The Chaotic Reality of Industrial Construction

Industrial construction sites are notoriously dynamic and fast-paced environments. Multiple crews operate heavy machinery, materials flow in and out, and project plans evolve daily. Amid this constant motion, small inefficiencies can quickly snowball into big problems. A delayed steel delivery or a missing specialized tool might seem minor at first, but each hour lost has a ripple effect on labor costs, schedules, and even safety.

In fact, studies show that construction professionals often spend a huge portion of their week on non-productive tasks – up to 35% of their time (about 14 hours per week) on activities like searching for information or resolving issues, which translates to over $177 billion in lost productivity annually in the U.S. construction industr. This chaotic baseline makes it clear: time truly is money on the job site.

Industrial construction managers often find themselves grappling with chaotic job sites – from missing materials to miscommunications – which can threaten schedules and budgets.

Several factors contribute to the chaos on industrial construction sites. These projects involve many moving parts – materials arriving from various suppliers, equipment shared between teams, and ever-changing work areas. Yet inventory management and communication often become afterthoughts amid the rush. Teams might rely on ad-hoc methods like spreadsheets, text messages, or even scribbled notes on a whiteboard, with no single source of truth. It’s easy for things to fall through the cracks: a pallet of parts left off the inventory list, a tool taken by one crew and not returned, or a critical update not communicated to the right people. The result is what can only be described as “job site chaos.”

Common Sources of Chaos and Inefficiency on Site

What does “chaos” look like day-to-day on a construction site? Here are some of the most common sources of inefficiency that plague industrial projects:

- Miscommunication and Data Silos: When information is fragmented across emails, phone calls, and paper notes, miscommunication is almost guaranteed. Important details (like design changes or delivery updates) get lost in the shuffle. Nearly 30% of construction projects are delayed due to miscommunication, leading to frustration and cost overruns. Poor communication also means teams often work from outdated data, causing mistakes and rework. In fact, almost 48% of all rework in construction is caused by miscommunication or bad data, representing over $31 billion in rework costs every year in the U.S. These breakdowns not only delay projects but also create a culture of blame and confusion.

- Missing or Misplaced Tools and Materials: How often have crews scrambled to find a specific tool or part, only to discover it’s been misplaced or was never ordered? Lost or unavailable equipment is a huge drain on productivity. Some surveys have found that workers spend up to 47% of their time simply looking for tools instead of working. Whether due to misplacement or theft, missing assets bring work to a standstill. On busy sites with hundreds of items, equipment and materials can “disappear” easily – sometimes permanently. Construction sites are unfortunately prime targets for theft; in the U.S., an estimated $300 million to $1 billion worth of construction equipment is stolen each year, and only about 21% of stolen assets are ever recovered. Tools and materials that are not tracked can walk off site or be left behind when moving between jobs. All of this leads to crews standing idle or spending hours hunting down a generator or shipment that should be on site.

- Scheduling Conflicts and Delays: Timing is everything in construction. Yet chaotic sites often suffer from poor scheduling and coordination. A concrete crew might arrive ready to work, only to find that the rebar delivery is late or the excavation isn’t finished. Without real-time updates, one delay cascades into another. For example, a late materials shipment or a last-minute change might not get communicated across all teams, causing hours or days of delay. Unplanned downtime on construction sites can cost hundreds or thousands of dollars per hour – and downtime rates of 20–30% are common in the industry, much of it due to waiting on missing equipment or information. These schedule slips not only threaten the timeline but also incur extra costs (overtime, rental of replacement equipment, or penalty fees for late completion).

- Lack of Accountability and Visibility: When it’s unclear who last used a piece of equipment or where materials were allocated, accountability suffers. For instance, if a power drill or a welding machine goes missing, crew members might point fingers or assume “someone else has it.” Without a system to log usage, no one knows who had what last or where it went. This lack of transparency leads to duplicate orders (because one team didn’t realize another already took the spare parts) and overstocking as a “just in case” measure. It’s not uncommon for companies to buy extra materials or tools they didn’t actually need, simply because they lost track of existing stock. All of this waste adds up. (One UK study noted that 13% of construction materials end up wasted without ever being used, often due to poor tracking and over-ordering.) Furthermore, when nobody is clearly responsible for inventory control, critical questions like “Do we have enough conduit for tomorrow’s work?” or “Where’s the generator we used last week?” are met with shrugs. This is a sure recipe for chaos.

