Cloud-based inventory management is rapidly transforming how warehouses operate. In an era of global supply chains, e-commerce growth, and fast-paced fulfillment, relying on traditional paper logs or on-premises software is no longer sustainable. Warehouse managers and small business owners worldwide are seeking more agile, real-time, and scalable solutions to control stock. This is where cloud-based inventory management comes in – offering the accessibility and intelligence needed for modern warehousing. Embracing cloud inventory systems isn’t just a tech upgrade; it’s a strategic move to future-proof warehouse operations and stay competitive in the digital.

Early adopters of cloud-based systems have seen significant improvements in accuracy, efficiency, and visibility across their warehouse operations. The future of warehousing is undeniably tied to digital transformation, and cloud-based inventory management lies at its core. In this comprehensive post, we’ll explore what cloud-based inventory management means, why it’s set to define the future of warehousing, and how solutions like CyberStockroom are pioneering this shift.

What is Cloud-Based Inventory Management?

Cloud-based inventory management refers to using internet-based software and databases to track, manage, and organize inventory, instead of local servers or spreadsheets. In a cloud model, all inventory data – stock levels, orders, locations, etc. – is stored on secure remote servers (the “cloud”) and accessed through the web. This means you can use the system from anywhere, on any device, without being tied to an office computer. The cloud platform updates information in real time across all connected locations. For example, if one warehouse ships an item, stock counts update instantly for everyone else viewing the system, whether they’re on the warehouse floor or at a headquarters across the country.

In essence, a cloud-based inventory system provides a single source of truth for inventory data. It is characterized by real-time data tracking, remote accessibility for users, easy scalability to add more products/locations, and integration with other tools – all maintained by the service provider. You typically pay a subscription for the service, and the provider handles the IT infrastructure, backups, and software updates behind the scenes. There’s no need to install software on individual warehouse computers or worry about manual updates. The result is an inventory management approach built for the modern, connected warehouse environment.

Legacy inventory methods – like manually updating spreadsheets or using on-premises software – often struggle to keep up with today’s demands. They might require tedious data entry, only update daily (or less), and silo information at single locations. By contrast, cloud systems operate at the speed of your operations, updating continuously and accessible to all authorized personnel in real time. The shift from these traditional systems to cloud-based inventory management is a key part of warehousing’s digital transformation. Businesses once reliant on paper-based processes or locally installed software with heavy maintenance needs can now manage inventory with flexible, future-proof cloud solutions. This fundamental change lays the groundwork for the many benefits discussed next.

Key Benefits of Cloud-Based Inventory Management

Implementing a cloud-based inventory management system offers numerous advantages that directly address common warehousing challenges. Below are some of the key benefits explaining why cloud-based inventory management is considered the future of efficient warehousing:

- Enhanced Operational Efficiency & Accuracy: Cloud inventory systems automate and streamline many inventory processes, reducing the need for manual data entry and paperwork. This automation minimizes human errors in tracking stock levels or recording transactions. For instance, barcode scans can feed data directly to the cloud, instantly updating inventory counts without hand-written logs. Fewer mistakes in counts or order picking means less time spent fixing errors and more time fulfilling orders correctly. The result is a more efficient operation with near-perfect inventory accuracy. In fact, automated cloud tracking dramatically cuts down issues like picking errors and fulfillment mistakes, leading to faster, more reliable warehouse workflows.

- Real-Time Inventory Visibility: A hallmark of cloud-based systems is that they provide real-time updates on stock levels and movements. This means at any given moment you can see exactly what’s in stock, what’s been sold or shipped, and what’s on order. Real-time visibility enables better decision-making and responsiveness – you can identify low stock and reorder fast, or halt sales of an item that’s running out to prevent overselling. This level of visibility helps combat the costly problems of inventory distortion (like out-of-stocks and overstocks), which globally amount to an estimated $1.77 trillion in losses due to lost sales or excess stock. With cloud systems, all stakeholders see the same up-to-date data, eliminating communication lags. For example, imagine an item that usually sells 50 units a week suddenly sells 100; a cloud system’s real-time alerts would prompt you to raise the reorder level immediately to avoid a stockout. Such agility in adjusting to demand spikes is only possible when your inventory data is live. Real-time tracking also builds trust – sales teams can confidently promise customers available stock, and management can rely on data for forecasting without second-guessing its freshness.

