Industrial construction and manufacturing share a common goal: maximize efficiency and minimize cost. In these industries, materials, parts, and equipment are the lifeblood of projects – and managing them effectively can make or break the bottom line. This is where cloud-based inventory management comes into play. Adopting a cloud inventory system isn’t just a technological upgrade; it’s a strategic investment.

What does “ROI of cloud inventory” mean in practical terms?

It means quantifying the benefits (like reduced costs and increased productivity) that a cloud inventory management system delivers, relative to its cost. Project-driven industries now demand transactional outcomes – tangible improvements that justify technology investments.

Understanding Cloud Inventory ROI

ROI (Return on Investment) is a simple formula: gains from an investment minus the cost of the investment, divided by that cost, usually expressed as a percentage. In the context of cloud inventory systems, ROI encompasses all the ways these tools contribute value, from direct cost reductions to indirect improvements in operations.

Traditional inventory management, often relying on spreadsheets or on-premise software, can be fraught with inefficiencies, hidden costs, and data silos. Cloud-based inventory management offers a modern alternative that addresses these pain points.

Why focus on cloud solutions? Studies have shown that cloud technology deployments deliver significantly higher ROI compared to on-premises systems. This is due to lower upfront costs, faster implementation, and continuous improvements delivered via updates. In fact, many organizations see ROI figures multiple times higher with cloud-based tools because they can quickly scale and adapt without heavy IT expenses. In industrial projects, where margins are tight and delays are expensive, these ROI advantages are especially compelling.

Key ROI Drivers in cloud inventory management typically include:

- Efficiency Gains and Productivity Improvements – Automation and real-time tracking streamline workflows.

- Cost Savings and Waste Reduction – Optimized inventory levels and loss prevention reduce expenses.

- Better Decision-Making – Data visibility and analytics lead to smarter, faster choices.

- Scalability and Flexibility – Cloud systems grow with your business without large capital spend.

- Faster Deployment and Updates – Quicker go-live and continuous enhancements mean benefits (and ROI) are realized sooner.

Boosting Efficiency and Productivity with Cloud Inventory

One of the most immediate ROI boosts from cloud inventory systems comes through efficiency gains. By digitizing and automating inventory processes, industrial companies can do more with less effort and fewer errors.

- Real-Time Tracking & Automation: Cloud inventory software provides real-time updates on stock levels, movements, and usage. In practice, this means your team spends far less time doing manual data entry or searching for parts. For example, rather than walking through a warehouse to find materials or update counts on a spreadsheet, staff can scan items with mobile devices and the system updates instantly. This automation saves labor hours and frees up your team for higher-value tasks. Over the course of a project, those saved hours translate directly into lower labor costs or the ability to handle more work with the same staff – a clear ROI win.

- Elimination of Manual Errors: Manual inventory tracking is prone to mistakes – a typo in a spreadsheet or a missed entry can lead to discrepancies that take hours to reconcile. Cloud inventory systems drastically improve accuracy, often achieving inventory accuracy levels of 98-99%. By contrast, traditional methods may hover around 60-70% accuracy. Every error avoided spares the company the costs of investigating issues, expediting missing items, or halting production to address stock discrepancies. Fewer errors and stockouts mean less firefighting and smoother operations, which in turn saves money.

- Faster Inventory Operations: Common tasks like stock counts, audits, and transfers between locations become quicker with a cloud system. Many solutions support barcode scanning, RFID, and batch updates. For instance, cycle counting can be done on a rolling basis with scanners, instead of shutting down for a full manual count. One person can accomplish in hours what might have taken a whole team a full day before. These productivity improvements reduce overtime and avoid disruption. In a manufacturing plant, faster cycle counts mean production doesn’t need to pause; in construction, it means you can verify on-site materials without delaying work. The time savings gained directly contribute to ROI by lowering labor expenditure for inventory management.

- Optimized Workforce Allocation: With better visibility and planning tools, companies can optimize how they allocate personnel. If your cloud inventory system shows clear activity trends, you might discover you don’t need as many people dedicated to inventory on slower days, or you can cross-train workers to handle inventory alongside other duties. Some businesses have found they could avoid hiring extra staff or even reduce overtime hours after implementing an inventory management system, because the existing team becomes more efficient. Those savings in payroll contribute directly to ROI.

Efficiency gains from cloud inventory result in tangible cost savings. When fewer hours are spent on inventory admin and more time on productive work, the investment in a new system quickly pays for itself. Many companies see the payback period for a cloud inventory platform measured in months due to these productivity boosts.