- Outdated Manual Processes: A underlying factor in all of the above is the continued use of manual or outdated methods to manage complex operations. Many job sites still rely on paper logs, spreadsheets, or memory to track inventory and progress. These methods are error-prone and slow. Handwritten notes get lost or misread, and spreadsheets updated in the office may not reflect the reality in the field. Because manual updates are often entered long after events occur (if at all), managers make decisions based on incomplete or stale information. For example, a supervisor might send a crew to use a scissor lift that, unbeknownst to him, was moved to a different site the day before. Manual tracking also struggles to keep up with the scale of industrial projects – conducting a physical inventory count across a large site can take hours or days, and by the time it’s done the situation may have already changed. In short, relying on pen-and-paper in a digital age creates a blind spot in operations, allowing all the above issues – miscommunication, missing items, scheduling slip-ups – to persist.

Each of these issues feeds into the others, creating a vicious cycle of inefficiency. Miscommunication leads to scheduling mistakes, missing tools lead to delays and further miscommunication as people call around to find them. It’s a chaotic feedback loop. But what does all this chaos truly cost construction firms? The toll is higher than you might think.

The Cost of Chaos: Delays, Lost Time, and Budget Overruns

It might be tempting to write off some of the chaos as “just part of construction.” However, the cumulative impact of these inefficiencies is staggering. When projects run in constant crisis mode, companies pay the price in multiple ways:

- Project Delays: When key tasks slip, the entire schedule can be thrown off. Deadlines get pushed, delivery dates are missed, and crews have to be rescheduled. As noted, nearly 30% of projects get delayed due to communication issues alone. Every delay often comes with a financial penalty – whether liquidated damages in contracts or simply higher overhead from a longer project timeline. For contractors, delays also mean lost opportunities (you can’t start the next project if you’re still stuck finishing this one).

- Lost Productivity: Time spent waiting or searching is time not spent building. One study found construction pros devote about 18% of their working hours just to searching for project information and documents. Add to that the time looking for tools or materials on site, and the lost hours multiply. For example, if a team of 50 employees spends even 90 minutes a day each “looking for stuff,” that adds up to 18,750 hours in a year wasted on unproductive activity. This is essentially paying your crew not to work, because of process failures. Over the span of a multi-month project, those idle hours inflate labor costs significantly.

- Rework and Errors: Mistakes on site – often due to using wrong or outdated information – lead to rework, which is extremely costly. Redoing work not only doubles the labor and material cost for that scope, but it can also delay subsequent tasks. Industry research has shown that rework can eat up close to 5–9% of a project’s budget on average, and up to 30% of all work performed in extreme cases is actually redoing something that was done before. Much of this rework stems from the chaos we described (e.g. the wrong materials installed because the correct ones weren’t on site or a task had to be ripped out due to a miscommunicated change). Every instance of rework is essentially an avoidable do-over that directly hits the project’s bottom line.

- Excess Costs and Purchases: In a chaotic system, companies frequently spend money just to cover for lack of organization. They expedite last-minute orders at premium rates because they didn’t realize stock was low. Or they rent an extra bulldozer because the one they own is misplaced on some job site. These unplanned expenses accumulate. For instance, a typical firm with a half-dozen heavy machines might lose over $200,000 a year due to idle time and unnecessary rentals or purchases caused by poor tracking. Similarly, over-ordering materials “just in case” ties up capital and often leads to waste if those materials aren’t used.

- Theft and Shrinkage: As noted earlier, theft is a very real cost of not having proper oversight. Losing valuable equipment or batches of materials to theft (or simple loss) not only means replacement costs, but also work stoppages until the item is replaced. The construction industry loses over $1 billion annually to theft of equipment, tools, and materials. And most of those stolen items are never recovered. A lack of tracking makes theft easier – thieves know there’s a low chance the missing asset will be noticed immediately or traced. Beyond the direct cost of stolen goods, there’s also increased insurance premiums and the cost of downtime while new equipment is procured.

