In today’s fast-paced, competitive environment, information is everything. Warehouses that still rely on manual logs or end-of-day inventory reports often find themselves a step behind. Mistakes in inventory counts, delays in updating stock levels, and lack of visibility can lead to lost sales, frustrated customers, and chaotic workflows. In fact, studies have shown that inventory mishaps like stockouts and overstocks cost businesses trillions globally each year – a clear sign that the old ways of managing inventory just aren’t cutting it anymore.

Real-time inventory tracking is more than a tech buzzword; it’s a practical solution that keeps your business running smoothly and efficiently by maintaining an up-to-the-minute pulse on your stock. From increased accuracy to happier customers, the benefits of going real-time are wide-reaching.

Below are the five major benefits of real-time inventory tracking for warehouse managers, each illustrated with practical examples. These aren’t abstract, theoretical perks – they’re real problem-solvers that can make your daily operations easier and your warehouse more productive. Let’s get started!

1. Instant Inventory Visibility and Accuracy

Benefit in a nutshell: Know exactly what you have and where you have it, the moment it changes.

One of the biggest headaches in warehouse management is not knowing your true inventory status until it’s too late. Maybe an item was misplaced on a wrong shelf, or a manual entry error left your system thinking you have 50 units when there are only 5. Real-time inventory tracking virtually eliminates these blind spots. Every time a product is received, moved, or sold, the inventory system updates immediately. This means your stock counts are always accurate and up-to-date, across all locations and sales channels.

With real-time visibility, you can see your entire inventory at a glance. No more guesswork or end-of-week surprises. For example, imagine you receive a shipment of 200 widgets in the morning. As soon as the warehouse associate scans them into your system, those widgets instantly show up in your available stock. Your sales team sees it, your procurement system sees it, and you see it – all in real time. If 10 units are picked for an order an hour later, your counts immediately drop by 10. This level of transparency helps prevent errors like double-selling an item or forgetting to restock a location.

Why it matters: Improved accuracy and visibility mean fewer costly mistakes. You catch discrepancies as they happen, so an incorrect count or a misplaced pallet can be fixed now, not discovered months later during an audit. As a warehouse manager, that confidence in your data is priceless – you can make decisions knowing the information in front of you reflects reality. In short, real-time tracking gives you total inventory control.

2. Improved Operational Efficiency and Productivity

Benefit in a nutshell: Streamline your warehouse operations and save everyone time and effort.

Think about how much time is wasted in a warehouse when people have to search for products or manually update records. Real-time inventory tracking supercharges efficiency by automating and simplifying those tasks. With up-to-the-minute data and tools (like barcode scanners or RFID), your team can get more done in less time, with less hassle.

Here are a few ways real-time tracking makes daily operations run smoother:

- Faster picking and receiving: When every item’s location and quantity are updated live, pickers and receivers don’t need to double-check or hunt around. A picker can use a mobile device to see exactly which bin an item is in right now, not where it was last week. Likewise, as soon as new stock is received and scanned in, it’s available in the system for orders – no lag time.

- Less manual paperwork: In a real-time system, data entry is largely automated. Scanning a barcode or moving an item updates the database immediately, eliminating duplicate entry later. Your staff spends less time filling out forms or typing updates into spreadsheets and more time on value-adding work.

- Streamlined transfers and adjustments: Need to move 100 units from Aisle 3 to Aisle 8? Do it and update the system on the fly as you move them. Everyone else will see the new location instantly. This cuts down on miscommunication and prevents the classic “I can’t find the stock, it was supposed to be here” scenarios.

For warehouse managers, this efficiency translates to lower labor costs and faster turnaround. You can process more orders in a day with the same team, or reallocate time saved to other important tasks (like training or facility improvements). Improved efficiency also means less stress on your staff – when everything is running like clockwork, people aren’t scrambling to solve needless problems. Real-time inventory tracking essentially lets your warehouse run on autopilot for routine tasks, freeing you and your team to focus on exceptions or bigger-picture improvements.

