In today’s global supply chains, effective inventory management is more critical than ever. Excess stock can tie up capital and incur carrying costs of around 20–25% of its value per year, yet stockouts can halt production lines or leave customer orders unfilled. Striking the right balance – having exactly what you need, when you need it – is the essence of inventory optimization.

For manufacturing plants and warehouses, optimized inventory means lower costs, smoother operations, and improved customer satisfaction. It also entails tackling challenges like shrinkage (lost or stolen stock) and adapting to demand fluctuations in a volatile market. While managers once relied on spreadsheets and guesswork, today they have data-driven techniques and advanced tools (like cloud inventory systems and visual warehouse mapping) that make optimization more achievable than ever.

For example, modern software such as CyberStockroom provides a map-based, real-time view of inventory across all locations, changing how teams track and optimize stock.

Modern inventory optimization techniques combine process improvements and technology. In this article, we’ll explore key methods – from demand forecasting and lean inventory strategies to leveraging cloud-based systems and warehouse mapping tools – that help operations managers and supply chain professionals optimize inventory in manufacturing and warehousing environments worldwide.

Forecasting and Demand Planning

One of the foundational inventory optimization techniques is demand forecasting. This involves using historical data, market trends, and analytics to predict future product demand so that you can plan inventory accordingly. Accurate forecasting allows businesses to align their purchasing and production with what customers will need, reducing the guesswork. By anticipating demand, companies can pre-position inventory, ramping up stock before peak seasons and scaling back during lulls to avoid both gluts and shortages.

Demand forecasts can be generated through methods ranging from simple moving averages to advanced algorithms. Time-series analysis, regression models, and newer AI-driven tools all help project future sales based on past patterns. The benefits of good forecasting are significant: it minimizes the risk of overstocking (which ties up cash in excess inventory) and understocking (which leads to missed sales or production downtime). It also enables more efficient scheduling of production runs and purchasing, since materials and components arrive in sync with needs rather than accumulating unused. In short, forecasting is about getting ahead of demand – a proactive approach that keeps inventory levels and customer demand in balance.

Data-driven demand planning is especially vital in manufacturing, where lead times for raw materials can be long. For instance, a car manufacturer must forecast demand for each model and component well in advance – misjudging it could mean a warehouse full of unused parts or an assembly line idle for lack of a critical item. Many companies use software to constantly update forecasts as new sales data comes in, allowing them to adjust purchase orders on the fly. The more data and analytics you feed into forecasts, the more refined they become. Effective demand forecasting not only reduces stockouts and overstocks, it also increases supply chain efficiency and reduces lead times by aligning inventory with real consumption patterns.

Invest time in developing reliable forecasting processes

Use historical sales, market research, and even machine learning where possible to predict demand. By knowing what’s likely around the corner, you can position your inventory to meet customer needs without costly excess. And remember, forecasting is an ongoing process – continually compare your forecasts to actuals and refine your models for better accuracy over time.

ABC Classification and Inventory Segmentation

Not all inventory is created equal. ABC analysis (also known as ABC classification) is a technique that segments your inventory based on importance, so you can manage each segment with appropriate attention. Typically, “A” items are the top sellers or highest value items that constitute a large portion of your inventory value (for example, the top 20% of items that make up 80% of value – the Pareto principle). “B” items are moderately important, and “C” items are the long tail of low-value or low-frequency goods. By categorizing stock this way, you focus your efforts where they matter most.

Using ABC analysis, operations managers give tight control to A items – e.g. frequent cycle counts, robust safety stock, close supplier relationships – because a shortage or overstock of these has the biggest impact.

Meanwhile, C items might be managed with simpler methods or less frequent reordering since they’re lower risk. This prioritization helps prevent overstocking or under-stocking of products by ensuring the right items are stocked in the right quantities.

In practice, businesses that implement ABC analysis often find they can reduce inventory on the less-critical “C” items (freeing up capital) while making sure the “A” items are always available for customers.

Benefits of ABC segmentation

Benefits include reduced carrying costs and improved service levels. By not over-investing in slow-moving inventory, you cut down on holding costs like storage and insurance. And by closely managing high movers, you reduce lost sales. It also shortens lead times and increases efficiency in the supply chain by aligning inventory levels with actual demand priorities. For example, a spare parts warehouse might classify fast-moving critical components as A (to always keep in stock), common nuts and bolts as B, and rarely-used specialty parts as C with minimal stock. This way, resources (capital and effort) are allocated optimally.