- Stress and Safety Risks: Although harder to quantify, the stressful environment of a mismanaged site can impact worker morale and even safety. When workers are rushing to make up lost time or improvising because the right tool isn’t available, accidents are more likely to occur. A chaotic site is an unsafe site. Additionally, frustrated employees facing constant hiccups may experience burnout or disengagement, which hurts productivity further. It’s a vicious circle: chaos breeds stress, and stress can breed more mistakes.

In short, job site chaos directly translates into lost dollars and frayed nerves. One report succinctly called out that inefficiencies (like those above) are draining billions from construction – identifying over $177 billion in excessive costs tied to outdated processes and coordination problems. The message is clear: the status quo is unsustainably expensive. The good news is that there are modern solutions designed to tame this chaos. Chief among them are real-time tracking tools that give construction managers eyes on every facet of their operations. Let’s explore how these technologies can bring much-needed order to the frenzy of an industrial construction project.

Real-Time Tracking: Bringing Order to the Chaos

Imagine if you could know the status and location of every important item on your construction site in real time – every tool, every piece of equipment, every pallet of materials – all updated live and accessible at your fingertips. That’s the promise of real-time tracking in industrial construction. In essence, real-time tracking tools (such as modern inventory and asset management systems like CyberStockroom, and others) use technology to monitor assets continuously so that information is always current and centralized.

At its core, a real-time tracking system typically includes a cloud-based platform accessible by all team members and some form of on-site tagging or scanning for assets.

Rather than relying on memory or sporadic spreadsheet updates, crews use barcode scanners, QR codes, or IoT asset tags to log the movement of tools and materials in the moment. For example, when a delivery arrives, each item’s code is scanned into the system, updating the available quantity. If a tool is checked out from the tool crib, that checkout is recorded under a person’s name; when it’s returned or moved to another site, another quick scan updates its new location. All these transactions happen in real time, meaning anyone looking at the system (from the site or the office) sees the same up-to-date information.

Mobile accessibility is also key – modern tracking solutions come with smartphone and tablet apps so that field crews can input or retrieve information on the go. This is crucial because construction work isn’t done at a desk; the tracking solution travels with the team. Many systems even work offline and then sync to the cloud when a signal is available, ensuring remote or enclosed sites aren’t left out. The end result is a live, shared dashboard of all assets and inventory. Project managers can see, for instance, that Site A has three spare pressure valves and Site B has none, in real time – and then make an informed transfer before Site B runs into a shortage.

In summary, real-time tracking brings order and visibility. It creates a single source of truth for the entire project’s inventory and assets, updated to the minute. Instead of chaos and guesswork, managers and crews operate with concrete data: they know what they have, where it is, and what’s needed next. Let’s delve into specific ways this helps mitigate the earlier problems and improves efficiency.

How Real-Time Tracking Solves Site Inefficiencies

Real-time asset and inventory tracking directly tackles the sources of chaos on construction projects. By implementing these tools, construction managers can expect improvements in several critical areas:

- Centralized, Up-to-Date Information Sharing: With all inventory and asset data in one cloud-based system, miscommunication is drastically reduced. Everyone from the site supervisor to the procurement office works off the same information, so there’s less chance of someone being out of the loop. For example, if a shipment is delayed or a change order requires additional materials, a real-time system can update the status immediately and even send notifications. This prevents the scenario of one team starting work unaware of a change – they’ll see the update in the system (often accompanied by a push alert). In practice, this centralization has huge effects: when BuilderComs introduced a unified communication platform, they noted a significant drop in delays and errors, because teams were no longer relying on scattered emails or calls. Real-time tracking extends that concept to physical assets and inventory, eliminating data silos. The result is that decisions and coordination are based on facts, not assumptions or outdated info.

- Full Visibility of Tools, Equipment, and Materials: Instead of wondering who has a certain tool or where a piece of equipment was left, project leaders can instantly locate anything tracked. Every tool or asset is tagged or logged, so you can pull up a map or list that shows, for instance, that the electric generator is currently at Site #3 and was checked in by John Doe yesterday. This level of visibility means no more time wasted searching the yard or calling around. Crews can confidently go straight to the item they need because the system tells them where it is. This addresses the huge productivity black hole of searching for misplaced items. If workers currently spend nearly half their day looking for tools in the worst cases, even cutting that down by a fraction represents hours saved each week. Also, knowing exactly what’s on hand prevents unnecessary reorders – if five pipes are left in storage, the team won’t mistakenly order five more thinking they’re out. One construction firm that adopted a digital inventory reported that their supervisors stopped making “just in case” purchases once they trusted the live inventory count, leading to immediate cost savings.