3. Proactive Stock Level Management (No More Stockouts or Overstock)

Benefit in a nutshell: Maintain optimal inventory levels at all times and respond quickly to demand changes.

Few things are as painful for a warehouse manager as a stockout (when you completely run out of an item) or its opposite, having way too much of something collecting dust. Both situations are largely preventable with real-time inventory tracking. Because you have a constant pulse on stock levels, you can catch issues early and act before they become major problems.

With real-time tracking, your system can alert you the moment an item falls below a preset threshold. Instead of discovering a critical part is out-of-stock only when someone tries to order it, you’ll get a heads-up when it’s, say, down to 10 units so you can reorder in time. This kind of proactive inventory management keeps your service levels high – customers and other departments get what they need when they need it – while also avoiding the costs of rush ordering or downtime.

Equally important, real-time data helps prevent overstocking. When you’re not confident in inventory data, it’s tempting to over-order “just in case” or because the last report was outdated. This leads to excess inventory tying up capital and warehouse space. In a real-time system, you can trust the numbers and order just the right amount. You might notice, for example, that a product isn’t selling as fast as forecasted this month – the live sales and inventory data will reflect that, so you can adjust future orders downward before you end up with a six-month supply of a slow mover.

Why it matters: Running out of stock means lost sales and unhappy customers, while overstocking means wasted money and space. Real-time inventory tracking acts like a safety net, catching these issues in advance. It also provides valuable insights for demand forecasting – over time, the continuous stream of data lets you notice trends and seasonal patterns, improving your future inventory planning. In short, you can run a leaner, more responsive operation.

Your warehouse becomes agile, adjusting to demand changes almost as they happen. This level of control keeps your business nimble and can significantly boost your profitability (fewer stock emergencies, less surplus to discount or write off). No warehouse manager misses the days of surprise stockouts or overstuffed stockrooms – and with real-time tracking, those days can be firmly in the past.