To implement ABC analysis, gather data on annual usage or sales value of each SKU. Rank the items and classify them into groups:

A = top 20% by value, B = next 30%, C = bottom 50%, though criteria can vary.

Review and adjust periodically, because an item’s importance can change over time. Some companies extend this idea further with inventory segmentation by other factors (like XYZ analysis based on demand variability, or classifying by criticality to operations). The core idea is the same: segment your inventory to apply the right level of control to the right items. This ensures effort (and cash) isn’t wasted managing everything with a one-size-fits-all approach.

Safety Stock and Reorder Point Optimization

Even with excellent forecasting and classification, demand and supply will never be 100% predictable. That’s where safety stock comes in. Safety stock is an extra buffer of inventory kept on hand to guard against variability – unexpected spikes in demand or delays in supply. In essence, it’s the inventory you hope you never have to use, but keep “just in case” to prevent a stockout. For example, a distributor might keep two weeks’ worth of extra supply of a crucial component so that if a shipment from the supplier is late, production can continue uninterrupted.

Calculating the optimal safety stock is a classic inventory optimization exercise. Hold too little and you’ll run out when something goes wrong; hold too much and you’re tying up money for no reason. The calculation typically considers factors like forecast error (demand variability) and supplier lead time variability.

A simple approach is to use the formula based on service level targets (desired probability of not hitting a stockout) combined with the standard deviation of demand during lead time. In practice, many companies use software or standard formulas (e.g. Safety Stock = Z-factor × σ<sub>demand LT</sub>, where Z is based on desired service level) to compute this. The key is that safety stock should cushion the unpredictable portion of demand or supply.

Safety stock is essentially insurance against uncertainty. For instance, retail stores carry extra wrapping paper going into the holidays beyond forecasted demand – if sales exceed expectations, they won’t miss out, and if not, the leftover can be stored for next year. Manufacturers might keep safety inventory of critical raw materials in case of a supplier disruption. An everyday example is at gas stations: they maintain a bit more fuel than average sales indicate, to handle surge buying or late deliveries.

Closely related to safety stock is the concept of reorder points (ROP). A reorder point is the inventory level at which you should trigger a replenishment order.

The basic formula for ROP is: ROP = average demand during lead time + safety stock.

Optimizing reorder points ensures that you order at the right time so that new stock arrives just as existing stock is nearly depleted (accounting for that safety buffer). Modern inventory systems often automatically calculate and adjust reorder points based on consumption data, seasonality, and lead time changes.

In optimizing safety stock and ROP, a data-driven approach is essential. Analyze your demand variability – do sales of an item fluctuate wildly or are they stable? Also examine supply reliability – does your supplier deliver on time consistently, or are there frequent delays? High variability in either means you should carry more safety stock. You might choose different service level targets for different item categories (for example, 99% service level for A items, 95% for B, etc., meaning you’re willing to tolerate a stockout 1% or 5% of the time respectively). By tailoring safety stock to the criticality of the item and variability, you avoid a one-size-fits-all cushion that could be too large (wasting money) or too small (risking stockouts).

Bottom line: Safety stock is a vital cushion in inventory optimization. Use it strategically – not as an excuse to overstock everything, but as a targeted measure for uncertainty. Continuously refine your safety stock levels and reorder points as conditions change (new demand patterns, new suppliers, etc.). This ensures you maintain high service levels (keeping production running and customers happy) with the minimum necessary inventory.

Just-in-Time (JIT) and Lean Inventory Management

For decades, the gold standard in manufacturing inventory management has been Just-in-Time (JIT) – a system where materials and products arrive “just in time” for production or sale, rather than being stockpiled for weeks or months.

JIT, a key component of lean manufacturing, aims to minimize inventory holding costs by receiving goods only as they are needed in the production process, thereby reducing waste.

When done correctly, JIT means you’re holding virtually no excess inventory: components show up at the factory right when the assembly line needs them, and finished goods are shipped out to customers shortly after production. This dramatically cuts storage needs and carrying costs, and it exposes problems in the supply chain (like delays or quality issues) which can then be fixed for overall efficiency improvement.