- Improved Asset Utilization & Reduced Idle Time: Real-time tracking isn’t just about finding lost items; it also optimizes the use of assets. By monitoring how often equipment is used and where, managers can spot underutilization. For example, the system might show a skid-steer loader hasn’t been used in 3 days on one site – it could be relocated to another site where it’s needed, instead of renting an additional one. Industry data suggests roughly 30% of construction equipment time is idle on average, which is essentially wasted capital. Tracking solutions help cut this idle time by enabling resource sharing and timely reassignments. If a project phase is complete and materials or tools are lying around, those can be quickly transferred to where they’re needed next. This just-in-time allocation keeps the project lean and efficient. It also means fewer instances of renting or buying extras “just in case,” since you have confidence in redeploying what you own. Over a year, better utilization of assets can save hundreds of thousands of dollars that would otherwise be lost in idle equipment costsl.

- Proactive Scheduling and Planning: Inventory tracking systems shine in tying together with project schedules. Because you have real-time counts of materials, you can practice true just-in-time delivery. For example, you can plan concrete deliveries to arrive phase by phase, rather than all at once, because you’ll always see how much is left and when to reorder. One best practice is to link inventory levels to the project plan – e.g. when a phase is 80% done, automatically trigger the next batch of materials. This prevents both shortages and the clutter of excess materials on-site. It also reduces the risk of project delays due to missing components, because the system helps you stay ahead of demand. Moreover, real-time tracking provides data to better forecast needs on future jobs (e.g. knowing exactly how many units of something were used in a past project so you estimate more accurately next time). In essence, it allows data-driven scheduling: making sure the right materials and tools are in the right place at the right time, consistently. Crews can then work without interruption, and the project stays on its timeline.

- Accountability and Loss Prevention: When every movement of inventory is logged to a person and time, people naturally become more accountable with equipment. It’s immediately clear who last had each item. This transparency tends to discourage carelessness and even dishonesty. It’s much harder for tools to just “go missing” when there’s a digital paper trail for each checkout. Additionally, many real-time tracking systems include theft-prevention features. GPS trackers on high-value equipment can alert managers if something is moved off the site after hours (a geofence breach). Some systems will sound alarms or send texts if an asset leaves a predefined zone. Knowing that tools are being actively monitored is itself a deterrent – workers and outsiders alike are less likely to attempt theft if they’re aware that an item can be traced. In the unfortunate event something does go missing, the system helps pinpoint when and where it was last seen, aiding in recovery. All of this can significantly cut down on losses. Fewer lost tools means less money spent replacing them and less downtime waiting for replacements. As a bonus, preventing theft and maintaining clear records can even lower insurance premiums for equipment on site.

- Streamlined Workflows and Productivity Boost: Perhaps the most immediate benefit crews will feel is the reduction in friction during daily tasks. With a good tracking system in place, a worker can request a tool via the app, see that it’s available, and go get it (or have it delivered) without a chain of phone calls. Site managers can approve and track these movements in seconds. No more wandering around the site or depot looking for that “one missing loader” – the software shows exactly where it is. This means crews spend more time on actual construction work and less on logistical scavenger hunts. Managers, too, can make quicker decisions because they have data at their fingertips (should we move the excavator from Site A to Site B? Let’s check usage levels – ah, it’s not being used today at Site A, so yes.) All told, real-time tracking helps projects progress faster and with fewer hiccups. Companies often report improvements in labor productivity after implementing these tools – for example, one contractor noted that adopting a mobile inventory app eliminated the hour-long waits they used to have when checking out tools each morning, effectively saving $5,000 per day in crew idle time that was previously spent waiting in line. While results vary, the overall trend is clear: less chaos = more work gets done. By cutting out the downtime and confusion, real-time tracking can compress project schedules and even allow firms to take on more work with the same resources.