CyberStockroom’s Map-Based Tracking: Bringing These Benefits to Life

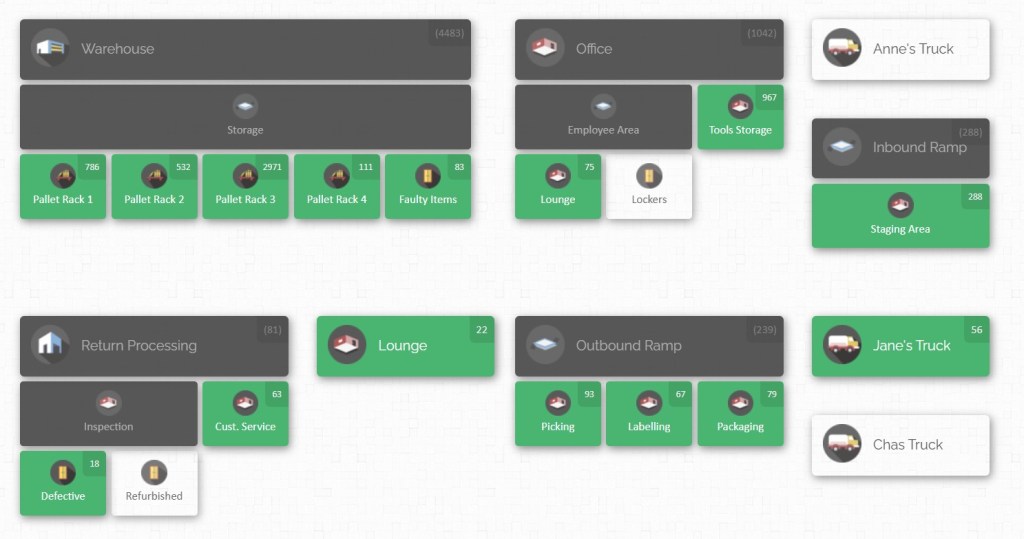

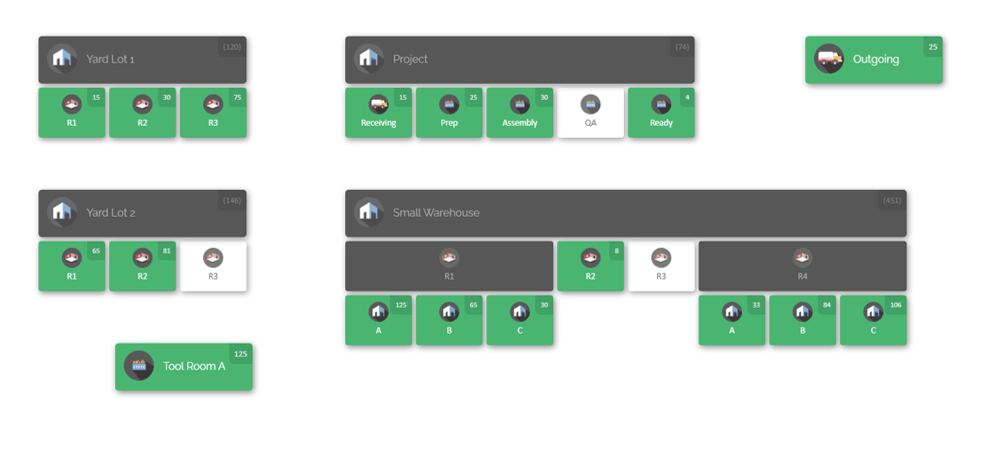

Technology is the enabler of all the advantages we’ve discussed so far, and one standout example is CyberStockroom – a warehouse management tool that uses a unique visual map interface to deliver real-time inventory tracking.

We’ve touched on scenarios like seeing your inventory on a digital dashboard or instantly locating a product; CyberStockroom is built exactly for those purposes. Here’s how it directly connects to the benefits we’ve outlined:

- Visual Real-Time Inventory Map: CyberStockroom lets you create a visual map of your warehouse where every zone, shelf, and item is represented. As inventory moves or levels change, this map updates immediately. This feature takes inventory visibility to the next level – instead of just reading numbers on a screen, you’re literally seeing your operations unfold. For example, if a pallet is moved from the receiving dock to Aisle 5, you’ll see that movement on the map in real time. It’s like having a live blueprint of your warehouse with all inventory positions marked, helping you and your team instantly pinpoint where things are.

- Instant Updates and Alerts: The platform is cloud-based and updates continuously, meaning whether you’re on your warehouse computer or checking on your phone from home, you’re always looking at the latest info. CyberStockroom shows an indicator when items hit reorder levels or if something unexpected occurs (e.g., a negative stock count or an item checked into a strange location), helping you stay proactive and prevent problems like stockouts. This directly feeds into optimal stock level management – you’re never in the dark about your inventory status.

- Streamlined Operations with Easy Tools: Because CyberStockroom is map-centric, many warehouse managers find it very intuitive for staff to use. New employees can literally see where products belong and what’s happening, shortening training time and reducing errors. The system supports barcode scanning and even integrates with other software, which means those efficient workflows (like scanning items on the spot to update inventory) are built right in. One of your workers can walk up to a bin, scan an item with a handheld device, and CyberStockroom will immediately reflect the new count and location on the map – no extra data entry needed. This keeps operations fast and accurate.

- Holistic View for Better Decisions: CyberStockroom’s approach isn’t just about today’s transactions; it also gives you reporting and history. You can replay movements on the map or generate reports on inventory levels over time. This means better data for analyzing trends, which ties back to forecasting and cost management. You might discover, for instance, that certain products consistently sit in a back corner and gather dust – insight that could prompt you to optimize your stock levels or warehouse layout. In essence, the tool helps convert real-time data into actionable intelligence, driving smarter decisions and cost savings.

In practice, using CyberStockroom can feel like having a bird’s-eye view of your warehouse at all times. Say you get a call from an important client asking if you can expedite 50 units of a product. Instead of saying “Let me check and get back to you,” you can glance at your CyberStockroom map and see not only that you have exactly 50 available, but also see where they are and that they’re ready to go. You confidently answer “Yes, we have it in stock and can ship immediately,” impressing the client. That’s the power of combining real-time tracking with a user-friendly visualization – it empowers you to respond quickly and accurately.

