Adopting agile inventory strategies like just-in-time (JIT) inventory management can keep factories responsive and efficient.

In 2025, manufacturers face both exciting technology-driven opportunities and serious supply chain challenges. The classic lean manufacturing principles of JIT – reducing waste and holding minimal stock – are still vital. However, recent events like the pandemic, trade disruptions, and geopolitical shifts have forced firms to rethink how they balance efficiency with resilience.

Understanding Just-In-Time Inventory Manufacturing

Just-In-Time (JIT) inventory manufacturing is a lean production strategy designed to match raw material orders with the exact needs of the production schedule. In practice, manufacturers using JIT keep low on-hand inventory and receive supplies “just in time” for use on the factory floor.

This approach reduces carrying costs and waste, allowing capital to remain in play until needed. JIT was famously pioneered by the Toyota Production System in the mid-20th century and has since influenced industries worldwide. The core idea is simple: only produce what customers demand, when they demand it, and in the quantities required.

Key principles of JIT include:

- Demand-Driven Production: Manufacturing schedules are closely aligned with actual customer orders or market demand forecasts, rather than producing large batches in advance.

- Inventory as Waste: Excess stock is seen as waste in lean philosophy. By minimizing buffers, manufacturers aim to cut storage costs and prevent overproduction.

- Kanban and Pull Systems: Many JIT operations use Kanban cards or signals to trigger replenishment. When a bin or line is almost empty, a Kanban card signals the next batch is needed. This “pull” system replaces push-based, forecast-driven stocking.

- Supplier Integration: JIT relies on close coordination with suppliers. Manufacturers often share forecasts or commit to frequent deliveries so suppliers can plan production just in time as well.

- Continuous Improvement: Also known as kaizen, JIT manufacturing emphasizes ongoing process refinement. Teams regularly analyze the workflow to eliminate delays, defects, and bottlenecks.

In today’s manufacturing jargon, you’ll often see JIT inventory management referred to as lean manufacturing, lean inventory strategy, or just-in-time manufacturing. These terms all emphasize efficiency and waste reduction.

Why JIT Works: When JIT is executed well, companies unlock numerous benefits: lower warehousing costs, faster cash flow, higher product quality, and more flexible production. By avoiding excess stock, cash can be invested in technology or expansion instead. For example, a carmaker using JIT might receive smaller weekly shipments of parts rather than keeping a year’s worth of components on the shelf. This means fewer idle parts if design changes occur, and less capital tied up in inventory.

Typical Sectors: JIT originated in automotive manufacturing, but it’s used in many industries today. Electronics, appliances, and aerospace companies also embrace JIT to stay nimble. Essentially, any manufacturer that can forecast reasonably well and maintain reliable supplier relationships can benefit from a just-in-time inventory system.

Benefits of Just-In-Time Inventory

Implementing JIT brings multiple advantages when supply chains are smooth and predictable. Key benefits include:

| Lower Inventory Costs | Less stock on hand means lower warehousing, insurance, and handling costs. Capital is free to invest in new projects instead of tying up in shelves full of parts. |

| Reduced Waste | JIT reduces obsolete or expired inventory. If design changes or demand drops, there’s less chance of piling up unsellable stock. This also cuts waste and contributes to sustainability goals. |

| Improved Cash Flow | By buying and storing only what’s needed, companies avoid overpaying for materials upfront. Cash flow is smoother when inventory outlays are spread over time. |

| Improved Cash Flow | By buying and storing only what’s needed, companies avoid overpaying for materials upfront. Cash flow is smoother when inventory outlays are spread over time. |

| Higher Quality and Agility | Frequent deliveries often come with more frequent quality checks. Any defect in a small batch is easier to identify and fix before it can contaminate a big production run. Also, smaller batch sizes mean manufacturers can change or update products more easily in response to customer feedback. |

| Enhanced Supplier Partnerships | JIT tends to foster tight partnerships with suppliers. This collaboration can lead to sharing of technology, joint process improvements, and faster problem-solving. |

| Streamlined Operations | Lean production lines with JIT are often better organized. Visual controls (like Kanban boards or digital dashboards) help teams see inventory status at a glance. Production flow is smoother when materials flow in sync with the line. |

Example: A furniture manufacturer using JIT might receive a daily shipment of wood panels timed to match its production schedule. If a large order comes in, the company might still be ready to ramp up assembly without a warehouse full of extra panels. If demand suddenly dips, that company isn’t left with a massive stockpile, helping it stay financially lean.

