple statistical methods like moving averages can smooth out noise and give a baseline projection.

- Collaborate with sales and customers: The people closest to the market often have insights that raw data doesn’t show. Talk with your sales team about upcoming promotions or market conditions. If you have key customers, consider implementing a collaborative forecasting process with them – for instance, they might share their upcoming needs or point out trends in their industry that could affect your demand.

- Use technology and tools: Modern forecasting software can automatically analyze large datasets and identify complex patterns. Many ERP and inventory management systems include forecasting modules. Some companies are even leveraging AI and machine learning models that factor in everything from economic indicators to social media trends. If your operation is large enough to warrant it, these tools can significantly refine your forecasts. However, even small manufacturers can use spreadsheet-based models or simpler demand planning software to get a handle on expected demand.

- Continuous update and feedback: Forecasting is not a set-and-forget task. Embrace a rolling forecast approach – update your forecasts regularly (monthly, weekly, or even daily for fast-moving businesses) as new data comes in. Compare your forecasts to actual demand and measure the error. This feedback loop helps you learn and adjust: if you consistently overshoot or undershoot for certain items, you can tweak your model or add a manual adjustment. Over time, your goal is to narrow the gap between forecasted and actual demand.

By improving forecast accuracy, you enable leaner operations. For instance, if you know with confidence that next month’s demand for Product X will be around 1,000 units (±5%), you can plan production and materials accordingly, perhaps keeping just a small safety stock. On the other hand, if your forecasting is off by 50% regularly, you’ll be forced to carry large buffers “just in case.” In short, good forecasts allow you to trust a lean inventory. They reduce the guesswork.

That said, no forecast is perfect – uncertainty is always there. This is why we complement forecasting with techniques like safety stock, which we’ll discuss next. But as a rule of thumb: the more you can get ahead of demand, the less you have to hoard inventory. Forecasting is your proactive tool for staying lean and meeting customer needs reliably.

Safety Stock: Your Buffer Against Surprises

Even with excellent forecasting and classification, demand and supply will never be 100% predictable. That’s where safety stock comes in. Safety stock is an extra buffer of inventory kept on hand to guard against variability – unexpected spikes in demand or delays in supply. In essence, it’s the inventory you hope you never have to use, but keep “just in case” to prevent a stockout. For example, a distributor might keep two weeks’ worth of extra supply of a crucial component so that if a shipment from the supplier is late, production can continue uninterrupted.

Calculating the optimal safety stock is a classic inventory optimization exercise. Hold too little and you’ll run out when something goes wrong; hold too much and you’re tying up money for no reason. The calculation typically considers factors like forecast error (demand variability) and supplier lead time variability.

A simple approach is to use the formula based on service level targets (desired probability of not hitting a stockout) combined with the standard deviation of demand during lead time. In practice, many companies use software or standard formulas (e.g. Safety Stock = Z-factor × σ<sub>demand_during_lead_time</sub>, where Z is based on desired service level) to compute this. The key is that safety stock should cushion the unpredictable portion of demand or supply.

Safety stock is essentially insurance against uncertainty. For instance, retail stores carry extra wrapping paper going into the holidays beyond forecasted demand – if sales exceed expectations, they won’t miss out, and if not, the leftover can be stored for next year. Manufacturers might keep safety inventory of critical raw materials in case of a supplier disruption. An everyday example is at gas stations: they maintain a bit more fuel than average sales indicate, to handle surge buying or late deliveries.

Closely related to safety stock is the concept of reorder points (ROP). A reorder point is the inventory level at which you should trigger a replenishment order.

The basic formula for ROP is: ROP = average demand during lead time + safety stock.

Optimizing reorder points ensures that you order at the right time so that new stock arrives just as existing stock is nearly depleted (accounting for that safety buffer). Modern inventory systems often automatically calculate and adjust reorder points based on consumption data, seasonality, and lead time changes.

