In today’s fast-paced manufacturing world, information is as valuable as the materials on your production line. One piece of information in particular can make or break your operation’s efficiency: real-time inventory data. From the smallest component on the shop floor to finished goods in the warehouse, knowing exactly what you have and where it is at any given moment is crucial. This blog post explores how real-time inventory in manufacturing is revolutionizing operations, improving efficiency, and solving age-old inventory challenges in a conversational, accessible way.

Let’s start by looking at why traditional inventory methods often fall short in manufacturing, and then see how real-time inventory data offers a compelling solution.

Challenges of Traditional Inventory Management in Manufacturing

Manufacturing operations have a lot of moving parts – literally and figuratively. Traditional inventory management methods (think periodic stock counts, paper logs, or even standalone spreadsheets) struggle to keep up with the complexity and speed of modern production. Here are some of the key challenges manufacturers face with old-school inventory management:

- Lack of Real-Time Visibility: In a traditional setup, inventory levels are often updated only at intervals – maybe at the end of the day, or even weekly. This delay means that by the time you notice a component stock is low, it might already be gone. The visibility gap can lead to unpleasant surprises, like a critical part running out right when it’s needed on the assembly line.

- Inaccurate or Outdated Data: Manual processes are prone to human error. Miscounts during stock takes, data entry mistakes, or simply forgetting to record a transaction can all lead to discrepancies. In manufacturing, an inaccurate inventory count for a raw material could halt production if you thought you had more materials than you actually do. Outdated data forces managers to rely on guesswork or build in large safety stocks “just in case,” which ties up capital.

- Frequent Stockouts or Overstocking: Without a clear picture of inventory in real time, manufacturers often swing between two problems: running out of stock (stockouts) and overstocking. Stockouts of a key component can cause expensive downtime on production lines and delay order fulfillment. On the other hand, overstocking to play it safe leads to excess inventory holding costs, wasted warehouse space, and potential obsolescence (especially for perishable or tech components that might become outdated).

- Production Downtime: Perhaps the scariest word in manufacturing is “downtime.” Traditional inventory systems that rely on periodic checks might not flag a low supply of a part until it’s too late. If a machine goes down waiting for a replacement part or a batch is halted due to missing raw materials, the costs rack up quickly. Downtime isn’t just lost production – it’s labor standing idle, delivery deadlines at risk, and overtime costs to catch up. A lack of timely inventory data is a major culprit behind unplanned downtime.

- Siloed Systems and Poor Communication: In many manufacturing companies, different departments or locations use separate systems that don’t talk to each other. The warehouse might use one software, procurement uses another, and the production floor might be tracked on a whiteboard. This siloed approach means information doesn’t flow quickly. For instance, the purchasing team may not realize a certain material was just used up in production an hour ago, so they don’t reorder it in time. By the time everyone updates each other in the next meeting or email thread, the issue has already snowballed.

- Labor-Intensive Processes: Traditional inventory control can be very labor-intensive. Consider physical stock counts where staff scan or count every item in a warehouse periodically. It takes hours or days, especially in a large facility, and during that time, normal operations might be interrupted. Cycle counting (counting portions of inventory on a rotating schedule) helps, but without real-time tracking, these counts still only give a snapshot. The constant labor needed for manual tracking, reconciling records, and hunting down parts is time that could be spent on more value-adding activities.

- Difficulty in Forecasting and Planning: When your inventory data is always a step behind reality, forecasting demand and planning production becomes a serious challenge. Planners end up building in extra buffers everywhere – extra time in the schedule, extra units in inventory – to compensate for uncertainty. This is inefficient and costly. Moreover, without insights into how inventory is actually moving right now, it’s hard to adjust plans on the fly. For example, if one product’s sales spike unexpectedly, a manufacturer with delayed inventory info might miss the chance to reallocate materials from a slower product to that hot seller.

- Waste and Inefficiency: All the above issues ultimately contribute to waste – whether it’s wasted time, wasted money, or wasted materials. Lean manufacturing principles aim to eliminate waste and improve flow, but if you’re using outdated inventory methods, you’re likely carrying excess “just-in-case” inventory (waste of resources), experiencing wait times when stock isn’t available (waste of time), and expediting shipments last-minute (waste of money). Traditional systems often can’t support lean initiatives effectively because they don’t provide the needed agility or accuracy.