When done right, JIT turns inventory from a cost center into a finely-tuned process. Products get built faster, less is wasted, and teams stay focused on value-added tasks.

Modern Challenges to JIT

While JIT offers many upsides, the manufacturing landscape of 2025 presents new challenges. Recent years have shown that global supply chains can be unexpectedly volatile. These issues force manufacturers to rethink strict JIT practices and introduce resilience into their planning.

1. Supply Chain Disruptions: Events like the COVID-19 pandemic, natural disasters (e.g., tsunamis or hurricanes), and geopolitical conflicts have caused sudden factory shutdowns and shipment delays. A single point of failure – one key component supplier – can disrupt the entire line. In a pure JIT world, there’s little buffer if a truck or ship is late.

2. Demand Volatility: Consumer demand can swing quickly due to economic shifts or competitive actions. JIT depends on accurate forecasts; if demand suddenly spikes or crashes, inventory plans may be off. For instance, a sudden trend in electronics could lead to stockouts if manufacturers didn’t anticipate the surge.

3. Tariffs and Trade Policy: In 2025, some governments are using tariffs or trade restrictions to encourage local production. For example, the U.S. is considering higher tariffs on imports, which could affect supply costs and lead times. Manufacturers relying on just-in-time imports may find material costs unpredictable if trade policies change overnight.

4. Labor and Regulation: New labor laws, minimum wage hikes, or regulations on working hours can impact how quickly goods move. If trucks have to stop more often due to labor limits, even a well-planned JIT schedule might falter. Likewise, environmental or safety regulations can slow down production or shipping.

5. Transportation Bottlenecks: Even routine logistics can be unreliable. In 2021, a container ship blocking the Suez Canal showed how a single jam can delay thousands of containers worldwide. If your JIT model assumes fast global shipping, delays like these can leave production lines starved for parts.

Because of these factors, many manufacturers are blending JIT with more caution. The buzzword “just-in-case” (JIC) is often paired with JIT today. Instead of pure JIT, companies might keep a small safety stock of critical components. That way, if a delay occurs, they still have some buffer. The key is deciding which items need a buffer and which can stay lean.

JIT vs. JIC: A Balancing Act

The pandemic and other disruptions have taught a lesson: relying only on just-in-time can be risky. In fact, many companies temporarily abandoned strict JIT at the height of COVID shortages. Now, best practice is often to balance JIT efficiency with just-in-case resilience. For example:

- Hold extra inventory of high-value or long-lead-time items (like rare earth metals or specialized chips).

- Keep minimal stock of commodity parts (like standard screws or off-the-shelf supplies) that can be quickly reordered.

- Use multi-sourcing: find at least two suppliers for each critical part so you’re not dependent on one factory.

- Build flexible supplier contracts that allow for quick small-batch orders without penalties.

Modern JIT doesn’t mean zero inventory; it means the right inventory at the right time. The “right time” in 2025 may include a short delay to account for real-world turbulence.

Adapting JIT for 2025: Building Resilience

Manufacturers can keep the advantages of JIT while addressing volatility. Here are strategies to make JIT more robust:

- Inventory Stratification: Not all items have equal risk or value. Categorize your parts by importance and demand frequency. For example, use the ABC analysis: A-items are critical and high-value (tight control, maybe some buffer stock); B-items are moderate; C-items are low-value and high-usage (JIT fits well). Review these categories regularly as contracts change.

- Frequent Replenishment: Break orders into smaller, more frequent deliveries rather than one big shipment. This reduces the impact of any single delay and keeps stock levels adjusted to actual usage. Digital tools (like ERP systems) can automate reorder triggers.

- Supplier Collaboration: Invest in technology that gives end-to-end visibility. When suppliers see exactly what’s happening on your floor, they can schedule production more accurately. Sharing real-time demand data (even loosely via cloud dashboards) lets suppliers prepare better.

- Nearshoring and Onshoring: Reducing geographic distance shrinks lead times. Many U.S. and European companies are relocating portions of their supply chain closer to home. Even partial onshoring – say, producing half the components domestically and half abroad – can reduce risk.

- Diversified Transportation: Don’t rely on a single shipping route or mode. If possible, plan shipments via different ports or carriers. Consider rail or air freight for critical orders if ocean shipping is congested.