In optimizing safety stock and ROP, a data-driven approach is essential. Analyze your demand variability – do sales of an item fluctuate wildly or are they stable? Also examine supply reliability – does your supplier deliver on time consistently, or are there frequent delays? High variability in either means you should carry more safety stock. You might choose different service level targets for different item categories (for example, 99% service level for A items, 95% for B, etc., meaning you’re willing to tolerate a stockout 1% or 5% of the time respectively). By tailoring safety stock to the criticality of the item and variability, you avoid a one-size-fits-all cushion that could be too large (wasting money) or too small (risking stockouts).

Bottom line: Safety stock is a vital cushion in inventory optimization. Use it strategically – not as an excuse to overstock everything, but as a targeted measure for uncertainty. Continuously refine your safety stock levels and reorder points as conditions change (new demand patterns, new suppliers, etc.). This ensures you maintain high service levels (keeping production running and customers happy) with the minimum necessary inventory.

ABC Analysis: Focus on What Matters Most

Not all inventory is created equal. ABC analysis (also known as ABC classification) is a technique that segments your inventory based on importance, so you can manage each segment with appropriate attention. Typically, “A” items are the top sellers or highest value items that constitute a large portion of your inventory value (for example, the top 20% of items that make up 80% of value – the Pareto principle). “B” items are moderately important, and “C” items are the long tail of low-value or low-frequency goods. By categorizing stock this way, you focus your efforts where they matter most.

Using ABC analysis, operations managers give tight control to A items – e.g. frequent cycle counts, robust safety stock, close supplier relationships – because a shortage or overstock of these has the biggest impact.

Meanwhile, C items might be managed with simpler methods or less frequent reordering since they’re lower risk. This prioritization helps prevent overstocking or under-stocking of products by ensuring the right items are stocked in the right quantities.

In practice, businesses that implement ABC analysis often find they can reduce inventory on the less-critical “C” items (freeing up capital) while making sure the “A” items are always available for customers.

SKU Rationalization and Turnover Optimization

An often-overlooked aspect of inventory optimization is managing the assortment of products itself. SKU rationalization is the process of evaluating your stock-keeping units (SKUs) to determine which ones are genuinely contributing to the business and which are not. Over time, product lines tend to expand – new variants are introduced, old ones linger, custom items pile up – and you could end up with too many SKUs that complicate inventory management and increase costs. Every SKU carries overhead: forecasting, purchasing, storing, tracking, etc. If certain products sell rarely or have razor-thin margins, they may be candidates for discontinuation to streamline operations.

In manufacturing and warehousing, SKU rationalization often involves analyzing sales data and profitability for each item. For example, a manufacturer might find that out of 1,000 different parts they keep, a few hundred haven’t been used in over a year. Those could be obsolete or slow-moving items that are occupying shelf space and capital. By cutting those SKUs (or sourcing them on-demand instead of stocking), the company can reduce carrying costs and complexity. Too many products can actually hinder effective inventory management, as it spreads management attention and forecasting effort too thin.

Another angle is to look at inventory turnover for each SKU – how many times per year (or period) the stock of that item is sold/used and replenished. Low turnover items might indicate either low demand or overstocking. High turnover is generally positive (indicates efficient use of stock), but if it’s too high it could signal frequent stockouts if not managed well.

Optimizing turnover means aiming for a healthy rate where inventory isn’t sitting for too long (which would incur holding costs and risk obsolescence), but also isn’t turning so fast that you’re constantly expediting orders.

Industry benchmarks can help; for instance, a turnover ratio of 8 might be healthy in one industry, whereas in another, 2 is the norm due to longer production cycles.

Practical steps for SKU optimization: perform regular reviews of your catalog. Identify dead stock (items that haven’t sold in X months) and decide whether to discontinue them, or run a promotion to clear them out. Use the 80/20 rule – typically 20% of products generate 80% of sales. Ensure that long-tail items are truly needed for strategic reasons (like completing a product range or fulfilling niche but profitable demand). Work with sales/marketing to prevent the proliferation of nearly identical SKUs that add complexity without much benefit.

By rationalizing SKUs, companies often see immediate benefits: inventory levels drop, storage space is freed, and the remaining items become easier to manage. It’s all about simplifying – a lean inventory isn’t just about less quantity of stock, but often less variety of stock as well (at least in areas where variety isn’t adding value).