- Easy Access & Collaboration from Anywhere: Because it’s cloud-based, your inventory system becomes accessible from any location or device with internet. Warehouse managers, store owners, and even remote workers can log in to the same system to view and update inventory information in real time. This anywhere-access breaks down silos – no more being tied to the office computer or calling someone at a specific warehouse to ask for a stock count. Teams in different locations all work off the same cloud database, which fosters collaboration and a true “single source of truth” for inventory. A manager traveling off-site can still monitor warehouse stock levels on their tablet, or multiple warehouse teams can coordinate transfers of goods between facilities using the shared system. This collaborative visibility means faster communication and coordination. There’s less risk of miscommunication since everyone is literally on the same page (or rather, the same cloud screen) looking at identical data. In an era where remote and hybrid work is more common, having inventory management that works wherever your team does is a huge advantage.

- Scalability and Flexibility: Cloud-based inventory management makes it much easier to scale your operations as your business grows or your needs change. Unlike on-premise systems that might require buying new servers or installing software at each new site, cloud systems can quickly accommodate additional warehouses, sales channels, or products. You can add new users or locations with just a few clicks, and the system will handle the larger data volume without a hitch. This flexibility is invaluable for growing businesses and for handling seasonal demand surges. For example, if you open a new warehouse in another city, a cloud platform lets you integrate that new facility into your inventory network instantly, making it part of your overall management dashboard from day one. Similarly, expanding to online channels or new stores is easier – the cloud system centralizes inventory across all channels, preventing scenarios like selling an item online that’s out of stock because your stores and website weren’t synced. Cloud-based solutions are essentially built for multi-location, multichannel management, which is critical in modern commerce. You can scale up (or down) on demand without significant infrastructure investments, paying only for what you need as you grow. This agility allows warehouses to respond swiftly to market changes and business expansion.

- Cost Savings and Lower IT Burden: Shifting to a cloud inventory system often translates into cost reductions in several ways. First, you eliminate the need to buy and maintain expensive servers and hardware on-site – everything is hosted by the provider. This reduces upfront capital expenditures and ongoing IT maintenance costs. Small businesses especially benefit by not having to hire dedicated IT staff to manage a complex on-premise system. Instead, updates and server upkeep are handled by the cloud vendor, usually rolled into a predictable subscription fee. In fact, enterprises have found that moving to cloud can save 10–20% of their IT budget by trimming infrastructure and efficiency gains. Secondly, cloud systems often consolidate functions (inventory, order management, etc.) that might otherwise require multiple software – saving additional license costs. The pay-as-you-go model means you’re only paying for the capacity and features you use, avoiding the waste of underutilized resources. Moreover, because updates are automatic and included, you don’t incur downtime or consulting fees to upgrade software; your system is always up-to-date with the latest features. Fewer maintenance headaches and unplanned outages also mean indirect cost savings through higher productivity. Overall, cloud inventory management offers enterprise-level capabilities with a lower total cost of ownership than traditional systems – making advanced inventory control accessible even to small and mid-sized businesses.

- Improved Security and Data Backup: Reputable cloud inventory providers offer robust security measures and data backup protocols that most small businesses could not afford on their own. All data is typically encrypted and stored in secure data centers with protections against cyber threats and physical hazards. Regular backups are performed automatically in the cloud, safeguarding your inventory records from accidental loss or disasters. This means your data remains safe even if a local computer crashes or a device is stolen – you can simply log in from another device and continue working. Cloud providers also stay on top of security updates and patches, often providing a level of protection (like enterprise-grade encryption, intrusion monitoring, etc.) that far exceeds a typical in-house setup. By offloading much of the security burden to third-party experts, businesses reduce the risk of breaches caused by human error or outdated systems. In fact, many data breaches stem from on-premise misconfigurations or user mistakes, which cloud services help mitigate by managing security centrally. Additionally, with disaster recovery and redundancy built-in, cloud systems ensure business continuity. If one server location has an issue, data is replicated elsewhere, meaning your warehouse operations can continue with minimal interruption. This reliability and peace of mind – knowing that your inventory data is always protected and available – is a significant benefit. It allows warehouse managers to focus on operations rather than worrying about server rooms, backups, or security loopholes. As a result, cloud-based inventory management boosts resilience against unforeseen events, whether it’s a hardware failure or a cybersecurity threat.