Lean inventory management goes hand in hand with JIT. It’s about eliminating waste in all forms – not just excess stock, but also wasted motion, time, and effort. In inventory terms, lean thinking encourages keeping inventory levels as low as possible while still reliably meeting demand. Techniques like Kanban (a signaling system to trigger replenishment) are often used to implement JIT on the shop floor: for example, a Kanban card or electronic signal might tell a supplier or an internal warehouse to deliver a bin of parts when the current bin is almost empty.

The benefits of JIT and lean inventory are significant: lower holding costs, less capital tied up, and often improved quality and throughput (since issues are identified and resolved quickly). However, JIT is not without risks. It relies on a very dependable supply chain and accurate demand forecasts. If a key supplier is late or if demand suddenly surges beyond forecast, a pure JIT system can result in a stockout because there’s no buffer.

Many companies experienced this downside during recent global supply chain disruptions – when COVID-19 and other events struck, some found their JIT systems left them with no inventory to ride out the storm.

As a result, the industry conversation has evolved from purely “just-in-time” to a more balanced approach sometimes called “just-in-case.” In fact, about 64% of companies have pivoted from just-in-time toward just-in-case strategies, building in extra buffers of stock for critical or high-risk items. Just-in-case inventory means holding a bit more than needed as a hedge against disruptions. The current best practice is often a hybrid: continue running lean and efficient for most predictable items, but maintain safety stock or alternate sourcing for items that are prone to variability or are strategically crucial. For example, a manufacturer might keep an additional month’s supply of a critical microchip (that has a volatile supply) even if they JIT everything else, or dual-source from two suppliers to reduce risk.

Implementing Lean/JIT: If you’re looking to adopt JIT, start by strengthening relationships and communication with your suppliers. Sharing production schedules and inventory data with suppliers can help ensure they deliver exactly when needed. Internally, create a culture of quick response – if something is out of stock, the team should know immediately and address the issue. Also, ensure quality control is robust. With JIT, there’s no safety net of extra parts if a batch has defects. Lean inventory management might also involve reorganizing the warehouse for faster picking (so that small frequent restocking is feasible) and using tools like kanban cards, bins, or digital triggers to signal when to replenish an item.

Finally, keep an eye on the broader supply chain risk. Lean doesn’t mean being oblivious to risks – it means managing them smartly without blanket overstocking. Scenario planning (what if this supplier shuts down for a week? what if transport is delayed?) can help identify where you do need contingency stock. JIT remains extremely effective in stable, predictable environments and for items with steady usage. But for unpredictable times, don’t be afraid to carry a little just-in-case inventory. The goal is resilience with efficiency – a lean operation that can also absorb shocks.

SKU Rationalization and Turnover Optimization

An often-overlooked aspect of inventory optimization is managing the assortment of products itself.

SKU rationalization is the process of evaluating your stock-keeping units (SKUs) to determine which ones are genuinely contributing to the business and which are not. Over time, product lines tend to expand – new variants are introduced, old ones linger, custom items pile up – and you could end up with too many SKUs that complicate inventory management and increase costs. Every SKU carries overhead: forecasting, purchasing, storing, tracking, etc. If certain products sell rarely or have razor-thin margins, they may be candidates for discontinuation to streamline operations.

In manufacturing and warehousing, SKU rationalization often involves analyzing sales data and profitability for each item. For example, a manufacturer might find that out of 1,000 different parts they keep, a few hundred haven’t been used in over a year. Those could be obsolete or slow-moving items that are occupying shelf space and capital. By cutting those SKUs (or sourcing them on-demand instead of stocking), the company can reduce carrying costs and complexity. Too many products can actually hinder effective inventory management, as it spreads management attention and forecasting effort too thin.

Another angle is to look at inventory turnover for each SKU – how many times per year (or period) the stock of that item is sold/used and replenished. Low turnover items might indicate either low demand or overstocking. High turnover is generally positive (indicates efficient use of stock), but if it’s too high it could signal frequent stockouts if not managed well.

Optimizing turnover means aiming for a healthy rate where inventory isn’t sitting for too long (which would incur holding costs and risk obsolescence), but also isn’t turning so fast that you’re constantly expediting orders.