- Scenario Planning: Conduct “war games” or stress tests for your supply chain. What happens if a key port closes? If a supplier goes offline? Having contingency plans (alternate suppliers, emergency orders) is vital.

- Safety Stock for Critical Parts: Determine minimum buffer levels for items that would shut down production if delayed. This might be just enough for one extra day of production. The idea is not to hoard, but to hedge against the worst delays.

In practice, an automotive parts maker might use JIT for common fasteners and fittings but keep a few months’ supply of unique semiconductors. A trend noted by supply chain experts in 2025 is exactly this hybrid model.

Companies like FDH Aero (a distributor in aerospace) openly say they keep “the opposite of just in time” stock for their highest-value, hardest-to-get parts, while still applying lean principles to everything else.

The goal is a resilient JIT: one that flexes when needed but still cuts waste. That means revisiting the JIT concept with a strategic lens.

Trends Influencing JIT in 2025

Several technological and global trends are reshaping how JIT inventory systems work. Manufacturers who stay on top of these trends can make their JIT practices smarter and more reliable.

Automation and Robotics

Modern factories are becoming more automated. Robotics and smart machines can make JIT more precise:

- Warehouse Robots: Mobile robots (like the orange Amazon robots in Figure below) move goods around warehouses with speed and accuracy. They can fetch parts on demand, effectively shrinking lead times within a facility. With automated storage and retrieval systems, warehouse layouts can be more compact, aiding JIT’s lean footprint.

- Automated Assembly Lines: Robotic arms and conveyors on the production floor ensure consistent cycle times. When machines set precise rhythms, it’s easier to time deliveries of materials exactly to the line. For example, a car assembly line with synchronized robots can run smoothly only if parts arrive right on schedule – a hallmark of JIT.

- Collaborative Robots (“Cobots”): In small and medium factories, cobots assist human workers for tasks like picking or packaging. Cobots can be reprogrammed quickly and don’t require complex guarding. This flexibility lets manufacturers adapt lines for different products without long changeovers – a plus for JIT responsiveness.

- Vision and AI Inspection: Robots equipped with cameras and AI can inspect parts instantly as they arrive or are produced. Early defect detection means bad components are caught before they enter inventory, reducing delays caused by quality issues.

According to industry reports, manufacturers are aggressively investing in robotic technology. By 2025, many factories will use robots not just for heavy lifting, but for material handling and quality checks. These robots need fewer scheduled breaks than humans and can run 24/7, helping deliver materials on a JIT schedule without labor constraints.

Artificial Intelligence and Data Analytics

AI and advanced analytics are powerful enablers for JIT:

- Smart Demand Forecasting: Machine learning models can analyze vast datasets (market trends, seasonality, social media sentiment) to predict demand more accurately than traditional methods. Better forecasts mean fewer last-minute production changes. In one survey, companies using AI saw improved forecast accuracy, which directly feeds JIT scheduling.

- Real-Time Alerts and Anomaly Detection: AI systems can monitor supply chain signals (shipment data, supplier inventories, weather forecasts) and alert managers to potential disruptions. For example, if a supplier’s production falls behind, an AI dashboard can recommend increasing orders from an alternate source before the line runs dry.

- Inventory Optimization Algorithms: AI-driven tools can recommend the optimal reorder points and quantities dynamically. Instead of static rules, the system adjusts reorder triggers based on lead-time changes and demand fluctuations. This continuous optimization is a key trend in 2025.

- Predictive Maintenance: On the production side, AI predicts machine failures before they happen. If a critical machine is about to break, JIT schedules can be adjusted or stock can be drawn down preemptively. This ensures that the production schedule (which JIT depends on) doesn’t suddenly collapse.

- Digital Twins: More manufacturers are building a “digital twin” of their supply chain – a virtual model where scenarios can be simulated. By simulating demand spikes or supplier outages, companies can refine their JIT strategies. The insights from these simulations are guiding smarter JIT implementation.

In short, AI is giving companies the visibility and agility that JIT requires. Instead of relying solely on human estimates, decision-makers now have AI as a “formidable ally” to deliver real-time insights and automate routine tasksthroughput.world. Companies that harness these tools can fine-tune JIT to be faster and less prone to mistakes.

Digital Platforms and Cloud Integration

The era of cloud computing has brought new tools for inventory management:

- Cloud-Based Inventory Systems: Modern JIT relies on knowing exactly what you have and where you have it – all the time. Cloud software makes it easy to see inventory across multiple warehouses or even multiple countries in one dashboard. This single source of truth prevents the “blind spots” that used to cause JIT errors.

