Managing inventory is like walking a tightrope: lean too far one way and you end up with overflowing warehouse shelves; lean too far the other and you’re out of stock when you need items most. Excess inventory ties up cash, takes up space, and can even become obsolete before you use it. On the flip side, running out of a critical part or material can halt production or delay a construction project, costing time and money. Both are pains. For managers, it’s a constant seesaw: order extra parts early (risking overstock) or hold back and risk a stockout. In fact, carrying excess inventory can cost a business roughly 20–30% of the inventory’s value each year in storage, insurance, and lost opportunity costs.

This guide will walk you through how to avoid overstock and stockouts by adopting smart inventory control practices. Whether you’re running a factory or managing a construction site, the right approach to inventory planning can save you headaches and help projects run smoothly. We’ll cover everything from demand forecasting and safety stock to lean strategies and technology tools.

Effective inventory planning is a key part of strategic planning, ensuring that resources are available when projects need them without waste.

What Are Overstock and Stockouts?

Overstock (also called excess inventory) happens when you carry more items than you actually need in the short term. Stockouts happen when you run out of stock of an item and can’t meet demand. Both scenarios are costly. Overstocking means cash is sitting on the shelves instead of being invested in your business; you pay more in storage, insurance, and handling, and sometimes have to throw out or heavily discount outdated items. On the other hand, stockouts can lead to delayed deliveries, paused production lines, frustrated customers, and even lost contracts.

For example, imagine a construction site waiting for a shipment of steel beams that never arrived on time – the crews stop work while the site sits idle. Or picture an auto plant that can’t assemble vehicles because a small but vital fastener is out of stock. In both cases, stockouts create a ripple effect of wasted labor and unhappy clients. Meanwhile, a warehouse full of unused parts might tie up cash that could have been used to improve equipment or stock up on fast-moving items. Understanding these risks is the first step to avoiding them.

Why It Matters in Manufacturing and Construction?

Overstock and stockouts hit manufacturing and construction projects hard. Both industries deal with complex parts and strict schedules, so inventory missteps can quickly snowball into big problems:

- High-Value Materials: Construction materials like lumber, steel, and concrete or manufacturing components like electronics and machine parts can be expensive. Overstocking these ties up serious capital (working capital that could be used elsewhere), while running out of them can stop progress on a dime.

- Project Delays and Costs: In both fields, time is money. A single missing widget on the assembly line or a delayed delivery of cement can pause an entire project. Those delays usually cost far more in rush shipping and labor overruns than the inventory itself.

- Complex Bills of Materials: Construction projects often require dozens or hundreds of different materials at the right phases. Manufacturing products usually have multi-level bills of materials (BOMs) with many sub-components. Keeping track of all those SKUs (stock-keeping units) and timing their arrival is tricky but essential.

- Seasonality and Demand Spikes: Construction has busy seasons (spring/summer builds, slower winters), and manufacturing can face seasonal peaks or sudden product launches. Misjudging demand during these times easily leads to excess stock or shortages.

- Customer Impact and Reputation: On-time fulfillment builds trust. In manufacturing, failing to ship products as promised can mean lost orders or customers. In construction, delays can trigger penalties or damage your reputation with clients. Keeping stock aligned with demand helps you deliver on commitments and protect your brand.

- Space and Waste: Construction sites and factories have limited storage. Overstock can clutter work areas, reduce efficiency, and even lead to wasted materials if items degrade. Efficient stock management means less clutter, less waste, and safer job sites.

Proper inventory control means your team can build, make, and deliver without unnecessary stops. Companies that get this right see more consistent timelines, better cash flow, and happier customers and stakeholders.

Key Strategies to Optimize Inventory

Avoiding too much or too little inventory starts with smart planning and processes. Here are core tactics that businesses—especially in manufacturing and construction—use to balance stock levels:

Forecast Demand Accurately: Use historical usage data, sales projections, and market insights to predict how much of each item you’ll need. For construction, factor in project schedules and seasonal trends. In manufacturing, consider planned sales and long lead times for raw materials. Better forecasting helps you ramp up before a known busy period and cut back when demand is slow – reducing both shortages and excess.

Set Smart Reorder Points & Safety Stock: Determine the inventory level (reorder point) at which you place new orders so items arrive just as you run low. Include lead time (how long orders take to arrive) and add a safety stock buffer for unexpected delays or spikes. For example, if you know it takes three weeks to get custom piping and you want two extra weeks of safety, set your reorder point at five weeks of average usage. This way you reorder early enough to avoid a stockout, but not so early that you unnecessarily build up excess stock.

Classify and Prioritize Inventory (ABC Analysis): Not all items are equal. ABC analysis sorts inventory into three groups:

- A-items: The most important or highest-value (maybe the top 20% of SKUs that represent 80% of usage value). Keep tight control on A-items – frequent counts, strong suppliers, reliable reorder.