In short, the old ways of managing inventory can hold back your entire operation. The good news is that each of these challenges has a modern solution. And that solution is rooted in real-time inventory data.

The Real-Time Inventory Solution: What It Is and How It Transforms Operations

So, what do we mean by real-time inventory in manufacturing? At its core, it’s the practice of using up-to-the-minute data to know exactly what inventory you have, where it is, and where it’s needed, at any given moment. It’s a shift from reactive management (finding out about problems after they happen) to proactive management (addressing issues before they cause trouble).

Defining Real-Time Inventory Data

Real-time inventory data means that every addition, movement, or usage of an item is recorded and reflected immediately in a centralized system. If a technician pulls 5 units of a component from storage to use on the production line, the system updates right then and there – no waiting until end of day. If a supplier delivers a pallet of materials, it’s logged as soon as it’s received and available for use. In other words, the inventory records are synchronized with reality on a continuous basis.

How is this achieved? Thanks to technology like barcode scanners, RFID tags, sensors, and inventory management software, the flow of information can accompany the flow of physical goods. For example:

- Workers scan materials when they arrive, and when they’re moved or consumed in production.

- Sensor-enabled bins or shelves can automatically count usage (for instance, a smart scale that knows when the bin’s weight drops as parts are taken, and updates quantity).

- Machines can signal the system when they’re running low on certain inputs, triggering an update and even an automatic reorder.

- Cloud-based software platforms aggregate all this input, so whether you’re on the shop floor or in the corporate office, you’re looking at the same live inventory dashboard.

Transforming Operations

Having real-time inventory data transforms manufacturing operations in several important ways:

- Proactive Replenishment: Instead of reacting to stockouts, manufacturers can set up alerts or automatic triggers. When inventory of a part drops below a set threshold in real time, the system can alert the purchasing team or even auto-generate a purchase order to the supplier. This dramatically reduces the chance of running out of materials unexpectedly.

- Single Source of Truth: With a centralized real-time system, everyone from production supervisors to supply chain managers is looking at accurate, up-to-date information. This eliminates confusion and conflicting data. The production team knows what’s available for today’s schedule, procurement knows what needs ordering, and sales knows what finished goods are ready to ship – all without a flurry of phone calls and emails.

- Faster Decision-Making: Decisions in manufacturing often need to be made quickly – whether it’s swapping one job for another on a production line, expediting a purchase, or reallocating stock between plants. Real-time data enables informed decision-making on the fly. For example, if a sudden large order comes in, a manager can instantly check if there are enough materials to take it on, instead of digging through reports or physically checking stock.

- Alignment with Production Planning Systems: Modern Manufacturing Execution Systems (MES) and production planning tools can integrate with inventory data. When inventory status updates in real time, your production schedule can adjust dynamically. Say a delivery of crucial raw material is delayed – the system can flag this to planners immediately, who might rearrange the production sequence or speed up an alternate job. This agility keeps the factory running smoothly even when surprises happen.

- Empowering Lean and JIT (Just-in-Time): Real-time inventory is a foundational piece of lean manufacturing and just-in-time production. Lean/JIT aims to minimize inventory and produce only what is needed when it’s needed. You can’t confidently do that if you don’t have precise, real-time control over inventory. With real-time data, manufacturers can run with lower buffer stocks because they trust the system to signal when something needs replenishing. It’s like having a continuous Kanban signal that’s tracked by software – when a bin is empty, the system immediately knows and reacts.

- Traceability and Quality Control: In industries with strict quality and regulatory requirements (like aerospace, automotive, or pharmaceuticals), real-time inventory tracking provides a traceable record of every part and batch. If there’s a quality issue, you can quickly trace which materials were used in which lots of finished product, because all movements were recorded in real time. This speeds up root-cause analysis and any necessary recalls or quarantines, minimizing the impact on operations and customers.

In essence, real-time inventory management turns inventory from a static snapshot into a live movie. It enables a level of responsiveness and efficiency that simply wasn’t possible when relying on yesterday’s data. Now, let’s look more closely at the key benefits that come from this transformation.