Industry benchmarks can help; for instance, a turnover ratio of 8 might be healthy in one industry, whereas in another, 2 is the norm due to longer production cycles.

Practical steps for SKU optimization: perform regular reviews of your catalog. Identify dead stock (items that haven’t sold in X months) and decide whether to discontinue them, or run a promotion to clear them out. Use the 80/20 rule – typically 20% of products generate 80% of sales. Ensure that long-tail items are truly needed for strategic reasons (like completing a product range or fulfilling niche but profitable demand). Work with sales/marketing to prevent the proliferation of nearly identical SKUs that add complexity without much benefit.

By rationalizing SKUs, companies often see immediate benefits: inventory levels drop (as you’re no longer replenishing items that don’t move), carrying costs fall, and management focus can be concentrated on the products that drive the business.

It’s also worth coordinating SKU rationalization with suppliers and customers. If you decide to drop a SKU that a particular customer always buys, have a conversation and perhaps offer an alternative. If a supplier has large minimum order quantities for a slow-moving SKU, that might be inflating your inventory – negotiate smaller batches or consider dropping it. Rationalization is as much a business strategy as an operational one. The end goal is a leaner, more profitable inventory portfolio that supports your service goals without excess baggage.

Inventory Tracking and Automation

Optimizing inventory involves more than determining how much to stock. It also includes knowing precisely where items are and how they move in real time. Inventory tracking and automation technologies, notably barcoding and RFID, offer businesses significant enhancements in accuracy and operational efficiency.

Barcoding

Barcoding is fundamental in modern warehouses. Every product or pallet receives a barcode or QR code, allowing employees equipped with scanners or mobile devices to efficiently manage receiving, picking, and shipping. This straightforward technology significantly reduces human error associated with manual data entry. Rather than manually recording picked quantities—which can lead to mistakes or illegible entries—scanning barcodes immediately updates inventory records. Barcoding ensures continuous, accurate tracking of stock levels, providing a real-time view of inventory movements.

RFID (Radio Frequency Identification)

RFID technology elevates inventory tracking by enabling wireless, non-line-of-sight scanning of tagged items. RFID tags attached to products or bins can be automatically scanned by strategically placed antennas as goods move through entryways or loading docks. This automation dramatically accelerates tasks such as physical inventory counts, allowing warehouse personnel to quickly and accurately record inventory by merely walking through storage areas with an RFID reader. Additionally, RFID systems can provide real-time location tracking of high-value assets, significantly improving asset visibility within a facility.

Inventory Automation

Inventory automation utilizes software and technologies to perform repetitive inventory management tasks with minimal human intervention. Examples include automated reordering of products upon reaching predefined reorder points and algorithm-driven allocation of inventory to fulfill orders optimally. Automation also encompasses materials handling equipment, such as Automated Storage and Retrieval Systems (AS/RS) and conveyor systems, which automatically manage the flow and sorting of goods, directly impacting efficient inventory management.

Benefits of Inventory Tracking and Automation

Inventory tracking and automation deliver substantial benefits:

- Real-time visibility into inventory movements

- Significant reduction in manual errors

- Enhanced decision-making capability through immediate access to accurate inventory data

- Improved demand forecasting and inventory optimization driven by reliable, real-time data

Implementing barcode and RFID systems frequently elevates inventory accuracy to above 99%, practically eliminating discrepancies between system records and actual counts. This precision enables higher-level inventory optimization methods, as accurate tracking forms the foundation of effective inventory management.

To begin integrating these technologies, first ensure comprehensive barcoding of every SKU and location, coupled with thorough employee training on scanning practices. Achieving this foundational step can considerably enhance accuracy. Next, assess whether RFID technology aligns with your operational needs, particularly for managing high-value items or when rapid processing of numerous items through a single area is essential. Although RFID involves a higher initial investment compared to barcodes, decreasing tag costs have made it increasingly viable for many applications.

Cloud-Based Inventory Management Systems

The era of on-premise inventory systems and siloed spreadsheets is rapidly giving way to cloud-based inventory management systems. In a nutshell, a cloud inventory system means your inventory data and software live online (on secure servers), accessible through a web browser or mobile app from anywhere, rather than being tied to a specific computer or local server. This shift to the cloud brings a host of advantages for inventory optimization in manufacturing and warehousing.