For warehouse managers considering a move to real-time inventory tools, CyberStockroom is a compelling example of how technology can make all these benefits tangible. The mid-point takeaway here is that having the right system in place bridges the gap between theory and reality. It’s one thing to know that real-time tracking is good in principle; it’s another to actually see it in action on a colorful map with your own inventory. As you evaluate solutions, think about how well they provide visibility, ease of use, and timely data – those are the features that turn into concrete gains in accuracy, efficiency, and cost savings.

(Now, back to the benefits – there are two more big ones to cover!)

4. Reduced Costs and Waste

Benefit in a nutshell: Save money by cutting down on inventory-related costs and avoiding wasteful practices.

Warehouse operations have a direct impact on the bottom line. Inefficient inventory management isn’t just an organizational headache – it’s expensive. Real-time tracking helps trim many hidden (and not-so-hidden) costs by ensuring you only carry what you need, when you need it, and by preventing costly mistakes.

Here are some of the key ways real-time inventory tracking leads to cost savings:

- Lower inventory holding costs: Storing inventory isn’t free – it ties up capital and incurs warehousing expenses. By maintaining optimal stock levels (as discussed earlier), you avoid overstocking, which means you’re not paying to store excess product that just sits there. You’ll use warehouse space more efficiently, possibly even allowing you to handle more goods without expanding facilities.

- Preventing lost sales and emergency expenses: A stockout doesn’t just upset customers; it often forces you into reactive spending. This can include paying for expedited shipping from a supplier to replenish stock quickly, or splitting shipments (incurring extra postage) to partially fulfill an order. With real-time tracking minimizing stockouts, you avoid those panic purchases and premium freight costs. Plus, every sale that isn’t lost to an out-of-stock is revenue saved – over time, that adds up significantly.

- Reduced labor and admin costs: Think of all the manual hours spent on inventory reconciliation, searching for missing items, or fixing errors. Real-time systems drastically cut those hours. For example, if your team usually spends the last Friday of each month doing a massive stock count, a live tracking system might let you skip that ritual (or do it much faster with cycle counts) because the data is already accurate. Less overtime and fewer labor hours spent on inventory fixes = direct savings.

- Lower error-related costs: Mistakes like shipping the wrong item or ordering too much of something have costs too – returns handling, write-offs, and so on. By improving accuracy and processes, real-time tracking means fewer of these costly oops-moments. For instance, if your system ensures the picker grabs the correct item via barcode verification, you won’t be eating the shipping cost to get a wrong item back and re-send the right one. Similarly, catching a discrepancy in real time (like noticing you received less stock than you ordered, right at receiving) might let you claim a supplier credit immediately, rather than discovering it weeks later when it’s harder to resolve.

Ultimately, real-time inventory tracking helps your warehouse do more with less. It’s about efficiency translating directly into financial savings. When you cut out waste – be it time, excess stock, or rush fees – you’re essentially increasing your profit margin. For a warehouse manager, it also means you can better justify the investment in modern inventory tools by pointing to these savings. Many companies find that a good real-time system pays for itself relatively quickly through the cost reductions it enables. Plus, when the finance team sees accurate inventory values and fewer write-offs, you’ll definitely earn some brownie points for keeping the books in great shape!

5. Better Customer Satisfaction and Service

Benefit in a nutshell: Keep customers happy and confident by delivering orders accurately and on time, thanks to reliable inventory information.

While a lot of inventory management happens behind the scenes, its effects are absolutely felt by the customer. Whether your “customers” are end consumers buying products, retail stores you supply, or internal branches of your company, inventory reliability translates into trust and satisfaction. Real-time inventory tracking plays a big role in making sure that what you promise is what you can deliver.

Here’s how real-time inventory tracking boosts customer satisfaction:

- Fewer backorders and shipping delays: When your inventory data is accurate in real time, you won’t be selling something you don’t actually have. Customers won’t place an order only to get an “Oops, we’re actually out of stock” message later. If an item is available for purchase, it truly is available – and it ships when expected. Hitting promised ship dates consistently makes customers confident in your service.