- Integration with Other Systems: Modern cloud-based inventory platforms are designed to integrate seamlessly with a range of other business systems and emerging technologies. This is a growing necessity in warehousing. A cloud inventory system can connect with your e-commerce platforms, accounting software, shipping carriers, warehouse robotics, and more through APIs and built-in integrations. Such connectivity means data flows automatically between your inventory and other tools – for example, online orders from Shopify or Amazon can instantly update inventory levels, and your inventory system can trigger fulfillment actions in the warehouse. Integration also extends to advanced technologies: cloud systems work hand-in-hand with IoT devices (like smart shelves or RFID scanners) that update stock data in real time, and they feed data to analytics or AI engines for forecasting. This interoperability ensures that your warehouse can leverage automation and analytics to the fullest. In contrast, older standalone inventory programs might not play well with newer tools, causing data silos. By using a cloud platform as a central hub, you enable a smoother digital ecosystem where everything from sales channels to automated picking systems are synchronized. This level of integration not only improves efficiency (no more double data entry between systems) but is increasingly crucial for smart warehouses that rely on multiple technologies working in concert.

Each of the above benefits contributes to why cloud-based inventory management is seen as the future for warehousing. In summary, a cloud approach offers real-time, anywhere access to accurate inventory data, scales with your business needs, cuts costs and IT headaches, and positions your warehouse to integrate with cutting-edge technologies.

These advantages directly address the pain points of traditional inventory management, from stock inaccuracies and delayed information to high upkeep costs and rigid systems. Next, we will look at how these benefits translate into broader trends shaping the future of warehousing and why embracing cloud solutions is a key part of that evolution.

How Cloud-Based Systems Are Shaping the Future of Warehousing

Adopting cloud-based inventory management isn’t just an isolated improvement – it’s a central driver in the digital transformation of warehousing. Modern warehouses are evolving into technology-driven hubs often termed “smart warehouses” or “digital warehouses.” In these environments, connectivity, data, and automation reign supreme. Cloud inventory systems provide the backbone for this evolution by enabling and supporting a host of advanced technologies and practices that define the future of warehousing.

Real-Time Connectivity and Visibility

Cloud systems gather real-time data from sensors and devices across the warehouse, enhancing visibility and control:

- Smart shelves and pallet trackers continuously update stock information.

- Real-time alerts help managers respond immediately to issues, such as temperature changes or low stock levels.

- Centralized dashboards provide complete transparency across multiple locations, enabling proactive inventory management.

One major trend is the integration of devices and sensors in warehouse operations. From smart shelves that sense stock levels to pallet trackers and environmental sensors, IoT devices generate a constant stream of data. Cloud-based inventory platforms can capture and consolidate this data in real time, giving managers granular visibility into inventory and conditions across the facility.

Automation and Robotics

Cloud technology acts as the central coordinator for automated systems:

- Autonomous robots and Automated Storage and Retrieval Systems (AS/RS) communicate directly with cloud-based Warehouse Management Systems (WMS).

- Real-time updates ensure inventory accuracy as robots move goods, enabling efficient, continuous operations.

- Automation helps address labor shortages and maintains warehouse efficiency by allowing continuous operations, even overnight.

Cloud-based management plays a crucial role here by acting as the central “brain” that these automated tools interact with. A cloud warehouse management system (WMS) can dispatch tasks to robots and receive inventory updates from them in real time, keeping inventory records perfectly synchronized with physical movements. This integration has huge benefits: for instance, robotic pickers can operate 24/7, and as they work, the cloud system instantly logs each item moved or order fulfilled. The result is highly efficient, lights-out warehousing where inventory data is always up-to-date without manual scanning.

Enhanced Supply Chain Integration

Cloud-based inventory management improves collaboration across the supply chain:

- Suppliers and clients gain limited access to real-time inventory information, increasing transparency and trust.

- Integration with e-commerce platforms provides customers with accurate product availability.

- Cloud logistics platforms offer real-time shipment tracking, creating a responsive, visible supply chain.

Another aspect of the future warehouse is greater interconnectivity across the supply chain. Cloud inventory management enables better collaboration not just internally, but also externally with partners and customers. For example, because cloud systems can be accessed via web portals, some warehouses allow suppliers or clients limited access to view inventory or order statuses in real time. A logistics provider might give a major client a login to see current stock of their product in the warehouse, improving transparency and trust. On the consumer side, integration between cloud inventory and e-commerce means customers can see live inventory availability on an online store – preventing orders for out-of-stock items and improving customer satisfaction.