Real-time, anywhere access is the most immediate benefit. With a cloud platform, all stakeholders – whether on the warehouse floor, at a corporate office, or in a field location – see the same up-to-date inventory information. For instance, a plant manager in one country can check the stock levels of a component at a distribution center across the world instantly. Sales teams can see what’s in stock before making promises to customers. Because data is centralized and updated in real time, it eliminates the version-control nightmare of spreadsheets and ensures everyone is on the same page.

Cloud systems also tend to integrate easier with other systems and scales. Need to connect your inventory to an e-commerce platform or an accounting system? Cloud software often provides APIs or built-in integrations to do that. And if you open a new warehouse or expand to new locations, you simply add new users or modules to the same cloud system – no need to install new servers at each site. The scalability and flexibility are much greater than legacy systems.

Another benefit is reduced IT overhead. The software provider manages the infrastructure, security updates, backups, and upgrades. This is especially helpful for mid-sized companies that may not have a large IT team. You always have the latest features without a big project to upgrade your software. Cloud inventory systems also usually come with modern user interfaces (since they’re accessed via web/app), which can be more intuitive and easier to train people on, compared to older green-screen or desktop applications.

From an optimization standpoint, a cloud-based system enables some advanced practices. Multi-location tracking is naturally handled, since the system is online – you can map and manage inventory across various warehouses, production sites, or even consigned stock at vendor locations in one unified view. It also opens up possibilities like analytics and dashboards that aggregate data globally. For example, you can easily get an overview of your total inventory across the network, identify where excess is sitting, and perhaps make transfers instead of new purchases. If one warehouse is overstocked and another understocked, a cloud system makes that visible (where older systems might have been isolated per site).

Cloud = Collaboration. Consider a warehousing scenario: A purchasing manager notices a raw material is running low in the main warehouse – they can quickly check the cloud system and see that a secondary warehouse has surplus of that material, then coordinate a transfer rather than ordering new. Or in manufacturing, a production planner can see the real-time inventory of parts as the assembly line consumes them, even if they’re working remotely, allowing them to adjust schedules immediately if a shortage is looming. This kind of cross-team collaboration is fueled by having a single source of truth accessible from anywhere.

Moreover, cloud-based inventory systems often support mobile use – employees can update inventory via tablets or smartphones on the warehouse floor, doing cycle counts or receiving goods without having to go back to a desk. This boosts efficiency and immediacy of data capture.

Security is sometimes a concern raised about cloud systems, but reputable providers typically offer robust security measures (encryption, regular backups, etc.) that often exceed what a small company could implement on their own in an on-prem system. Data on the cloud is also less vulnerable to local disasters (like a fire or hardware failure in your server room – scenarios that could be catastrophic for local inventory data).

Warehouse Mapping and Inventory Visibility

If you walk into a well-organized warehouse, you’ll often see large signs indicating aisles, bin numbers, and sections of the facility. Workers have maps in their heads of where each product category is stored. Now, imagine taking that physical map of your warehouse and digitizing it – making an interactive map that mirrors your operation in software. That’s the idea behind warehouse mapping software and visual inventory systems. These tools allow you to visualize your warehouse layout and see inventory levels represented within that layout in real time.

With warehouse mapping, every location – from whole warehouses down to individual shelves or bins – can be represented on a digital map. For example, on your screen you might see a floorplan of the warehouse with sections for Receiving, Bulk Storage, Pick Zones, Shipping, etc. Drilling in, you could click a particular aisle and see the racks and what’s on them. The system might show that Aisle 5, Bin B3 contains 50 units of Product X. If Product X is running low, that bin might be highlighted in a color (say red) on the map. Essentially, it turns rows in a spreadsheet into dots on a map.

The benefit of this visual approach is instant clarity and spatial awareness. Humans process images faster than text; seeing your inventory spread on a map answers questions like “where is item Y stored?” or “how much space do we have left in Zone A?” much faster than scanning a stock report. It’s especially useful in large warehouses or manufacturing facilities where items are distributed across multiple areas or buildings. New employees can learn the layout quicker with a digital map that labels every zone. And managers can identify bottlenecks or inefficiencies – for example, noticing that fast-moving goods are stored in a far corner, suggesting they should be relocated closer to the shipping bay to speed up picking.