- Improved order accuracy: Mistakes in orders (like receiving the wrong item or quantity) can sour customer relationships. Real-time systems often integrate with scanning and verification processes to ensure that the correct items are picked and packed. For example, if a picker tries to scan an item that isn’t on the order, the system can flag it immediately. The result? Customers get exactly what they ordered more reliably, leading to fewer returns and complaints.

- Transparency and communication: Some real-time inventory tools allow you to give visibility to customers or at least your sales/support teams. This means if a customer inquires about an item, your team can instantly answer whether it’s in stock and even reserve it. In some cases, customers themselves can see stock levels or get notifications (for instance, “only 3 left in stock” prompts on websites powered by real-time data, or alerts when an out-of-stock item is available again). This transparency builds trust – you’re seen as a reliable partner or seller who has their act together.

- Handling the unexpected: Let’s face it, sometimes things go wrong – maybe there’s a sudden spike in demand or a shipment from a supplier is late. Real-time inventory tracking helps you react swiftly in these scenarios to still keep customers satisfied. If demand surges and stock is depleting faster than expected, you’ll catch it and can possibly allocate remaining stock to your best customers or fast-track a restock. If a promised item truly does run out, a real-time system will help you immediately identify alternatives (perhaps a similar product in plenty supply) and communicate proactively with customers. Being able to address issues in the moment often turns potential disappointments into opportunities to show great service.

This benefit boils down to reliability. Real-time inventory tracking makes your warehouse reliable in the eyes of those depending on it. When warehouse managers can consistently say “Yes, we have that in stock” (and be right), or ensure that orders go out without errors, it builds a strong reputation. Customers remember that. In surveys, a majority of shoppers say they won’t wait for a product if a seller is out-of-stock – they’ll go somewhere else. By minimizing stockouts and keeping your inventory information truthful and current, you’re directly defending against that loss of business. Instead, you’re turning inventory management into a competitive advantage: your warehouse becomes known as the one that delivers on its promises. And as any business owner will tell you, a happy customer is the best asset to have.

Embrace the Real-Time Revolution

Real-time inventory tracking isn’t just a fancy upgrade for your warehouse – it’s quickly becoming a necessity in the modern supply chain. As we’ve seen, the benefits range from behind-the-scenes improvements in accuracy and efficiency to front-facing wins like better customer service. In a world where every minute counts and customer expectations are higher than ever, relying on yesterday’s inventory data (or last week’s spreadsheet) simply won’t cut it. The difference between a warehouse that operates in real time and one that doesn’t is like night and day: one is agile, responsive, and cost-effective, while the other is constantly playing catch-up.

If you’re a warehouse manager looking to improve operations, now is the perfect time to explore real-time inventory tools. Not only can they save you money and headaches, but they also empower you and your team to do your jobs with confidence and clarity. Remember the scenario we opened with – seeing your whole warehouse on a live map and knowing exactly what’s happening? That level of control is within reach. Whether it’s through a solution like CyberStockroom’s map-based platform or another system that fits your business, making the switch to real-time tracking can be a game-changer.

Change can be daunting, but think of it this way: every step towards real-time inventory management is a step towards a more streamlined, profitable, and stress-free warehouse. Start small if you need to – maybe pilot a system in one area or for one product line. You’ll quickly see the difference it makes. Once you experience the ease of having accurate data at your fingertips and the relief of dodging a few inventory crises thanks to timely alerts, you’ll wonder how you ever managed without it.

In summary, the benefits of real-time inventory tracking for warehouse managers aren’t just theory – they’re very real and very attainable. By embracing the tools and technology available today, you can transform your warehouse into a well-oiled machine that not only meets the challenges of the present but is also prepared for the future. So why wait? The sooner you get on board with real-time inventory tracking, the sooner you’ll reap the rewards of a smarter, faster, and more responsive operation. Your team will thank you, your finance department will thank you, and most importantly, your customers will thank you. Happy tracking!

Leave a comment