Companies continually seek methods to improve their production processes, lessen waste, and increase efficiency. JIT Manufacturing has become a potent tool for achieving these objectives. JIT Manufacturing, sometimes referred to as Just-In-Time Production or Lean Manufacturing, is a process that emphasizes manufacturing the appropriate number of goods at the appropriate time to satisfy customer demand while reducing waste and inventory levels. We’ll explore JIT Manufacturing in this blog post, including its fundamental ideas, advantages, difficulties, and implementation approaches.

Understanding JIT Manufacturing

First, what is JIT Manufacturing? JIT Manufacturing is a production strategy that emphasizes the importance of delivering products exactly when they are needed, neither earlier nor later. Toyota first developed it in the 1950s and has since been adopted by companies worldwide.

JIT Manufacturing Principles

Inventory Reduction

In JIT Manufacturing, inventory minimization refers to minimizing inventory levels. This idea intends to cut storage expenses, lessen the chance of having outmoded inventory, and improve cash flow. Businesses that carry too much inventory waste money and warehouse space that could be used more effectively for other things. JIT Manufacturing lowers carrying costs by minimizing inventory, which includes expenditures for handling, storage, and insurance.

Production Driven by Demand

Instead of relying on forecasts, JIT Manufacturing runs based on actual customer demand. This strategy makes sure that things are only produced after confirmed customer orders. This strategy also eliminates the requirement for significant safety stock amounts, which can go out of date or expire, by synchronizing production with demand. Because of the decreased waste and avoidance of overproduction, businesses are better able to adapt to shifting market conditions.

Continuous Improvement

JIT Manufacturing promotes a culture of waste reduction and ongoing improvement. All levels of staff members have the authority to find and fix process inefficiencies. This idea emphasizes the value of kaizen, a Japanese concept for ongoing development. Teams are urged to continuously analyze and improve their production processes as they look for ways to improve productivity, decrease faults, and increase efficiency. This constant quest for improvement characterizes JIT Manufacturing.

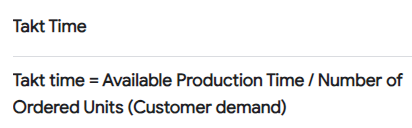

Takt Time

The rate at which goods must be produced to satisfy consumer demand is known as takt time. JIT Manufacturing synchronizes production with takt time to ensure a seamless process. It offers a precise timeline for manufacturing, assisting teams in avoiding overproduction or bottlenecks. Takt time is calculated by dividing available production time by the customer demand within that time frame. In JIT Manufacturing systems, it acts as a crucial instrument for preserving production harmony.

Pull System

The “pull” system is a vital component of JIT Manufacturing. It employs a pull strategy rather than pushing goods onto the market in accordance with production schedules. Production in this system starts in reaction to real consumer orders or requests. The production of the specified items begins after an order is received. By ensuring that products are produced in direct response to consumer demand and minimizing the risk of overproduction, this strategy eliminates the need for unnecessary inventory storage.

Zero Defects

In JIT Manufacturing, obtaining zero defects is extremely important. Quality is not checked into the product, rather, it is included into the manufacturing process from the very start. At every level of the production process, teams diligently endeavor to prevent defecst. This dedication to zero defects raises product quality, lowers the need for rework, and increases client happiness. JIT Manufacturing decreases waste caused by defective products and the costs of rework or returns by addressing quality issues at the source.

The Benefits and Challenges of JIT Manufacturing

| Benefits | Challenges |

|---|---|

| Shorter Lead Times | Supplier Reliability |

| Operational Efficiency | Possible Stockouts |

| Cost Reduction | Multi-location Management |

| Improved Quality | Compliance and Quality Control |

| Flexibility |

The Benefits

Implementing JIT Manufacturing principles can yield a multitude of benefits for businesses:

1. Shorter Lead Times

JIT Manufacturing drastically shortens lead times—the period of time it takes for a product to go from manufacturing to delivery. Organizations can streamline their production processes by generating goods in response to actual client demand. By doing this, queue times are kept to a minimum, waiting periods between production processes are decreased, and the entire production cycle is sped up. Businesses are able to react to consumer requests and market changes more swiftly as a result.

2. Operational Efficiency

Process improvement and eliminating waste are two of JIT Manufacturing’s main goals. Its principles urge companies to recognize and discontinue processes that do not improve the quality of the end result. As a result, operating efficiency is increased. A leaner and more productive business benefits from streamlined processes, shorter setup times, and effective resource utilization. Teams that work smarter rather than harder allocate resources more effectively and waste fewer of them.

3. Cost Reduction

JIT Manufacturing is famous for its ability to reduce costs. It does cost reduction in several ways:

- Lower Inventory Carrying Costs: By keeping inventory levels low, businesses save money on charges such as warehousing, insurance, and security. Money held in excess inventory can be diverted to more profitable investments.

- Reduced Waste: Reducing waste results in immediate cost savings. JIT Manufacturing decreases wasted costs by lowering scrap, rework, or excessive material consumption.

- Increased Efficiency: It emphasis on resource allocation and efficient production techniques results in better cost management. It lessens extra labor, overproduction, and duplicate tasks that could raise operating expenses.

4. Improved Quality

The dedication of JIT Manufacturing to zero defects leads to a notable improvement in product quality. Quality is an essential component of the production process, not an afterthought. Teams put up a lot of effort at every level of the manufacturing process to avoid defects. As a result, there are fewer product flaws, less rework, and greater customer satisfaction. By lowering the costs related to faulty goods, returns, and warranty claims, improved quality also results in cost savings.