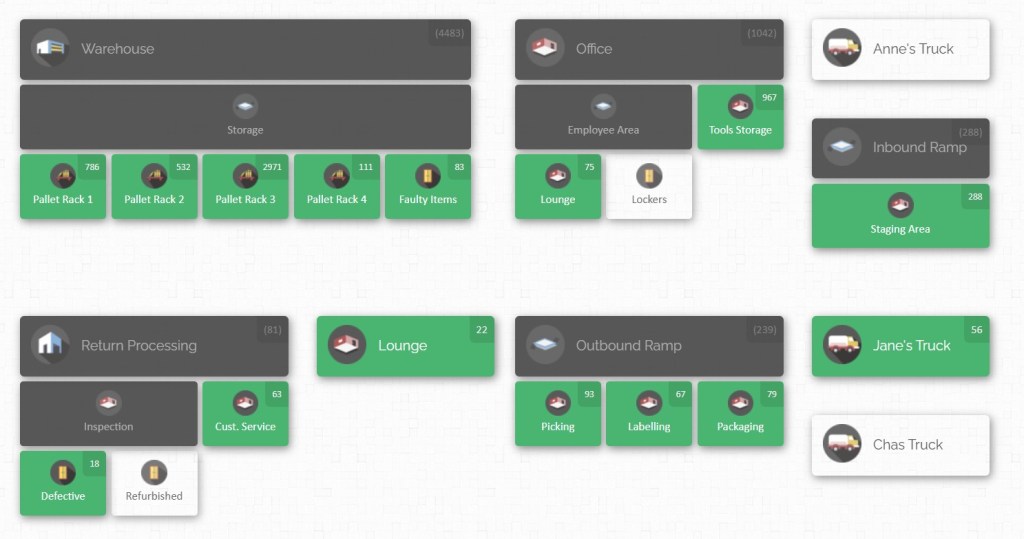

Inventory visibility dramatically improves with mapping. Instead of just knowing how many of an item you have, you also know where it is. This is crucial when optimizing operations. If an urgent order comes in, you can quickly pinpoint the nearest stock of that item for fulfillment. Or if you need to consolidate inventory from multiple small stockrooms, a map will show you all locations at once. CyberStockroom, for instance, is a tool that lets you build a live, interactive map of your entire operation – from bins to buildings – putting every location and product at your fingertip.

Another use of warehouse mapping is in space optimization and slotting. By visualizing the warehouse, you can plan arrangements that minimize travel distance for pickers (often, placing top sellers closer to packing stations), and ensure optimal space utilization. Sometimes certain areas might be underutilized; a map view can reveal blank spots or conversely congested areas. Rearranging layout is easier when you can drag and drop location representations on a screen (as some software allows), essentially performing a virtual re-slotting before physically moving goods. This reduces trial and error in reorganizing a warehouse layout.

Visual systems also help with multi-site operations. You might have a map for each warehouse, and a top-level map or dashboard that shows all warehouses as n odes. With one click, you dive into a specific site’s layout. This hierarchical mapping is valuable for a company with, say, regional distribution centers – each can be mapped internally, and centrally you oversee inventory distribution across the network.

Critically, mapping isn’t just for show – it ties directly into inventory data. A powerful mapping system updates in real time. If 100 units are moved from Warehouse A to Warehouse B, you’d see them “move” on the map or at least see counts decrement/increment in the respective locations. This real-time aspect means your map is not static; it’s a living dashboard. According to CyberStockroom, such visual mapping gives unmatched clarity and control, allowing you to instantly know where everything is and how it’s moving.

Studies and user experiences have shown that visualizing inventory reduces errors and improves efficiency. One source notes that by visualizing the warehouse and inventory levels, you can quickly identify discrepancies and streamline operations, leading to cost savings and increased productivity. For example, if a location on the map shows inventory where it shouldn’t (say an item in the wrong bin), it stands out more obviously than it might in a text list. This can prompt corrective action (like moving it to the right place) that prevents future picking errors.

To implement warehouse mapping, you typically need a software that supports making a digital replica of your layout. It may allow you to upload a floor plan or drag-and-drop elements (rooms, shelves, containers) to construct the map. Then you link inventory items or SKUs to those locations. It can be a bit of work initially to set up, but once done, the payoff is continuous situational awareness of your inventory. Staff can use the map to navigate the warehouse (“I need to pick item A from here”), and managers can use it to monitor operations at a glance.