In transportation and delivery, cloud connectivity means you can share pertinent inventory or shipping data up and down the supply chain quickly. All of this leads to a more transparent, responsive supply chain.

Data Analytics and AI-Driven Optimization

Cloud inventory systems leverage AI and data analytics to optimize warehouse operations:

- Real-time data and cloud computing power support advanced forecasting and predictive analytics.

- AI-driven insights help warehouses optimize inventory placement, streamline picking routes, and anticipate demand changes.

- Cloud WMS solutions now frequently include predictive analytics, improving warehouse responsiveness and efficiency.

The power of data analytics and AI (Artificial Intelligence) is another future force that cloud inventory management unlocks. Warehouses generate massive amounts of data (orders, movements, transactions) that can yield insights to optimize operations. Cloud platforms can easily aggregate and crunch this big data, especially when leveraging the virtually unlimited compute power of cloud infrastructure. This opens the door for AI-driven applications in warehousing.

Continuous Software Improvement

Cloud solutions ensure warehouses always operate with the latest software capabilities:

- Automatic updates deliver new features, UI improvements, and security enhancements without disruption.

- Warehouses gain resilience and security through continuous, automatic updates and reliable uptime guarantees.

Cloud inventory system can incorporate machine learning algorithms to analyze sales patterns and lead times, then automatically suggest optimal reorder points or predict stockouts before they happen. Advanced forecasting that would be computationally intensive on local systems becomes feasible with cloud-based AI tools. Moreover, AI can be used for things like optimizing pick routes in a warehouse or dynamically slotting inventory (deciding where to place products for fastest picking). Cloud-based systems support these innovations by providing the scalable computing environment needed for AI and by continuously feeding real-time data that AI models require. We’re already seeing cloud WMS solutions that offer predictive analytics modules – effectively giving warehouses a crystal ball to anticipate demand surges or supply issues and adjust inventory accordingly. As AI and analytics capabilities grow, warehouses that harness them will operate with unprecedented efficiency and responsiveness. Cloud inventory management is the conduit making this possible for even mid-sized operations, not just the Amazons of the world.

Furthermore, cloud systems ensure that warehouses are always running on the latest software capabilities. In the past, a new software feature (say, a better algorithm for picking or a new integration) required installing updates manually, which many operations would postpone or avoid due to complexity. Now, cloud providers roll out updates and new features automatically to all users. This means warehouses continuously gain improvements (like UI enhancements, new analysis tools, security patches) without disruption. Staying evergreen with technology is essential as the industry moves fast. With threats like cyberattacks evolving, having automatic security updates from cloud providers keeps warehouses protected without local IT scrambling. Cloud services often guarantee uptime and have redundancies that individual businesses would struggle to implement on their own, contributing to more resilient operations.

Global Adoption and Strategic Advantage

The widespread shift toward cloud adoption means warehouses that embrace cloud technology gain significant competitive advantages:

- Over 94% of enterprises already use cloud services, making cloud-based inventory management increasingly standard.

- Warehouses using cloud solutions are better positioned for omnichannel fulfillment, rapid scaling, and data-driven operations.

- Early adopters of cloud systems stand to significantly outperform competitors still reliant on legacy systems.

It’s worth noting the global shift towards cloud adoption. Across industries, cloud computing has gone from a novelty to the norm, and warehousing is part of this wave.

Experts predict that cloud-based logistics and inventory systems will become the default, and those who modernize early stand to gain a significant competitive edge. We’re already witnessing forward-thinking warehouse operators leverage cloud systems to enable omnichannel fulfillment, rapid scaling, and data-driven optimization – hallmark capabilities of the warehouse of the future.

CyberStockroom: A Closer Look at a Cloud Inventory Solution

Halfway through our exploration, it’s useful to highlight a concrete example of cloud-based inventory management in action. CyberStockroom is one such solution that encapsulates all the benefits discussed so far, while also offering unique features tailored to the needs of modern warehousing and small businesses.