- Better Budget Control and Cost Savings: All the efficiencies above translate into financial gains. Fewer rush orders and idle rentals mean direct cost savings. Tighter inventory control means less money tied up in unused stock sitting around (which could potentially get damaged or expire). By minimizing waste and preventing over-ordering, inventory costs drop. By preventing delays, projects avoid penalty costs and can finish under budget. And by reducing theft and loss, companies save on replacement expenses. There’s also an administrative saving – automated record-keeping simplifies audits and end-of-project inventory reconciliation (imagine closing out a project knowing exactly what materials are left to return or use elsewhere, as opposed to discovering wasted surplus). Many firms find that an investment in a tracking system pays for itself multiple times over via these savings. For example, if a tool tracking system prevents just a single instance of major rework or a week-long delay, it may have already justified its cost. The ROI is often evident within the first project using the system.

In short, real-time tracking solutions address the root causes of construction site chaos. They create a workplace where information flows seamlessly, every asset is accounted for, and surprises (the bad kind) are minimized. Workers can focus on their jobs rather than hunting for tools or wondering about materials, and managers can focus on building rather than firefighting daily crises. It’s a transformative shift from reactive to proactive management of construction operations.

Comparing Real-Time Tracking to Traditional Methods

It’s worth noting how real-time tracking systems stack up against older approaches, as well as other alternatives, to appreciate their value fully:

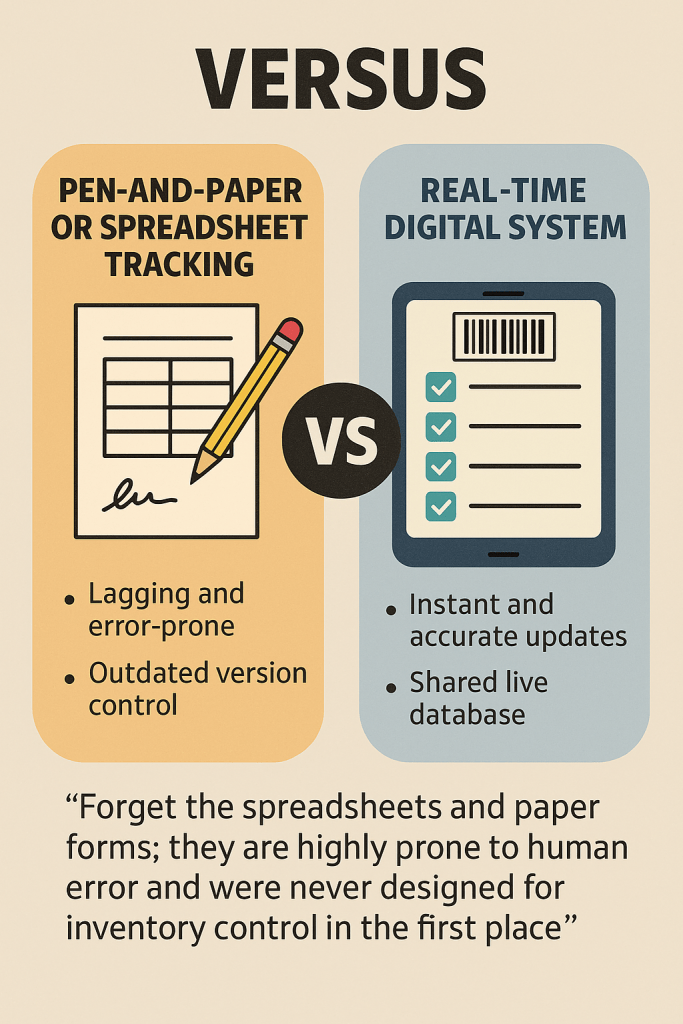

Versus Pen-and-Paper or Spreadsheet Tracking

The traditional way many construction managers kept track of inventory was through manual logs – signing tools in and out on paper, or updating Excel sheets at the end of the day. While this is better than nothing, it can’t keep pace with a busy job site. Manual records are inherently lagging (you often update them hours or days later) and prone to error. It’s easy to forget to note something, or make a typo, or use an outdated version of a spreadsheet.

In contrast, a real-time digital system updates instantly with each scan or entry, and it maintains an error-free history. There’s no ambiguity about handwriting or version control – everyone sees the same live database. As one inventory solution provider bluntly put it, “forget the spreadsheets and paper forms; they are highly prone to human error and were never designed for inventory control in the first place”. Real-time systems are purpose-built for this task.