- Integration with Supply Chain Partners: Cloud systems make it easier to share data with suppliers and logistics providers. For instance, an integrated portal might let a supplier see your on-hand levels and upcoming demand, which helps them plan their output just as precisely.

- Visual Inventory Maps: Innovative platforms (like CyberStockroom, discussed below) offer map-based inventory views. Think of it as a Google Maps of your warehouses and bins. With a click, you can see that Item A is on Shelf 3 in Warehouse B, even if your company operates globally. This visual approach is more intuitive than old spreadsheets, and it accelerates locating parts.

- Mobile Connectivity: Warehouse workers can use tablets or smart glasses to scan barcodes and instantly update inventory in the cloud. Sensors like smart pallets or RFID tags can even auto-report when stock is picked or when shelves run low. This constant flow of data tightens up the JIT feedback loop.

- Collaboration Tools: Many cloud platforms include communication features. If one factory’s line is unexpectedly halted, it can instantly notify procurement or other plants. This helps re-route materials or orders in real time.

The bottom line: digital platforms in 2025 make JIT more manageable. Inventory software is no longer a static log; it’s an active partner, using cloud power to keep everything visible and coordinated.

Global Logistics and Manufacturing Shifts

The big picture of global trade is changing, and that affects JIT models:

- Reshoring and Nearshoring: In response to past disruptions, many companies are moving manufacturing closer to end markets. For example, 58% of UK manufacturers are reshoring their supply chains, aiming for lower risk. Shorter transport routes mean shorter lead times, which makes JIT easier. Even the US is encouraging onshoring with tariffs on Mexico/Canada/China (as of 2025 policy proposals) to bolster domestic production.

- Regional Manufacturing Networks: Within Europe, the EU is supporting “European value chains” to reduce dependency on distant source. This means components for a German factory might increasingly come from Poland or the Czech Republic instead of Asia. Regional networks strengthen JIT because logistics are less likely to break.

- Logistics Innovations: Autonomous trucks and delivery drones are emerging. A future where goods can be shipped by self-driving freight trucks or last-mile drones could shorten delivery times and reduce human error. Ports and rails are also getting smarter – for example, automated cranes and blockchain tracking speed up handoffs, cutting uncertainty.

- Strategic Stockpiling and Hubs: Some industries are creating regional distribution hubs. For instance, critical components might be pre-positioned in multiple warehouses around the world. This adds an element of just-in-case planning. In 2025, we see more hybrid warehouses: central hubs keep a cushion of high-demand parts, while local facilities operate on thinner JIT levels.

- Geopolitical Sourcing Policies: Manufacturers also must monitor global policy. For example, restrictions on imports from specific countries could force companies to identify alternate suppliers or build duplicate production lines. Keeping track of these political risks is a new part of supply planning.

In practice, if you’re a US auto plant in 2025, JIT might mean working closely with North American suppliers instead of Asia-Pacific ones. In Europe, a machinery firm might buy more from neighboring EU countries to avoid Brexit-like complications. The trend is to align JIT with more robust regional networks rather than fully globalized chains.

Sustainability and Compliance

Sustainability goals are influencing inventory strategies:

- Green Supply Chains: Manufacturers are pressed to reduce waste not just in production, but across the entire supply chain. Lean inventory (JIT) inherently cuts waste, but companies are taking it further by tracking environmental impact. For example, optimizing shipping routes or loads can reduce CO₂ even while practicing JIT.

- Circular Economy Practices: By 2025, many manufacturers are designing products with reuse in mind. JIT plays a role here too: if components are returnable or recyclable, inventory systems must track “reverse logistics” as well. Visual mapping tools help in tracing used parts that come back for remanufacturing.

- Regulatory Transparency: Laws now often require tracing the origin of materials (for ethical or safety reasons). JIT systems must capture that data on the fly. Cloud-based inventory software makes it easier to embed compliance data (like certificates or eco-labels) with each item.

- Social Responsibility: Consumers demand that even JIT partnerships meet labor and human rights standards. This adds another layer of supplier vetting. Many JIT teams now have checks to ensure a supplier’s practices are sustainable.

In summary, sustainability is becoming a criterion in JIT planning. A 2025 manufacturer can’t just think about cost and speed – they also have to consider the environmental and social footprint of their lean operations.