Key Benefits of Real-Time Inventory Management in Manufacturing

Real-time inventory data doesn’t just sound good in theory – it delivers tangible benefits that address many of the challenges we outlined earlier. Under the umbrella of operational efficiency, here are the major benefits and what they mean for a manufacturing business:

1. Reduced Downtime and Disruptions

In manufacturing, downtime is the enemy of productivity and profitability. One of the primary benefits of real-time inventory tracking is a drastic reduction in downtime caused by material shortages. With continuous monitoring, you get early warning signs when critical parts or materials are running low. Instead of a production line suddenly stopping because a component bin went empty, you would have been alerted hours or days beforehand by the system’s low-stock alert or an automated reorder. For example, if you require 100 units of a certain part each day and the inventory falls to 200 units, a real-time system can notify you immediately – giving you enough lead time to replenish before production grinds to a halt.

By preventing last-minute surprises, manufacturers avoid emergency expedites, frantic supplier calls, and costly line stoppages. The result is a more consistent production flow and the ability to hit delivery targets reliably.

2. Leaner Operations and Lower Inventory Costs

Carrying too much inventory is like having money stuck on a shelf. Real-time data enables leaner operations by helping you keep inventory levels optimized. When you trust that your system will tell you the moment you need to restock, you don’t have to pile up excess “just in case” stock. This is aligned with just-in-time and lean manufacturing principles. The benefit? Lower carrying costs (less money tied up in inventory, less warehouse space needed, less waste from expired or obsolete stock). Manufacturers can move toward a “right-size” inventory, where you have exactly what you need – no more, no less.

Leaner inventory means less clutter in the facility as well, which improves workflow and even safety. Plus, if demand changes, you’re not stuck with mountains of excess product; you can adjust more nimbly. Overall, operational efficiency improves as you trim the fat from your inventory and supply chain processes.

3. Improved Forecasting and Demand Planning

Real-time inventory systems often come hand-in-hand with data analytics that can greatly improve forecasting. By collecting usage and sales data continuously, companies can analyze trends with greater accuracy. You’ll know how fast each item is being used or sold right now, which allows demand planning to be much more precise. Perhaps you notice that a certain component is consistently used faster than forecasted every Friday – maybe due to a particular product being assembled then – you can adjust your forecasts or safety stock levels accordingly.

Moreover, real-time data can be shared with forecasting algorithms or planners to update plans more frequently (even daily or hourly, rather than monthly). This means your production planning and material purchasing become dynamic processes that respond to actual demand patterns in near real-time, rather than static plans that might be off-base. In short, you can better anticipate needs and avoid the whiplash of the “bullwhip effect” (where small demand fluctuations get magnified through the supply chain due to slow information updates). The outcome is improved customer service too – because you produce and stock closer to what customers are actually ordering, reducing backorders or long lead times.

4. Better Decision-Making with Data

When managers and team leaders have real-time, accurate data at their fingertips, every decision is better informed. Whether it’s deciding how to allocate inventory between orders, prioritizing production schedules, or negotiating with suppliers, having the latest information means decisions can be data-driven rather than guesswork. For example, if a customer asks for an earlier delivery on an order, a quick glance at the live inventory and work-in-progress might show you can spare some finished units from another stockpile – or it might show you don’t have the inventory, prompting you to negotiate a different solution.

Real-time data can also feed into dashboards and KPIs that management monitors. Key performance indicators like inventory turnover, order fulfillment rate, or production throughput are more meaningful when they’re updated continuously. This transparency helps identify issues (like a station on the line that’s constantly waiting for parts) and opportunities (like noticing one product has surplus stock that could be reallocated to another order). In essence, real-time inventory visibility creates a culture of responsive, evidence-based decision-making throughout the organization.

5. Greater Supply Chain Transparency and Collaboration

Manufacturing doesn’t happen in isolation – it’s part of a bigger supply chain that includes suppliers, distributors, and sometimes customers (especially if you’re a component supplier yourself). Real-time inventory data provides supply chain transparency, meaning the status of materials and products is visible not just internally but can be shared (securely) with partners. This has huge benefits for collaboration. For instance, sharing real-time inventory levels of raw materials with your supplier can enable vendor-managed inventory (VMI) arrangements where the supplier automatically refills stock when it gets low, without you even having to place an order. It builds trust when both sides are looking at the same data. Similarly, you might share finished goods inventory information with key customers, so they know what’s available and can plan accordingly (common in retail supply relationships).