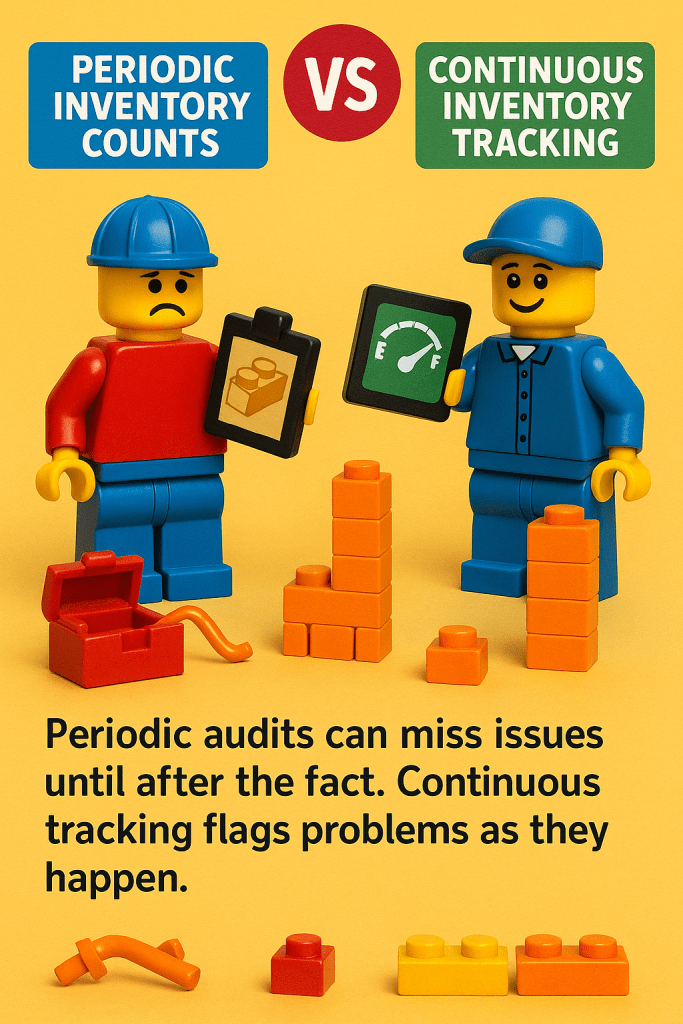

Versus Periodic Inventory Counts

Some companies conduct inventory checks once a week or at project milestones to get a handle on their supplies. While periodic audits can catch discrepancies eventually, they don’t prevent problems in between. You might discover on Friday that you’re low on copper wire, but that doesn’t help if you actually ran out on Wednesday and lost productive time.

By contrast, a continuous tracking system prevents surprises because it flags issues as they arise, not after the fact. It’s the difference between having a live fuel gauge versus checking your tank only at the end of the day – one helps you avoid running dry in the first place.

