In today’s rapidly changing industrial world, managing tools requires more than having a secure storage place. It involves establishing a connection between functionality, accountability, and efficiency. This involves more than just keeping track of where a tool is—it includes understanding where it should go, making sure it is maintained, and ensuring it is in the right hands.

Effective tool crib management can be a challenging job, and several businesses encounter different difficulties in this area. These difficulties often involve lost tools, stockouts, ineffective tracking methods, issues with accountability, and difficulties maintaining ideal inventory levels.

The Modern Tool Crib Management

A tool crib is the nerve center of many companies and industries. It serves as a hub for the storage and management of necessary tools, equipment, and supplies. Whether an employee is working in manufacturing, out in the field, or in a specific department, tool cribs are crucial in ensuring that the correct tools are always available to them.

The hubs or modern tool cribs are where tools come and go, each one necessary for bigger projects and operations. In such a situation, the lack of a tool or simply one that has been out for too long for maintenance could have a huge impact on production and services. Management becomes increasingly challenging when industries expand and the technologies they rely on become more complicated.

Challenges in Managing a Tool Crib

1. Misplaced Tools. Tool misplacement is a common issue in tool crib management. When a tool is misplaced, it can lead to frustration and delays. Imagine needing a specific wrench for a key task and discovering it isn’t where it should be. This not only wastes time but also has the potential to interrupt workflow and cause project delays. The more tools you have, the more likely they will be misplaced.

2. Stockouts. When you run out of important tools in your tool crib, you experience a stockout. This can be a significant issue as it hinders work and productivity. Running out of crucial tools when they are most needed can bring operations to a halt. Stockouts can cause disruptions in workflow, project delays, and missed deadlines. Finding the right balance between maintaining an appropriate inventory and avoiding overstocking can be challenging.

3. Inefficient Tracking. Many organizations still use manual tracking systems, such as spreadsheets or paper records, for their tool cribs. These procedures are error-prone, time-consuming, and can result in inaccurate information. It becomes difficult to ensure that tools are where they should be. Consider having to update a list every time a tool is checked out or returned. Errors are common, and the procedure is time-consuming.

4. Accountability and Loss Prevention. Accountability is essential in tool crib management. It is about knowing who used a tool when they used it, and when it was returned. Without an effective tracking system, it’s challenging to hold individuals accountable for tool usage. This lack of transparency can result in tools being misplaced or stolen.

5. Optimal Inventory Levels. Keeping appropriate inventory levels in your tool crib is tricky. You need enough equipment to meet demand without overstocking, which can waste valuable resources. Striking the right balance can be challenging, especially when tools have different usage patterns.

Transform Your Tool Crib with CyberStockroom

CyberStockroom is a cloud-based inventory management solution that addresses the challenging tasks of tool crib management. CyberStockroom includes several features that will not only tackle your current issues but also transform your tool crib operations into a well-organized, efficient, and transparent system.

Real-Time Tracking: Keeping Tools in Their Place

The real-time tracking capabilities of CyberStockroom provide an accurate and up-to-date overview of your tool inventory. You’ll always know where your tools are, saving you time searching for misplaced goods.

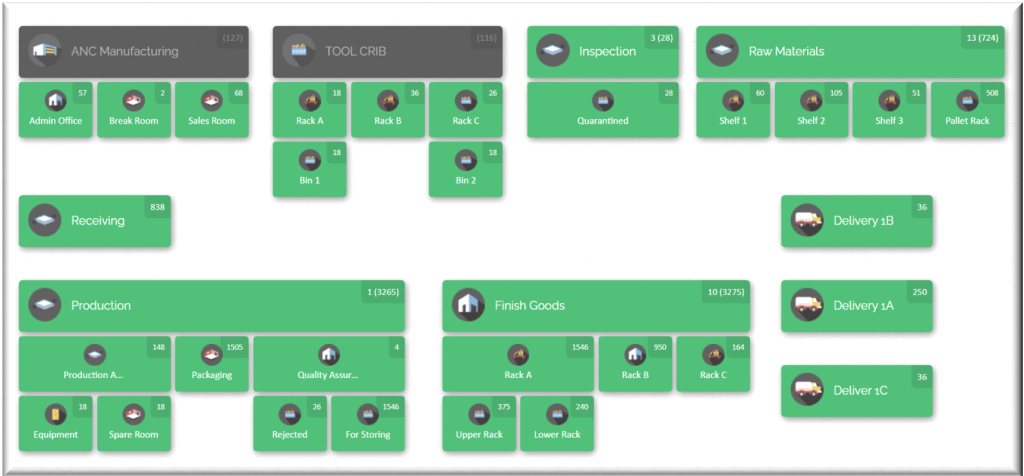

Visualizing Your Tool Crib Layout Using an Inventory Map

You can create a visual representation of your tool crib using CyberStockroom’s adaptable inventory map. This user-friendly feature makes it simple to identify and access tools. The inventory map allows you to determine the exact location of the tools, speeding up the tool location process. You can customize the map to match the layout of your crib, ensuring that each tool has a specific location

Barcode Integration: Streamlining Tool Transactions

Say goodbye to manual data input errors and the headaches associated with traditional tracking systems. With barcode integration, CyberStockroom streamlines tool management by allowing for quick and error-free tool check-in and check-out processes. A simple scan captures all the relevant data when a tool is used or returned, ensuring accuracy and efficiency in every transaction. This feature lowers the chance of human mistakes and improves the tool management process, allowing your team to focus on the task at hand.

Tool Transfers via Drag and Drop

Using CyberStockroom’s drag-and-drop feature, you can easily move tools between locations within your tool crib or transfer them to various departments. This feature simplifies tool distribution, saving downtime. Whether you need to relocate equipment to meet changing processes or distribute resources to other teams, CyberStockroom makes the process simple and efficient. There will be no more challenging record-keeping or paperwork—just smooth, trouble-free tool transfers at your fingertips.

Traceability: Knowing Your Tool’s History

Accountability is essential in preventing tool loss or theft, and CyberStockroom takes it a step further by providing comprehensive traceability. You can track the history of each tool’s usage, making it easier to identify and address any discrepancies. CyberStockroom maintains an activity history, which ensures transparency and accountability.

Additional CyberStockroom Features

In addition to the core features mentioned above, CyberStockroom offers several additional capabilities that further enhance tool crib management:

Custom Fields: Customize tool data to meet your specific needs. Add information to each tool record, such as maintenance schedules, warranty data, or usage instructions.

Batch Processing: Save time and effort by efficiently managing bulk updates. Whether you need to update tool data or count inventory, batch processing makes the job easier.

Document or File Attachments: Document and file attachments can be used to enhance your tool records. Keep crucial documents, instructions, or photos associated with each tool in the system. This feature simplifies maintenance and troubleshooting activities by providing quick access to critical information. When a team member needs reference materials or visual instructions for a certain item, they can quickly locate them, saving time and reducing errors.

Conclusion

To summarize, managing a tool crib does not have to be an impossible task. With CyberStockroom, you can optimize your tool crib management, solve common problems, and ensure that your tools are always available and where they should be. Say goodbye to the problems of misplaced tools, stockouts, and ineffective tracking methods.

Upgrade your tool crib management with CyberStockroom. Get in touch with us here for assistance or explore our resources to optimize your tool crib. Transform your tool crib with CyberStockroom now!

Leave a comment