As a cloud-based inventory management platform, CyberStockroom not only provides real-time, anywhere access to your data, it also introduces innovative approaches to simplify inventory control. Here’s a look at some of CyberStockroom’s key features and how they relate to cloud-based warehousing:

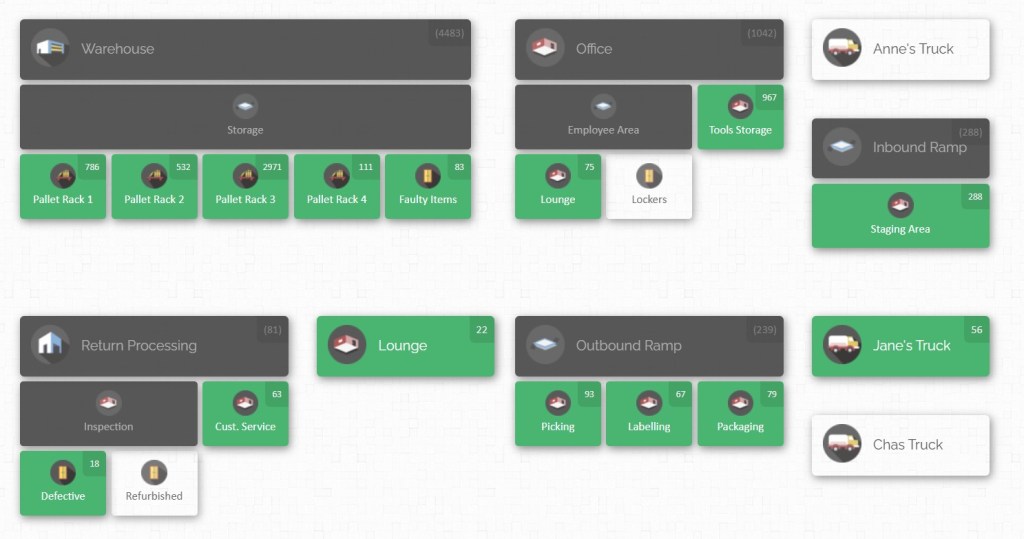

- Unique Visual Inventory Mapping: CyberStockroom sets itself apart with an intuitive map-based interface for inventory. It is one of the only cloud inventory solutions that lets you build a visual map of all your locations and sub-locations – essentially creating a virtual layout of your warehouses, stockrooms, or stores. This interactive map becomes your dashboard. You can click on a specific room, shelf, or bin on the map to instantly see the contents and stock levels at that location. This visual approach simplifies the process of managing multiple locations because you can literally see how inventory is distributed. For warehouse managers, it’s like having a bird’s-eye view of every storage area without walking the floor. The visual map makes it easy for anyone (even non-technical staff) to navigate the inventory system, since it mirrors the actual physical layout of the business. This unique feature enhances inventory visibility and is especially useful for businesses that have complex or distributed storage setups.

- User-Friendly Interface: A major focus of CyberStockroom is on ease of use. The platform is designed to be highly intuitive and easy to navigate, even for those who may not be tech-savvy. This is crucial because a system is only as good as its adoption by the team – if it’s too complex, employees might resist using it or make errors. CyberStockroom’s clean interface and visual cues help reduce the learning curve. Common tasks like searching for a product, updating quantities, or transferring stock are straightforward. For example, it offers drag-and-drop functionality to move items from one location to another on the map, which feels natural and avoids the need to manually enter transfer orders. By prioritizing a friendly user experience, CyberStockroom ensures that warehouse staff and managers can fully leverage the cloud system’s capabilities with minimal training friction. This aligns with the broader benefit of cloud solutions providing better collaboration – when everyone finds the tool accessible, it’s used consistently as the single source of truth.

- Customization and Flexibility: Every warehouse operates a little differently, and CyberStockroom addresses this by providing customization options to fit various business needs. Users can tailor fields and categories in the system (for example, adding custom attributes to track expiry dates or supplier info), and configure the inventory map to mirror their unique layout. This flexibility makes the software adaptable for different industries – whether it’s a retail stockroom, a manufacturing parts warehouse, or a field service van inventory. CyberStockroom’s cloud foundation means it can scale with the business as it grows, just as discussed earlier. You can add new locations or product lines in the software easily, and adjust the map and settings accordingly. The system’s versatility has made it a popular choice for small businesses and startups that need enterprise-grade functionality but in a right-sized package. Essentially, CyberStockroom delivers the scalability of cloud with the ability to mold the tool around your processes, rather than forcing you to follow a rigid template.