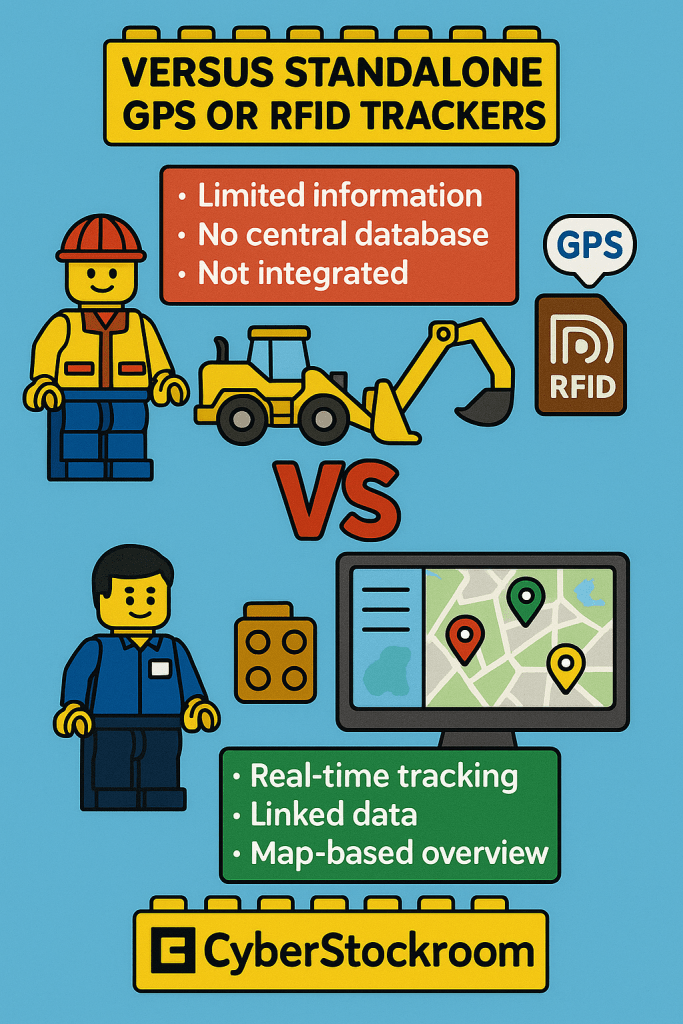

Versus Standalone GPS or RFID Trackers

There are point solutions like GPS trackers for heavy equipment or RFID tags for tools that some firms use in isolation. These can be helpful, but without integration into a broader inventory system, they might only solve part of the problem. For instance, a GPS unit on a bulldozer will tell you where it is, but it won’t tell you who is using it, its maintenance status, or how it fits into the project schedule. Similarly, RFID tags can automate identification of tools, but you still need a central database to log and interpret that data.

Modern real-time tracking platforms often combine these technologies (they can incorporate GPS, RFID, QR codes, etc. as needed) into one cohesive interface. The key is the integration – linking location, usage, and inventory data together. Competing solutions that address only location tracking or only count quantities are better than nothing, but they may leave visibility gaps. A comprehensive system like CyberStockroom, for example, provides a map-based overview of all inventory and assets along with a detailed history of movements, ensuring nothing slips through unnoticed.

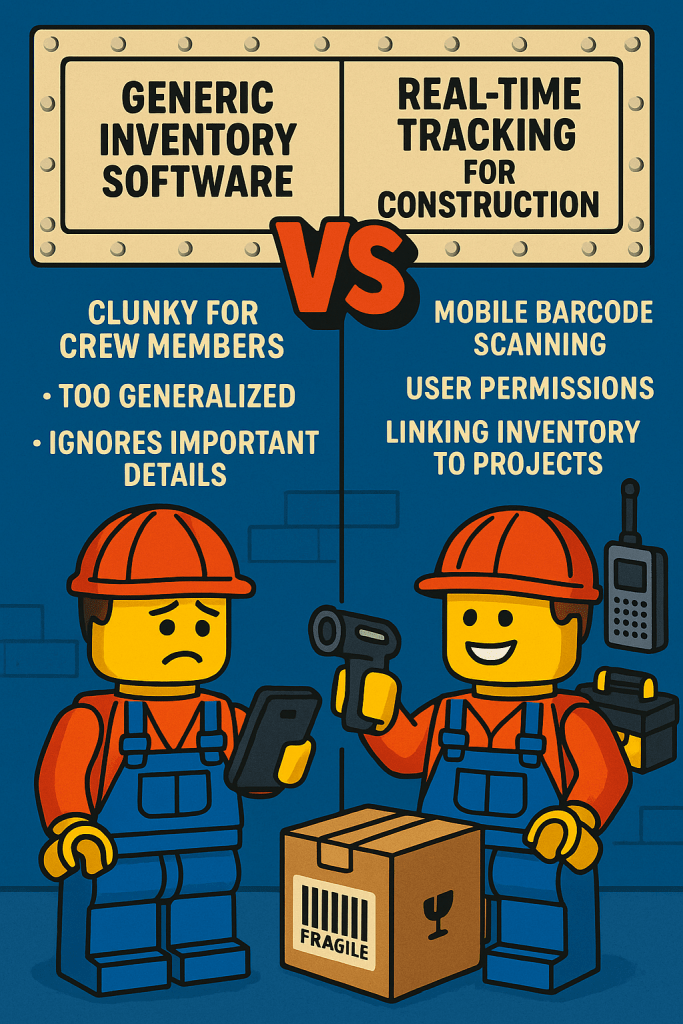

Versus Generic Inventory Software

Construction has specific challenges (like working offline in the field, or handling bulk materials and serialized assets) that generic inventory or warehouse software might not handle well. Some contractors try to use a basic inventory app or even an ERP module not tailored to construction. These can be clunky for crew members to use or too generalized to capture important details (such as associating items with project phases or tracking tools that move daily between sites).