Efficiency in Action

Imagine a construction equipment supplier that implemented cloud inventory and mobile barcode scanning. Previously, their warehouse team of 5 spent each Monday morning (4 hours) doing manual inventory counts and reconciling paperwork from the past week. That’s 20 hours a week on counting alone. After going cloud-based, cycle counts are done in real-time with scanners throughout the week, taking only 5 total hours. They save 15 hours weekly. Over a year, that’s ~780 hours saved – roughly half a year of one employee’s working time. Whether they reassign that employee to other tasks or reduce temporary labor, this efficiency gain directly improves their ROI.

Reducing Costs and Waste through Inventory Optimization

Perhaps the most compelling ROI factor is the direct cost savings that cloud inventory systems enable. Industrial projects are often large-scale and complex, which also means small inefficiencies can balloon into huge expenses.

Cloud-based inventory management attacks waste and excess costs on multiple fronts:

- Optimal Inventory Levels (Less Overstock): Construction and manufacturing firms traditionally kept “just in case” inventory buffers due to poor visibility – tying up capital in excess materials. A cloud inventory system provides accurate demand data and usage trends, allowing you to maintain optimal stock levels. Companies frequently report a 10-30% reduction in inventory holdings after implementing inventory optimization tools. For example, a manufacturing company might reduce its raw material on-hand from 90 days’ worth to 60 days without increasing stockouts, because the new system forecasts demand better. That reduction frees up cash and lowers carrying costs (like warehousing, insurance, and spoilage). Carrying inventory isn’t free – it can cost around 20% of the inventory’s value per year in storage, capital cost, and depreciation. Cutting excess stock directly boosts ROI by cutting those carrying costs. Essentially, cloud inventory helps you do away with the “dead stock” that sits on shelves eating into your budget.

- Reduced Stockouts and Downtime: On the flip side of overstock, running out of critical materials or parts (stockouts) can be equally costly – causing project delays or halted production lines. Cloud inventory systems send alerts for low stock levels, automatically trigger reorders, or allow you to quickly redistribute items from another location. The result is far fewer stockouts. In construction, this means avoiding expensive crew idle time waiting for materials or last-minute rush orders from suppliers. In manufacturing, it prevents line stoppages that can cost thousands of dollars per hour. By preventing downtime, companies save money and protect revenue (finishing projects on time, fulfilling customer orders on schedule). Some businesses have seen inventory availability (having the right item when needed) improve so much that lost sales or delay costs drop by 50% or more. The ROI from preventing one major project delay or one day of factory downtime can justify the inventory system investment on its own.

- Lower Procurement and Expediting Costs: Better inventory visibility enables more strategic procurement. When you know exactly what is in stock across all sites, you can avoid over-ordering items you already have and consolidate purchases of items you truly need. Bulk ordering and longer lead-time purchasing (instead of emergency buys) typically result in lower unit prices. Moreover, fewer last-minute orders mean you’re not paying rush shipping fees or premium prices to get something at the eleventh hour. Over time, these smarter purchasing practices – enabled by accurate inventory data – can shave a significant percentage off your materials cost. For example, a construction firm using cloud inventory might realize that Site A has surplus pipes that Site B needs next week; they transfer internally instead of buying new, saving the purchase cost. Or a factory might see that a particular component is used by two separate product lines and coordinate a single large order with a volume discount. These cost savings drop straight to the bottom line, improving ROI.

- Waste and Scrap Reduction: In industries like construction, it’s common to factor in a certain percentage of materials as waste (cut-offs, breakage, surplus) and even theft. Without good tracking, leftover materials from one project might never be reused, or might spoil because no one realized they were available. A cloud inventory system brings visibility to all materials, including leftovers and off-cuts, so they can be returned to stock and allocated to future jobs instead of thrown out. Moreover, improved oversight tends to reduce wasteful practices – when crews know materials are being tracked, they handle them more carefully and plan usage more efficiently. Even a 5-10% reduction in material waste can equate to huge cost savings in a large project. For instance, if a $5 million construction project budgets 10% ($500k) for waste, cutting that to 5% saves $250k. That alone can exceed the cost of an inventory system subscription for the year.

- Shrinkage and Theft Prevention: Sadly, theft and loss are perennial problems on job sites and in warehouses. Construction sites experience high rates of equipment and material theft – estimates in the U.S. run in the hundreds of millions of dollars lost annually. Cloud inventory platforms combat this by providing detailed tracking and accountability. Every movement of stock can be logged by user and location; for example, CyberStockroom and similar systems keep a history of who moved or used an item and when. This level of transparency acts as a deterrent to internal theft and makes it far easier to pinpoint losses when they occur. Some companies have reported cutting shrinkage by 50% or more after implementing stricter inventory control – and some virtually eliminate it. When a tool or material goes missing, you can quickly see the last known location and user, which often leads to recovery or at least prevents repeat incidents. The financial impact is clear: if you were losing $100,000 a year in unaccounted inventory and you reduce that to near-zero, that $100k now stays in your profits, greatly improving ROI.