In a broader sense, transparency helps quickly pinpoint issues in the supply chain – if a shipment is delayed or a batch fails quality checks, everyone upstream and downstream can see the impact on inventory immediately and adjust. Additionally, having traceability (knowing exactly which batch of materials went into which product, updated in real time) improves compliance and accountability across the supply chain. Ultimately, real-time data acts like a common language for all supply chain stakeholders, leading to better coordination and fewer misunderstandings or surprises.

Beyond these main benefits, there are other positives worth mentioning. Real-time inventory management usually boosts accuracy – when every transaction is recorded as it happens, the system is far less likely to have errors than when data is entered by memory hours later. It can also reduce theft or loss because discrepancies show up faster, deterring shrinkage. And an accurate, efficient inventory system translates into improved customer satisfaction – orders are fulfilled on time, and customers get clear information on product availability.

Now that we’ve covered the why and what of real-time inventory, let’s look at an example of a solution that helps manufacturers achieve this: CyberStockroom.

CyberStockroom: Supporting Real-Time Inventory in Manufacturing

So, how can manufacturers implement real-time inventory tracking in practice? This is where modern inventory management tools come into play – and CyberStockroom is one such tool designed to make real-time inventory easy and visual.

Let’s discuss what CyberStockroom offers and how it aligns with the needs of manufacturing operations:

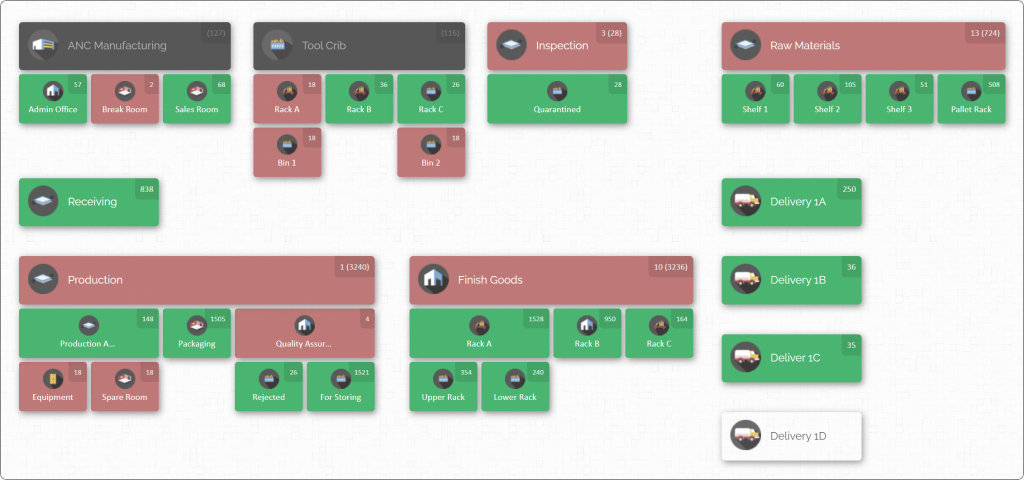

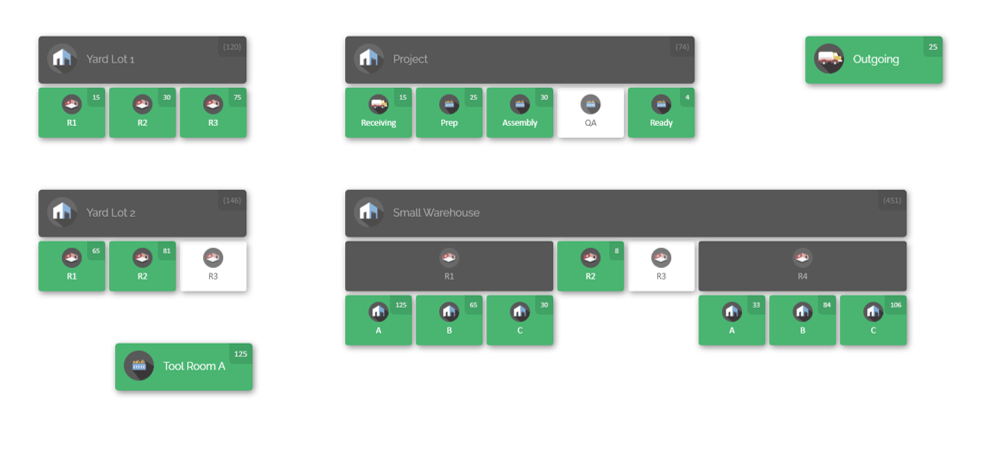

Visual Inventory Map

CyberStockroom’s standout feature is its Inventory Map – a dynamic, visual dashboard (like the one shown in the introduction image) that displays your entire inventory across all locations. Instead of browsing through rows in a spreadsheet or clicking through menu trees, you get a bird’s-eye view of your manufacturing operation.

For a manufacturer, this could mean seeing your warehouse, production floor, storage rooms, tool cribs, and even in-transit shipments all laid out on a map. Each location on the map is interactive and holds real-time inventory data, so you always know what’s where. This visual approach is incredibly intuitive – it’s much easier for a plant manager to glance at a map and see that “Production Line A’s component bin is yellow (low) or red (empty)” than to interpret a numeric report.

Real-Time Updates and Tracking

Under the hood, CyberStockroom is a cloud-based inventory management system that updates continuously. When items are checked in or out, moved, or adjusted, those changes are reflected instantly on the map and in all inventory records. Manufacturing staff can update inventory with barcode scans or quick manual adjustments via a user-friendly interface (e.g., dragging and dropping items from one location to another on the map when they’re physically moved).

The platform can serve as a single source of truth whether you’re on a computer in the office or using a tablet on the factory floor. And because it’s cloud-based, different teams (warehouse, production, purchasing, management) can all access the same real-time information from wherever they are – even multiple manufacturing sites can be managed together.

Features Tailored to Efficiency

CyberStockroom includes features that directly support the efficiency goals we discussed:

- Barcode Scanning: You can use barcodes to scan items in and out, which speeds up data entry and reduces errors. For instance, scanning a pallet of raw material as “received” immediately logs it into stock.

- Drag-and-Drop Transfers: The interface allows users to simply drag items from one location to another on the map to record a transfer. This is great for manufacturing environments where materials might move from a main stock area to a production line, or finished goods move from the line to a finished goods warehouse. It makes it almost fun to do the “paperwork” of inventory because it feels like organizing your workspace rather than filling a form.

- Custom Fields and Flexibility: Manufacturers often have specific data they need to track (lot numbers, supplier, expiration dates, etc.). CyberStockroom lets you add custom fields to inventory items. If you’re in food manufacturing, maybe you need a field for batch expiration date; if in electronics, a field for serial or lot number; in automotive, maybe a part model or revision number. This flexibility ensures your real-time system isn’t just fast, but also informative for your specific operational needs.

- User Permissions and Collaboration: You can invite team members onto the platform with appropriate access. Shop floor workers might only mark quantities used, whereas managers have full control, etc. This means everyone participates in keeping data real-time, without risking unauthorized changes or confusion.

- Cloud and Mobile Access: Because CyberStockroom is cloud-based, you can access it from anywhere. A plant manager traveling between global factory sites can check the inventory status on their phone. During a supplier meeting, you could pull up current stock levels to discuss what’s needed. This anytime/anywhere access ensures decisions don’t get stalled waiting for someone to “get back to the office and check”.

Alignment with Manufacturing Needs

Perhaps most importantly, CyberStockroom’s approach aligns well with the key benefits of real-time inventory we highlighted:

- It provides instant visibility (you literally see all locations and stock counts live).

- It helps reduce downtime by ensuring everyone knows when something’s low (and you could set up process triggers for reorders).

- It encourages lean inventory by making it easy to monitor and trust lower stock levels – since you know you’ll see immediately if something runs out.