How CyberStockroom Supports Lean Inventory Optimization

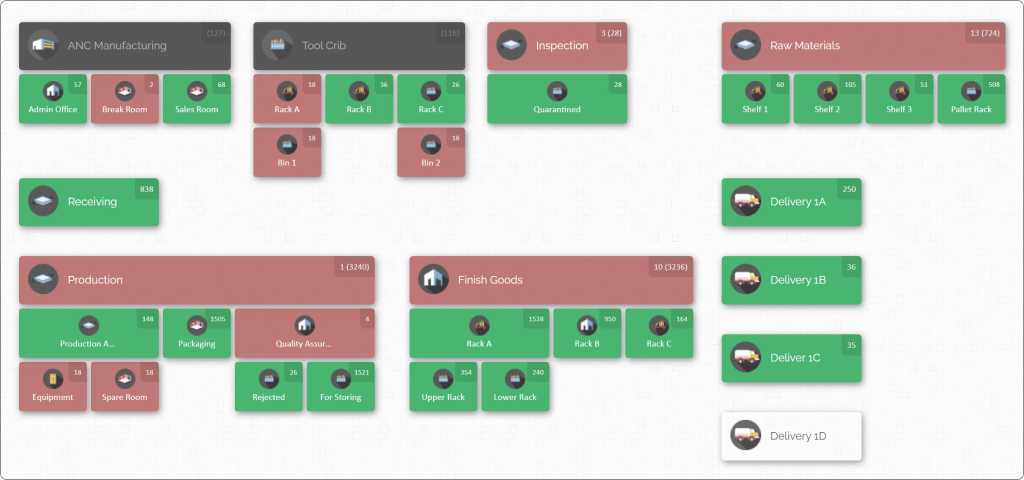

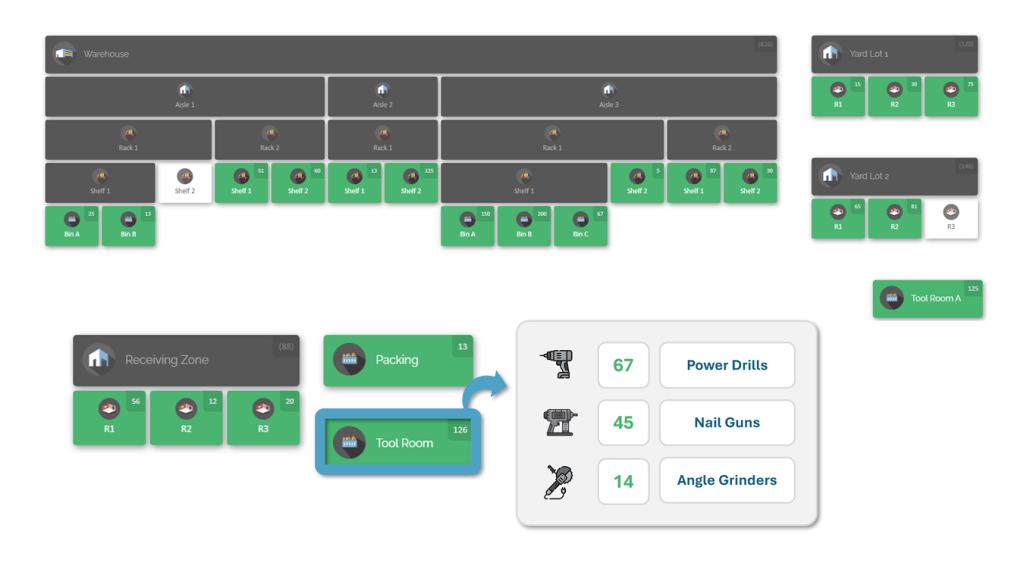

All these lean strategies are powerful, but managing them effectively requires good tools. One such tool is CyberStockroom, an inventory management software that takes a unique map-based approach to tracking stock. By providing a visual, interactive map of your operations, CyberStockroom helps you achieve many of the optimization techniques we’ve been discussing.