- Lower Storage and Logistics Costs: Optimizing inventory also means you may need less storage space or can delay expansion of warehouse facilities. If you consistently reduce excess stock, you free up warehouse racks and yards. This could allow a company to rent a smaller storage facility or avoid building new storage as the business grows. Additionally, efficient inventory means fewer shipments (consolidated orders, less emergency transport), which cuts down on freight and handling costs. These savings can be subtle but add up over time – all contributing to the ROI of a cloud inventory solution.

Cost Savings Snapshot – Potential Improvements

To visualize the impact, here’s a snapshot of potential improvements industrial companies see with modern inventory management:

| Aspect | Improvement with Cloud Inventory | ROI Impact |

|---|---|---|

| Inventory Levels | 15–30% reduction in average stock on hand | Lower carrying costs; frees up working capital for other uses. |

| Stockouts & Downtime | Major decrease in stockouts (near 0 for critical items) | Avoids project delays and lost production, protecting revenue. |

| Inventory Accuracy | Increase to ~99% (from ~70% manual) | Fewer errors to fix; trust in data for planning (saves time & money). |

| Shrinkage (Loss/Theft) | 50–80% reduction (often near-elimination) | Recovers value previously lost to theft or misplacement. |

| Labor Efficiency | 20–40% less time on inventory tasks | Labor cost savings; staff focus on higher-value activities. |

| Purchasing Costs | 5–10% savings through better procurement | Lower unit costs and rush fees; improves profit margins on projects. |

*Each company’s results will vary, but the trends are clear: cloud inventory systems systematically drive down costs and waste, converting those savings into a strong financial return.

Improving Decision-Making with Real-Time Data

In fast-paced industrial environments, information is power. Another often underestimated contributor to ROI is how cloud inventory platforms improve decision-making at all levels of the organization. Better decisions lead to actions that save money, avoid pitfalls, and capitalize on opportunities.

Here’s how cloud-based inventory management sharpens decision-making and boosts ROI:

Organization-Wide Visibility

Cloud inventory systems provide a centralized view of all inventory, accessible to everyone with the right permissions. Executives can see what’s available across all sites, and managers can track raw materials in real time. This helps teams avoid duplicate purchases and make smarter decisions—like checking for surplus items before ordering more. By sharing accurate inventory data across departments, companies spend less and use resources more efficiently, boosting ROI.

Faster Response and Adaptability

With real-time updates, cloud systems let managers act fast. If materials run low or defects are detected, teams can respond immediately—no need to wait for weekly reports. For example, procurement can reorder supplies before work stops, or defective items can be isolated quickly to avoid production issues. This quick decision-making reduces delays and waste, helping projects stay on time and within budget, improving ROI.

Data-Driven Planning

Cloud platforms track trends over time—like seasonal demand or supplier performance. This data helps teams forecast better and plan smarter. For example, noticing a spike in Q3 demand allows early stocking at lower prices. Or identifying frequently unused components can cut waste. With insights like these, companies can refine their purchasing and inventory strategies, saving money and improving long-term profitability.

Enhanced Collaboration and Accountability

When everyone—from field teams to executives—sees the same inventory data, it encourages teamwork and responsibility. Procurement and project managers can align better on purchases. Team members are more engaged when they know their usage is tracked. This visibility reduces errors and inspires improvement ideas. In the long run, better teamwork and ownership lead to cost savings and more efficient operations—further increasing ROI.

Strategic Capital Allocation

For executives, having a clear picture of inventory across the organization supports smarter, high-level decisions. When you know how much capital is tied up in stock, you can reduce it and redirect funds where they’ll make a bigger impact. That might mean selling off slow-moving items, returning extras to suppliers, or investing in team training to fix process issues. For example, freeing up $500K from excess inventory could fund new equipment that boosts production and revenue. In short, better inventory visibility helps unlock capital and create new growth opportunities—directly enhancing ROI.