- It offers data for better decisions – the map and associated reports show patterns of movement, fast vs slow moving items, etc. at a glance.

- It supports supply chain transparency – you could even show parts of your CyberStockroom map or reports to a supplier or auditor to demonstrate stock levels and movements in real time (imagine an auditor asking for inventory records and you show them a live map!).

In summary, CyberStockroom acts as a practical enabler of real-time inventory management. It’s especially useful for manufacturing operations that have multiple storage areas and process stages, because the visual mapping ties it all together. By implementing such a solution, manufacturers can gain the control and insight needed to run a tighter, more efficient ship.

(Side note: If you’re reading this and thinking, “My operation could use something like that,” many such tools including CyberStockroom offer free trials or demos. It can be worth exploring hands-on to see how it might fit your processes.)

Next, let’s illustrate how real-time inventory data works in practice with some scenarios, and then we’ll wrap up with a look at future trends and tips on adopting these systems.

Real-Time Inventory in Action: Practical Examples and Scenarios

To truly understand the impact of real-time inventory, it helps to envision it in real-world manufacturing scenarios. Here are a few practical examples where real-time inventory management improves efficiency and solves problems:

Example 1: Preventing a Production Line Halt – Automotive Parts Manufacturer

Imagine a car parts factory where multiple assembly lines build complex components (e.g., engine control units). In the past, the factory had occasional line stoppages because small but critical parts (like specific electronic chips) ran out unexpectedly. With a real-time inventory system in place, each bin of chips on the assembly line is tracked. As workers use the parts and the bin count drops, the system automatically logs the usage. One day, a sudden surge in demand causes one line to consume chips faster than usual. The inventory system flags that the bin will likely empty by end-of-day. An alert goes to the materials manager’s phone immediately.

Solution: The manager quickly reallocates stock from another line that has a surplus and places an urgent order with a supplier or pulls from a regional warehouse. The line keeps running with only a brief pause to swap in the new supply – no prolonged downtime occurred. In fact, operators on the line were unaware of the potential crisis because it was averted proactively. The manufacturer saved countless dollars and met its production target, all thanks to real-time visibility and alerts.

Example 2: Lean Manufacturing and Just-in-Time Replenishment – Electronics Assembly Plant

A mid-sized electronics manufacturer adopts a lean approach and aims for just-in-time (JIT) delivery of parts to the production floor. They use Kanban cards traditionally, but now they supplement it with real-time tracking. Each time a Kanban card (which signals a bin is empty) is triggered, it’s scanned into the new inventory system, which updates the central dashboard immediately. The purchasing system (integrated with inventory software) instantly creates a replenishment request to the supplier’s online portal. The supplier, who also has visibility into the manufacturer’s inventory levels via a shared interface, prepares the shipment without delay.

The result: parts arrive exactly when needed, often within hours, with minimal manual emails or calls. Because the system ensures no lag in communication, the factory was able to cut down its on-hand inventory of certain components by, say, 30% without risking production – freeing up cash and space. This tight coordination was only possible by linking real-time data between manufacturer and supplier in a seamless loop.

Example 3: Multi-Plant Coordination – Global Production Network

Consider a company that has several manufacturing plants across different regions, each feeding into a central distribution network. Previously, each plant managed inventory in isolation and occasionally one plant would be idle waiting for parts while another plant had excess of the same part. By implementing a cloud-based real-time inventory management system across all facilities, they achieved end-to-end visibility.

Now, if Plant A is running short on a component but Plant B has plenty, the system highlights this. The company can make a quick decision to transfer stock from B to A, or at least re-route incoming supplier shipments accordingly. In one instance, a natural disaster delayed a supplier delivery to Plant A. Because of the real-time inventory network, the managers saw the risk immediately and shifted production of some orders to Plant B (which had the parts on hand) until Plant A caught up. They met customer orders without a hitch. This scenario shows how real-time data across the supply chain allows for agility and resilience – adapting to disruptions by leveraging inventory information company-wide.