- B-items: Moderately important (the next 30% of SKUs). Manage these with a moderate level of oversight.

- C-items: Low-cost or infrequently used (the remaining 50% of SKUs). You can keep these simple – less frequent ordering, perhaps buying in bulk when prices are low.

Focus on A-items to prevent shortages or overstocks of what matters most, while not wasting effort on dozens of minor parts. For example, a critical machine spindle might be A-class, while loose nails at a construction site could be C-class.

- A-items: The most important or highest-value (maybe the top 20% of SKUs that represent 80% of usage value). Keep tight control on A-items – frequent counts, strong suppliers, reliable reorder.

Rationalize Your Inventory: Periodically review and trim your list of stocked items. Identify slow-moving or obsolete parts that tie up cash and consider phasing them out or only stocking them on demand. Reducing unnecessary SKUs frees up space and effort for the items that truly matter. For example, if a specific bolt or electronic component hasn’t been used in years, it may not make sense to keep it on the shelf. Fewer products to manage means less forecasting overhead and lower carrying costs.

Implement Lean Inventory & JIT (Just-in-Time): Adopt lean principles to reduce waste. With JIT, materials arrive right when they are needed instead of being stockpiled, cutting holding costs. For example, coordinate with a concrete supplier so trucks show up just as crews need the concrete mix, rather than weeks in advance. Another lean tool is Kanban: a simple card or digital signal on each bin that triggers replenishment when stock is low. However, pure JIT can be risky if suppliers face delays (as seen in recent global supply chain crises). Many businesses now use a hybrid approach: operate lean most of the time while keeping a small “just-in-case” buffer of critical or high-risk parts. This way you stay efficient for predictable items, yet have a cushion for the high-stakes ones.

Conduct Regular Audits and Cycle Counts: Physical counts of inventory should happen routinely. Instead of counting everything once a year, do cycle counts on key items weekly or monthly. Assign responsibility so counts happen on schedule. This catches errors like misplaced stock or scanning mistakes early. For example, if a bin of screws was miscounted and the system thinks it’s full when it’s nearly empty, a cycle count will reveal the gap before it causes a stockout. Good records from audits mean your system actually reflects reality, helping you plan better.

Collaborate Closely with Suppliers: Strong vendor relationships are golden. Share your forecasts and schedules with suppliers so they can plan production and deliveries. Ask about programs like Vendor-Managed Inventory (VMI) or consignment stock at your site. Negotiate order sizes and lead times – sometimes ordering a bit more often in smaller batches keeps fresh stock on hand without tying up too much cash. Identify backup suppliers for critical items. Suppliers in manufacturing and construction often have their own insights, so leverage that to reduce lead times and surprises.

Leverage Technology and Automation: Modern tools can make these strategies easier. Use inventory software and barcode or QR scanning to keep track of stock. Instead of a dusty spreadsheet, imagine updating stock levels with a quick scan on your smartphone or tablet. This gives everyone the same up-to-date picture of inventory (increasing supply chain efficiency) and removes guesswork. Many systems can automate alerts when stock dips below a threshold and even integrate with your ERP or accounting software, tying purchasing and inventory together seamlessly. These systems often include dashboards and analytics to visualize stock trends and key metrics at a glance.

Each of these strategies supports inventory optimization. Often they work best together: for example, accurate demand forecasting helps set smart reorder points, and reliable cycle counts improve your forecasts. The key is to make inventory decisions based on data and clear rules, not just gut feeling or messy spreadsheets.