JIT in the US and Europe

To ground these ideas, let’s consider how manufacturers in key regions approach JIT:

United States

U.S. manufacturers have a history of using JIT (think Ford and Toyota USA). Today’s U.S. companies are mixing JIT with new policies. For example, a major appliance maker in Ohio might run its plants on a hybrid model: lean on the assembly line side, but with strategic buffer stocks of imported semiconductor chips (a scarce resource after recent shortages).

U.S. automotive firms are also partnering with suppliers to build more local chip and battery plants, enabling shorter just-in-time loops. Meanwhile, the White House’s push for tariffs and onshoring (as of late 2024 policies) means manufacturers are evaluating the cost of domestic sourcing vs. efficient JIT imports. Tech companies like Dell (an early JIT innovator) are investing in AI-driven logistics to tighten their supply chains further.

Europe

European manufacturers have long embraced lean methods, especially in Germany’s auto and machinery sectors. In 2025, many German factories still run daily supply deliveries timed to the production schedule, but they are adding digital visibility tools.

For instance, a German machine tool maker might use an intelligent ERP system that tracks parts from supplier to line in real time, mitigating JIT risk from a supplier in Eastern Europe. The COVID crisis and the war in Ukraine spurred a wave of reshoring or dual-sourcing within the EU.

French and Italian firms, often smaller-scale operations, are also using local sourcing – for example, an Italian electronics component manufacturer may double down on EU-based suppliers and lean on software platforms to balance inventory. Across the EU, compliance with regulations (like REACH for chemicals) means JIT producers build extra traceability into their systems.

Transatlantic Differences

One key difference is regulatory and policy context. European companies tend to emphasize data-driven Industry 4.0 initiatives (often supported by EU grants) to keep JIT running smoothly. U.S. firms, on the other hand, may rely more on private-sector innovation (like commercial AI startups) and face different trade incentives. That said, both regions report that agility is crucial. The common thread is that integrated digital systems (often cloud-based) are becoming as important as the physical logistics.