Example 4: Improved Inventory Audits and Compliance – Pharmaceutical Manufacturer

A pharmaceutical plant must adhere to strict regulations and be ready for surprise audits. With a real-time inventory system, every batch of ingredients and every finished lot is tracked with timestamps and locations. When an auditor arrives asking to verify inventory and trace a product’s components, the company can generate a report (or even use the inventory map) to show exactly where each ingredient came from, how it moved through production, and what’s currently in stock. What used to be a frantic scramble through paper records becomes a straightforward task.

Not only does this save the company from potential regulatory penalties by proving compliance, but it also streamlines the audit process, saving time and reducing stress on employees. Meanwhile, internally, the quality assurance team uses the same data to isolate batches if there’s a quality issue – since they know precisely which other products might contain an ingredient from a suspect batch, they can quarantine only the affected items rather than stopping everything.

These examples underscore a common theme: real-time inventory data leads to proactive management. Problems are addressed before they escalate. Opportunities (like transferring stock to fulfill a big order) are seized promptly. The day-to-day life of employees, from line workers to managers, becomes less about fire-fighting and more about smooth, planned operations.

Each manufacturing environment will have its own specific scenarios, but chances are wherever you have inventory and movement of materials, real-time data can find a way to improve the situation.

Future Trends, Adoption Strategies, and Final Thoughts

Embracing real-time inventory management is not just a trend of today – it’s the foundation for the future of manufacturing operations. As we look ahead, and as you consider implementing these ideas, here are some future trends and practical adoption strategies to keep in mind:

Future Trends in Real-Time Inventory Management:

- Automation: The rise of the Industrial Internet of Things means more devices on the shop floor will be connected and communicating. Smart sensors and RFID tags can automatically update inventory counts as materials move, without any human scanning. For example, a sensor could detect when a bin’s weight drops below a threshold and send a restock request. Autonomous mobile robots in warehouses might soon navigate on their own to pick and move inventory, updating the system in real time as they do so. Automation and real-time data will go hand in hand to create self-regulating inventory systems.

- Advanced Analytics and AI: With more real-time data available, manufacturers are leveraging analytics and artificial intelligence to gain deeper insights. Machine learning algorithms can predict demand spikes or potential supply issues by analyzing patterns in the real-time data combined with historical trends. AI could automatically adjust reordering parameters or suggest optimized production schedules based on live inventory and production rates. In the future, you might have an AI assistant that tells you, “Based on current run rates and transit delays, increase the order quantity of Component X for next week to avoid a shortfall.”

- Blockchain for Supply Chain Transparency: To take transparency even further, some companies are exploring blockchain technology to record inventory movements across the supply chain. Blockchain can provide an immutable, shared ledger of every inventory transaction from raw material source to finished product delivery. This can enhance trust between partners and make audits or traceability extremely robust. In a blockchain-enhanced inventory future, a manufacturer, its suppliers, logistics providers, and customers could all be nodes in a network seeing verified real-time status of products with no single party controlling the data – it’s decentralized but trusted.

- Unified Platforms and Digital Twins: There’s a trend toward having unified digital platforms where inventory is just one part of a larger real-time picture of operations. The concept of a “digital twin” of the factory is becoming popular – a digital replica of your entire production process, including machines, inventory, people, and workflows. Real-time inventory data is a critical component of that, feeding into simulations and scenario planning. For instance, before making a change on the actual line, a manager could simulate it on the digital twin, which uses live data to predict outcomes. This helps in optimizing processes continuously.

- More User-Friendly Tech: As the workforce evolves, inventory tools are becoming more user-centric. Expect to see more mobile apps, voice interfaces, and wearable tech for inventory management. Technicians might use smart glasses to see stock information superimposed on the physical world as they look at a shelf. Voice commands could update inventory (“Computer, I’m taking 5 units of Part ABC123 from Stockroom B”). All these innovations aim to make real-time inventory updates as natural and effortless as possible, further reducing any delay between the physical event and the digital record.

Adoption Strategies for Real-Time Inventory Systems:

While the future is exciting, getting started today with real-time inventory management requires thoughtful change management. Here are some strategies if you’re looking to adopt these practices:

- Assess and Map Your Current Process: Begin by understanding how inventory currently flows in your operation. Where are the pain points? Which processes are manual and could be automated? Identify the critical points where real-time data would have the biggest immediate impact (e.g., a frequently bottlenecked component supply, or a particular warehouse that’s always disorganized). This will help prioritize what to tackle first and also choose the right system features.