CyberStockroom: A Tool for Inventory Optimization

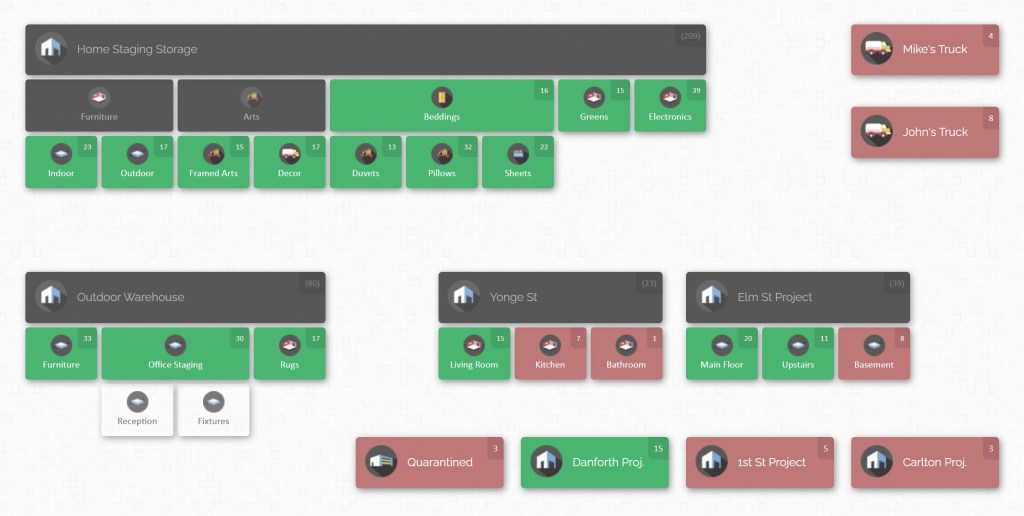

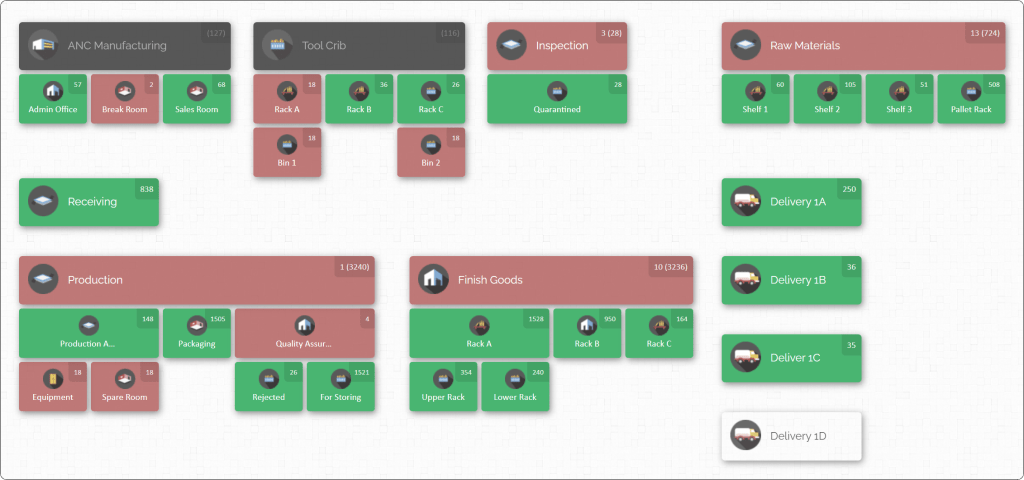

Modern tools can make all the above strategies much easier to implement. One such tool is CyberStockroom, an inventory management system built for real-time visibility and control. CyberStockroom lets you build a live, interactive map of your warehouse or job site, showing exactly where every part or material is located and how much is left.

Imagine walking into your warehouse and seeing on a tablet or computer screen a color-coded map: aisles, racks, bins – all laid out with their contents. If a bin of bolts is running low, it might be highlighted. This visual map means you know instantly where to find things, and where you have space or surplus stock. You don’t have to guess or sift through a spreadsheet.

Here are some ways CyberStockroom supports avoiding overstock and stockouts:

- Real-Time Tracking: Every time stock is received or used (via a connected scanner or mobile app), the system updates the counts. This ensures your inventory data is always current.

- Automated Alerts: You can set reorder points or minimum thresholds for each item.

- Data-Driven Forecasts: CyberStockroom keeps historical usage data so you can analyze trends. For example, you might notice that cement usage spikes every August. Having this insight helps plan purchases ahead of time, avoiding surprise shortages or excess.

- Enhanced Collaboration: Since it’s cloud-based, multiple people see the same inventory picture. A site manager in the office and a foreman on the field both see live updates. If one team notices low stock at one location, they can quickly transfer materials from another warehouse or place an urgent order. Everyone stays on the same page.

- Reduced Carrying Costs: By highlighting exactly what’s where, CyberStockroom helps you consolidate stock. Suppose Warehouse A has extra plywood while Warehouse B is running low; the map makes transfers obvious, so you move surplus stock instead of ordering new. This prevents hidden overstocks and cuts carrying costs.

- Audit Trails and Accountability: Every inventory movement is recorded with user and timestamp. This visibility discourages loss or theft and quickly surfaces any discrepancies so you can fix them. Knowing exactly when and how stock changed keeps your data accurate.

In essence, CyberStockroom ties directly into the strategies we discussed: it gives you accurate data for forecasting and reorder points, a visual overview for prioritization, and mobile tools for fast counting. It’s one example of how inventory control software can turn best practices into an easy daily routine.