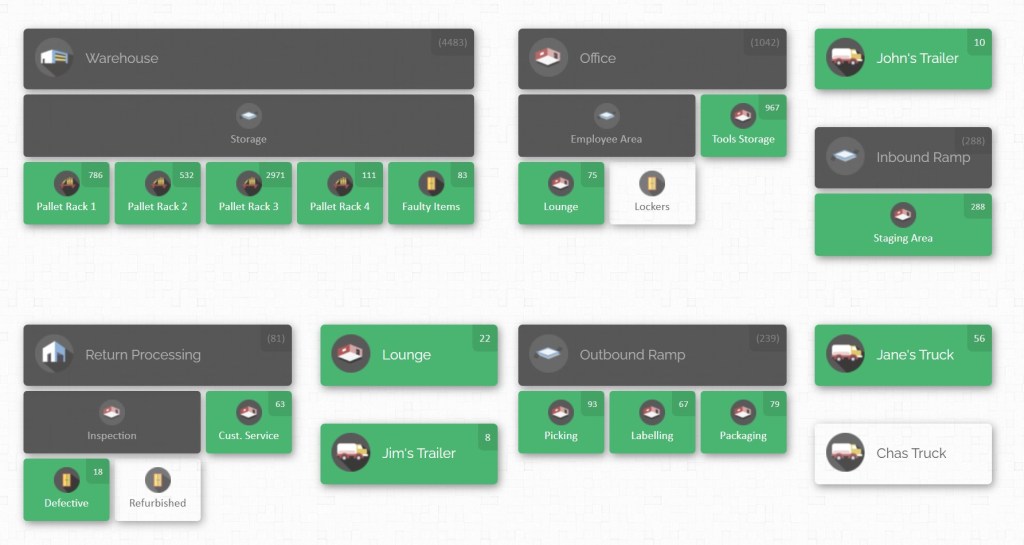

CyberStockroom: A Cloud Inventory Platform for Maximizing ROI

CyberStockroom deserves a spotlight as a cloud inventory platform particularly well-suited to industrial projects aiming for high ROI. As a leading solution under the Technology & Tools umbrella, CyberStockroom combines powerful inventory management features with ease of use – enabling companies to realize benefits quickly.

Let’s explore CyberStockroom’s capabilities, and how each can contribute to ROI in construction and manufacturing settings:

| Feature | What It Does | How It Supports ROI |

|---|---|---|

| Visual Inventory Mapping | Lets you create map-based views of all locations (warehouses, sites, trucks, etc.). | Quickly shows where everything is, improves coordination, avoids over-ordering or stockouts. |

| Real-Time Tracking & Accessibility | Cloud-based platform available via web or mobile. | Enables fast decisions from anywhere and reduces IT costs (no servers or updates needed). |

| User-Friendly Interface | Easy for non-technical users to learn and use (drag-and-drop, visual tools). | High adoption leads to quicker benefits, less training time, and more accurate data. |

| Customization & Flexibility | Supports custom fields, labels, and scalable structure. | Fits unique workflows, avoids workarounds, and grows with your business while controlling cost. |

| Drag-and-Drop & X-Ray Vision | Move inventory with simple drag-and-drop; click to see item location across all sites. | Saves time locating/moving items, reduces delays, and cuts down on wasted labor. |

| Robust Reporting & Audit Trails | Provides full logs and reporting for tracking inventory history and activity. | Helps detect issues early, prevent loss, and show measurable improvements in performance. |

CyberStockroom brings together all the ingredients needed to maximize the ROI of inventory management in industrial settings: real-time visibility, ease of use, comprehensive control, and adaptability. Whether you’re managing the constant flow of materials in a construction project or balancing supply and demand in manufacturing, the platform is designed to drive efficiency and cost-effectiveness. It’s a tool that not only manages inventory but also provides insights and control that directly translate into savings and improvements.

Why CyberStockroom for Industrial Projects?

Industrial projects are complex, and executives need solutions that deliver tangible value. CyberStockroom’s focus on visual clarity and intuitive control makes it easier to implement across project teams. The faster you implement and the more people use it correctly, the faster you see ROI. And because it’s cloud-based with straightforward pricing (including options to try it free), you don’t face large upfront costs – you can start small, see the benefits, and scale up, which is a low-risk approach to achieving ROI.

Best Practices to Maximize ROI from Cloud Inventory Systems

Whether in construction, manufacturing, or any other sector, getting the most ROI from a cloud inventory system also depends on how you implement and use it. The technology is a tool – powerful, but only as effective as the processes around it. Here are some universal best practices to ensure you truly capitalize on your cloud inventory investment:

- Secure Leadership Buy-In and Set Clear Goals: Before implementation, align with executives and project leaders on what ROI means for this project. Is it reducing inventory costs by 20% in a year? Cutting project delays related to materials to zero? Define key performance indicators (KPIs) such as inventory turnover rate, carrying cost reduction, stockout frequency, etc. Having clear goals and leadership support will drive adoption and proper resource allocation. It also sets a baseline to measure success post-implementation.