- Secure Buy-In and Build a Team: Change can be challenging in manufacturing environments. It’s important to get buy-in from both management and the shop floor team. Communicate the benefits (reduced stress from emergencies, less manual work, more predictable schedules). Involve key users (like inventory clerks, warehouse leads, production supervisors) in evaluating tools like CyberStockroom or others. When people feel involved in the selection and design of the system, they’re more likely to embrace it.

- Implement in Phases: You don’t have to flip the switch on every part of your inventory all at once. A smart approach is to pilot the real-time system in a single area first. For example, implement it just for raw material tracking in one production line, or in one warehouse section. Work out the kinks, gather feedback, and demonstrate success. Then expand to other areas. This phased rollout allows learning and adjustment without overwhelming the organization.

- Training and Standard Operating Procedures: Even the best technology fails if users don’t use it properly. Invest time in training the staff on the new system. Show them how to do their daily tasks in the new way (scanning, updating the map, etc.). Update your SOPs to incorporate real-time data practices – for instance, an SOP might state that “materials handler will scan each pallet’s barcode when moving it from receiving to storage rack” or “production operator will record usage at end of each shift via the system”. Clarity and practice will ensure the data remains real-time and accurate.

- Leverage Alerts and Reports: Configure your new system to work for you. Set up the low-stock alerts, dashboard reports, and email notifications that matter. In the beginning, it might be wise to get daily summary reports (e.g., what was used, what’s low, what was received) to build confidence that the system is capturing everything. Over time, you may not need such frequent reports, but early on they help catch any issues (like if something wasn’t scanned properly) and reinforce usage.

- Integrate where Possible: Plan how the real-time inventory system will interact with other systems. Maybe you’re not ready for full integration initially, but even simple steps like importing your existing product list, or syncing a supplier list can help. Eventually, integrating with your ERP or order management can unlock even more value (like automatically updating stock after a production run is completed in the MES). Keep integration capabilities in mind when choosing a solution – you want one that can grow with you.

- Measure and Celebrate Results: Track key metrics before and after implementing real-time inventory. For example, measure your stockout incidents per month, average inventory levels, production downtime hours, order fulfillment lead time, etc. As the new system takes hold, these metrics should improve. Celebrate those improvements! It’s important for the team to see the positive outcomes of their efforts – it could be as simple as acknowledging in a meeting that “Hey, we’ve gone 3 months without a line stoppage due to missing parts – great job everyone for keeping the system updated and responsive.” This reinforces the value of real-time practices and keeps momentum going.

Final Thoughts:

Real-time inventory data is transforming manufacturing operations from reactive to proactive, from uncertain to controlled. It empowers manufacturers to be more efficient, agile, and competitive in a global market where every advantage counts. By addressing the perennial challenges of traditional inventory management – lack of visibility, inaccuracy, and delays – real-time systems open the door to leaner inventories, smarter planning, and stronger collaboration across the supply chain.

For manufacturing managers and teams, the shift to real-time inventory management is more than just a technology upgrade; it’s a cultural shift towards data-driven decision-making and continuous improvement. The tone of operations changes – instead of constantly putting out fires due to inventory issues, teams can focus on optimizing processes, improving product quality, and innovating, because they trust their inventory process to keep things running smoothly.

If you’re still on the fence, consider this: companies that have adopted real-time inventory tracking are finding that what once were daily headaches become non-issues. The cost of technology has come down, and the user-friendliness has gone up, making now a great time to explore options like CyberStockroom and others. Start small, learn, and grow into it. Your manufacturing operation could soon be running with the synchronized efficiency of a well-conducted orchestra – each part where it needs to be, when it needs to be there, all thanks to that powerful, up-to-the-second inventory information.

In the ever-evolving landscape of manufacturing, real-time inventory data isn’t just an upgrade – it’s quickly becoming a necessity for those who want to lead in operational excellence. Embracing it will position your business to reduce waste, respond faster, and serve customers better. In other words, it will truly transform your manufacturing operations for the better. Here’s to a future with no more inventory surprises – only smooth, efficient production days ahead!

Leave a comment