Actionable Steps to Optimize Inventory Control

Let’s turn these concepts into action. Treat these like a checklist: start with step 1 and work through them, adapting to what makes sense for your business. Here’s a step-by-step guide to improving your inventory management and avoiding those costly overstocks or stockouts:

- Audit and Clean Up Your Inventory: Start by physically counting your stock and reconciling it with your records. Identify any discrepancies or obsolete items, and clear out anything you no longer need. This “inventory cleanup” frees up space and cash, and gives you a true baseline to work from.

- Analyze Usage and Demand: Look at past usage rates and sales for each item. Identify which materials or parts you use most often, and note any seasonal or project-based patterns. This data forms the basis of your demand forecast. For large projects, align purchases with your project schedule (materials should arrive when crews need them).

- Set Reorder Points and Safety Stock: For each critical item, calculate a reorder point that covers average usage during lead time. Add a safety stock buffer for variability (like supplier delays or demand spikes). For example, if a supplier takes 10 days to deliver and you want a 3-day cushion, set your reorder point at 13 days worth of inventory. Enter these thresholds into your tracking system or software so you get notified in time.

- Implement Regular Cycle Counting: Instead of a once-a-year full inventory, count smaller batches of items on an ongoing schedule. Count your highest-priority items weekly or monthly, and less-critical items quarterly. Assign clear responsibility so counts happen routinely. This catches errors early – for instance, if a bin of screws was miscounted as full when it’s nearly empty, a cycle count will reveal the gap before it causes a stockout.

- Collaborate with Suppliers: Communicate your forecasts and schedules to key suppliers so they can plan production and deliveries accordingly. Ask about vendor-managed inventory (VMI) or consignment stock options. Negotiate order sizes and lead times: sometimes placing smaller, more frequent orders in exchange for a slightly higher per-unit price is worth it to avoid tying up cash. Having backup suppliers for critical parts is also a good safety measure.

- Use the Right Tools: If you’re still relying on paper or spreadsheets, upgrade to an inventory system or app. At minimum, start using barcodes or QR codes on all items so you can scan receipts and usage. Even simple cloud-based inventory trackers or mobile apps will improve accuracy. Better systems (like CyberStockroom) track everything in real time and automate alerts and reports. The goal is a single source of truth, replacing outdated static lists.

- Train Your Team: A system is only as good as the people using it. Provide training on your inventory process and tools. Make sure everyone who handles stock knows how to scan items, log usage, and report discrepancies. Create clear procedures for receiving, moving, and using inventory. When your whole team follows the same steps, it reduces mistakes that lead to overstock or stockout surprises.

- Monitor Key Metrics: Keep an eye on important numbers. Inventory turnover (how many times you sell or use your inventory in a period) shows how efficiently stock moves. Fill rate (the percentage of orders met without delay) and on-time delivery rates indicate your service level. Track stockout incidents and carrying cost percentages. These metrics will highlight if something’s off and help you tweak your strategy accordingly.

- Review and Adjust: Inventory management is an ongoing cycle. At least quarterly, compare forecasts to actual usage. If you consistently have excess of an item, lower its reorder point or stop stocking so much. If you keep running out, raise your safety stock or speed up reordering. Use your metrics as a feedback loop to fine-tune reorder levels, safety stock, and forecasts over time. Over time, these disciplined habits become part of your operational culture.

- Continuous Improvement: Treat inventory management as a strategic process, not a one-time task. Periodically gather stakeholders from purchasing, operations, and finance to review performance together. Refine your forecasting models, reorder rules, and supplier agreements as your business changes. Continual tweaks – even small ones – help prevent problems and keep your inventory aligned with future goals.

Putting it all together, start by focusing on one area (maybe a critical product line or single site) and build from there. As these habits take root, they will help you maintain optimal stock levels across your operation. Even small gains add up: shortening reorder times or trimming minimal excess inventory can significantly improve cash flow and flexibility over a year. Over time, these efforts compound.

Conclusion

Avoiding overstock and stockouts boils down to good planning, smart processes, and the right tools. By forecasting demand, prioritizing key items, setting reorder triggers, and using inventory management systems, manufacturing and construction businesses can keep their operations humming along smoothly.

Inventory control isn’t just a day-to-day task – it’s a strategic advantage. Aligned stock levels mean leaner operations, lower costs, and greater supply chain efficiency. It also adds resilience against unexpected disruptions. Whether you use lean techniques like JIT, maintain safety stock as a cushion, or leverage a visual tool like CyberStockroom, the goal is the same – the right parts in the right place at the right time. With discipline and the right approach, you can transform inventory from a chaotic liability into a streamlined asset that supports business growth.

With these strategies built into your routine, you’ll reduce waste, free up cash, and ensure projects and orders proceed without delay. Keeping a close eye on your inventory today sets you up for smoother growth tomorrow. Above all, stay proactive: your inventory should be an asset, not a liability. Here’s to smoother supply chain operations. Good luck managing your stock!

Leave a comment