- Comprehensive Support and Training: Implementing new technology in a warehouse can be challenging, so CyberStockroom emphasizes customer support and training resources to help users get the most out of the platform. This includes documentation, tutorials, and responsive support channels. From the onset, new users can access onboarding assistance to configure their inventory map and import data. Ongoing support means any issues or questions can be resolved quickly, reducing downtime. This is an important feature in the context of cloud software – while the provider manages the technical infrastructure, the users still need to manage change within their operations. CyberStockroom’s strong support ensures that businesses can confidently transition to cloud inventory management and continuously improve how they use the system. For warehouse managers and small business owners, knowing that there’s help available when needed can significantly ease the change management aspect of adopting a new system.

- Enhanced Visibility and Control: Ultimately, CyberStockroom provides all the core advantages you would expect from a cloud-based inventory system: real-time visibility into stock levels, multi-location tracking, and detailed control over inventory movements. The software supports standard features like barcode scanning, audit trails for inventory changes, and reporting analytics to track usage and trends. What makes it stand out is how these features are presented in a centralized, visual manner that gives a high level of control. Users can quickly locate any product and see exactly where it’s stored across all locations (thanks to the mapping), and can generate reports to identify, say, slow-moving items or shrinkage. Because it’s cloud-based, all these capabilities are accessible on any device. A regional manager could, for example, check stock and transfer items between warehouses from a tablet while traveling. CyberStockroom’s emphasis on inventory visibility and control aligns perfectly with the future-focused needs of warehouses – ensuring that managers have at their fingertips the data and tools to optimize inventory levels, prevent stockouts or overstock, and respond swiftly to operational needs.

CyberStockroom exemplifies how a cloud-based inventory management solution can revolutionize warehouse operations in practice. By offering an easy-to-use, map-driven system with robust support and the full power of cloud technology, it helps businesses (especially small and mid-sized ones) achieve the efficiency and insight previously only attainable by large enterprises. CyberStockroom’s features directly map to the benefits of cloud inventory management we discussed earlier – from real-time visibility and scalability to cost-effectiveness and collaboration. For any warehouse manager or business owner exploring the move to cloud inventory management, CyberStockroom is certainly a solution worth considering as it highlights what the new generation of inventory tools can do.

Tips for Implementing Cloud-Based Inventory Management in Your Warehouse

Embracing cloud-based inventory management is a significant step toward modernizing your warehouse. To ensure a smooth transition and to get the most value from the new system, consider the following steps and best practices during implementation:

- Assess Your Needs and Pain Points: Begin by auditing your current inventory processes. Identify the challenges you face – for example, is it inaccurate stock counts, delayed reporting, difficulty managing multiple warehouses, or something else? Clarifying your requirements will help you choose the right cloud solution. Make a list of “must-have” features (like barcode scanning, multi-location support, or integrations with your e-commerce platform) and “nice-to-have” features. Understanding your workflow and pain points also provides a baseline to measure improvement after switching to a cloud system.

- Ensure Reliable Infrastructure (Internet & Devices): Since cloud-based systems rely on internet connectivity, ensure your warehouse has a stable, high-speed internet connection and proper network coverage (including Wi-Fi on the warehouse floor if mobile devices will be used). The good news is that internet availability is at an all-time high – in many regions, over 99% of business areas have access to broadband speeds suitable for cloud application. Still, it’s wise to have a backup connectivity option (like a secondary ISP or mobile hotspot) for redundancy. Additionally, equip your team with the necessary devices to use the cloud system effectively – whether that’s mobile barcode scanners, tablets, or simply updated computers. Modern cloud inventory software often has mobile apps or web portals that work on tablets and phones, which can greatly increase convenience on the warehouse floor. Make sure your hardware (devices, barcode printers, etc.) is compatible or can integrate with the new system.

- Choose the Right Cloud Inventory Solution: Do thorough research and compare cloud inventory management platforms before deciding. Consider factors like feature set, scalability, cost, user-friendliness, and industry focus. Many providers (including CyberStockroom) offer free trials or demos – take advantage of these to see the interface and capabilities firsthand. During trials, involve the actual end-users (warehouse staff, inventory managers) to gather feedback on ease of use. It’s also valuable to read reviews or case studies of each solution to learn how other businesses in similar situations have benefited. Ensure the solution can integrate with your other systems (e.g. your e-commerce store, ERP, or shipping software) to maximize efficiency. Selecting a platform that aligns well with your needs will set the foundation for a successful implementation.