- Thorough Training and Change Management: Investing in training for all users is critical. Even the best system provides ROI only if people use it correctly and consistently. Host training sessions, create easy reference guides, and utilize any vendor-provided tutorials (for example, CyberStockroom offers video tutorials and personalized onboarding). Make sure each role understands how the system makes their job easier – field staff should see it as a help, not a burden. By nurturing a culture that values accurate inventory data entry and usage, you’ll maintain data integrity and see the full efficiency benefits. A well-trained team will spot errors or opportunities in the system you might otherwise miss.

- Customize the System to Fit Your Workflow: Don’t hesitate to customize fields, categories, and processes in the software to mirror your real operations. If your projects are budgeted by phases or cost codes, set those up in the system so you can track inventory by those categories. If certain alerts would help (like “Notify if any item’s stock falls below 2 days’ usage”), configure them. A system like CyberStockroom provides flexibility for this. Tailoring the platform ensures it provides information in the context that your teams need to make decisions. This maximizes its usefulness and hence the ROI – a system that fits like a glove will naturally be used more and yield more insights.

- Integrate with Other Systems: Greater ROI can often be unlocked by integrating inventory data with other key systems such as your ERP, project management software, accounting system, or procurement platforms. Integration means less duplicate data entry and a more cohesive flow of information. For example, if your inventory system sends purchase requirements directly to a procurement system or generates accounting entries for inventory value, you save manual effort and reduce errors. While integration might require an upfront effort, the payoff is continuous efficiency. It also gives management a end-to-end view: from purchase, to inventory, to production, to costs, all linked. Many cloud inventory solutions offer APIs or built-in integrations; utilize them to streamline your tech stack and amplify ROI.

- Regularly Review Metrics and Adjust: Once the system is in place, make it a practice to review performance metrics at regular intervals (monthly, quarterly). Look at how inventory turnover is improving, how much stock levels have changed, and calculate the realized savings so far. Use the data to identify further optimizations – maybe you can lower safety stock on certain items because the system has proven reliable, or perhaps you notice one project is not using the system fully (and address that gap). Continuous improvement is key. By actively managing and tweaking how you use the tool, you’ll find new ways to save money or time. It’s also motivating for the team to see the progress: e.g., “we’ve saved $X in the last 6 months by using our inventory system effectively.” Celebrate those wins and push for even more. Essentially, treat the ROI calculation as ongoing, not a one-time justification.

- Leverage Supplier and Customer Collaboration Features: Many cloud inventory systems allow you to create portals or share data externally in a controlled manner. If applicable, let your suppliers have visibility into your relevant inventory levels (especially for vendor-managed inventory arrangements) or use the system to manage customer-owned inventory. These collaborative approaches can offload some inventory ownership (suppliers might hold stock for you and replenish as you use it) or increase customer satisfaction (by always having critical spares on hand, for instance). They can dramatically improve ROI by reducing your working capital needs and improving service levels, but they require trust and communication. Your cloud platform can be the backbone of that trust by providing transparency.

- Backup Plans and Data Security: While cloud systems are generally very reliable, part of maximizing ROI is also minimizing risk. Ensure your provider has solid data backup, security, and uptime practices (most do). Internally, have a small contingency process for critical operations if the system were ever temporarily unavailable (e.g., a way to log transactions and update later). This way, you never have to halt operations. Knowing that operations won’t be disrupted helps maintain the savings and efficiency you’ve gained – protecting the ROI you’ve built.

Turning Inventory Management into a Profit Center

Inventory management was once seen as a basic cost of doing business in construction and manufacturing. Today, with the rise of cloud-based systems, it has become a powerful tool for improving efficiency and profitability. These platforms help reduce delays, prevent waste, and support smarter, faster decision-making. As a result, companies are saving money and completing projects more smoothly.

Tools like CyberStockroom show how technology can simplify complex operations while delivering real value. Businesses that adopt cloud inventory are seeing measurable improvements. These include lower inventory levels, fewer lost items, faster coordination among teams, and better overall performance.

For managers and executives, the question is shifting. Instead of asking whether they can afford to invest in cloud inventory, many are asking whether they can afford not to. In fast-paced and competitive industries, improving operations through technology is not just helpful—it is essential.

Bottom line: Cloud inventory turns a routine task into a strategic advantage. Companies that embrace this shift are reducing costs, improving workflow, and increasing profit margins across their projects.

Leave a comment