5. Flexibility

JIT Manufacturing provides a significant degree of manufacturing flexibility. In order to adapt their production levels to changing demand patterns, businesses can do so fast. It is unnecessary to keep a large amount of inventory on hand to act as a safety net against uncertainty because manufacturing is demand-driven. Businesses may respond to changes in the market, seasonal variances, and unforeseen alterations in customer preferences because of this flexibility. Its adaptability makes guarantee that resources are used effectively even in dynamic businesses.

The Challenges

While this manufacturing strategy offers numerous advantages, it also presents challenges:

1. Supplier Reliability

Suppliers must deliver materials and components in the required quantity and on time for JIT system to function effectively. Production schedules may be negatively impacted by any delays or interruptions in the supply chain. JIT systems place a high priority on supplier reliability, therefore in order to reduce the possibility of disruptions, businesses must build solid connections with their suppliers. In order to monitor and prevent any problems in advance, this may include setting up supply chain visibility tools or creating backup supplier options.

2. Possible Stockouts

Stockouts could occur as a result of this sysem’s focus on keeping low inventory levels to cut waste and expenses. When supply is insufficient to meet demand, stockouts happen because there is no reserve inventory to handle the unexpected rise in demand. Companies must regularly monitor inventory levels, work closely with suppliers, and have backup plans in place for quick action in the event of unanticipated spikes in demand in order to reduce this risk.

3. Multi-location Management

It might be logistically difficult to organize JIT Manufacturing system across multiple locations or operations. The supply chain, the production procedures, and the demand patterns may differ depending on the location. Strong supply chain visibility, standardized procedures, and efficient communication channels are necessary to ensure consistent JIT implementation across these various circumstances. To support multi-location JIT Manufacturing, businesses frequently spend money on integrated supply chain management systems.

4. Compliance and Quality Control

In JIT Manufacturing situations, maintaining strict quality control and ensuring regulatory compliance can be challenging. Little room for error exists with a small buffer inventory. Throughout the production process, businesses must adopt strict quality assurance procedures and regulatory compliance inspections. Regular audits, quality control teams, and paperwork to prove compliance with rules and regulations may be used in this.

It’s essential to successfully overcome these challenges if you want to benefit from JIT Manufacturing while reducing risks and potential disruptions. Businesses that make substantial investments in technology, training, and supply chain management are better able to overcome these difficulties and prosper in a JIT environment.

JIT vs. Traditional Manufacturing

A comparison between JIT and traditional manufacturing reveals significant differences. While traditional manufacturing often involves high inventory levels and batch production, JIT focuses on efficiency, waste minimization, and flexibility. Businesses can choose their production strategy with greater knowledge if they are aware of the differences.

The Traditional Approach to Inventory Management

Manual counts, spreadsheet-based recording, and basic software programs are commonly used in the traditional approach to inventory management. These procedures can result in inefficient production and resource allocation because they are frequently time-consuming and error-prone.

The Revolution: Advanced Mapping and Visualization

Modern mapping and visualization techniques have completely changed JIT Manufacturing in recent years. These technological advancements add to the benefits of JIT by boosting compliance, streamlining workflows, and providing instant visibility.

How Advanced Mapping Complements JIT

- Instant Visibility: Advanced mapping tools provide real-time visibility into supply chain operations, production processes, and inventory levels. This enables quicker decision-making and improved demand and production coordination.

- Simplified Workflows: By locating bottlenecks and inefficiencies, mapping and visualization aid in streamlining workflows. This results in shorter lead times and more efficient production processes.

- Enhanced Compliance: JIT Manufacturing demands strict adherence to rules and quality standards. Advanced mapping tools assist in ensuring that all processes adhere to these standards, reducing the risk of compliance issues.

CyberStockroom’s Unique Solution: Bridging the Gap in JIT Manufacturing

Don’t settle for outdated methods and half-measures. CyberStockroom, a leading inventory management software, offers a unique solution that bridges the gap in JIT Manufacturing. CyberStockroom improves JIT implementation in the following aspects thanks to its real-time updates, advanced mapping capabilities, and workflow efficiencies:

Real-time Updates: Say goodbye to the days of uncertainty and outdated inventory data with real-time updates. You receive real-time updates from CyberStockroom to make sure your stock levels are not only accurate but also accessible. Better decision-making results from this, which ultimately results in a more efficient manufacturing process.

Inventory Mapping: But where CyberStockroom truly shines is in its unique advanced inventory mapping feature. You can create a visual map of your entire business, including all of the factories, storage facilities, and manufacturing stages. A modern manufacturer needs to have this technology since it provides an unmatched understanding of their inventory at this level of precision.

Workflow Efficiencies: CyberStockroom didn’t stop at inventory. Additionally, it can also serve as a comprehensive project and facilities management tool. From scheduling production to streamlining operations, CyberStockroom provides a 360-degree solution for all your operational needs.

Conclusion

In conclusion, Just-In-Time (JIT) Manufacturing is a proven strategy for streamlining operations, reducing costs, and enhancing product quality. By aligning production with customer demand and minimizing waste, companies can achieve greater efficiency and competitiveness. While implementing JIT may pose challenges, the benefits far outweigh the drawbacks. For businesses looking to thrive in today’s dynamic market, JIT Manufacturing is a strategy worth considering.

For more information on JIT Manufacturing and how it can benefit your business, please don’t hesitate to reach out. Our team is here to assist you in optimizing your production processes and achieving your operational goals.

Contact us today to learn more about JIT Manufacturing and schedule a discovery call here to explore its potential for your organization.

Leave a comment