By contrast, industry-focused real-time tracking solutions are designed with features like mobile barcode scanning, user permissions for crew leads, job site geolocation, and even linking inventory to cost codes or project tasks. This makes them much more effective on a chaotic job site. The easier and more relevant the system is for field use, the more the team will actually use it, which is crucial for success. In sum, while there are many ways to attempt to track assets, the integrated and real-time approach is what truly tackles the chaos in industrial construction, because it’s both timely and tailored to how construction projects operate.

Conclusion

Industrial construction projects will probably never be completely free of surprises – it’s the nature of building complex facilities in dynamic environments. However, the chaos and inefficiency that many assume to be “just part of the job” can be dramatically reduced.

Real-time tracking technology offers construction managers and executives a powerful tool to bring order to the disorder. By keeping tabs on every tool, every material, and every piece of equipment in real time, these systems strike at the heart of the typical pain points on a job site. Miscommunications are minimized because everyone can see the facts on the ground. Missing tools are no longer a mystery because their last known location is a click away. Scheduling is smoother because deliveries and resource allocation are data-driven. And the project as a whole becomes more predictable, efficient, and safe.

Adopting real-time inventory and asset tracking is not just about buying new software or gadgets – it’s about embracing a culture of visibility and proactivity. It means moving away from firefighting and toward foresight in project management. Early adopters in the construction industry have reported not only tangible savings (in time and money) but also improved team morale, because crews are empowered with information and freed from the frustration of constant mix-ups. Clients, too, notice the difference when projects run more smoothly and transparently.

In an industry where margins are thin and risks are high, the ability to reduce delays and avoid costly mistakes is a game-changer. Real-time tracking tools, such as CyberStockroom’s inventory management system or other comparable solutions, provide that edge. They turn the messy, moving puzzle of a construction site into a coordinated operation where each piece is accounted for. In the end, it means projects delivered on time and on budget, with far less stress along the way.

As the construction sector continues to modernize, those who leverage these technologies will be far better equipped to handle the demands of increasingly complex projects. The era of clipboards and guesswork is giving way to one of instant information and smart construction management. For construction managers tired of job site chaos, it’s time to make the leap to real-time tracking and usher in a new level of control and efficiency on every site.

Key Takeaways

- Industrial construction sites are prone to chaos due to miscommunication, lost or untracked tools, scheduling delays, and reliance on outdated manual processes – all of which can drive up costs and cause major delays.

- The cost of these inefficiencies is enormous: from nearly a day per week of productivity lost per worker searching for information or tools, to billions spent on rework and theft losses that could be avoided with better tracking. Projects suffer from frequent delays, budget overruns, and frustrated teams.

- Real-time tracking systems (inventory and asset tracking) provide a solution by offering continuous, cloud-based visibility of materials, tools, and equipment. They replace error-prone spreadsheets and guesswork with up-to-the-minute data accessible to the whole team.

- Implementing real-time tracking yields concrete benefits: crews spend far less time looking for items and more time working, managers can proactively reallocate underused assets (reducing idle time by tackling the ~30% average equipment idling), and companies can synchronize deliveries with project phases to prevent shortages or surpluses.

- Chaos is replaced by control: Missing tools are quickly found (or prevented altogether through accountability logs and theft alerts, communication improves as everyone references the same live information, and decisions are made based on facts rather than assumptions. The overall result is faster, smoother projects with fewer costly surprises.

- In today’s construction industry, real-time tracking is becoming a must-have technology for efficient site management. It directly addresses the root causes of job site chaos, helping projects stay on schedule and on budget. Managers who leverage these tools are better equipped to mitigate delays, save money, and deliver successful outcomes, consistently.

Leave a comment