Preventing Shrinkage and Theft (Inventory Loss Prevention)

Inventory optimization isn’t only about managing stock levels for efficiency – it’s also about protecting that inventory from losses. Inventory shrinkage refers to the loss of inventory that isn’t accounted for by sales – in other words, the recorded inventory on the books exceeds what’s actually on the shelves. Shrinkage can result from damage, miscounts, misplacement, or theft. In warehousing and manufacturing, the ideal shrinkage rate is zero (every piece that comes in should be accounted for), but in reality some loss occurs.

To combat shrinkage, companies implement a variety of loss prevention techniques. First and foremost is improving inventory tracking accuracy and visibility. When you have robust systems (as discussed earlier: barcodes, RFID, real-time inventory software), it becomes much easier to pinpoint discrepancies.

Another key strategy is implementing inventory control procedures. This can include regular cycle counts (continuous counting of portions of inventory) to catch errors sooner, reconciling differences promptly, and ensuring segregation of duties (the person who approves a stock adjustment isn’t the same who recorded it, for example). Many warehouses use RFID tags and management software to maintain an accurate, real-time view of stock across facilities, which has been shown to reduce shrinkage by catching discrepancies early.

Additionally, organizing the warehouse effectively – giving everything a designated location and keeping the layout orderly – helps reduce accidental loss. A messy, disorganized warehouse is an environment where items can easily be misplaced or “disappear” without notice. By assigning every product an ideal slot and maintaining order, you facilitate quick discovery of missing items and promote higher turnover of stock (so items aren’t forgotten in a corner).

Theft (internal or external) is a major cause of shrinkage that deserves special focus. In some industries like retail, theft (shoplifting and employee theft) accounts for the majority of shrinkage – over 65% of shrink in retail is due to theft, according to surveys. In manufacturing and construction, theft typically involves pilferage of materials, tools, or equipment. Job sites are particularly vulnerable: expensive tools or materials can be an attractive target, especially if left unattended. It’s estimated that in the United States, construction site theft leads to about $1 billion in losses annually – a staggering figure that underscores how prevalent the issue is.

Preventing theft requires a mix of process, culture, and technology. On the process side, strict receiving and issuing controls help – e.g., requiring signed documents for any inventory movement, performing exit checks, etc. Culturally, fostering an environment of accountability (and doing background checks on employees in sensitive positions) can mitigate internal theft. But technology gives a big assist: surveillance cameras, access-controlled storage areas, and alarm systems can deter thieves.

In practice, a combination of measures works best:

- Audit trails & permissions: Ensure your inventory system logs all changes and consider read-only access for some users (so data can’t be manipulated without authorization).

- Physical security: Lock high-value items in cages or secure areas, use cameras, and limit access to inventory areas to authorized staff.

- Regular audits: Besides cycle counting, do surprise audits on high-value or theft-prone items. Many companies will periodically audit tool cribs or electronics inventory since those tend to be theft targets.

- Theft response plan: If something is stolen, have a protocol (involving security or law enforcement if needed, reviewing camera footage, etc.) so that perpetrators know theft is taken seriously.

- Insurance: As a last resort, make sure you have insurance for theft and losses (especially for construction equipment left on sites overnight, etc.), though the goal is to never need it.

Shrinkage and theft prevention is an integral part of inventory optimization because losses effectively raise your costs and can cause stockouts (if something was stolen, you might not have enough inventory to fulfill an order, causing an unexpected shortage). By reducing shrinkage, you keep your effective inventory levels aligned with what you planned, which means your optimization calculations (safety stock, reorder points, etc.) remain valid. In short, you can’t optimize what you lose. Every percentage point of shrinkage you eliminate goes straight to the bottom line (less write-off) and improves service (since more of what you bought is actually available to use or sell).

CyberStockroom: Visual Inventory Optimization

CyberStockroom leverages visual inventory mapping to enhance management across multiple locations. Instead of traditional tables, its intuitive dashboard provides a clear view of inventory in warehouses, factory floors, or job sites, enabling quick decision-making and minimizing errors.