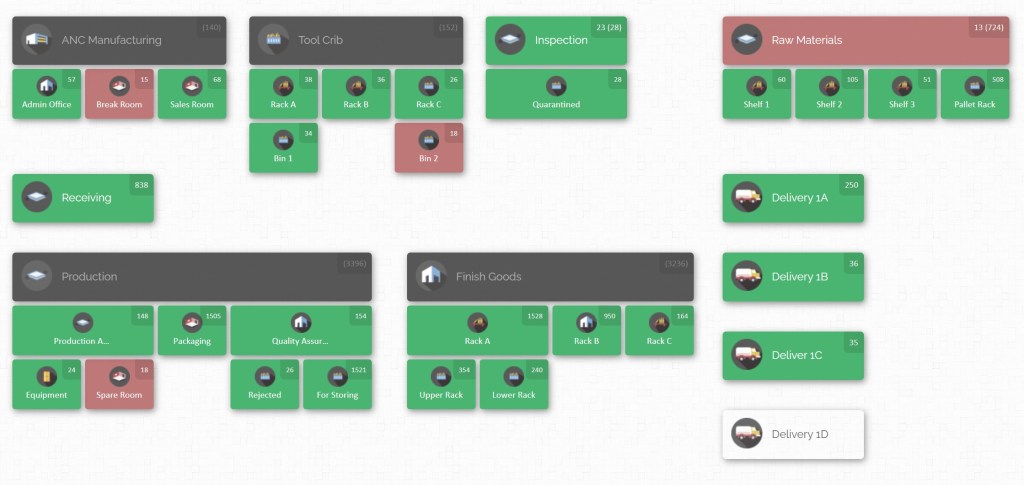

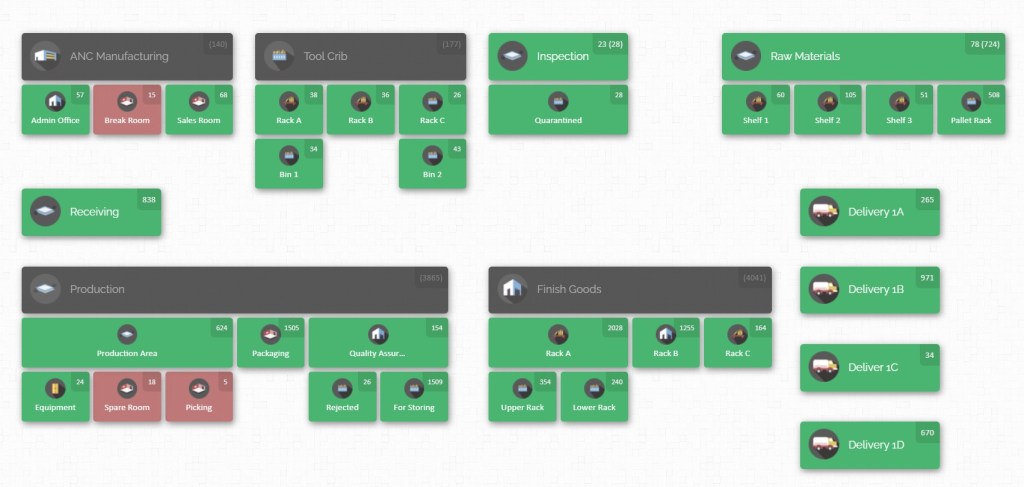

CyberStockroom: Visual Inventory Mapping for JIT Efficiency

Modern JIT strategies rely on advanced software to make them work. One example of such a platform is CyberStockroom, which brings a unique visual twist to inventory management.

CyberStockroom is a cloud-based inventory mapping tool designed to give manufacturers (and businesses in any sector) complete visibility over their stock. Here’s how it supports and enhances JIT practices:

- Inventory Mapping: Instead of rows of data, CyberStockroom lets you build a visual map of your physical locations – warehouses, rooms, shelves, even vehicles. You see a visual representation of where every item lives. For a JIT system, this means instant awareness of stock levels without digging through spreadsheets. When a line needs parts, the team can click on the map to confirm that those parts are ready to go.

- Real-Time Tracking: Every scan, transfer, or usage is updated live in the cloud. CyberStockroom’s dashboard shows inventory changes immediately. If a Kanban signal triggers a reorder, managers can watch as new items are received in real time. This level of transparency prevents the small gaps that can cause delays in a JIT flow.

- Drag-and-Drop Transfers: The platform includes an intuitive drag-and-drop feature for moving stock between locations. For example, if one assembly line runs low, a supervisor can visually drag needed items from one warehouse location to another on the map. This is much faster than manually creating paperwork or entries in a traditional system, speeding up the JIT restock process.

- Barcode and Custom Fields: CyberStockroom supports barcode scanning and custom data fields for each item. This means JIT users can scan parts in and out at every step, ensuring counts are always accurate. Custom fields allow teams to tag items with JIT-specific info (like lead time or safety stock levels) directly in the system.

- Cloud-Based Collaboration: Because it’s on the cloud (hosted on AWS), the system can be accessed by staff or suppliers anywhere. A purchasing manager can log in from home to check inventory before approving a just-in-time order.

- Enhanced Visibility: “Better inventory visibility means better cash flow.” For JIT, this is exactly the point. When manufacturers have an accurate, shared view of inventory across all sites, they avoid the twin problems of stockouts and excess. Teams get control over what’s stored where, and finance sees the real-time impact on cash.

In practical terms, a factory using CyberStockroom could map every shelf and bin. When production signals that more components are needed, the team knows instantly if those parts are on-site or if they need to be ordered.

If an urgent order comes in from marketing, operations can use the map to swiftly check and redirect stock across plants. All these actions happen visually, which helps cross-functional teams stay aligned. In this way, CyberStockroom acts as a digital partner to JIT systems: it gives manufacturers the tool to execute JIT principles with maximum accuracy.

As manufacturers move toward Industry 4.0, tools like CyberStockroom are a glimpse of the future: combining cloud connectivity, intuitive interfaces, and data transparency to keep lean processes humming. By removing the blind spots in inventory, such platforms make it easier for companies to run tight JIT cycles without fear of surprises.

Best Practices for Implementing JIT in 2025

Putting all of this together, what concrete steps can a manufacturer take to improve their JIT system today? Here are best practices distilled for the modern context:

- Review and Segregate Your Inventory: Start by analyzing your entire parts list. Use data to classify items (e.g. high-criticality vs. routine parts). This helps you decide where you can safely apply JIT and where you need buffers. Review these classifications every quarter, as product lines and market conditions change.

- Enhance Supplier Partnerships: Make suppliers part of your lean journey. Share forecasts, invite them into your planning meetings, and consider on-site vendor-managed inventory for some items. A true lean partnership might involve doing joint improvement workshops together.