Here’s how it correlates with lean inventory management:

- Visual Inventory Map: CyberStockroom’s standout feature is its customizable inventory map. You can create a digital layout of your entire operation – from warehouses and factory floors to individual storage rooms or even delivery trucks. Each location is represented on the map, and you can see at a glance what’s stored where and in what quantity. This visual management is very much in line with lean principles (recall how we discussed making problems visible). Instead of scanning through rows on a spreadsheet, you have a bird’s-eye view of inventory. For example, if one workstation is running low on a part, you’ll spot it immediately on the map by a low quantity indicator, and you can act before it causes downtime.

- Real-Time Updates & Cloud Access: The platform operates in real-time and is cloud-based. That means as inventory moves or transactions happen, the map updates instantly for everyone with access. If a production team consumes materials or a new shipment arrives and is logged, you’ll see it reflected on your dashboard. Multi-location management becomes much easier – whether you have one site or ten, you’re looking at the same up-to-date information. This supports JIT because everyone knows exactly how much is on hand at any moment (preventing surprises), and it aids collaboration up and down the supply chain.

- Easy Transfers with Full Traceability: CyberStockroom allows you to move inventory on the map via simple drag-and-drop actions. Say you want to transfer components from the warehouse to the assembly line station – just drag them on the map, and the system records the move. Every transfer or adjustment is logged automatically, creating an audit trail. This traceability means you always know where your stock went and when. It’s great for preventing shrinkage (loss or theft) and for accountability. In lean terms, it eliminates the waste of lost or untracked inventory. You can confidently run with lower stock levels when you have tight control and clear records of every item’s movement.

- Mobile and Remote Management: Because it’s cloud-based and designed to be user-friendly, CyberStockroom can be used on tablets or laptops right on the shop floor or even in the field. If you have technicians with service vehicles or a satellite storage at a job site, they can update inventory from wherever they are. The map might include a truck icon representing a field engineer’s van stock, for instance. Real-time visibility into those remote or mobile inventories helps coordinate with the main warehouse and ensures nothing falls through the cracks. For a lean operation, this means even decentralized stock (which is often hard to monitor) can be kept lean and in sync.

- User-Friendly Integration: Implementing new software can sometimes be a hurdle, but CyberStockroom emphasizes ease of adoption. It supports barcode scanning and bulk importing of data, so you can quickly get your inventory into the system and update it without tedious manual input. You can add custom fields and images for items, which helps in identifying parts (useful to avoid mistakes – another type of waste). The more intuitive and accessible the system, the more your team will actually use it, which is crucial. Lean processes only work if people follow them consistently; a tool that’s easy to use ensures that discipline.

- Better Decision-Making: Ultimately, CyberStockroom provides the visibility needed to make smart inventory decisions. By having a clear picture of stock levels and locations, you can more easily spot trends like overstock in one area or potential stockouts in another. The software essentially complements your demand forecasting and inventory analysis. It can act as a central “single source of truth” for inventory data, meaning less time spent arguing about whose spreadsheet is correct and more time acting on the insights. For operations managers, this means quicker, data-driven decisions – whether it’s adjusting a reorder point, reallocating stock to where it’s needed, or identifying an anomaly that needs investigation.

In summary, CyberStockroom’s map-based, real-time system is aligned with lean inventory optimization by providing clarity, speed, and control. It doesn’t replace the need for good strategy and processes (you still set the forecasts, the safety stock levels, etc.), but it greatly aids in execution. When your inventory information is organized visually and updated to the minute, maintaining lean practices like JIT, accurate forecasting, and swift response to issues becomes much more feasible. It’s a modern tool to help enforce and enhance the lean methodologies you put in place.

Putting It All Together: A Lean Inventory Optimization Roadmap

We’ve covered a lot of ground. To wrap up, here is a step-by-step roadmap summarizing how you can approach lean inventory optimization in your manufacturing operation:

- Identify Waste and Set Lean Goals: Start by evaluating your current inventory management. Where do you see excess stock piling up? Which items often sit untouched, and where do you experience stockouts? Map out these pain points. Define what “lean” means for your business – for example, you might set a goal to reduce overall inventory value by 20% while maintaining service levels.