- Plan Data Migration and Integration: One of the more challenging parts of transitioning to any new inventory system is migrating your existing data (product SKUs, current stock levels, locations, supplier info, etc.) into the new cloud system. Plan this step carefully: it may involve cleaning up data (removing obsolete SKUs, standardizing naming conventions) before import. Most cloud platforms provide tools or support to import data via spreadsheets or APIs. Take time to verify that the data migrated correctly and that inventory counts match reality through cycle counts. Additionally, set up integrations with other software at this stage. For example, connect your online store to the inventory system and test that orders flow and inventory updates sync properly. If you have legacy systems that must remain in place, see if the cloud provider offers middleware or APIs to connect them. It’s wise to schedule the cut-over or go-live of the new system during a relatively slow period, if possible, to minimize disruption while ironing out any kinks in data migration and system links.

- Train Your Team and Phase the Rollout: Even with a user-friendly system, proper training is crucial for success. Organize training sessions for your warehouse staff, managers, and anyone else who will use the inventory software. Many cloud providers supply tutorials or even on-site training – use these resources to ensure everyone is comfortable with the basic functions like receiving stock, logging shipments, doing inventory adjustments, etc. Emphasize the benefits to the team (less manual work, easier finding of inventory, etc.) to get buy-in. It can help to designate an “inventory champion” or super-user in your team who becomes especially proficient and can support others. Consider phasing the implementation: you might start with a single warehouse or a subset of products as a pilot to test the new system in action and resolve any issues, then roll it out fully. This phased approach can reduce the risk of disrupting operations. Expect a short adjustment period where productivity might dip as everyone learns the new system, but with training and support, users will soon find the cloud system far more efficient than the old ways.

- Leverage Vendor Support and Continuously Optimize: Once the cloud inventory management system is up and running, make full use of the vendor’s support and resources. If questions or problems arise, don’t hesitate to reach out to their support team – it’s part of what you’re paying for. CyberStockroom, for instance, offers ongoing support and even personalized onboarding to help businesses maximize the platform. Keep an eye on new features or updates the provider releases, as these can further improve your operations (e.g., new reporting tools or integrations might become available). Regularly review your inventory KPIs using the system’s analytics – such as inventory turnover, order accuracy, stockout frequency – to identify areas for improvement. The cloud system will make these metrics more visible. Use that insight to fine-tune your processes (perhaps you notice certain items should be reordered sooner, or some warehouse zones are slower to pick from and need reorganization). In essence, treat the implementation as an ongoing journey: you’ve given your team a powerful tool, so continue to refine how you use it. With time, you’ll likely discover new ways the cloud system can streamline work (for example, using mobile scanners to do cycle counts on the fly, or setting up automated low-stock alerts to suppliers). By engaging with the technology and the support available, your warehouse can continuously adapt and improve – which is exactly the kind of agility that cloud-based inventory management is meant to foster.

Following these steps will help ensure that the transition to a cloud-based inventory management system is smooth and yields the desired improvements. Implementation is as much about people as it is about technology – prepare your team, set realistic goals, and use the strengths of the cloud system to address your warehouse’s unique challenges. With proper planning and execution, you’ll quickly start seeing the benefits (accuracy, efficiency, visibility) materialize in day-to-day operations, validating why the move to the cloud was the right call.

Conclusion

Warehousing operations globally are growing more complex, and cloud-based inventory management has become essential for effectively managing this complexity. Cloud solutions address key challenges by providing real-time visibility, agility, scalability, and cost efficiency.

Key advantages include improved operational efficiency, rapid scalability, significant cost savings, and data-driven insights. These benefits are critical in meeting today’s high customer expectations and maintaining competitive advantage.

Industry experts predict that cloud-based inventory systems will soon become standard practice, offering substantial advantages to early adopters. For warehouse professionals, adopting cloud inventory management is a strategic investment ensuring long-term success and efficiency.

Solutions like CyberStockroom exemplify how cloud technology delivers tangible benefits for businesses of all sizes, transforming warehouses with enhanced accuracy, efficiency, and connectivity.

In short, cloud-based inventory management is more than just an upgrade—it’s foundational for future warehouse excellence and essential for staying competitive in the evolving logistics landscape.

Leave a comment