- Adopt Advanced Technology: Invest in inventory management software (cloud-based ERP or mapping tools) and analytics. Ensure your system can auto-reorder, flag low stock, and provide mobile access to inventory data. Implement barcoding or RFID to track parts at every step. Leverage AI/ML demand planning tools to fine-tune orders.

- Improve Production Scheduling: JIT requires synchronized production. Use techniques like finite capacity scheduling and real-time monitoring on the shop floor. Visual signals (lights, screens, notifications) can alert teams when it’s time to order or move parts.

- Regular Training: Keep your workforce trained in lean principles and any new tools you use. When people understand the “why” of JIT, they’re more likely to follow processes that reduce waste. Cross-train employees so roles are flexible if one area suddenly needs more hands.

- Buffer Strategically: If using safety stock, calculate it rigorously. Use inventory simulation or software to determine the minimum buffer that covers variability. Keep that buffer transparent (label the stock as “safety” in your system) so it isn’t accidentally consumed by routine orders.

- Monitor Key Metrics: Track performance indicators relevant to JIT: inventory turnover ratio, stockout incidents, supplier lead time variance, on-time delivery rate, and production downtime due to missing parts. Use dashboards to spot trends and flag issues early.

- Continuously Reassess: Build cadence into your process. Every month or quarter, review supplier performance and inventory levels. After any hiccup, conduct a quick “post-mortem” to see if adjustments are needed. The “zero-base” concept from strategy suggests occasionally reinventing processes from scratch rather than just tweaking old ways. This mindset can inspire innovation (e.g., a new logistics partnership or technology trial).

- Collaborate Across Functions: Ensure procurement, operations, sales, and finance all share information. Aligning these teams prevents conflicting actions (like sales overpromising on lead times, or procurement delaying orders). Regular cross-department meetings on inventory planning keep everyone informed.

- Plan for Disruptions: Have a “plan B” for key scenarios. Maybe set up emergency air freight channels with a logistics provider, or negotiate flexible contracts with alternate suppliers. Simulate disruptions regularly so the team knows how to act when the time comes.

By combining these practices, manufacturers position their JIT systems to thrive. Remember: the goal is agility. A well-implemented JIT system is not fragile; it’s finely tuned to respond to change. With smart use of technology and strategy, JIT can remain a powerful approach in 2025.

The Future of Just-In-Time Inventory Manufacturing

Just-in-Time inventory manufacturing is not going away – it’s evolving. The future promises even tighter integration of digital technology, global cooperation, and sustainable practices. Manufacturers who master this balance will gain a competitive edge.

In the short term (the late 2020s), expect to see:

- AI Everywhere: More factories will use AI not just to forecast demand, but to autonomously adjust production schedules moment-to-moment. We may reach a point where inventory orders self-trigger based on predictive algorithms, leaving humans to focus on strategy.

- Digital Twins and Simulations: Running JIT operations might involve a virtual clone of your factory floor. In the digital twin, you can test new layouts, supplier changes, or JIT policies without disrupting the real one. Insights from these simulations will drive better decisions.

- Increased Decentralization: Additive manufacturing (3D printing) is growing. In the future, some components might be printed on demand at or near the factory, dramatically reducing the need for complex supply chains for those parts. This could allow JIT to operate with even shorter “last mile” logistics.

- Stronger Emphasis on Networked Visibility: Supply chains will adopt more blockchain or interconnected ledger technologies. While cloud dashboards show you your own inventory, shared ledgers could allow every tier of supplier to see the same data. This all-hands transparency could transform JIT by virtually eliminating information delays.

- Sustainability as Driver: Environmental regulations will keep tightening. JIT production may become a selling point (lower waste, lower emissions from transporting only what’s needed). Companies might report JIT metrics as part of ESG (Environmental, Social, Governance) scores.

Regardless of these advances, the human factor remains key. Skilled supply chain professionals will need to interpret data and make judgment calls. By 2025, the stereotype of JIT as “zero inventory” is outdated. The modern view is “smart inventory” – minimal where possible, strategic where needed, powered by technology and foresight.

In conclusion, just-in-time inventory manufacturing in 2025 is about optimizing the flow of goods in an unpredictable world. It requires embracing digital tools (like CyberStockroom) for visibility, leveraging AI for foresight, and building resilient networks of suppliers and logistics partners. By combining lean thinking with 2025’s technology, manufacturers can achieve agility and robustness. That way, when the next disruption comes, they’ll be ready not just to survive, but to thrive.

Leave a comment