- Interactive Inventory Mapping: CyberStockroom’s standout feature is its customizable map interface. Users create visual representations of warehouses, storage rooms, trucks, and job sites, easily viewing item quantities and locations. This approach simplifies inventory management compared to traditional spreadsheet-based methods.

- Real-Time Cloud Accessibility: CyberStockroom operates in real-time via the cloud, offering immediate updates accessible from anywhere. Inventory transfers between locations instantly appear on the visual map, ensuring seamless multi-location management and collaboration among teams.

- Easy Transfers and Audit Trails: Inventory movements are easily recorded through drag-and-drop actions on the map, prompting quick, accurate updates. Every transaction is automatically logged, providing detailed activity histories, promoting accountability, and preventing shrinkage and theft.

- Mobile Inventory Management: CyberStockroom supports dynamic inventory management for mobile or remote locations, like trucks or job sites. Real-time visibility helps reduce theft and loss, improving coordination between central warehouses and field operations.

- User-Friendly Implementation: Designed for ease of use, CyberStockroom supports barcode integration and bulk data imports, simplifying system adoption without extensive manual input. Custom fields and images further enhance identification and tracking.

- Optimizing Inventory: CyberStockroom improves inventory visibility, aids demand planning, supports lean practices, and helps prevent shrinkage through clear accountability. Its centralized cloud approach ensures consistent inventory management across dispersed operations, making inventory optimization more intuitive and efficient.

Bringing It All Together

Inventory optimization for manufacturing and warehousing is a multifaceted journey. It involves getting the right processes in place (like accurate forecasting, lean inventory practices, and segmentation strategies) and augmenting them with the right tools (from barcodes and RFID to cloud platforms and visual maps). The payoff for doing this is substantial: lower operational costs, higher fulfilment rates, less waste, and more agile responses to market changes. In an environment where supply chain disruptions and shifting demand patterns have become the norm, the companies that excel in inventory optimization gain a clear competitive advantage.

A few closing thoughts for the operations managers and supply chain professionals embarking on this journey:

- Stay data-driven: Let data guide your decisions on how much to stock and when to reorder. Continuously monitor key metrics like turnover rates, stockout frequency, and carrying cost percentage. Modern analytics (even AI and predictive models) can uncover patterns you might miss – for example, subtle seasonality or correlations in demand. Embracing these advanced techniques can further fine-tune your inventory levels across the network.

- Enhance visibility: Aim for end-to-end inventory visibility. Whether you achieve it through a single integrated system or a combination of systems, ensure you’re not operating in silos. A transparent view from suppliers to the warehouse to the end customer order is ideal. The visual mapping approach is one powerful way to achieve this clarity, but even if you use traditional dashboards, make sure you have a “single source of truth” for inventory data accessible to all stakeholders.

- Balance efficiency and resilience: The lesson from recent years is that lean inventory must be balanced with buffers for resilience. Optimize, but don’t optimize to the point of brittleness. It’s okay – even smart – to hold a bit of just-in-case stock for critical items or to maintain dual sourcing. Inventory optimization is about overall value, not just minimization. The goal is to meet demand at lowest cost while managing risk.

- Continuous improvement: Treat inventory optimization as an ongoing process, not a one-time project. Regularly revisit your parameters (forecasts, safety stock levels, ABC categories) and adjust as business conditions change. Encourage a culture of asking “why do we stock this item this way?” so that complacency doesn’t lead to build-up of excess or blind spots. Tools like CyberStockroom can provide the visibility, but it’s up to the team to act on what the data and map are telling them.

In conclusion, mastering inventory optimization techniques is both an art and a science. By combining technical insights (analytics, systems, formulas) with practical know-how (experience of what works on the warehouse floor and production line), you can create an inventory management approach that drives efficiency and supports your business strategy. As you implement the techniques outlined – from forecasting to theft prevention – involve your entire team in the transformation. When everyone from the warehouse picker to the CFO understands the importance of optimal inventory and has the tools to manage it, inventory management becomes a source of strength rather than a headache.

In the fast-paced world of manufacturing and warehousing, the companies that will thrive are those that can deliver the right product at the right place, at the right time, consistently and cost-effectively. Optimizing your inventory is a cornerstone to achieving that. With modern techniques and technologies at your disposal, now is the time to elevate your inventory game and turn it into a true competitive advantage for your organization.

Leave a comment