- Improve Demand Forecasting: Get your forecasting process in order early. Gather historical data and involve key stakeholders to predict demand as accurately as possible. Put a system or routine in place for regular forecast updates. This will be the foundation that informs all other decisions.

- Implement Just-in-Time Practices: Work on transitioning to smaller, more frequent orders and deliveries. Coordinate closely with suppliers and set up kanban or similar pull systems on the production floor. You might pilot JIT with one product line or a subset of materials first, to learn and adjust before wider rollout.

- Calculate Safety Stock (Don’t Overdo It): Determine reasonable safety stock levels for critical items. Use the data from your forecasting and supplier performance to guide this. Remember, the idea is a safety net, not a big cushion. Set reorder points based on your lead times and safety stock so that replenishments happen right on time.

- Classify and Prioritize (ABC Analysis): Segment your inventory into A, B, C categories (or other categories that make sense for you). Apply tighter controls and more frequent monitoring to the high-impact A items. Ensure you’re never caught short on these. For C items, simplify their management to save effort.

- Rationalize SKUs and Inventory Policies: Review your catalog for low-value or low-turnover SKUs. Decide if any can be discontinued, consolidated, or switched to special-order status. For the remaining SKUs, consider if each needs a lean approach – perhaps some items are fine to keep in larger stock if they’re cheap and storage is no issue, whereas others need strict control.

- Leverage Technology and Inventory Visibility: Adopt tools that give you real-time visibility and control. This could be an inventory management system like CyberStockroom that provides a visual map and live data. Technology will help enforce discipline – automatic alerts for low stock, centralized data, and easy ways to update inventory all ensure that your lean processes run smoothly day-to-day.

- Train Your Team and Build a Lean Culture: Ensure that everyone from procurement to warehouse staff understands the new approach. Explain the why – that keeping inventory lean helps the company and reduces waste. Train them on new processes (like how to use kanban signals or the software tools). Encourage a mindset of immediate problem-solving: if something’s out of stock or a process isn’t working, team members should flag it and collaborate on a fix rather than work around it quietly.

- Monitor Metrics and Continuously Improve: Once your lean inventory system is in motion, keep an eye on key performance indicators. Track inventory turnover, fill rates (service level), stockout incidents, and inventory carrying cost. Use these metrics to identify successes and areas for further improvement. Hold periodic reviews (e.g., monthly or quarterly) to adjust forecasts, safety stocks, and procedures based on what the data and your team’s feedback tell you. Lean is an ongoing journey – there are always tweaks that can be made to get closer to the optimal balance.

By following these steps, you create a cycle of planning, execution, and feedback that drives ongoing optimization. Start small if needed, learn as you go, and scale lean practices to broader parts of the operation as confidence builds.

Conclusion

Inventory optimization for lean manufacturing is a continuous balancing act – the art of doing more with less, without tipping over. It blends strategic planning (forecasting, risk assessment, segmentation) with tactical excellence (JIT execution, vigilant monitoring, quick response to issues). The reward for getting it right is substantial. You’ll see lower carrying costs and freed-up working capital, fewer instances of waste, and a more agile operation that can respond quickly to customer needs and market changes. Perhaps most importantly, you build a more resilient supply chain that can handle surprises with minimal disruption.

For manufacturing operations managers, adopting these lean inventory practices means transforming inventory management from a headache into a competitive advantage. When you deliver the right product in the right quantity at the right time – consistently – you win customer trust and streamline your own efficiency. Yes, it requires effort, culture change, and the right tools to maintain, but the payoff is a smoother-running production and less fire-fighting over inventory issues.

In the rapidly changing manufacturing landscape, those who continuously refine their inventory strategies will stand out. By staying data-driven, keeping visibility across your operations, balancing efficiency with prudent buffers, and fostering a team culture of continuous improvement, you can achieve the nearly “just-in-time” ideal that lean manufacturing strives for – and be ready with a backup plan for the unexpected. Inventory optimization isn’t a one-time project; it’s an ongoing journey of improvement. Start that journey now, and watch your operations become leaner, more responsive, and more profitable.

Leave a comment